Chemical nickel plating aging liquid reduction regeneration method

A technology of electroless nickel plating and aging solution, applied in liquid chemical plating, electrodes, coatings, etc., can solve the problems of high processing cost, high energy consumption, and non-recyclability, and achieve the reduction of concentration ratio and the reduction of chemical agents The effect of less, large exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

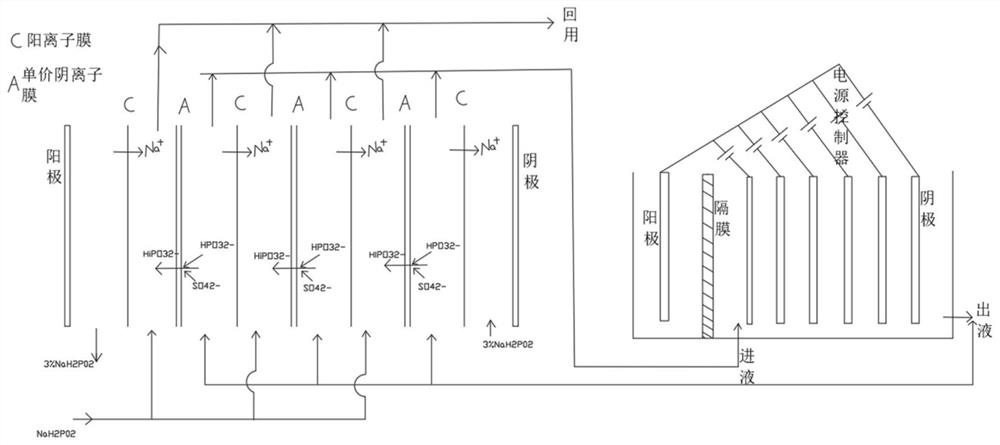

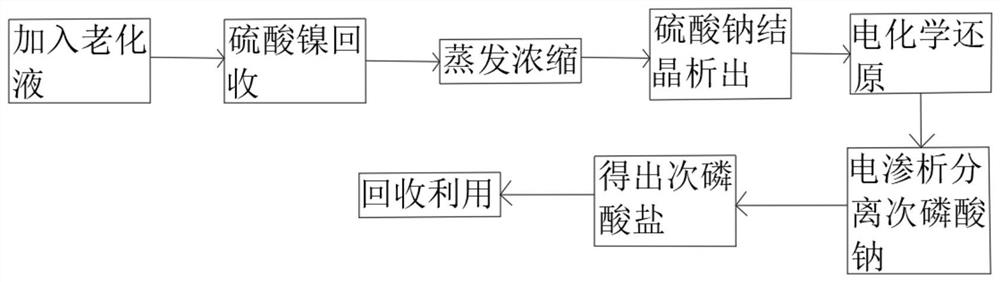

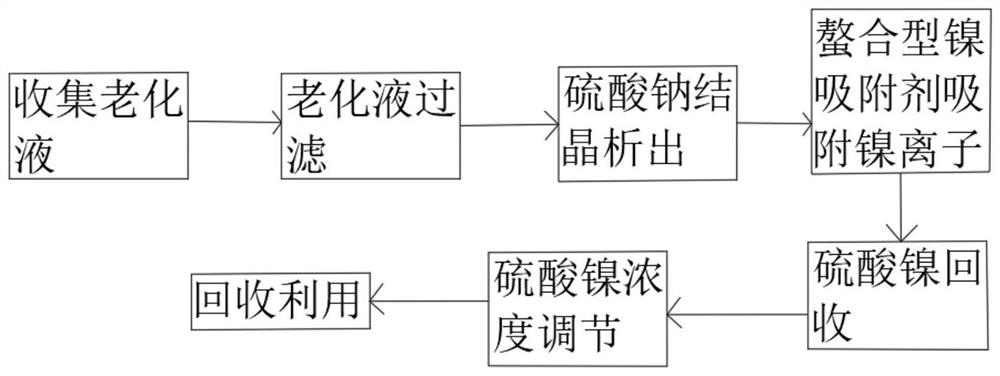

Method used

Image

Examples

Embodiment

[0047] Take 10 liters of aging solution, measure

[0048] Ni2+: 4.8g / l

[0049] NaH2PO2: 12.3g / l

[0050] Na2HPO3: 165.2g / l

[0051] Na2SO4:96.4g / l

[0052] Step 1: Filtrate, filter with an ultrafiltration membrane filter to remove solid impurities, and discharge it into the raw water tank that absorbs nickel;

[0053] Step 2: With a peristaltic pump, the nickel-containing aging solution is discharged into the nickel adsorption system with a flow rate of 2 liters per hour. After passing through three series adsorption columns, the nickel content in the water is measured to be 1.05 ppm, and the water output is 9.0 liters. It is discharged into the front storage tank of the evaporator. At this time, the first adsorption nickel column needs to be regenerated, and the following method is used for regeneration:

[0054] 1. Connect the effluent of the column to be regenerated to the original water tank of the system,

[0055] 2. Open the air valve to discharge the liquid in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com