A kind of bio-based slow and controlled release pesticide liquid mulch film and its preparation method and application

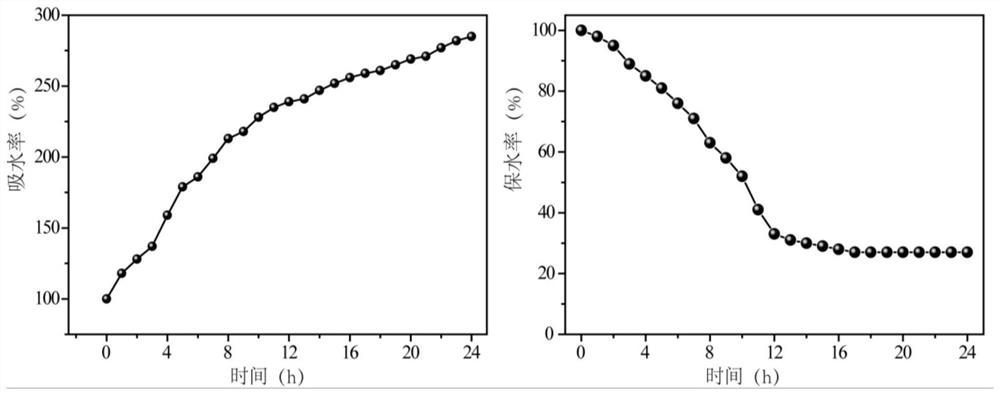

A technology of controlled-release pesticides and liquid mulch, applied in botany equipment and methods, chemicals for biological control, applications, etc., can solve the problem of soil heat preservation, insufficient water retention capacity, affecting the function of fertilizers and drugs, and the release of active ingredients Over-fast and other problems, to achieve slow and long-lasting biopesticide release ability, good water absorption and water retention, and shorten the cultivation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

