Integrated equipment and method for desulfurization and denitrification synergistic absorption

A denitrification and equipment technology, applied in chemical instruments and methods, separation methods, nitrogen fertilizers, etc., can solve the problems of difficult emission of flue gas, unrecycled sulfur and nitrogen elements, and unsatisfactory absorption. Absorption rate, efficient resource utilization, and the effect of realizing resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

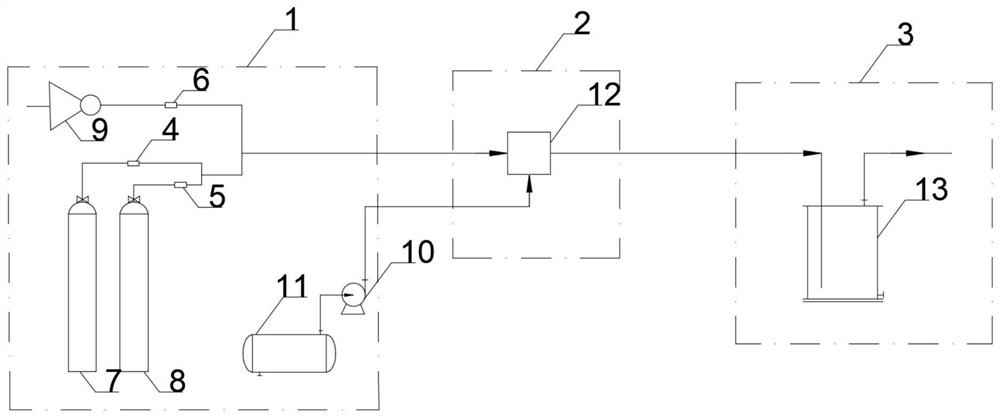

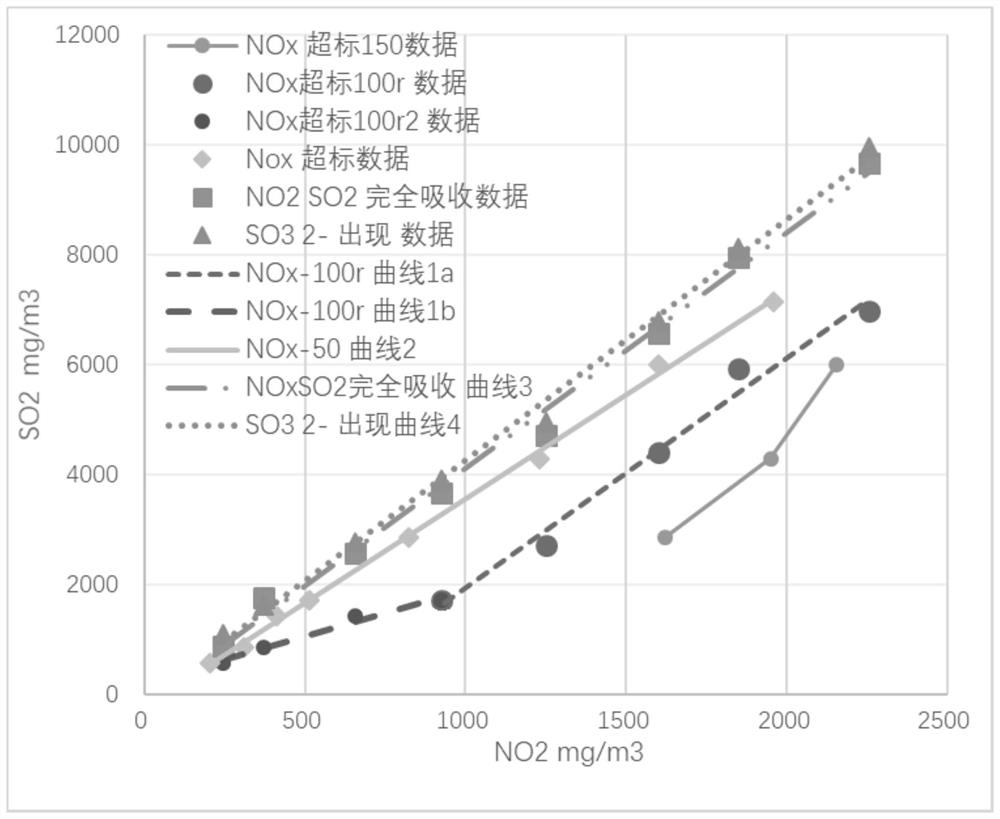

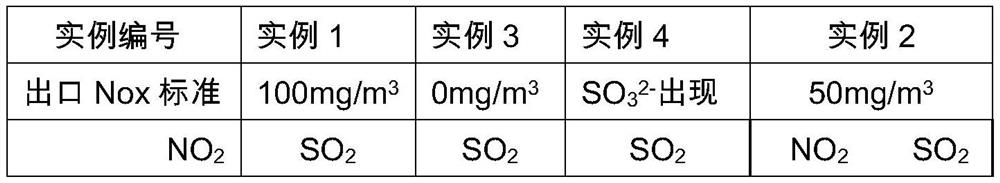

[0064] Turn on the air compressor, and respectively will contain a certain concentration of NO 2 , SO 2 Open the standard gas cylinder, get mixed gas with different proportions and contents by adjusting the mass flowmeter in each gas path, and pass it into the dispersed phase inlet of the microreactor, with a total flow rate of 1.0L / min. NO in the outlet mixed gas 2 , SO 2 , O 2 After the content of content, 5% NaOH solution is passed into microreactor continuous phase entrance, and flow rate is 10ml / min, and SO 2 At 550-7000mg / m 3 (200ppm-2500ppm) fixed at one point, then gradually increase NO 2 Content, gas absorption at room temperature, record to meet NOx3 , NO 2 When the content is maximum, NO 2 and SO 2 The data corresponding to the contents are recorded as (NO 2 , SO 2 ), a series of points satisfying the conditions are obtained, the data are shown in Table 1, and the graph is shown in figure 2 , marked with "NOx exceeded 100r data" and "NOx exceeded 100r2 d...

Embodiment 2

