Patents

Literature

32results about How to "Decrease in glossiness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

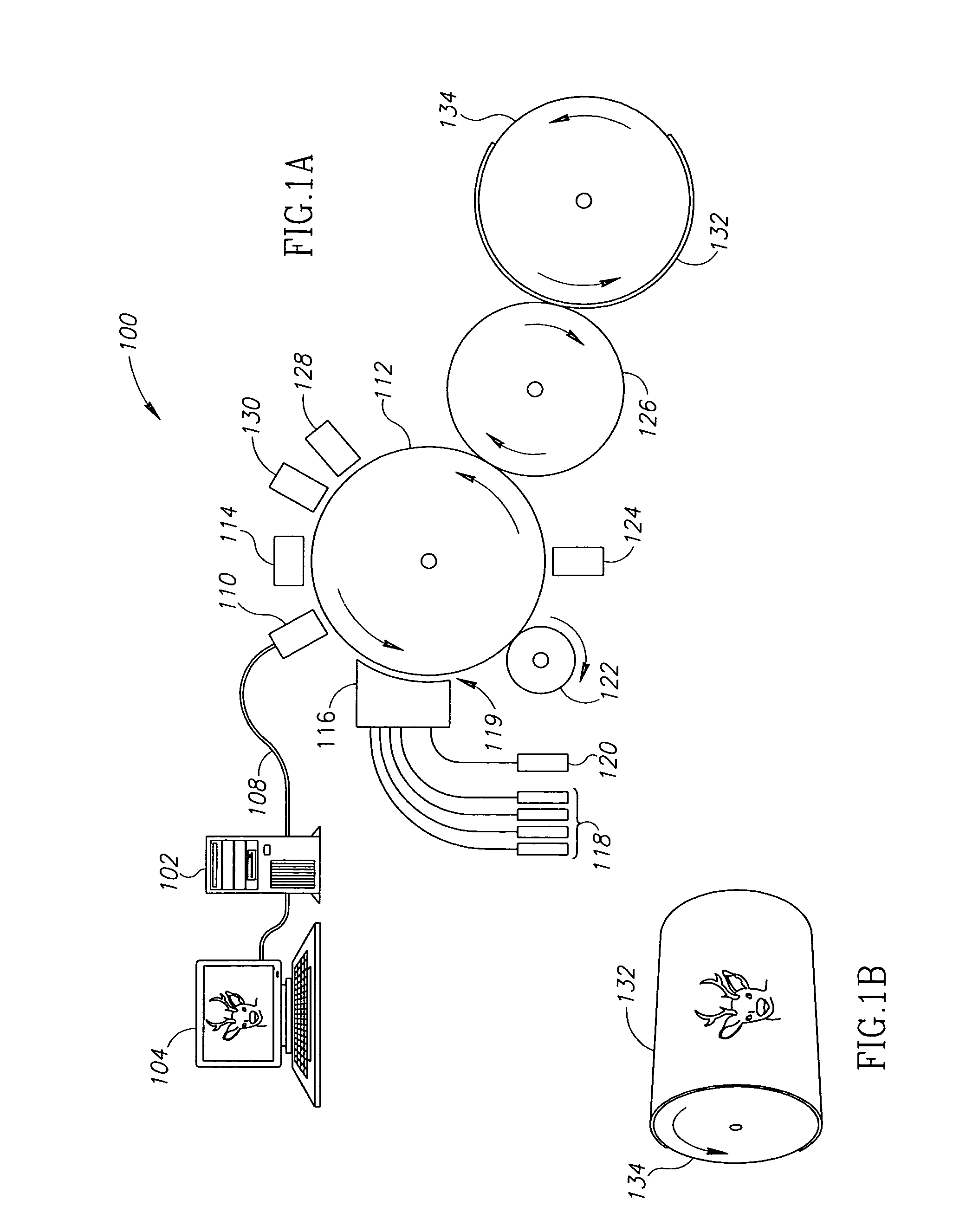

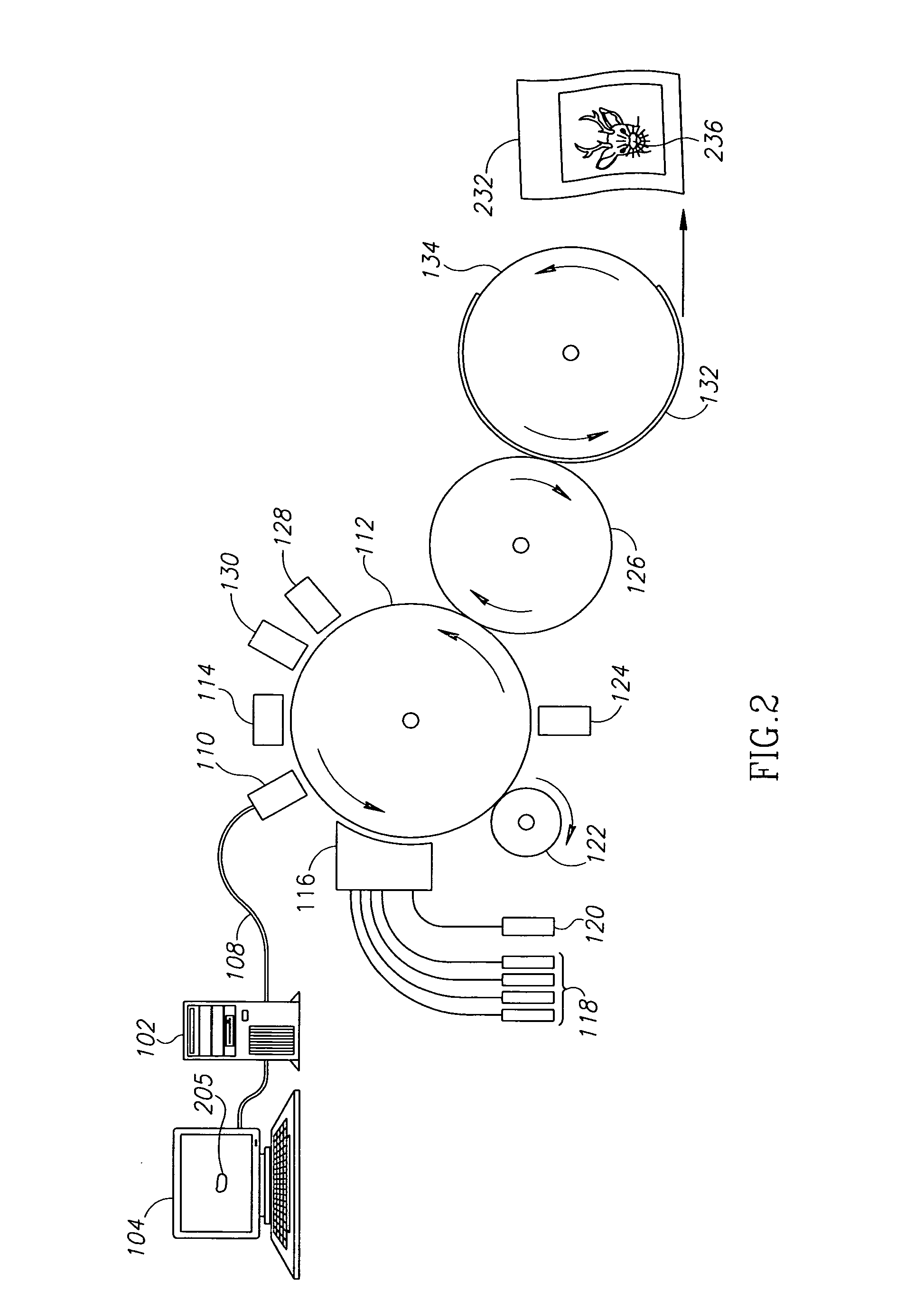

Printing of images with selective gloss and toners therefore

InactiveUS20070105034A1Optimization rangeDecrease in glossinessElectrographic process apparatusDevelopersMicrometerEngineering

A matte liquid toner suitable for use in a liquid toner printer, comprising a carrier liquid, toner particles comprising a resin and substantially uncolored additive particles of average diameter between 1 and 20 micrometers dispersed in the resin.

