Food-grade environment-friendly natural-degradable plastic bag

A plastic bag, food-grade technology, applied in the field of plastics, can solve the problems of long degradation time of plastic bags, easy breeding of bacteria, bacteria breeding, etc., achieve good biocompatibility and photoluminescence, inhibit bacterial adhesion, increase The effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

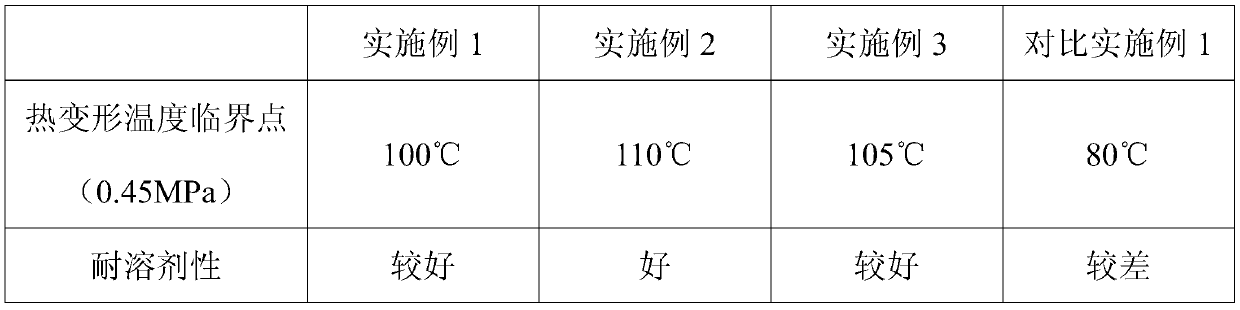

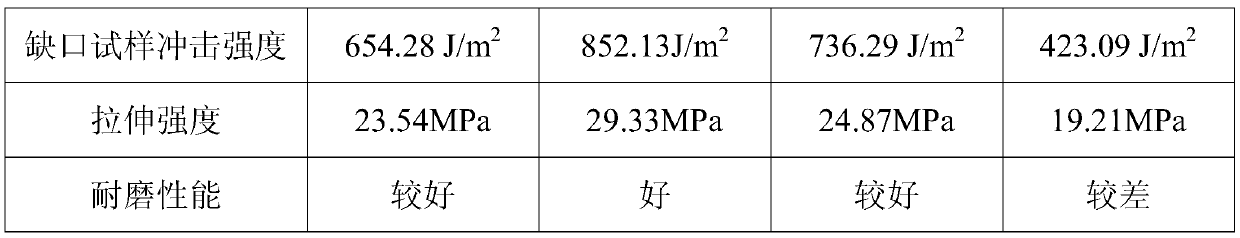

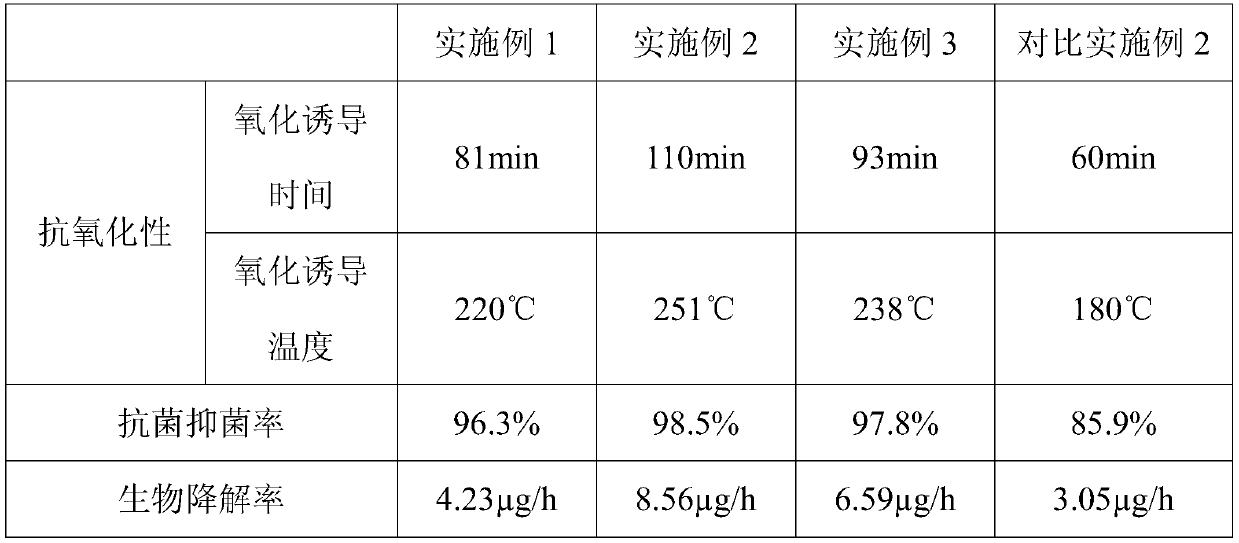

Examples

Embodiment 1

[0046] A food-grade environmentally friendly and naturally degradable plastic bag, the plastic bag material includes the following components in parts by weight:

[0047] 20 parts of high-density polyethylene;

[0048] 15.5 parts of polylactic acid;

[0049] 5 parts of poly-β-hydroxybutyrate;

[0050] 4.2 parts of crosslinking agent 1-n-butyl-3-(3(dimethylamino)propyl)carbodiimide hydrochloride;

[0051] 21 parts of discarded waste sawdust plant fiber;

[0052] 10 parts of modified starch;

[0053] (Proanthocyanidins-catechin)-lecithin / chitosan nanoparticles 11 parts;

[0054] 10 parts of nano molybdenum dioxide particles;

[0055] 10 parts of nano-embedded lactic acid bacteria and bifidobacteria particles;

[0056] 7.1 parts of adamantane;

[0057] 5.05 parts of ammonium polyphosphate;

[0058] 5 parts of N-hydroxysuccinimide;

[0059] 2 parts of β-cyclodextrin.

[0060] Wherein (proanthocyanidin-catechin)-lecithin / chitosan nanoparticle preparation method is:

[00...

Embodiment 2

[0071] A food-grade environmentally friendly and naturally degradable plastic bag, the plastic bag material includes the following components in parts by weight:

[0072] 59.8 parts of high-density polyethylene;

[0073] 25 parts of polylactic acid;

