Preparation method of intelligent self-repairing boundary surface material

A surface material and self-repairing technology, applied in chemical instruments and methods, botanical equipment and methods, antifouling/underwater coatings, etc., can solve the problems of complex equipment, high cost, strict preparation process requirements, etc., and achieve the cost of preparation Low, simple preparation process, improve the effect of hydrophilic and hydrophobic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing an intelligent surface-interface self-repairing functional film material, the specific steps are as follows:

[0037] Step 1, the present invention uses metal aluminum, zinc metal powder or oxide and calcium carbide, graphite under the condition of polyglutamic acid, polyethylene glycol (PEG) as dispersant, utilizes ball milling etc. to carry out microstructure processing to prepare modifier; Then the modifier is loaded on the surface of the membrane base by spraying and chemical impregnation; after immobilization treatment, the distribution of hydrophilic and hydrophobic groups on the surface is adjusted to prepare a smart material with pressure-sensing excitation of free radicals to clean organic fouling. Mainly use metals or oxides of aluminum, iron, zinc and other elements in proportion as raw materials, put them into a ball mill or a reamer crusher, and ball mill for 1-8 hours at a speed of 300-1000, and then use 0.01=0.1% Medium molecular we...

Embodiment 1

[0042] 1) Put the aluminum and zinc oxide powders into a ball mill with a mass ratio of 2:3, add the flake graphite with a mass ratio of 0.5-3% above and mix evenly;

[0043] 2) Put the mixture into a ball mill, and perform ball milling at a speed of 500 rpm for 1 hour;

[0044] 3) Disperse and dilute with ethanol, spray on the film base material, and obtain the product after curing.