Owner:HEWLETT PACKARD DEV CO LP

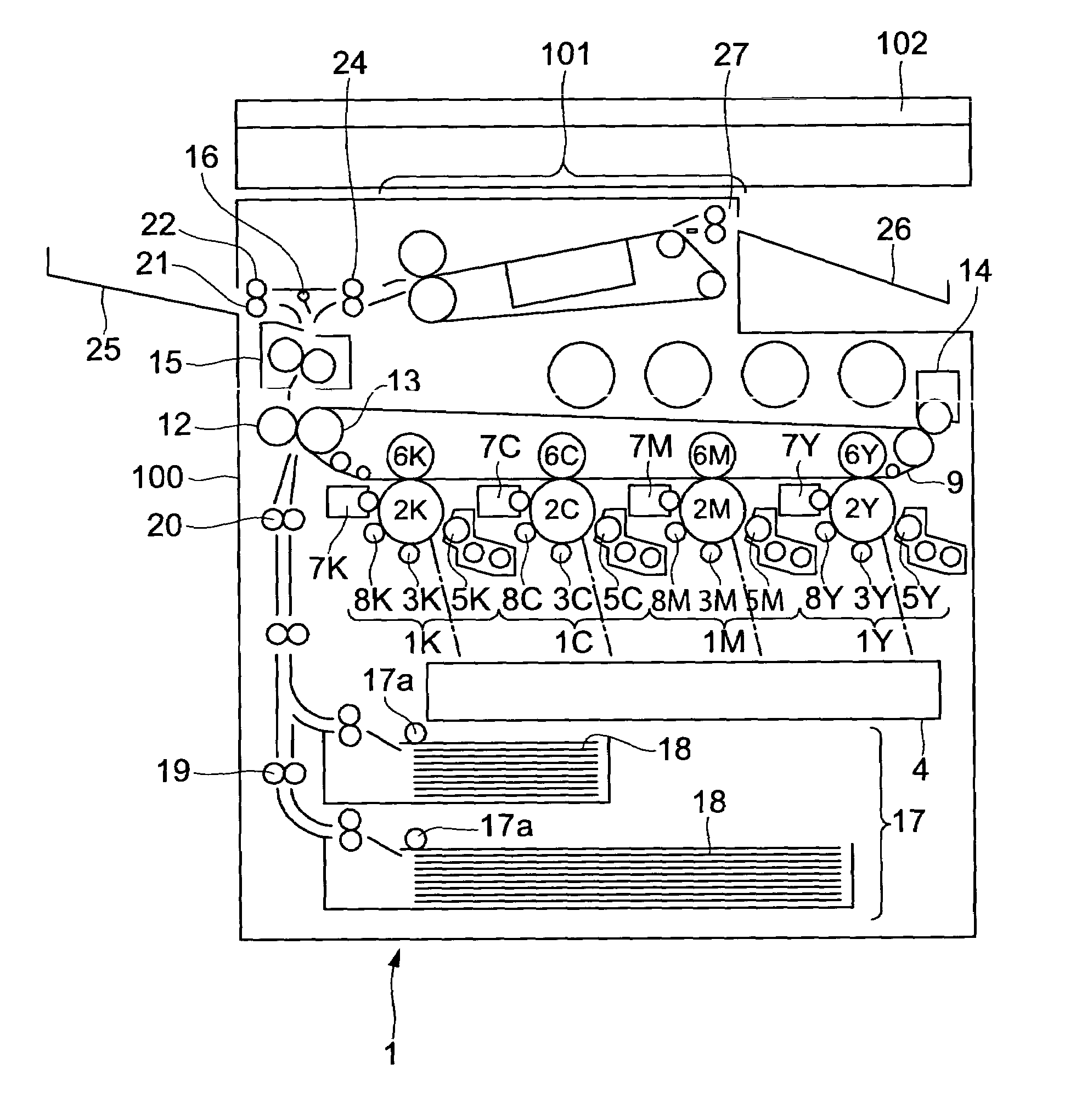

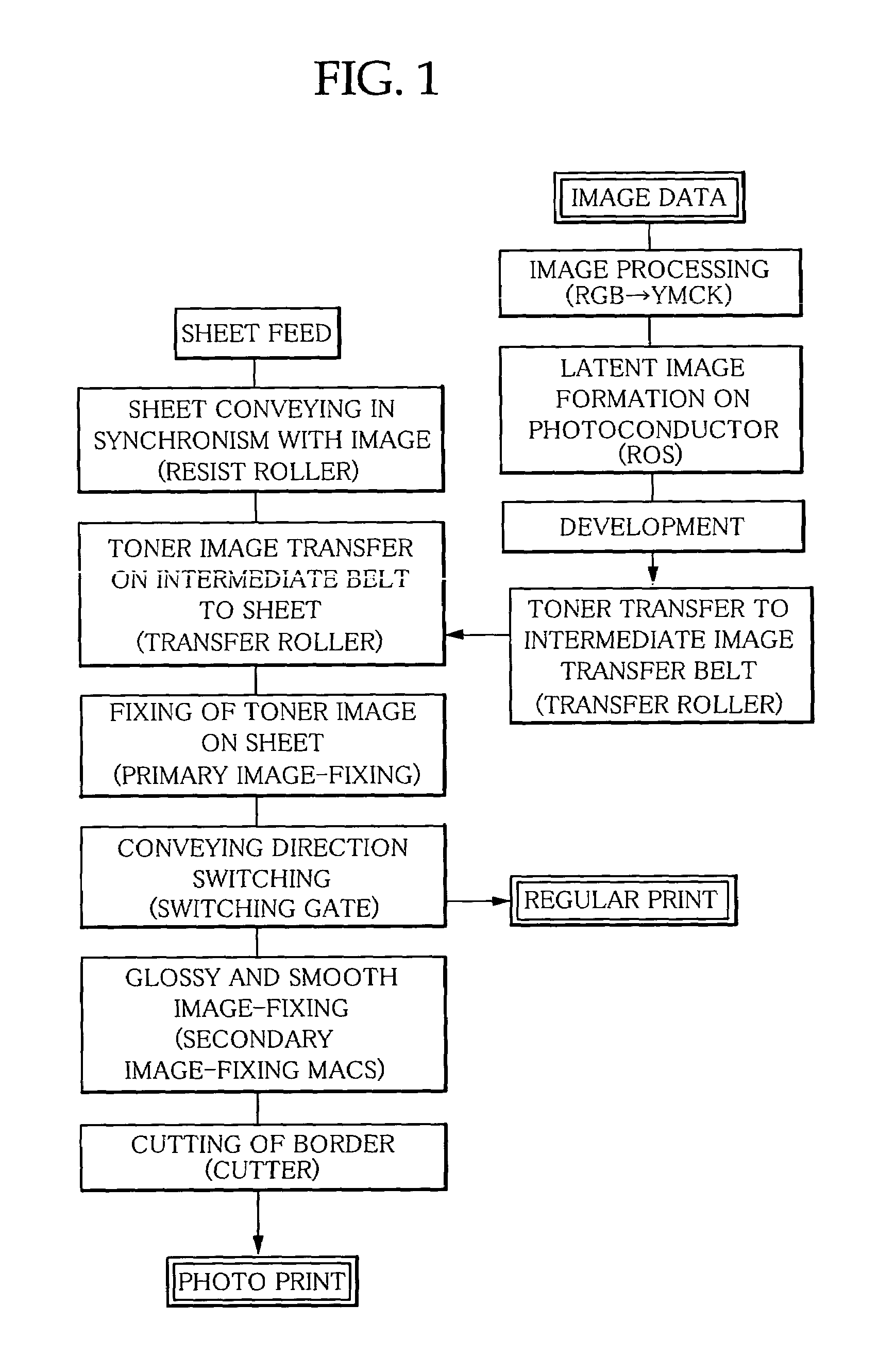

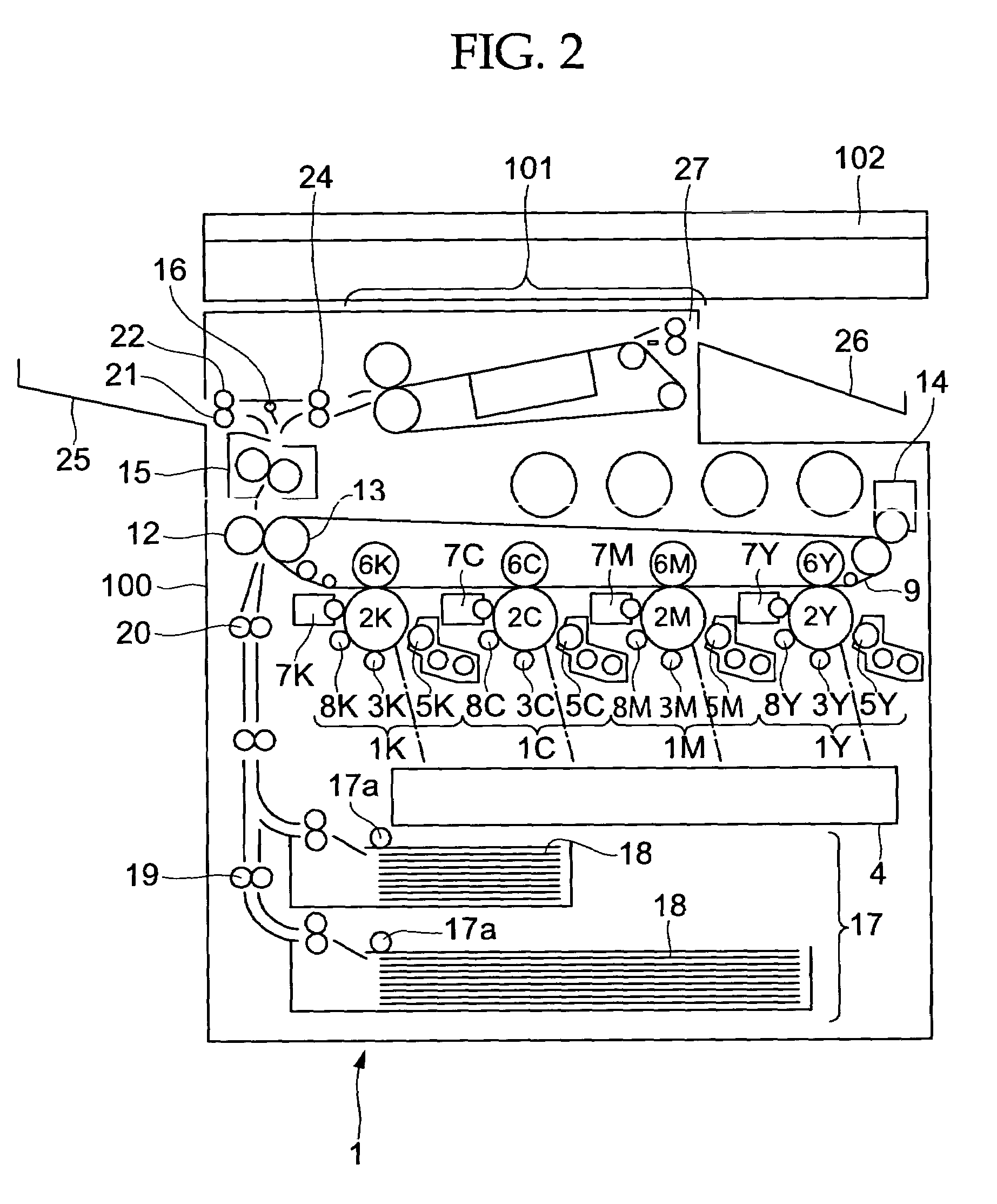

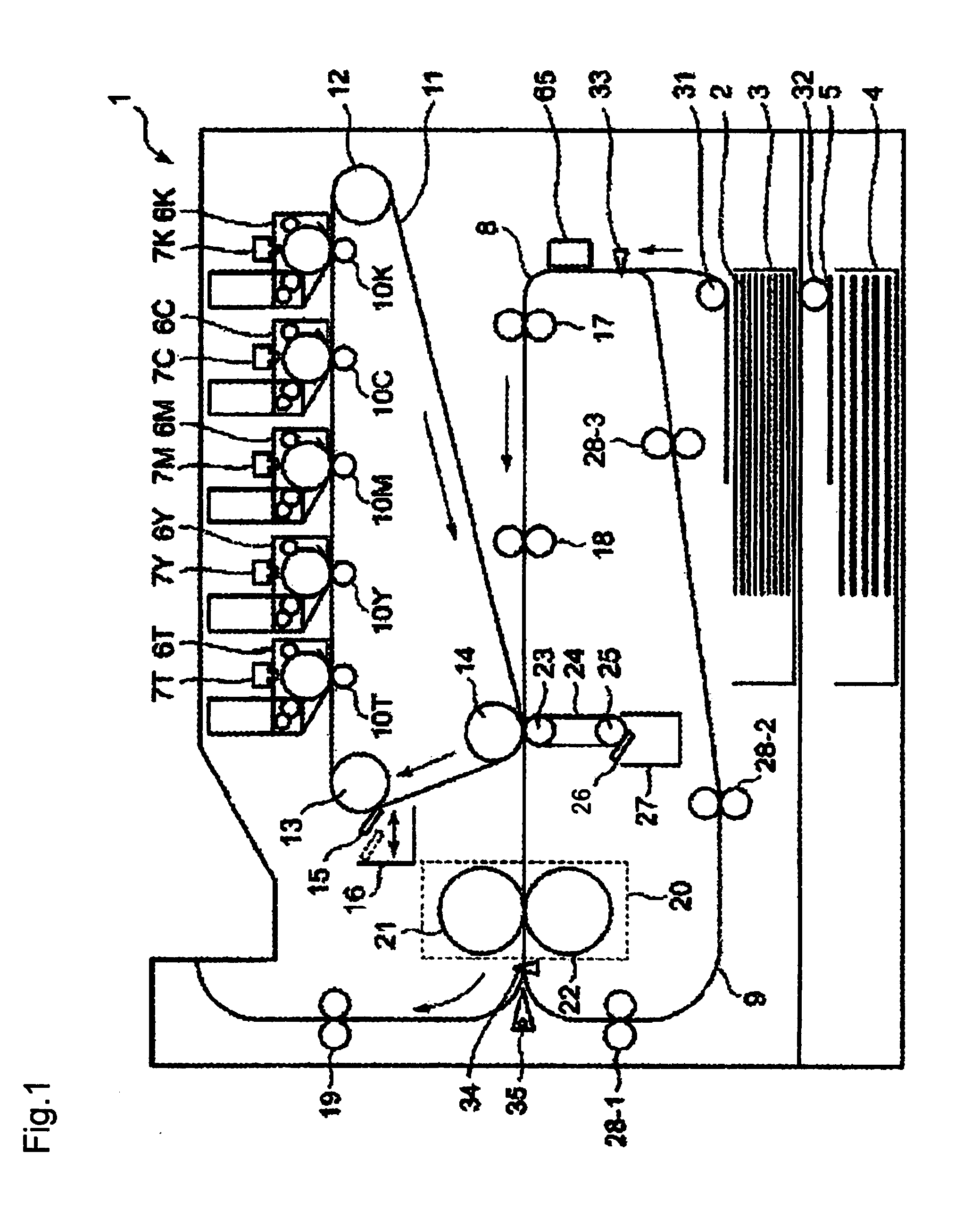

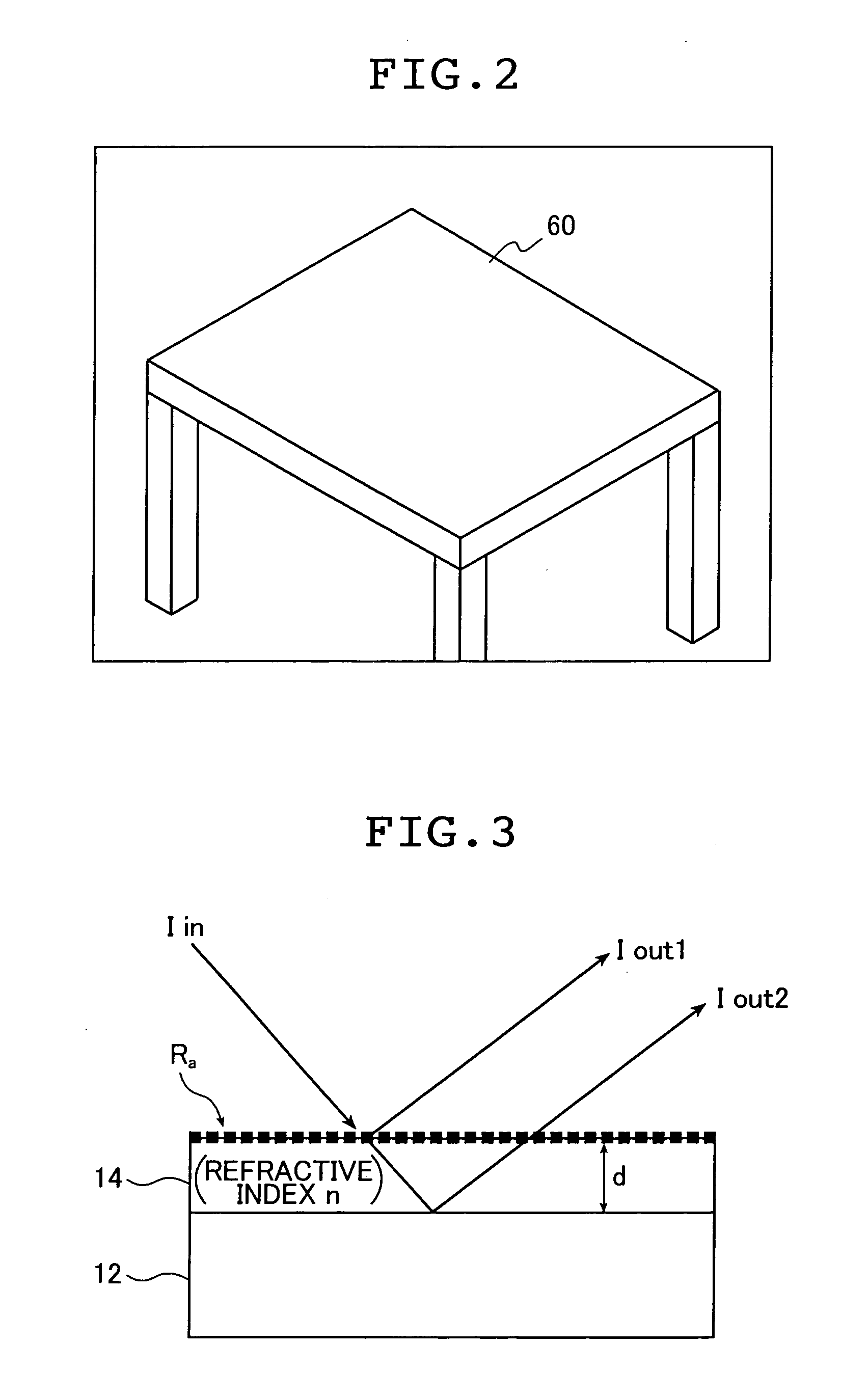

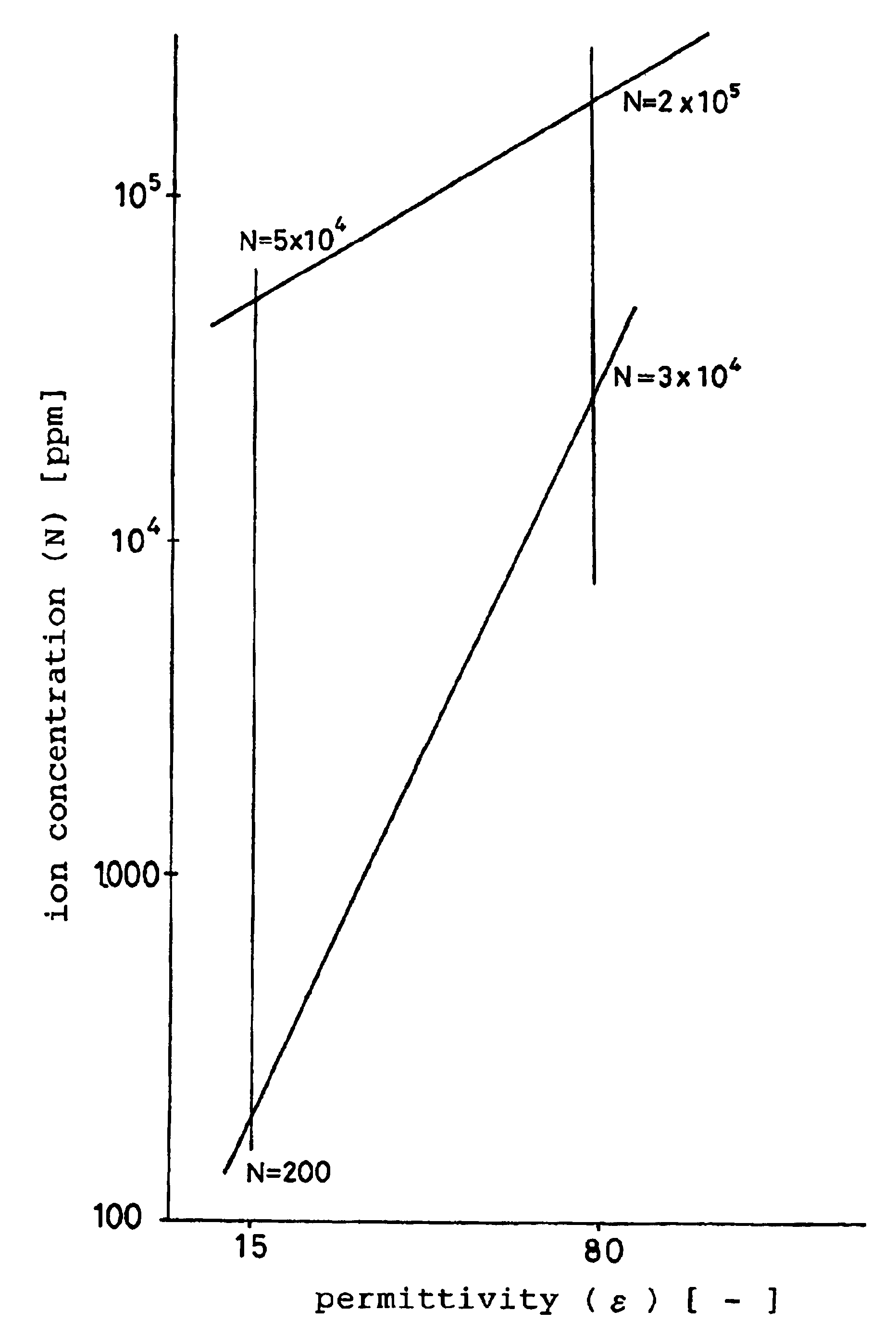