[0067] Turn on the air compressor, and respectively will contain a certain concentration of NO 2 , SO 2 Open the standard gas cylinder, get mixed gas with different proportions and contents by adjusting the mass flowmeter in each gas path, and pass it into the dispersed phase inlet of the microreactor, with a total flow rate of 1.0L / min. NO in the outlet mixed gas 2 , SO 2 , O 2 After the content of content, 5% NaOH solution is passed into microreactor continuous phase entrance, and flow rate is 10ml / min, and SO 2 At 550-7000mg / m 3 (200ppm-2500ppm) fixed at one point, then gradually increase NO 2 Content, gas absorption at room temperature, records meet NO x 3 , NO 2 When the content is maximum, NO 2 and SO 2 The data corresponding to the contents are recorded as (NO 2 , SO 2), a series of points satisfying the conditions are obtained, the data are shown in Table 1, and the graph is shown in figure 2 , marked as "NOx exceeding the standard 50 data".

[0068] When...

Embodiment 3

[0070] Turn on the air compressor, and respectively will contain a certain concentration of NO 2 , SO 2 Open the standard gas cylinder, get mixed gas with different proportions and contents by adjusting the mass flowmeter in each gas path, and pass it into the dispersed phase inlet of the microreactor, with a total flow rate of 1.0L / min. NO in the outlet mixed gas 2 , SO 2 , O 2 After the content of the 5% NaOH solution is passed into the continuous phase inlet of the microreactor, the flow rate is 10ml / min, and the NO 2 At 250-2260mg / m 3 (120ppm-1100ppm) fixed at one point, then gradually increase SO 2 Content, gas absorption at room temperature, records meet NO x =0 mg / m 3 , SO 2 When the content is the smallest, when, NO 2 and SO 2 The data corresponding to the contents are recorded as (NO 2 , SO 2 ), a series of points satisfying the conditions are obtained, the data are shown in Table 1, and the graph is shown in figure 2 , labeled "NOx Complete Absorption D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com