Microporous crystalline zeolite material (zeolite ITQ-22), synthesis method thereof and use of same as a catalyst

a technology of zeolite and microcrystalline zeolite, which is applied in the direction of physical/chemical process catalysts, silica-polymorphs, silicon compounds, etc., can solve the problems of reducing the selectivity of zeolite for the desired process, entail a considerable increase in gas, and the use of fluoride ions in the synthesis is less desirable from the industrial point of view than the use of ohsup>, so as to achiev

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0090] This example illustrates the preparation of the dihydroxide of 1,5-bis(methylpyrrolidinium)pentane. In a 500 ml flask, 18.7 g of 1,5-dibromopentane, 20 g of 1-methylpyrrolidine and 300 ml of acetone are mixed. The mixture is left to reflux for 24 hours, after which the precipitated solid is separated by decantation and then washed several times with acetone. Finally it is vacuum dried and 31.9 g of a white solid are obtained. The analysis of elements and the nuclear magnetic resonance spectrum in D2O of this solid indicate that it is the desired product, namely, 1,5-bis(methylpyrrolidinium)pentane dibromide. The dihydroxide form of the structure directing agent is obtained by means of anion exchange using a Dowex SBR resin (in molar excess). The exchange is carried out with stirring of the fluid bed of resin in hydroxide form and an aqueous solution of the bromide of the cation for one night. The solution obtained is titrated with HCl (aq.) using phenolphthalein as indicator,...

example 2

[0091] This example illustrates the preparation of ITQ-22 by means of using the cation 1,5-bis(methylpyrrolidinium) pentane.

[0092] 6.17 g of tetraethylorthosilicate (TEOS) are added to 23.14 g of a solution of 1,5-bis(methylpyrrolidinium) pentane dihydroxide (R(OH)2) containing 0.96 equivalents of hydroxide in 1000 g. In this mixture 1.55 g of germanium oxide are added, and it is left to evaporate with stirring until complete elimination of the ethanol deriving from the hydrolysis of the TEOS plus the necessary quantity of water so that the final composition of the gel is: [0093] 0.67 SiO2: 0.33 GeO2: 0.25 R(OH)2:3.5 H2O

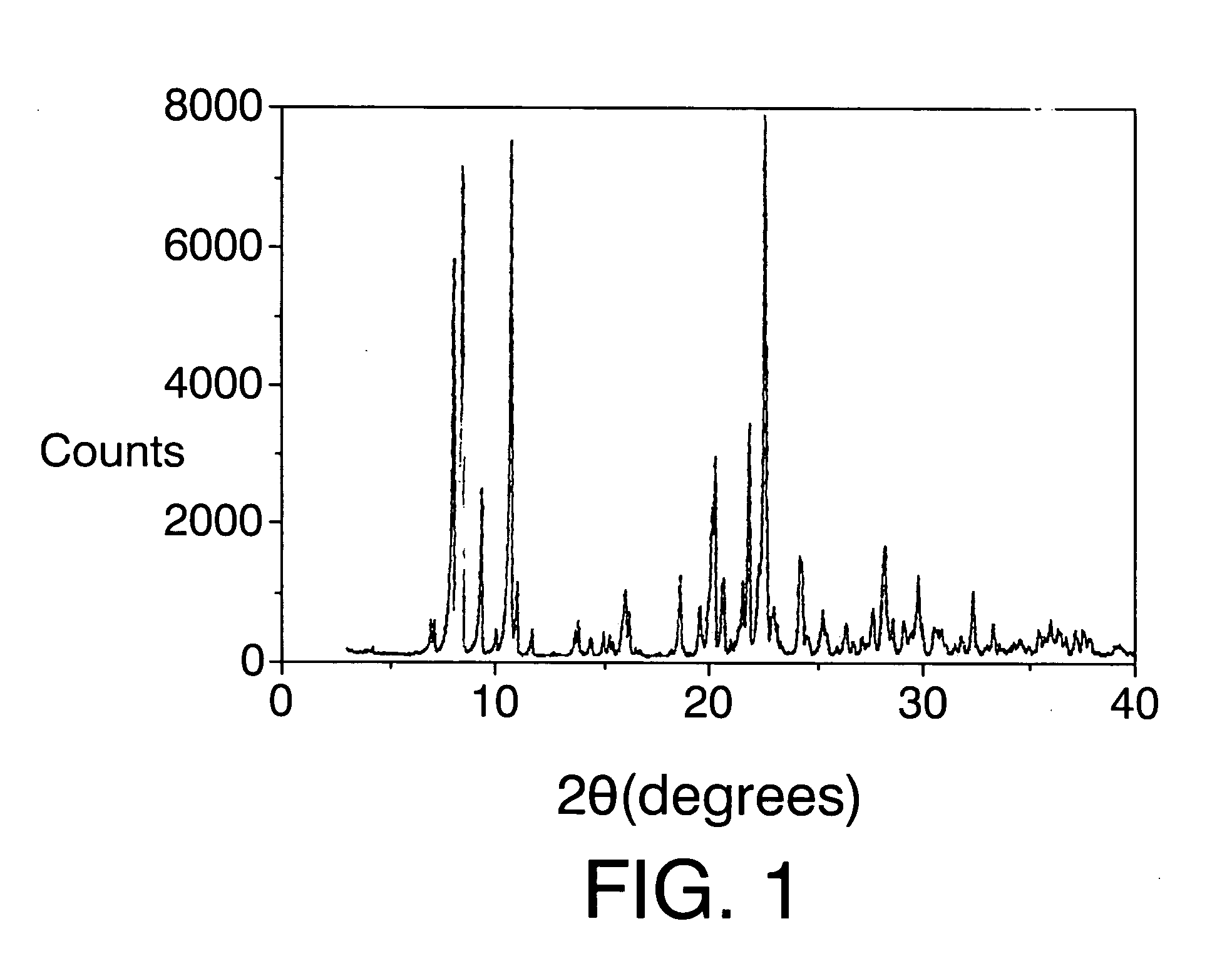

[0094] The mixture obtained is introduced into an autoclave internally lined with polytetrafluoroethylene and is heated at 175° C. for 14 days. The autoclave is then cooled, the contents are filtered, the solid is washed with water and dried at 100° C. The X-ray diffraction pattern is shown in FIG. 1 and the list of the most characteristic peaks appears in Table II...