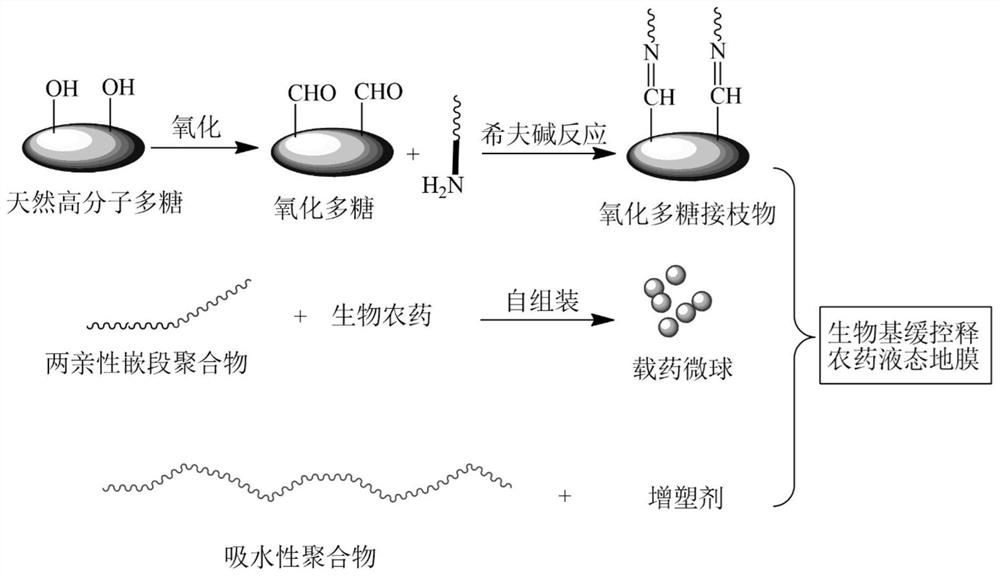

Method used

Image

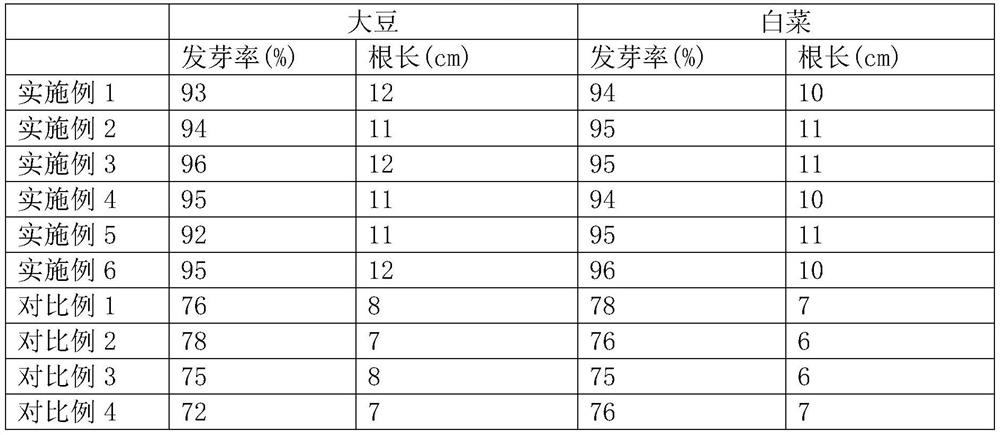

Examples

Embodiment 1

[0046] A preparation method for a xylan-based slow- and controlled-release pesticide liquid mulch film, comprising the following steps:

[0047] (1) At room temperature, add 1 g of xylan to 19 g of water at a speed of 500 r / min to obtain a uniform dispersion. Immediately add 0.1 g of the oxidant sodium periodate, place it in a microwave reactor, and wrap it with tinfoil, set the microwave radiation power to 50W, react at 25°C for 12 hours, dialyze with a 5000 molecular weight dialysis bag, and freeze-dry to obtain oxidized wood polysaccharides.

[0048] (2) Disperse 0.5 g of oxidized xylan in step (1) in methanol, add 1 g of chitosan, stir and react for 6 hours at 80 ° C, dialyze with a 10,000 molecular weight dialysis bag, and freeze-dry to obtain oxidized polysaccharide graft things.

[0049] (3) Dissolving 0.5g amphiphilic block polymer polyethylene glycol monomethyl ether-polycaprolactone in dimethyl sulfoxide, adding 1.5g of biopesticide avermectin, at 60°C, Ultrasonic...

Embodiment 2

[0053] The preparation method of ethyl cellulose-based slow and controlled release pesticide liquid mulch film comprises the following steps:

[0054] (1) At room temperature, add 3 g of ethyl cellulose into 21 g of water at a speed of 550 r / min to obtain a uniform dispersion. Immediately add 3g of oxidizing agent ortho-periodic acid, put it in a microwave reactor, and wrap it with tinfoil paper, set the microwave radiation power to 350W, react at 80°C for 4h, dialyze with a 5000 molecular weight dialysis bag, and freeze-dry to obtain oxidized ethyl fiber white.

[0055] (2) Disperse 1 g of oxidized ethyl cellulose in step (1) in tert-butanol, add 5 g of inulin lauryl carbamate, stir and react for 10 h at 60 ° C, dialyze with a 10,000 molecular weight dialysis bag, and freeze Dry to obtain oxidized polysaccharide grafts.

[0056] (3) Dissolve 0.5 g of the amphiphilic block polymer polyethylene glycol-polylactide in dimethyl sulfoxide, add 0.5 g of the biopesticide metalaxyl,...

Embodiment 3

[0060] The preparation method of sodium alginate-based slow and controlled release pesticide liquid mulch film comprises the following steps:

[0061] (1) At room temperature, add 1.5 g of sodium alginate to 18 g of tert-butanol at a speed of 600 r / min to obtain a uniform dispersion. Immediately add 0.6g of a mixture of di-ortho-sodium periodate and barium periodate with a mass ratio of 1:2, place it in a microwave reactor, wrap it with tinfoil paper, set the microwave radiation power to 200W, react at 100°C for 30h, and use 5000 molecular weight dialysis bag dialysis, freeze-drying to obtain oxidized sodium alginate.

[0062] (2) Disperse 1 g of oxidized sodium alginate in step (1) in methanol, add 10 g of collagen, stir and react at 90 ° C for 1 hour, dialyze with a 10,000 molecular weight dialysis bag, freeze-dry, and store for later use to obtain oxidized sodium alginate graft thing.

[0063] (3) Dissolve 1 g of the amphiphilic block polymer polymethyl methacrylate-polya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com