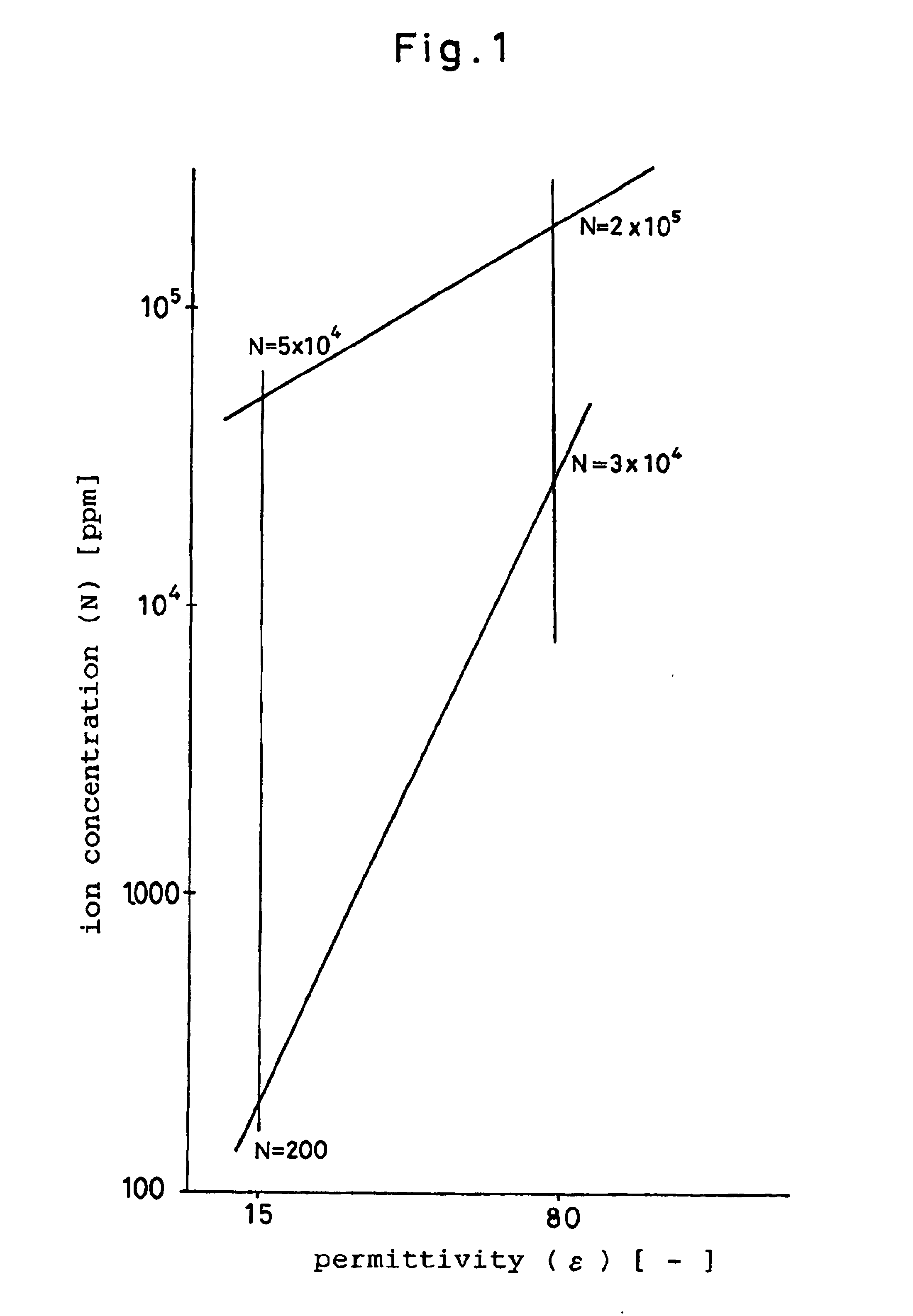

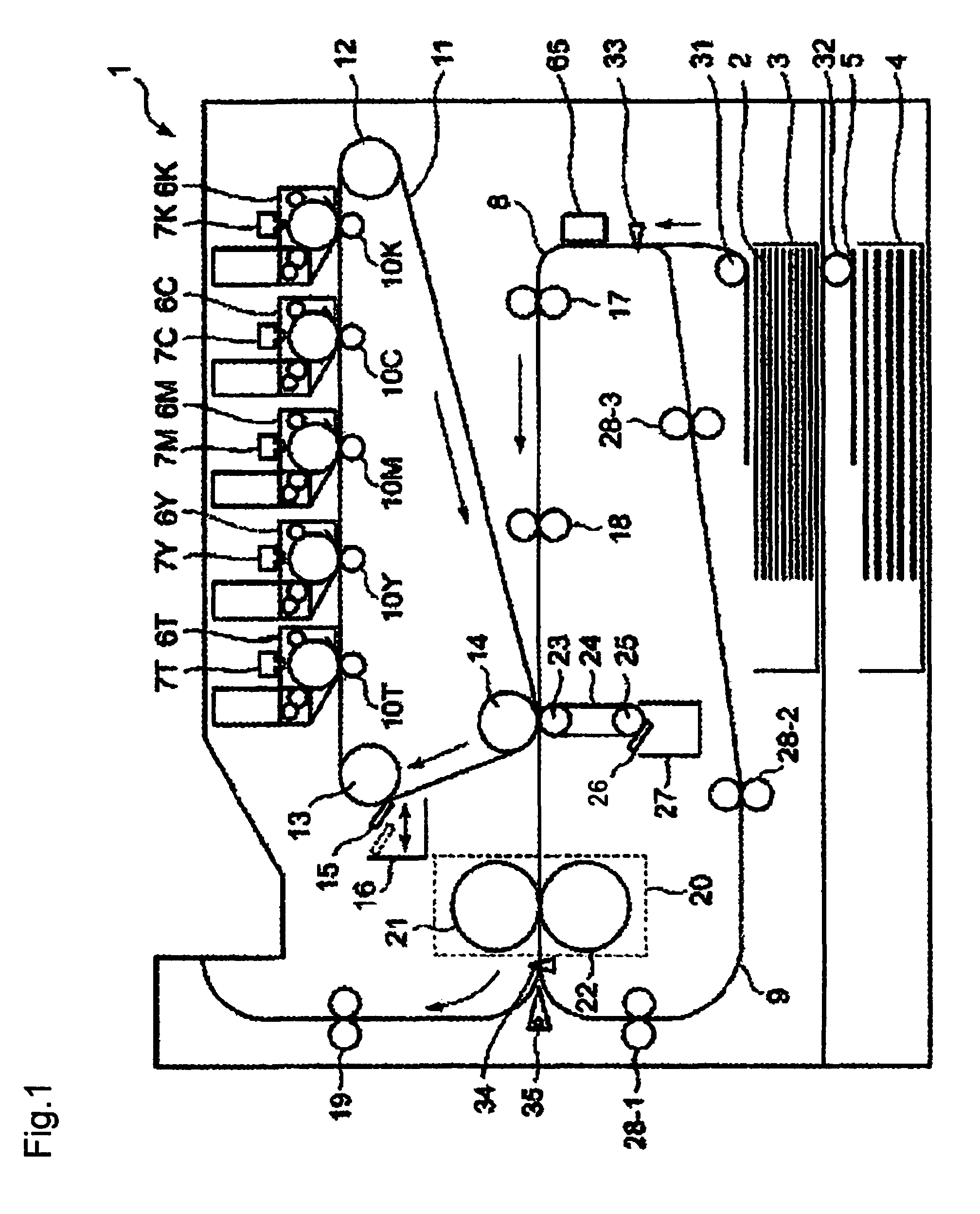

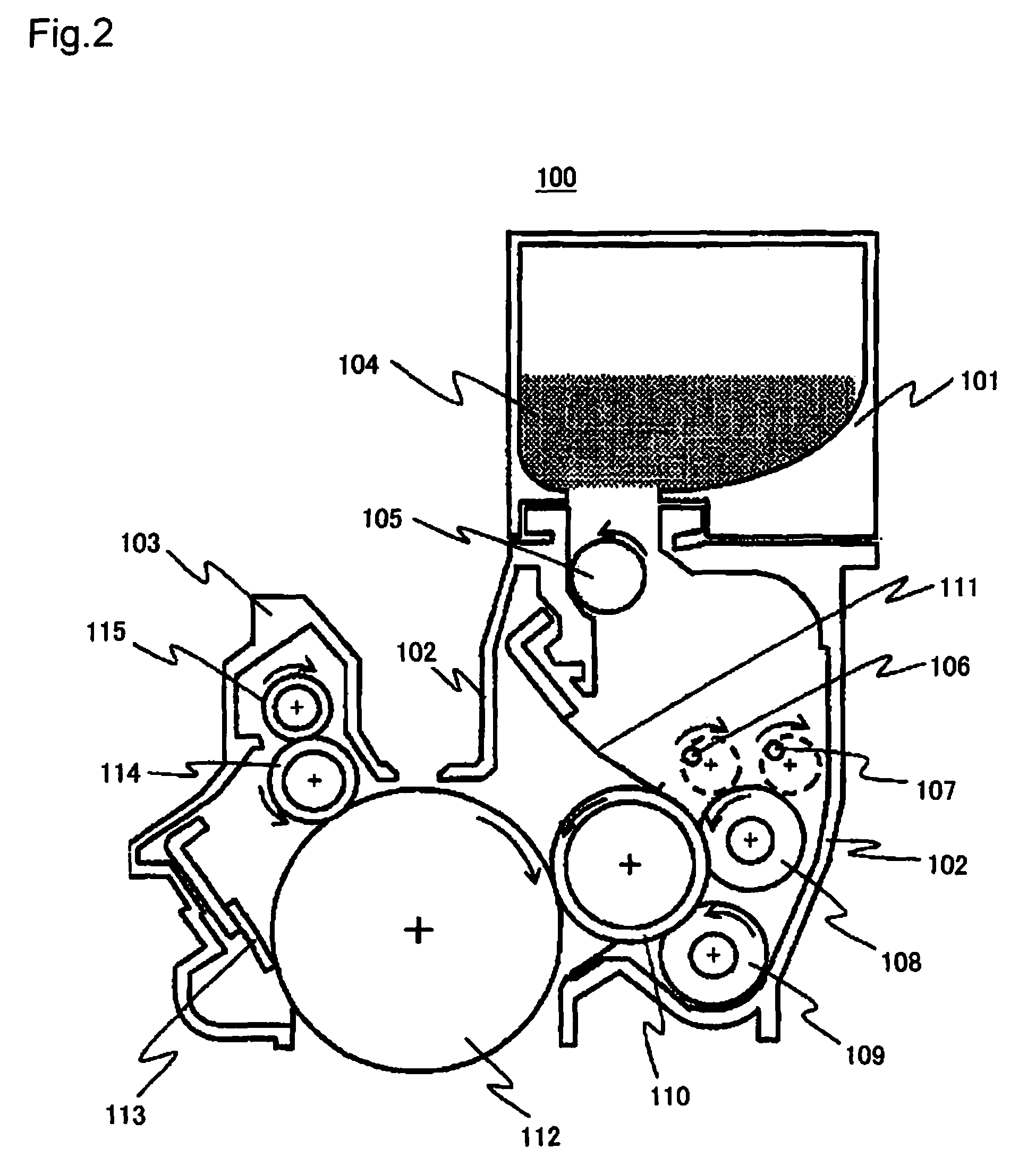

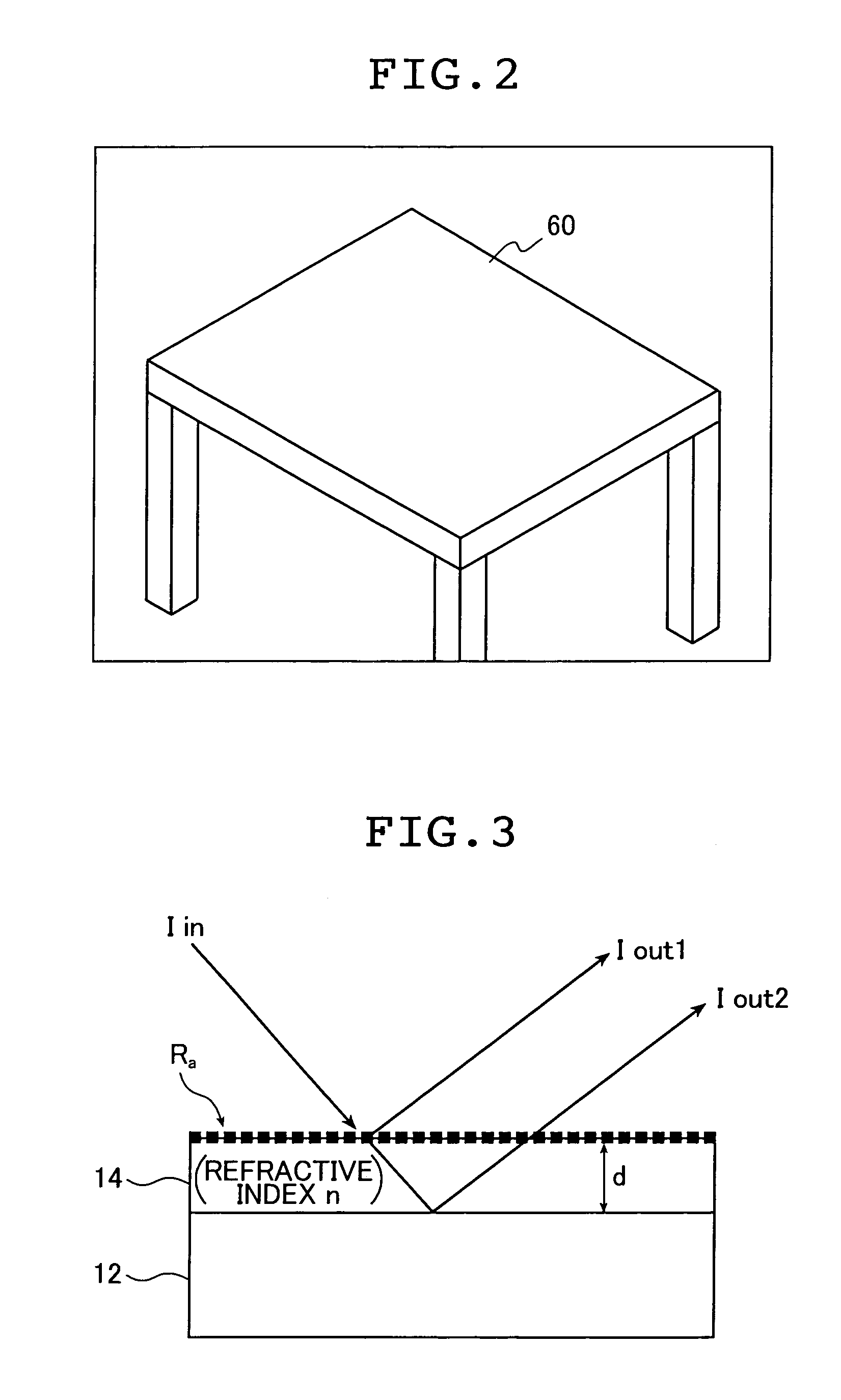

Image forming process and image forming apparatus, electrophotographic image-receiving sheet, and electrophotographic print

ActiveUS7057631B2Sufficient glossinessImprove image qualityRecording apparatusDigitally marking record carriersImaging qualityImage formation

An object is to provide an image forming process, an image forming apparatus, and a color electrophotographic print that can provide a color electrophotograph that has a sufficient density in its dark area, has gloss, has a high glossiness over the entire densities covering bright areas (a white area and a highlight area), areas at intermediate densities, and dark areas (a black area and a shadow area) and can achieve high image quality equivalent to silver halide photographs. An image forming process produces an electrophotographic print which has a black density of 2.0 or more, a black color satisfying the following condition in the CIE 1976 (L*a*b*) color space: (a*)2+(b*)2≦9, and a 20-degree minimum glossiness of 60 or more.