example 3

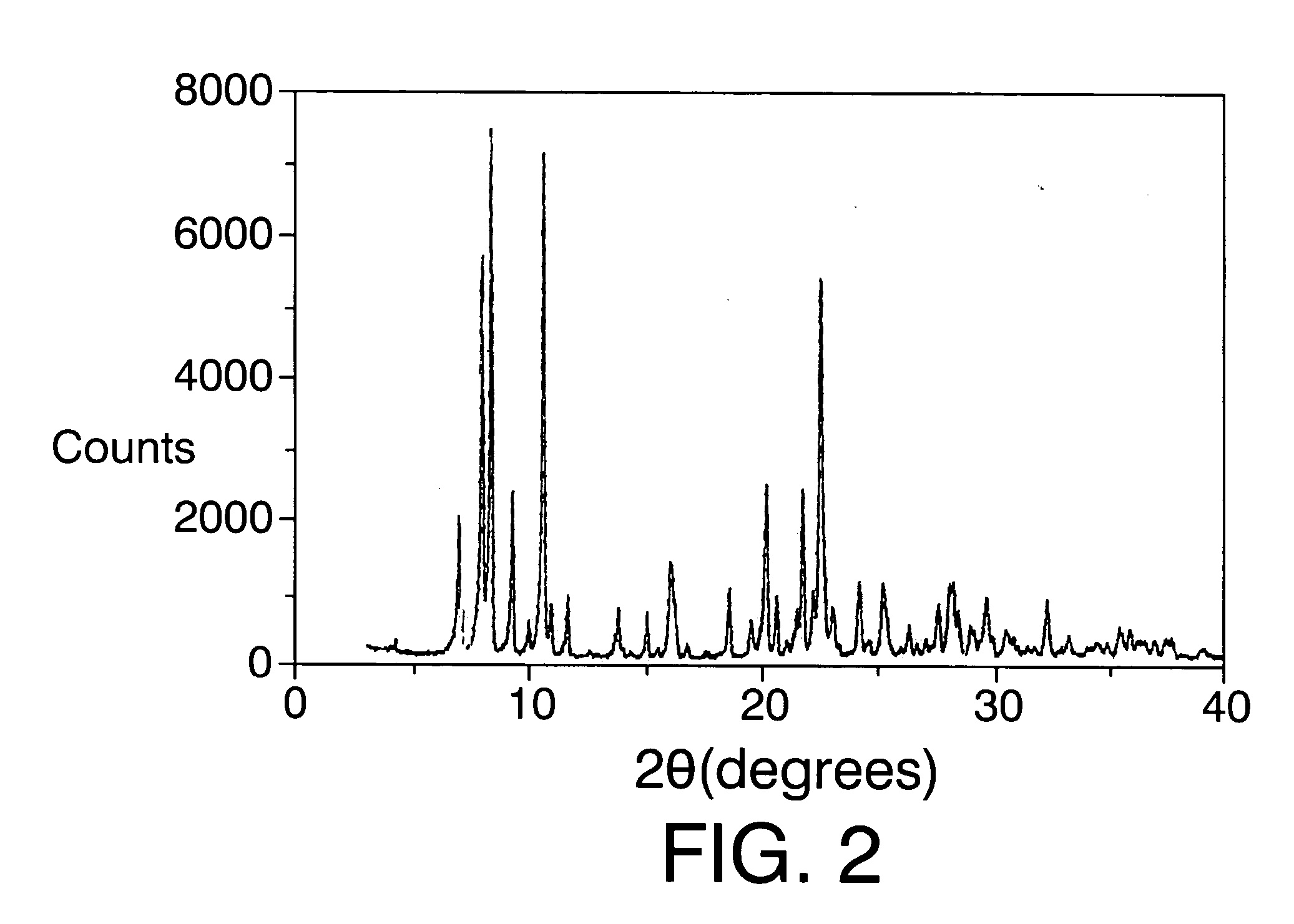

[0095] The following example illustrates the preparation of ITQ-22 of different composition.

[0096] 12 g of tetraethylorthosilicate (TEOS) are added to 27.3 g of a solution of 1,5-bis(methylpyrrolidinium) pentane dihydroxide (R(OH)2) containing 1.16 equivalents of hydroxide in 1000 g. In this mixture 0.6 g of germanium oxide are dissolved, and it is left to evaporate with stirring until complete elimination of the ethanol formed plus the excess of water so that the final composition is as follows: [0097] 0.91 SiO2:0.09 GeO2:0.25 R(OH)2:3.5 H2O

[0098] The mixture obtained is heated in autoclaves internally lined with polytetrafluoroethylene at 175° C. for 14 days. The solid obtained after filtering, washing with distilled water and drying at 100° C. is ITQ-22.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com