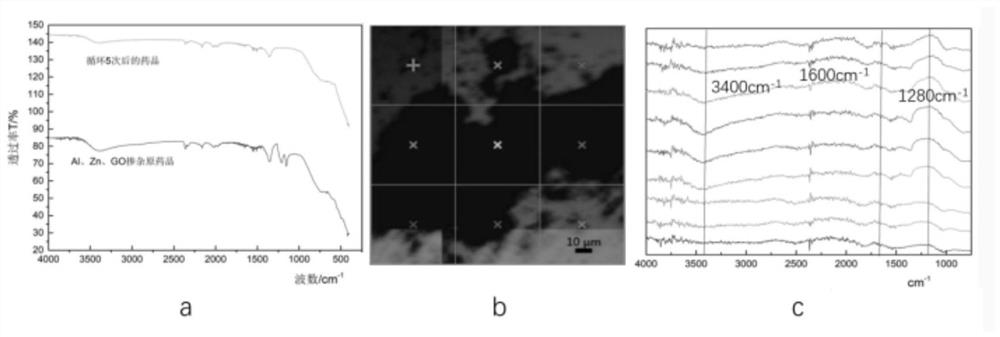

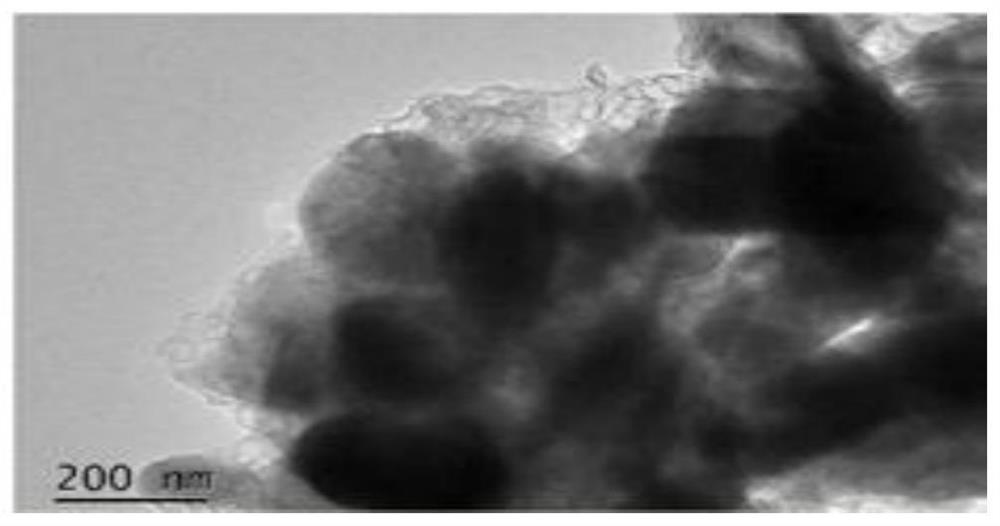

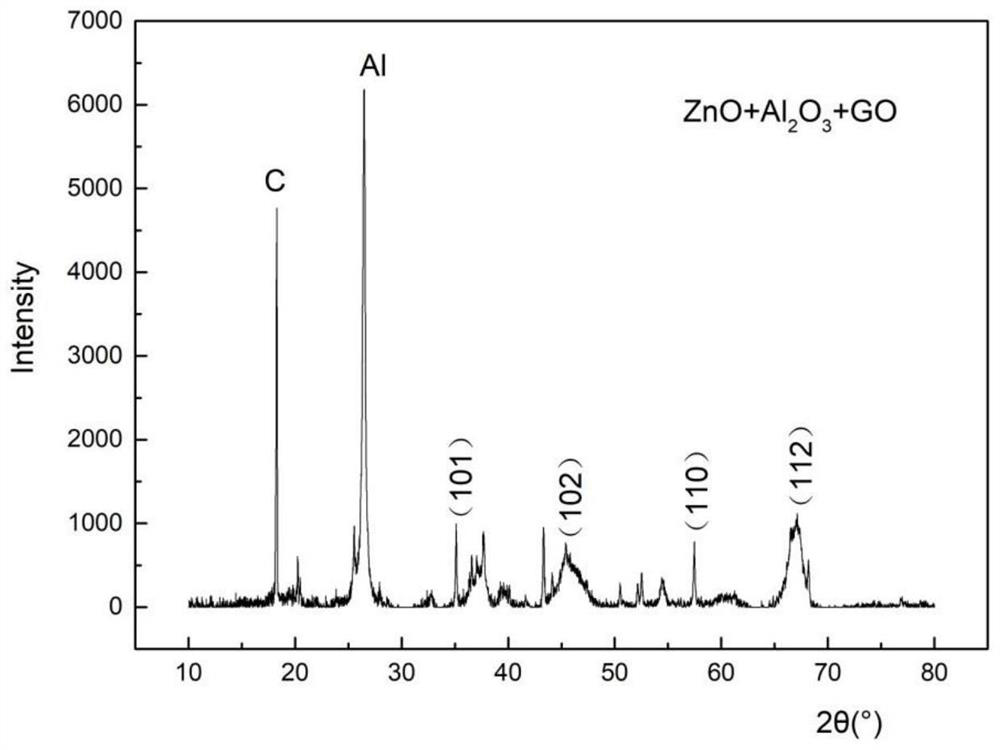

[0045] A series of characterizations were carried out on the prepared materials, transmission electron microscope TEM such as figure 1 , indicating that the material is a layered structure; the material was characterized by XRD (X-ray diffraction), and the spectrum is as follows figure 2 Shown; ESR (electron paramagnetic spectroscopy) test is carried out after DMPO captures free radical, the result is as follows image 3 As shown, it is qualitatively illustrated that hydroxyl radicals and superoxide radicals with oxidative degradation effects are produced in the ball milling process; the cont...

Embodiment 2

[0048] 1) Put aluminum, zinc, and iron oxide powders in a ball milling kettle with a mass ratio of 2:3:2, add the above-mentioned graphene oxide of 0.5-3% by mass and mix evenly;

[0049] 2) Put the mixture into a ball mill, and perform ball milling at a speed of 500 rpm for 1 hour;

[0050] 3) Add deionized water with a solid-to-liquid ratio of 1:2, and pass in hydrogen peroxide as an oxidizing agent for wet ball milling for 2 hours.

[0051] 4) Using the membrane as the substrate, the product is collected by suction filtration and drying.

[0052] Add catalyst and ultrasonic vibration to degrade Bacillus cereus, Escherichia coli, Staphylococcus aureus, and Salmonella, and the removal rate is as columnar Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com