Owner:FUJIFILM BUSINESS INNOVATION CORP +2

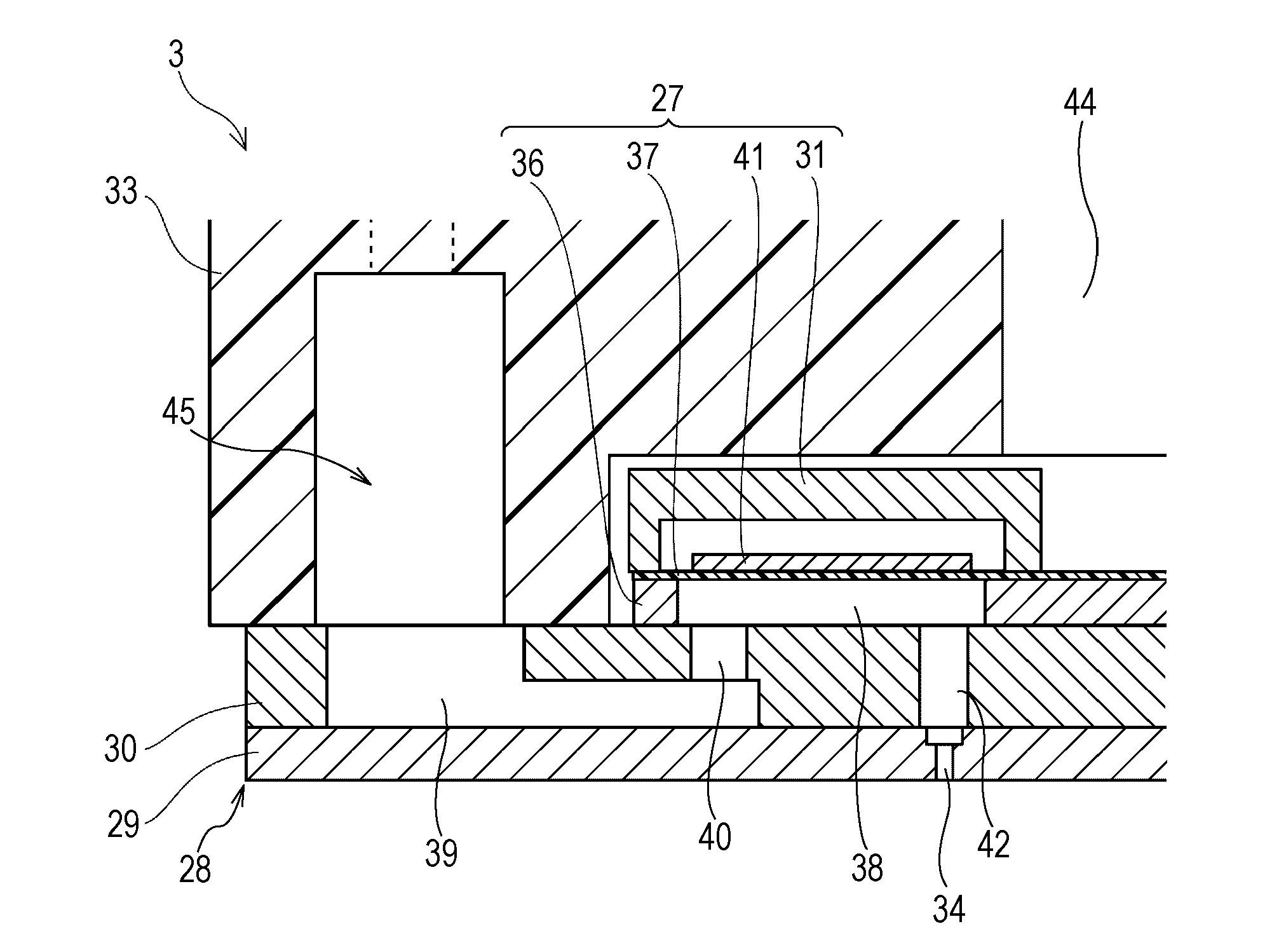

