Monocrystalline silicon wafer texturing additive and application thereof

A single crystal silicon wafer and additive technology, which is applied in the direction of single crystal growth, single crystal growth, sustainable manufacturing/processing, etc., can solve the problems of large environmental impact, low speed, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

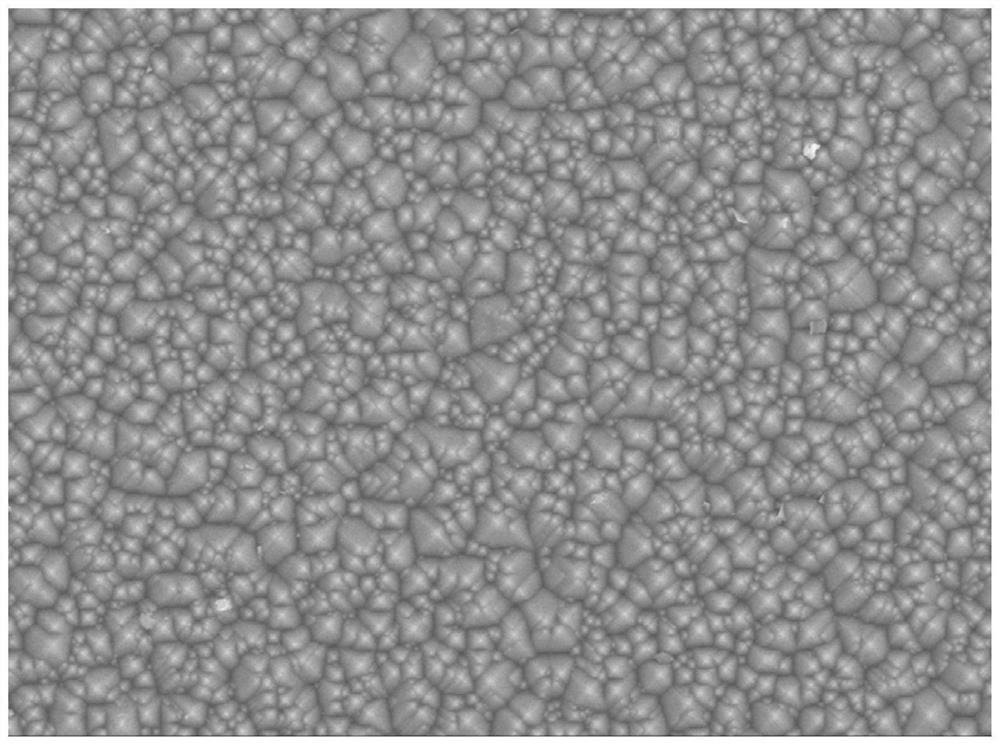

Embodiment 1

[0039] Embodiment 1 of the present invention: the application of a kind of monocrystalline silicon slice texturing additive, comprises the following steps:

[0040] S1. Preparation of monocrystalline silicon wafer texturing additives: 0.03g polyethylene glycol-600, 1.0g polyethylene glycol-400, 0.3g sodium carboxymethylcellulose, 1.0g potassium perfluorooctanesulfonate, 0.5 gN, N-methylenebisacrylamide, 0.8g gallic acid, 0.5g triethylene glycol monobutyl ether and 0.5g sodium benzoate were added to water to prepare 100g monocrystalline silicon chip texturing additive.

[0041] S2. Prepare monocrystalline silicon wafer texturing liquid: Add monocrystalline silicon wafer texturing additive to sodium hydroxide solution (mass fraction: 1.5%) to obtain monocrystalline silicon wafer texturing liquid; wherein, the texturing additive and hydrogen The volume ratio of sodium oxide solution is 0.8:100.

[0042]S3, cashmere making: sodium hydroxide solution, hydrogen peroxide solution an...

