A kind of construction method of engineering strain for producing tetrahydropyrimidine by biological method

A technology of tetrahydropyrimidine and engineering strains, which is applied to the construction of engineering strains for producing tetrahydropyrimidine, the production and application field of the strain can solve the problem of restricting the industrial production of tetrahydropyrimidine and the application in a wide range of fields, increasing the production cost of heating and cooling processes, Reduce the stability of enzymatic reactions and other problems, and achieve the effects of saving industrial energy consumption, large industrialization potential, and simple and easy purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

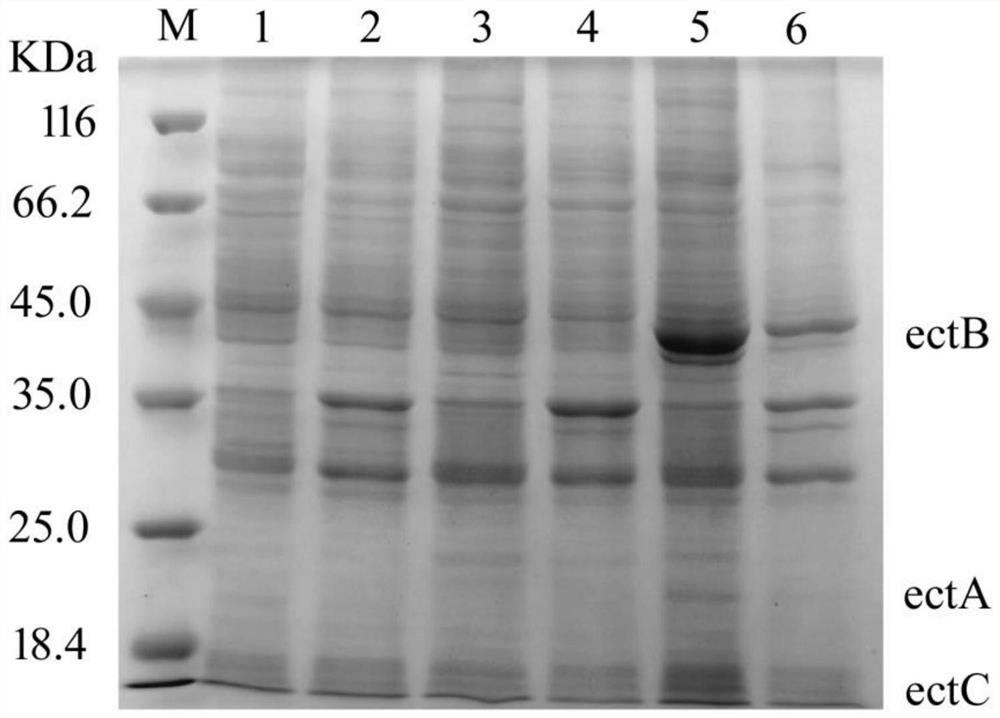

[0040] Example 1: Construction and identification of recombinant strains

[0041] 1. Construction of strains containing recombinant plasmid pET-ECT

[0042] 1) Plasmid construction

[0043] Plasmid pET24 is 4.97kb in size, contains kanamycin resistance gene, lactose repressor lac I gene, tac promoter, and multiple restriction endonuclease sites.

[0044] Commercially artificially synthesized DNA fragments derived from the tetrahydropyrimidine synthesis gene cluster of Salinicola salaria, the nucleotide sequence is as shown in SEQ ID NO: 1 in the sequence listing.

[0045] The synthetic tetrahydropyrimidine was digested with EcoR I and Nde I to synthesize the gene cluster DNA fragment, and the vector pET24 was digested with EcoR I and Nde I. Enzyme digestion system: DNA 43 μL, Buffer R 5 μL, Nde I 1 μL, EcoR I 1 μL, incubated at 37°C for 3 hours.

[0046] The digested DNA fragments were gelatinized, and T4 ligase was used to connect the tetrahydropyrimidine synthetic gene cl...

Embodiment 2

[0052] Example 2: Fermentation of recombinant strains

[0053] 100 mL of seed solution was prepared, and the seed solution contained 1% peptone, 0.5% yeast extract, 1% sodium chloride, and the balance was purified water. After being sterilized in a 250 mL Erlenmeyer flask, a single colony on the plate medium was inoculated, and the rotation speed of the shaker was 200 rpm. After culturing at 37°C for 16 hours, it was inoculated into a 500 mL conical flask containing 100 mL of fermentation broth. The fermentation broth contained 1.2% peptone, 2.4% yeast extract, 0.4% glycerol, 0.23% potassium dihydrogen phosphate, and 1.25% dipotassium hydrogen phosphate. The remainder is pure water. Fermentation culture conditions: inoculate at 1% of the fermentation volume, culture at 37°C, shake at 200 rpm, 2 hours after inoculation, cool down to 25-28°C, add final concentration of 0.2mM IPTG, and culture for 12 hours. After the fermentation and culture, take 1 mL of bacterial cells and co...

