Functional material capable of visually degrading formaldehyde and VOCs (Volatile Organic Compounds) at normal temperature and normal pressure and preparation method thereof

A functional material, normal pressure technology, applied in the fields of big health, environmental protection, new materials and gas pollution control, gas purification, can solve problems such as physical health hazards, limited wide application, easy damage, etc., to meet the requirements of low use environment, use Expansive, highly reactive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Preparation of Example Material 1: Weigh 23.5g of white carbon black, 17.2g of titanium dioxide, and 46.5g of activated carbon, mix and stir evenly, and heat in a muffle furnace at 850°C for 12h to form a loading agent. In the hydrochloric acid ethanol solution containing 13.1g nickel sulfate, 2.1g nitric acid, 4g cobalt nitrate, add 1.5g aluminum potassium sulfate, 1.1g sodium sulfate, adjust pH and temperature with 0.2~2mol / L ammonia water, make just have Precipitate, then add loading agent, adjust pH with 0.1-3 mol / L citric acid, place in 95°C water bath and stir for 24 hours to slowly form precipitate, stand for aging, and separate solid. The solid is calcined in a muffle furnace at 1000°C for 10 hours in a nitrogen atmosphere to obtain a functional material for visually degrading formaldehyde and VOCs at normal temperature and pressure. The prepared material will change from black to yellow-brown after reacting with formaldehyde and VOCs at normal temperature and p...

Embodiment 2

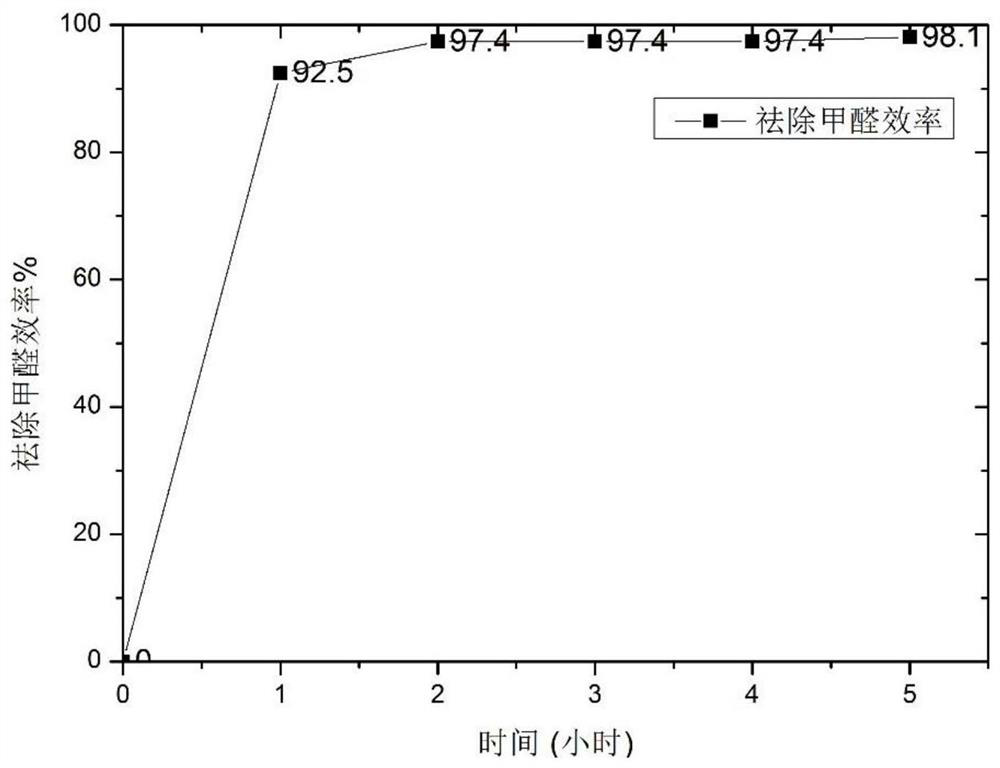

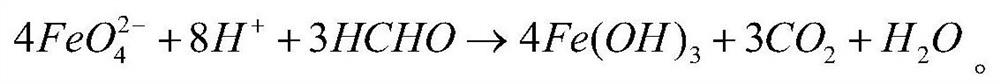

[0068] Weigh 21.8g of perlite, 19.6g of calcium carbonate, and 15.8g of kaolin, mix and stir evenly, and heat in a muffle furnace at 900°C for 15h to form a loading agent. In the sulfuric acid ethanol solution containing 16.2g ferric chloride, 15.8g potassium dichromate, 16.2g cobalt sulfate, add 0.11g sodium tartrate, 2.5g sodium borate, adjust pH and The temperature is such that there is just precipitation in the solution, and then the loading agent is added, the pH is adjusted with 0.1-0.5 mol / L hydrochloric acid, placed in a water bath at 80°C and stirred for 12 hours, left to age, and the solid is separated. The solid is calcined in a muffle furnace at 800°C for 12 hours in a nitrogen atmosphere to obtain a functional material for visually degrading formaldehyde and VOCs at normal temperature and pressure. The prepared material will change from purple to black after reacting with formaldehyde and VOCs at normal temperature and pressure, and the removal efficiency of forma...

Embodiment 3

[0070] Weigh 5.9g of diatomaceous earth, 4.6g of zeolite, 3.1g of gypsum, and 35g of barium sulfate, mix and stir evenly, and heat in a muffle furnace at 1000°C for 24h to form a loading agent. In the hydrochloric acid aqueous solution containing 15.7g iron sulfate, 0.09g potassium permanganate, 2.3g zinc nitrate, add 5.3g sodium pyrophosphate, 18g potassium phosphate, adjust pH and temperature with 0.2~2mol / L sodium bicarbonate solution, Just make the solution precipitate out, then add the loading agent, adjust the pH with 0.1-2mol / L acetic acid, put it in a 95°C water bath and stir for 24h, let it stand for aging, and separate the solid. The solid is calcined in a muffle furnace at 1000°C for 10 hours in a nitrogen atmosphere to obtain a functional material for visually degrading formaldehyde and VOCs at normal temperature and pressure. The prepared material will change from purple red to earthy yellow after reacting with formaldehyde and VOCs at normal temperature and press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com