Special catalyst for preparing p-chlorobenzonitrile by ammonoxidation process, preparation method and use

A technology of p-chlorobenzonitrile and ammoxidation, which is applied in the fields of organic chemistry and organic fine chemicals, can solve problems such as poor mechanical strength, decreased catalyst activity, and small specific surface area, and achieve good thermal stability, mechanical strength, and high Selectivity and activity, the effect of simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

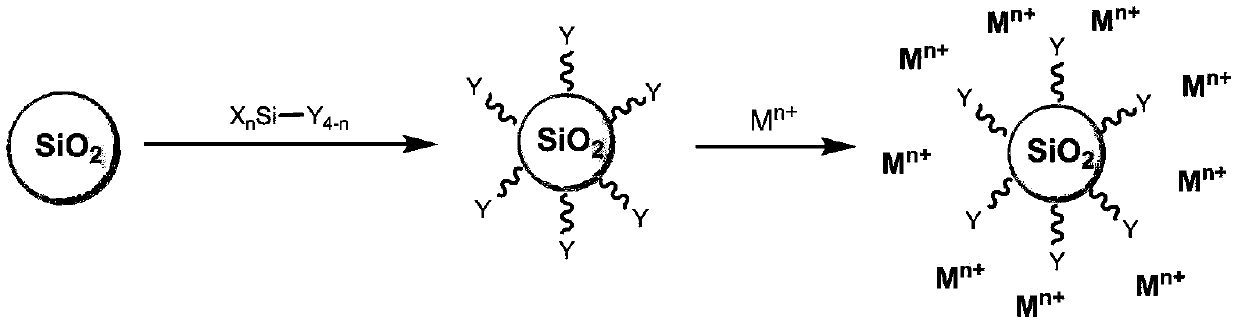

Method used

Image

Examples

Embodiment 1

[0023] 9.33 g H 2 C 2 o 4 2H 2 O was dissolved in 100 mL of 80°C distilled water, and 4.49 g of V was added 2 o 5 After complete reaction, slowly add 5.69 grams of 85% phosphoric acid, 7.89 grams of chromium nitrate nonahydrate, 0.77 grams of boric acid and 0.13 grams of sodium carbonate. 60-120 mesh silica gel, after stirring evenly, age for 12 hours, dry in a muffle furnace at 110°C, then gradually raise the temperature to 550°C, and keep the temperature for 6 hours. After natural cooling, set aside. The composition of the catalyst is: VPCr 0.4 B 0.25 Na 0.05 o 6 / m-SiO 2 .

[0024] 20g of the above-mentioned solid catalysts are filled in a quartz tube fixed-bed reactor with an internal diameter of 30mm, and the molar ratio of the reaction raw materials is: p-chlorotoluene:NH 3 :Air=1:5:40, the reaction temperature is 673±1K, and the catalyst load is 100g / (kgcat·h). After reacting for 8 hours, the conversion rate of p-chlorotoluene was 98.6%, and the molar yield...

