A kind of membrane electrode preparation method and its application method

An application method and membrane electrode technology, applied in the direction of material electrochemical variables, material analysis through electromagnetic means, instruments, etc., can solve the problems of lack of acetaminophen, etc., and achieve the effect of low cost, high sensitivity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

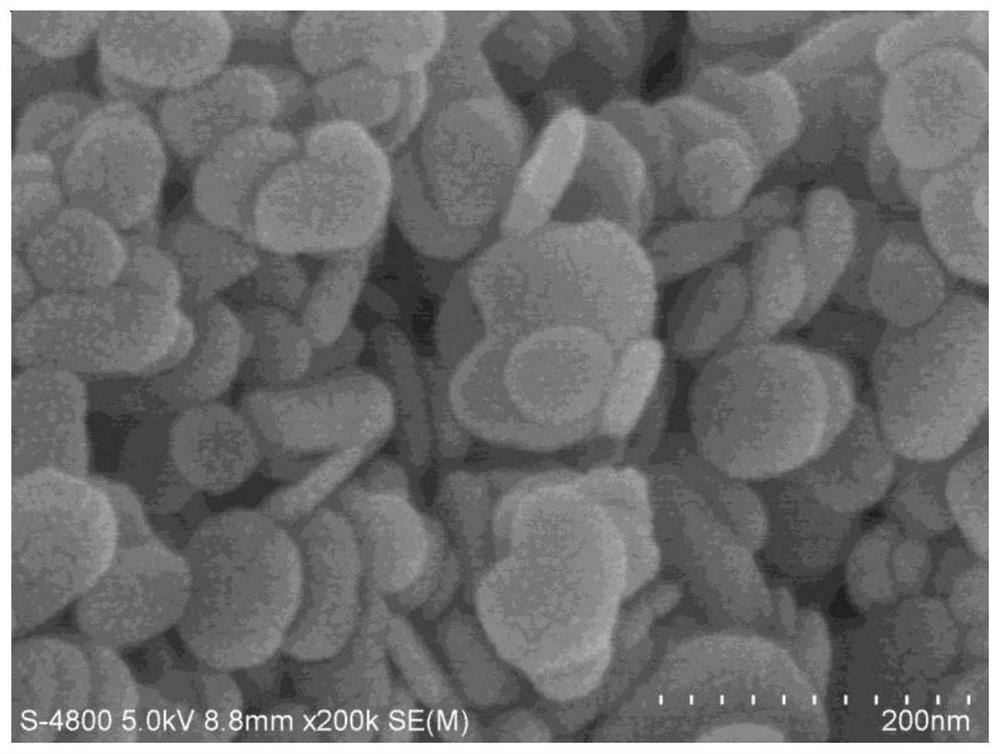

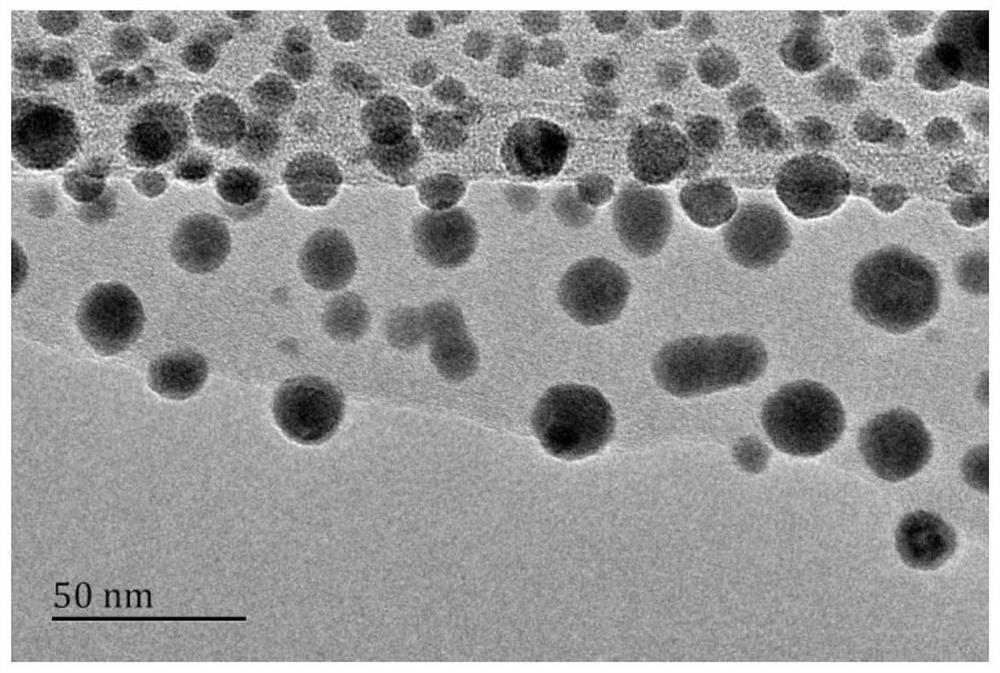

[0041] The preparation of embodiment 1, F-NGQDs / BiOBr / ITO

[0042]Dissolve 0.21g of citric acid monohydrate and 0.11g of urea in 5ml of deionized water, then transfer the solution to a 20mL Teflon-lined autoclave, and then put the autoclave into a forced air drying oven at 200 °C Heat for 3 hours; cool the autoclave to room temperature naturally, then transfer the resulting solution into a dialysis bag (retained molecular weight: 3000Da) and place it in a 1000mL beaker for dialysis for 72 hours. Replace deionized water once to obtain NGQDs aqueous solution. Then, add 2.24mg of bismuth nitrate pentahydrate to 5mL of ethylene glycol in a beaker, and magnetically stir until dissolved; then add 0.16mg of potassium bromide and 2.24mL of graphene quantum dot aqueous solution to the beaker, and transfer the solution to a 50mL high-pressure In the autoclave, hydrothermal reaction was carried out at 100°C for 6 h, the autoclave was naturally cooled to room temperature, centrifuged, an...

