Method of recovering and regenerating waste gas desulfurizing and defluorinating absorbent liquid continuously

A technology for absorbing liquid and waste gas, which is applied in separation methods, chemical instruments and methods, water/sludge/sewage treatment, etc. It can solve the problems of large alkali consumption, large amount of clear liquid circulation, and pH changes of the absorption liquid at the inlet and outlet of the absorption tower. Major problems, to achieve the effect of reducing investment and operating power consumption, reducing investment and operating costs, and high comprehensive utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

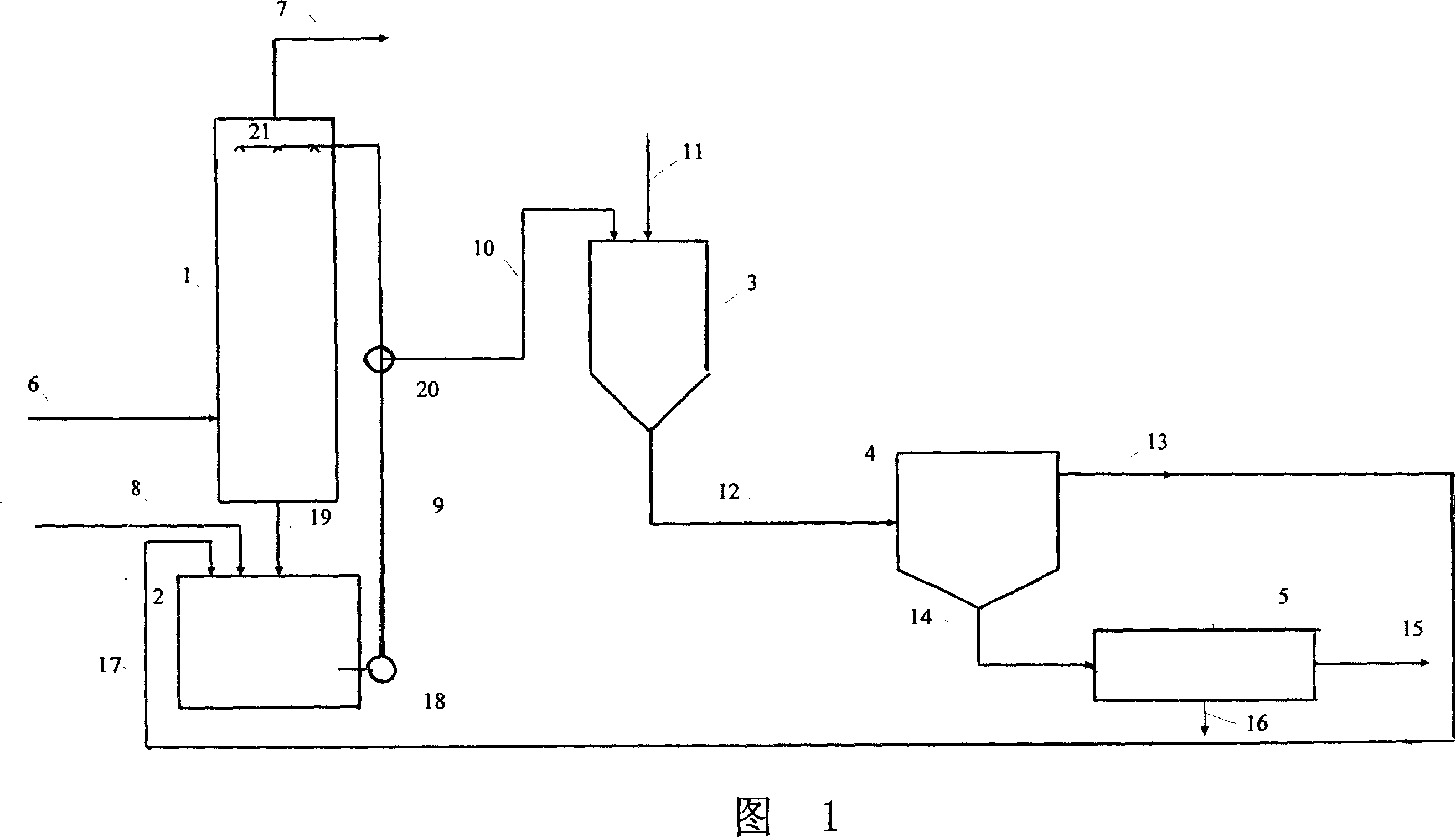

Image

Examples

Embodiment 1

[0024] Embodiment 1. Contrast experiment of processing sulfur-containing and fluorine-containing wastewater with magnesium-based suspension and calcium-based suspension

[0025] Get 200ml of circulating absorption solution containing sodium sulfite, sodium bisulfite and fluoride, its pH is 6.5, and the fluoride ion concentration is 1055mg / l, add magnesium-based suspension (50% magnesium hydroxide) 5g, the reaction temperature is 10 ℃, The reaction time was 10 minutes. After the reaction, the precipitate was filtered, the pH of the supernatant was 8.3, and the fluoride ion concentration was 151 mg / l.

[0026] Get 200ml of circulating absorption solution containing sodium sulfite, sodium bisulfite and fluoride, its pH is 6.5, and the fluoride ion concentration is 1055mg / l, add calcium-based suspension (50% calcium hydroxide) 8g, the reaction temperature is 10 ℃, The reaction time was 10 minutes. After the reaction, the precipitate was filtered, the pH of the supernatant was 7....

Embodiment 2

[0027] Embodiment 2. The comparative experiment of processing the circulating absorption liquid of sulfur-containing waste gas

[0028] Take 200ml of circulating absorption solution containing sodium sulfite and sodium bisulfite, its pH is 6.0, add 4g of magnesium-based suspension (50% magnesium oxide), the reaction temperature is 30°C, and the reaction time is 15 minutes. After the reaction, the precipitate was filtered, and the pH of the supernatant was 8.4.

[0029] Take 200ml of circulating absorption solution containing sodium sulfite and sodium bisulfite, its pH is 6.0, add 4g of calcium-based suspension (50% calcium hydroxide), the reaction temperature is 30°C, and the reaction time is 15 minutes. After the reaction, the precipitate was filtered, and the pH of the supernatant was 7.0.

Embodiment 3

[0030] Embodiment 3. Make magnesium-based suspension with magnesium carbonate

[0031] Get 200ml of circulating absorption solution containing fluoride sodium salt, its pH is 6.0, fluoride ion concentration is 2050mg / l, add magnesium-based suspension (50% magnesium carbonate) 4g, reaction temperature is 30 ℃, reaction time is 30 minutes. After the reaction, the precipitate was filtered, the pH of the supernatant was 7.1, and the fluoride ion concentration was 195 mg / l.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com