[0074] 8 parts of poly-β-hydroxybutyrate;

[0075] 10 parts of crosslinking agent 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride;

[0076] 30 parts of waste sawdust plant fiber;

[0077] 20 parts of modified starch;

[0078] 19.9 parts of epicatechin-lecithin / chitosan nanoparticles;

[0079] 20 parts of nano molybdenum dioxide particles;

[0080] 20 parts of nano-embedded Streptococcus thermophilus particles;

[0081] 10 parts of adamantane;

[0082] 10 parts of ammonium polyphosphate;

[0083] 10 parts of N-hydroxysuccinimide;

[0084] 5 parts of β-cyclodextrin.

[0085] Wherein the preparation method of epicatechin-lecithin / chitosan nanoparticles is:

[0086] S1: The chitosan aqueous solution of 0.49% we...

Embodiment 3

[0097] A food-grade environmentally friendly and naturally degradable plastic bag, the plastic bag material includes the following components in parts by weight:

[0098] 40 parts of high-density polyethylene;

[0099] 20.2 parts of polylactic acid;

[0100] 13.2 parts of poly-β-hydroxybutyrate;

[0101] 7 parts of crosslinking agent N-(3-dimethylaminopropyl)-N'-ethyl-carbodiimide hydrochloride;

[0102] 25 parts of discarded shavings plant fiber;

[0103] 15 parts of modified starch;

[0104] 15 parts of gallic acid-lecithin / chitosan nanoparticles;

[0105] 15 parts of nano molybdenum dioxide particles;

[0106] Nano-embedded Lactobacillus rhamnosus and Lactobacillus plantarum particles 15 parts;

[0107] 8.5 parts of adamantane;

[0108] 7.5 parts of ammonium polyphosphate;

[0109] 7.45 parts of N-hydroxysuccinimide;

[0110] 3.55 parts of β-cyclodextrin.

[0111] Wherein the preparation method of gallic acid-lecithin / chitosan nanoparticles is:

[0112] S1: the chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com