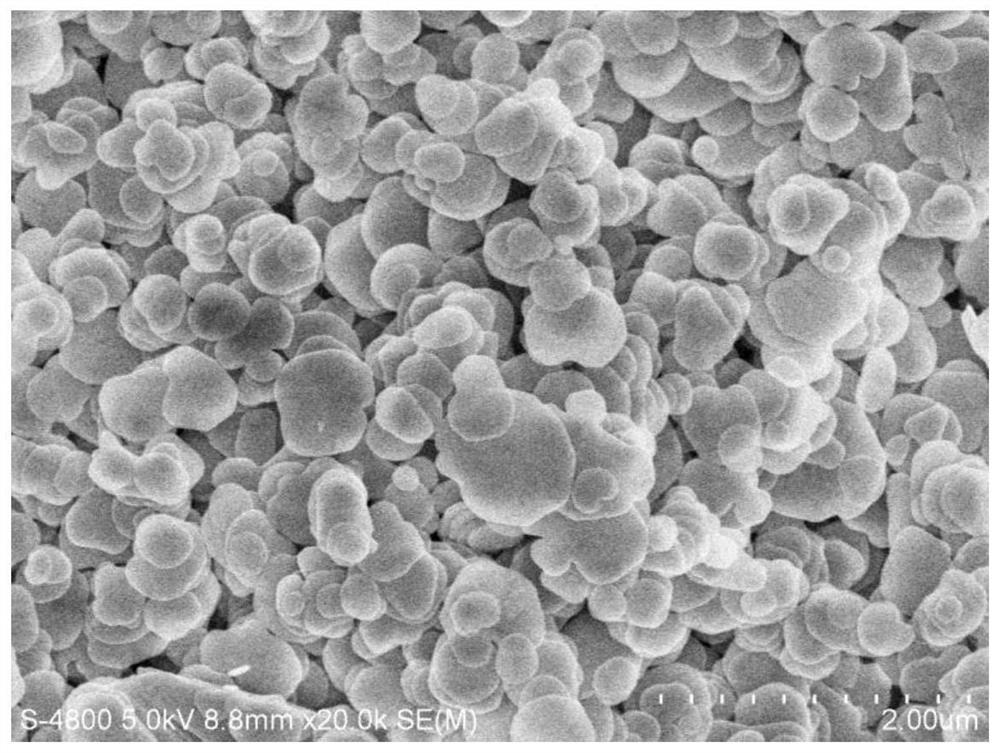

Embodiment 2

[0043] The preparation of embodiment 2, F-NGQDs / BiOBr / ITO

[0044] Dissolve 0.21g of citric acid monohydrate and 0.25g of urea in 5ml of deionized water, then transfer the solution to a 20mL Teflon-lined autoclave, and then put the autoclave into a blast drying oven at 120°C Heating for 5 hours; naturally cooling the autoclave to room temperature, then transferring the obtained solution into a dialysis bag (retained molecular weight: 500Da) and placing it in a 1000mL beaker for dialysis for 24 hours. Replace deionized water once to obtain NGQDs aqueous solution. Then, 2.24mg of bismuth nitrate pentahydrate was added to 15mL of ethylene glycol in a beaker, and magnetically stirred until dissolved; then 0.43mg of potassium bromide and 7.8mL of graphene quantum dot aqueous solution were added to the beaker, and the solution was transferred to a 50mL high-pressure In the autoclave, hydrothermal reaction was carried out at 140 °C for 4 h, the autoclave was naturally cooled to room...

Embodiment 3

[0045] Embodiment 3, the preparation of F-NGQDs / BiOBr / ITO

[0046] Dissolve 0.21g of citric acid monohydrate and 0.18g of urea in 5ml of deionized water, then transfer the solution to a 20mL Teflon-lined autoclave, and then put the autoclave into a forced air drying oven at 160 °C Heat for 4 hours; cool the autoclave to room temperature naturally, then transfer the obtained solution into a dialysis bag (retained molecular weight: 1000Da) and place it in a 1000mL beaker for dialysis for 48 hours. The length of the dialysis bag is 10cm and the volume of deionized water is 900mL. Replace deionized water once to obtain NGQDs aqueous solution. Then, 2.24mg of bismuth nitrate pentahydrate was added to 10mL of ethylene glycol in a beaker, and magnetically stirred until dissolved; then 0.30mg of potassium bromide and 5mL of graphene quantum dot aqueous solution were added to the beaker, and the solution was transferred to a 50mL autoclave , hydrothermally reacted at 120°C for 5h, coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com