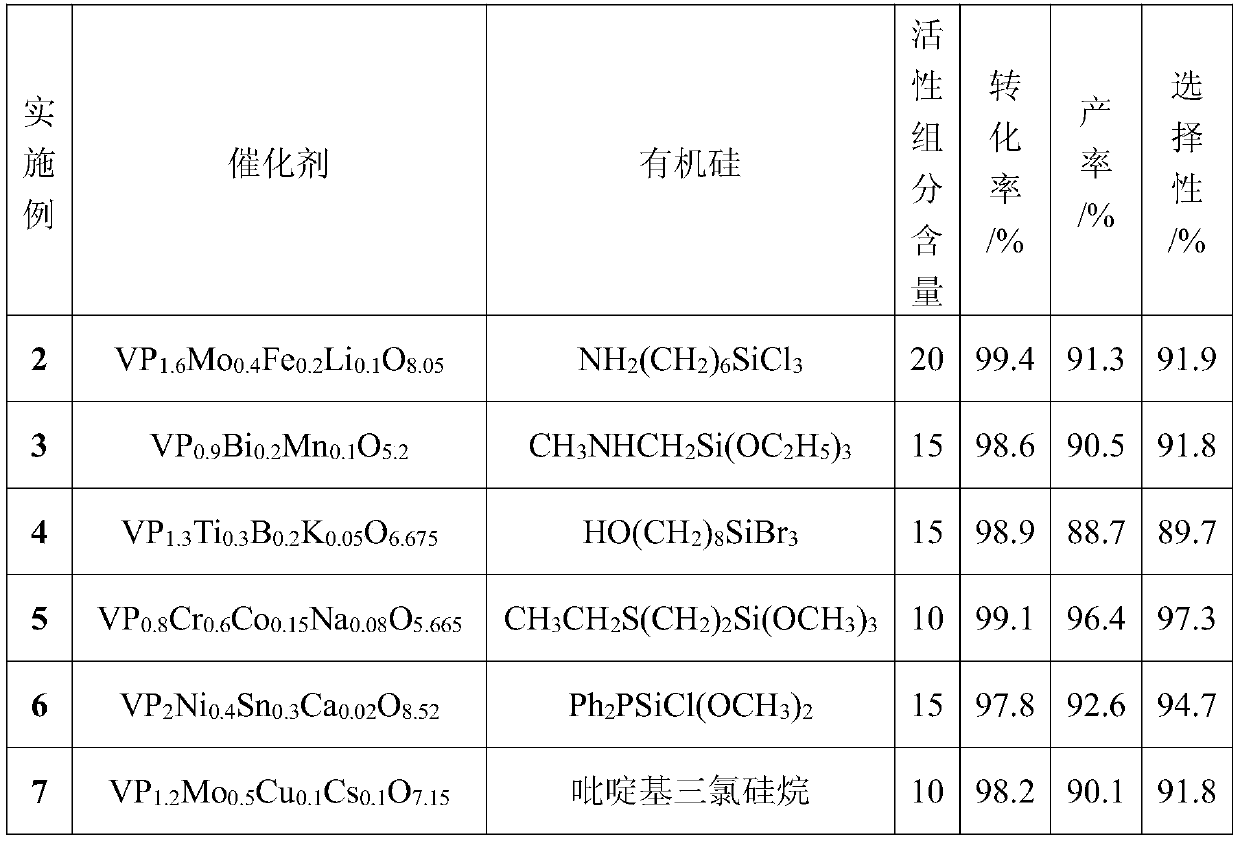

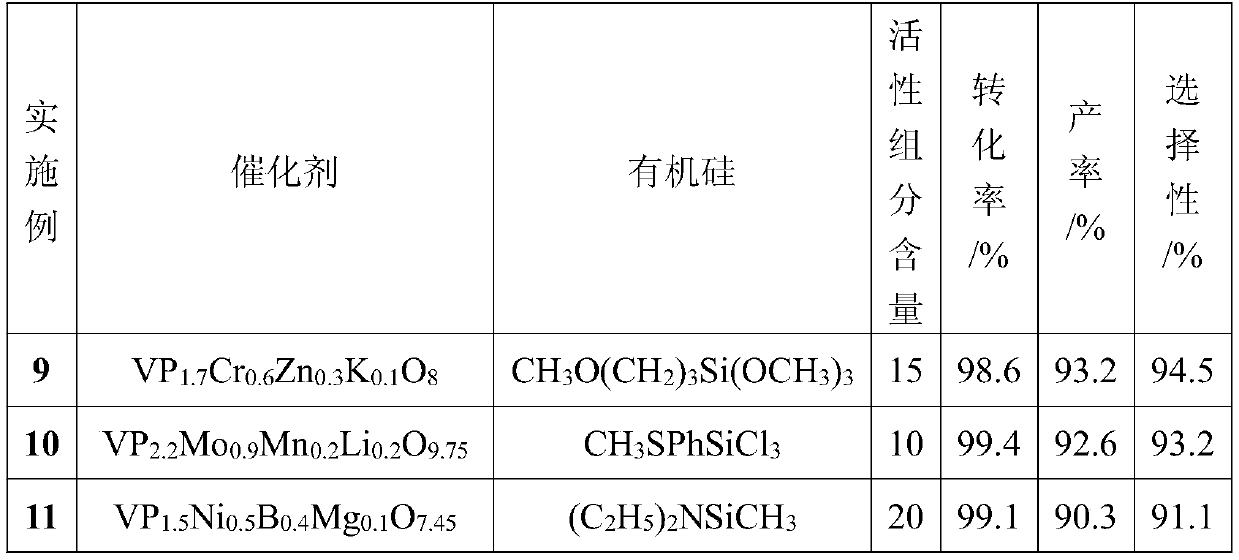

Embodiment 2~7

[0026] Catalyst formula is different, and reaction condition is with embodiment 1, and result is as follows:

[0027]

Embodiment 8

[0029] Dissolve 5g of thienyltrimethoxysilane in 50ml of ethanol, add 80g of silica gel and stir well, let it stand for 12 hours, evaporate the solvent, and dry it in vacuum at 60°C for later use. 13.93 g H 2 C 2 o 4 2H 2 O was dissolved in 80 mL of distilled water at 85 °C, and then 6.71 g of V 2 o 5 , 11.89 grams of phosphoric acid, 4.38 grams of nickel chloride and 2.15 grams of cobalt nitrate hexahydrate, after forming a uniform solution, slowly add 80 grams of the above-mentioned silica gel that was treated with thienyltrimethoxysilane. After stirring evenly, let stand for 12 hours, dry at 120°C in a muffle furnace, then gradually raise the temperature to 500°C, and keep the temperature for 12 hours. After cooling naturally, save for later use. The composition of the catalyst is: VP 1.4 Ni 0.25 co 0.1 o 6.4 .

[0030] 15g of catalyst is loaded into a fixed-bed reactor with a quartz tube with an inner diameter of 30mm, and the mixed gas of raw materials passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com