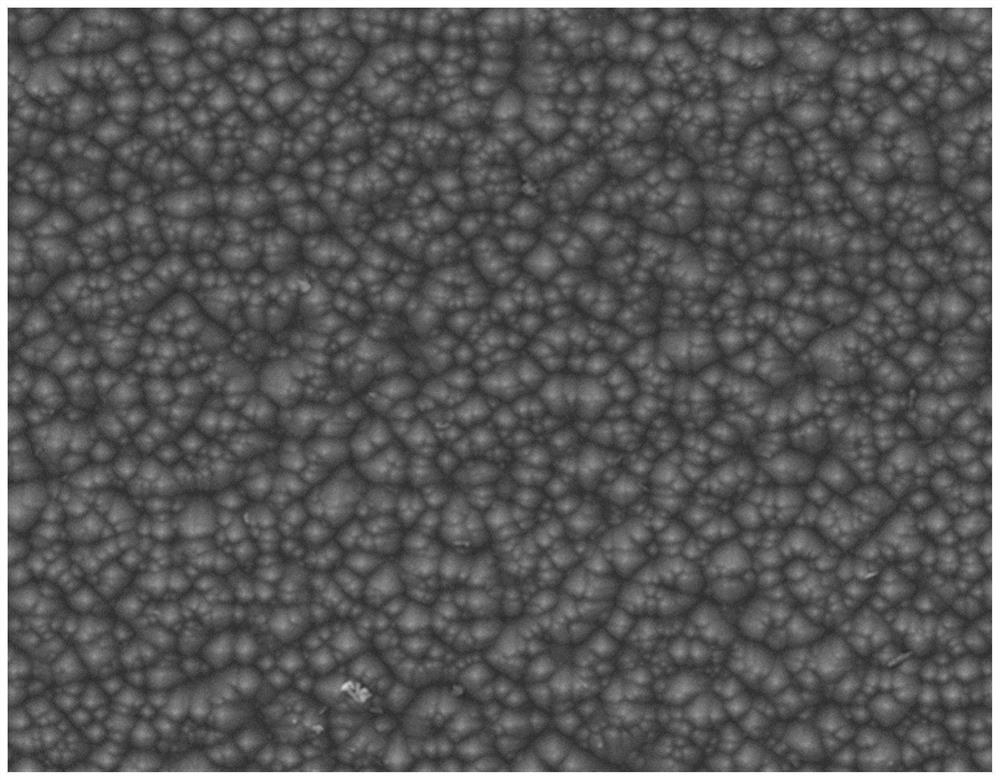

Embodiment 2

[0043] Embodiment 2 of the present invention: the application of a monocrystalline silicon wafer texturing additive, comprises the following steps:

[0044] S1. Preparation of monocrystalline silicon wafer texturing additives: 0.0005g of alkyl glucoside, 1.5g of polyethylene glycol-200, 0.5g of sodium alginate, 0.3g of tetraethylammonium perfluorohexylsulfonate, 10.0g of N-methyl Pyrrolidone, 0.3g of gallic acid, 0.6g of diethylene glycol monobutyl ether, 0.5g of sodium benzoate were added to water to prepare 100g of a monocrystalline silicon chip texturing additive.

[0045] S2. Preparation of monocrystalline silicon wafer texturing liquid: Add monocrystalline silicon wafer texturing additive to sodium hydroxide solution (2.0% by mass fraction) to obtain monocrystalline silicon wafer texturing liquid; wherein, the texturing additive and hydrogen The volume ratio of sodium oxide solution is 0.6:100.

[0046] S3, cashmere making: sodium hydroxide solution, hydrogen peroxide so...

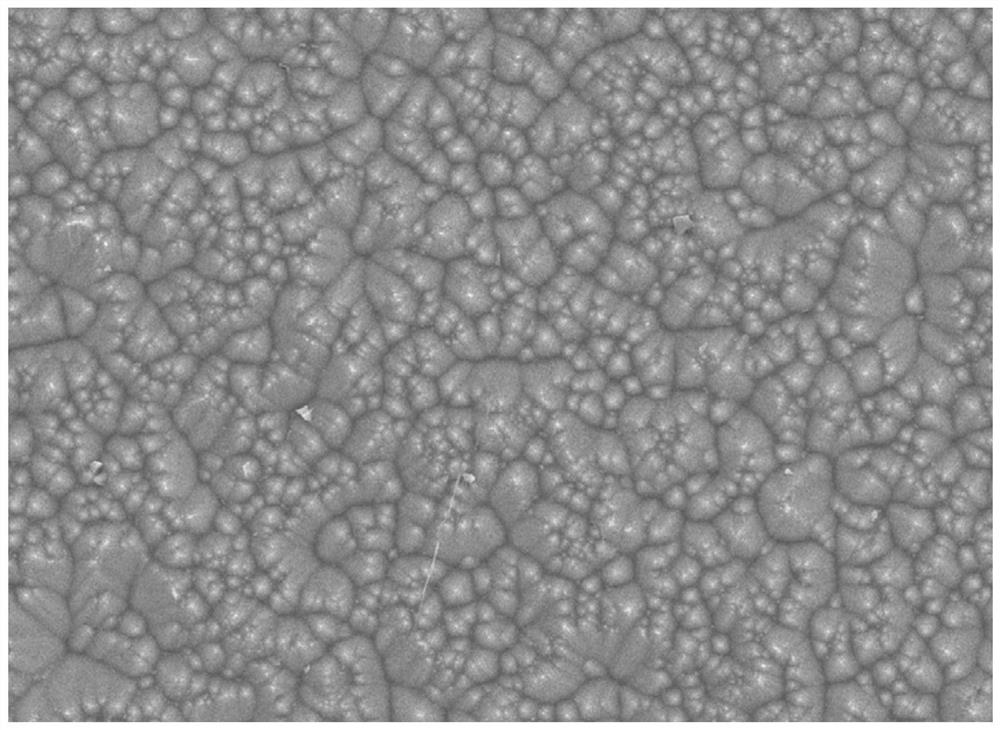

Embodiment 3

[0047] Embodiment three of the present invention: the application of a monocrystalline silicon chip texturing additive, comprises the following steps:

[0048] S1. Preparation of monocrystalline silicon wafer texturing additives: 1.0 g polyethylene glycol-400, 3.0 g polyethylene glycol-200, 0.3 g sodium carboxymethyl cellulose, 0.3 g perfluorooctyl ammonium sulfonate, 10.0 gN-methylpyrrolidone, 0.05gN-N-methylenebisacrylamide, 0.5g gallic acid, 0.7g diethylene glycol monobutyl ether and 0.3g sodium benzoate, add water to make 100g monocrystalline silicon chip texturing additive .

[0049] S2. Preparation of monocrystalline silicon wafer texturing liquid: adding monocrystalline silicon wafer texturing additive to potassium hydroxide solution (mass fraction: 1.5%) to obtain monocrystalline silicon wafer texturing liquid; wherein, the texturing additive and hydrogen The volume ratio of potassium oxide solution is 0.8:100.

[0050] S3, cashmere making: sodium hydroxide solution,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com