Embodiment 3

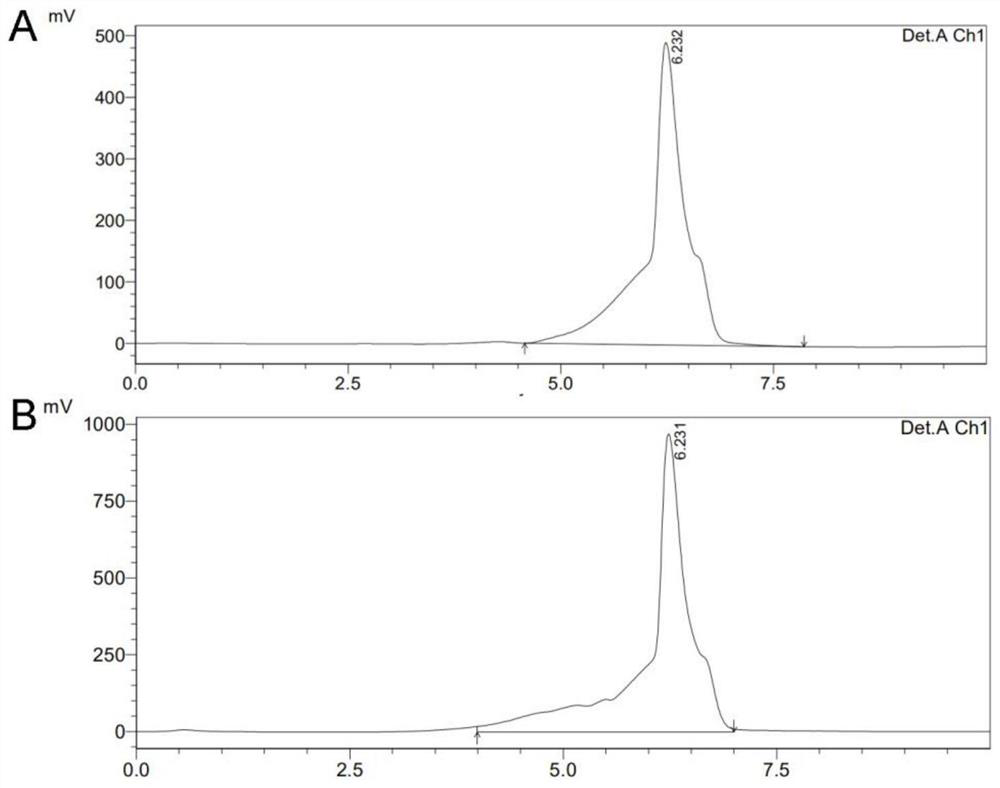

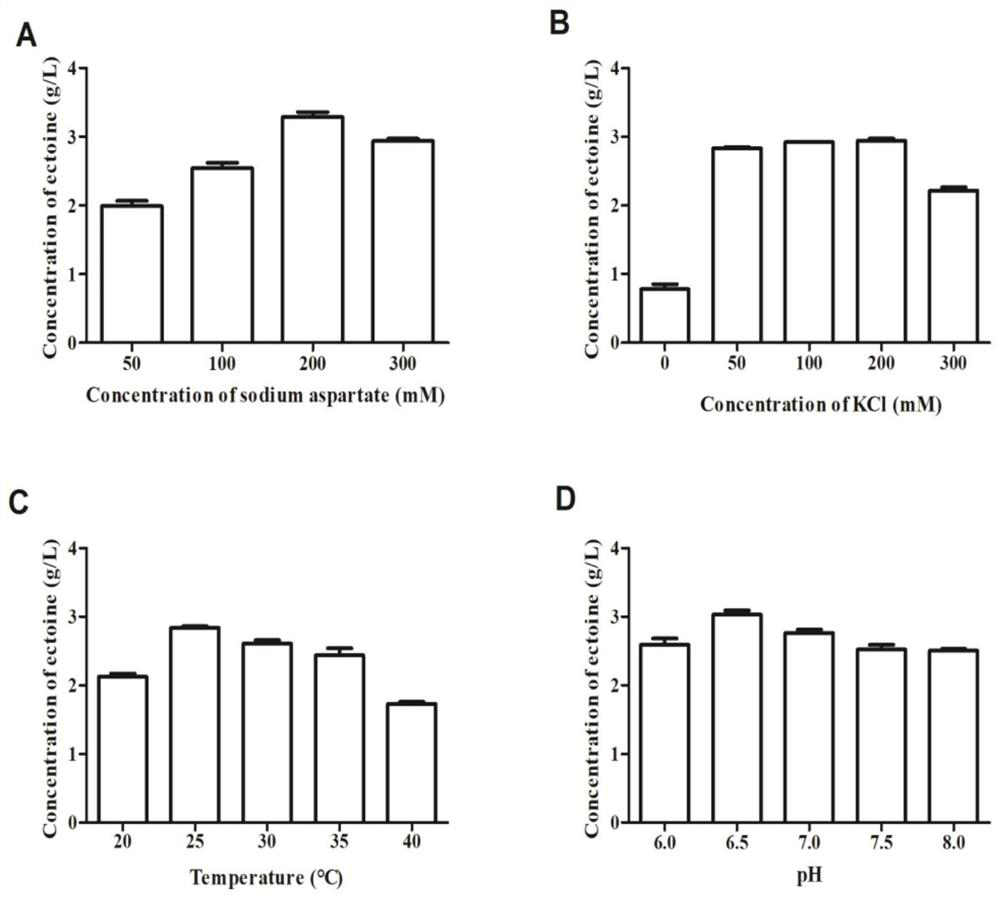

[0054] Example 3: Catalysis of sodium aspartate to generate tetrahydropyrimidine

[0055] After the fermentation was completed, the cells were collected by low-temperature centrifugation at 4000rpm at 4°C, and the cells were suspended with 20mL pH 6.5 phosphate buffer, 200mM sodium aspartate, 100mM glucose, 50mM potassium chloride, and transferred to a 100mL conical flask for transformation. The conditions were 20°C reaction, and the shaker revolution was 180 rpm. After 24 hours, the tetrahydropyrimidine yield was 2.15 g / L detected by high performance liquid chromatography (HPLC).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com