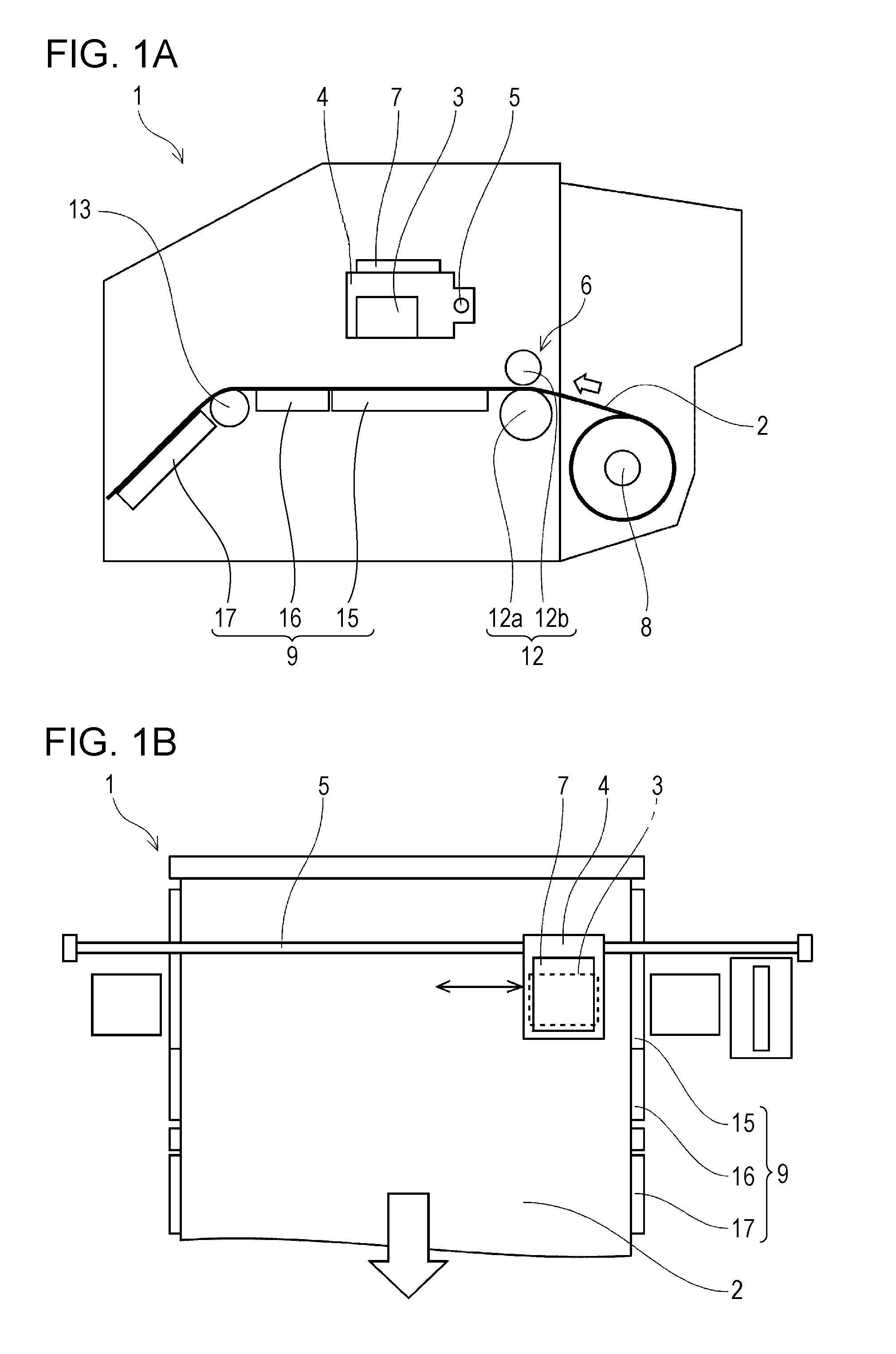

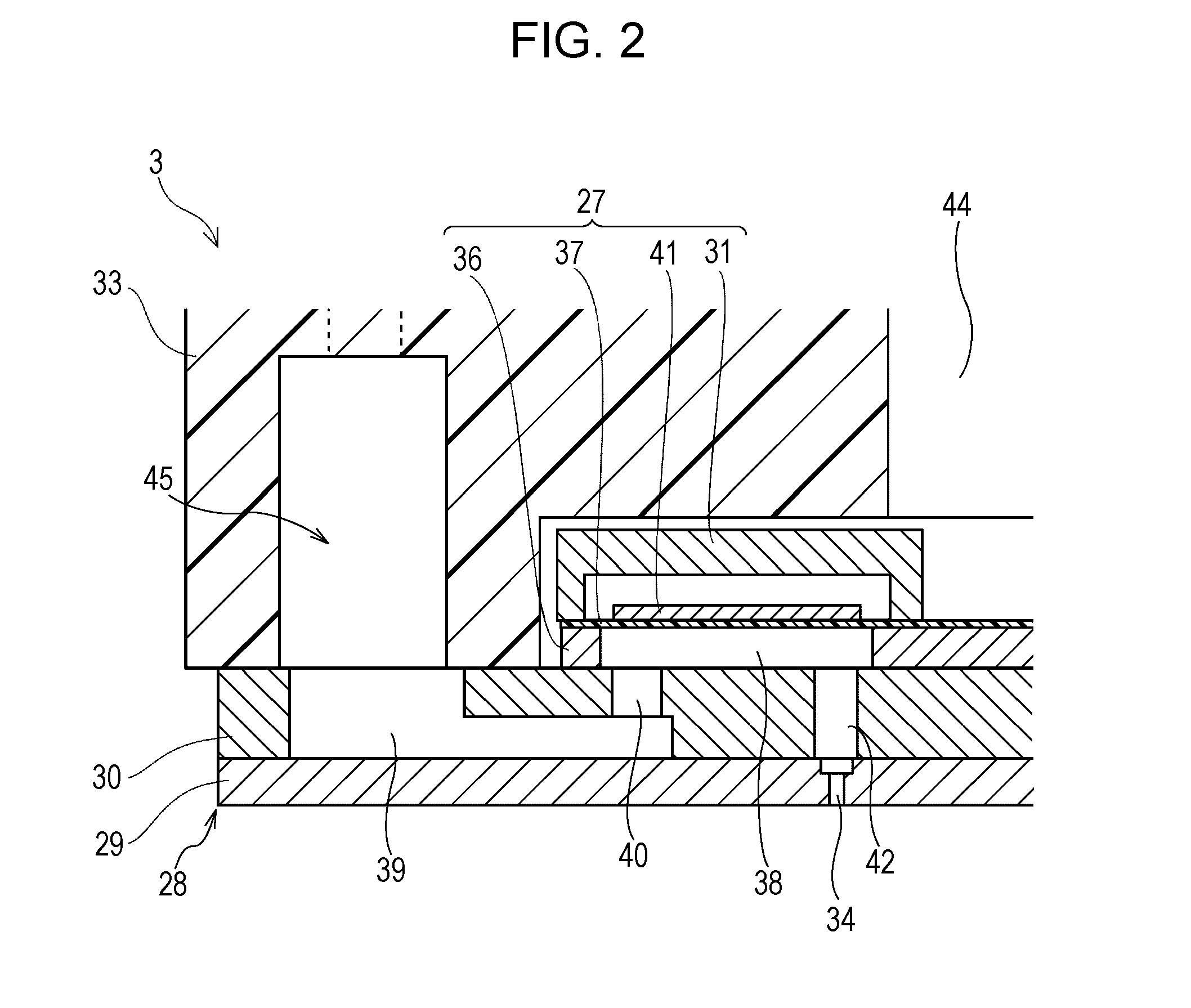

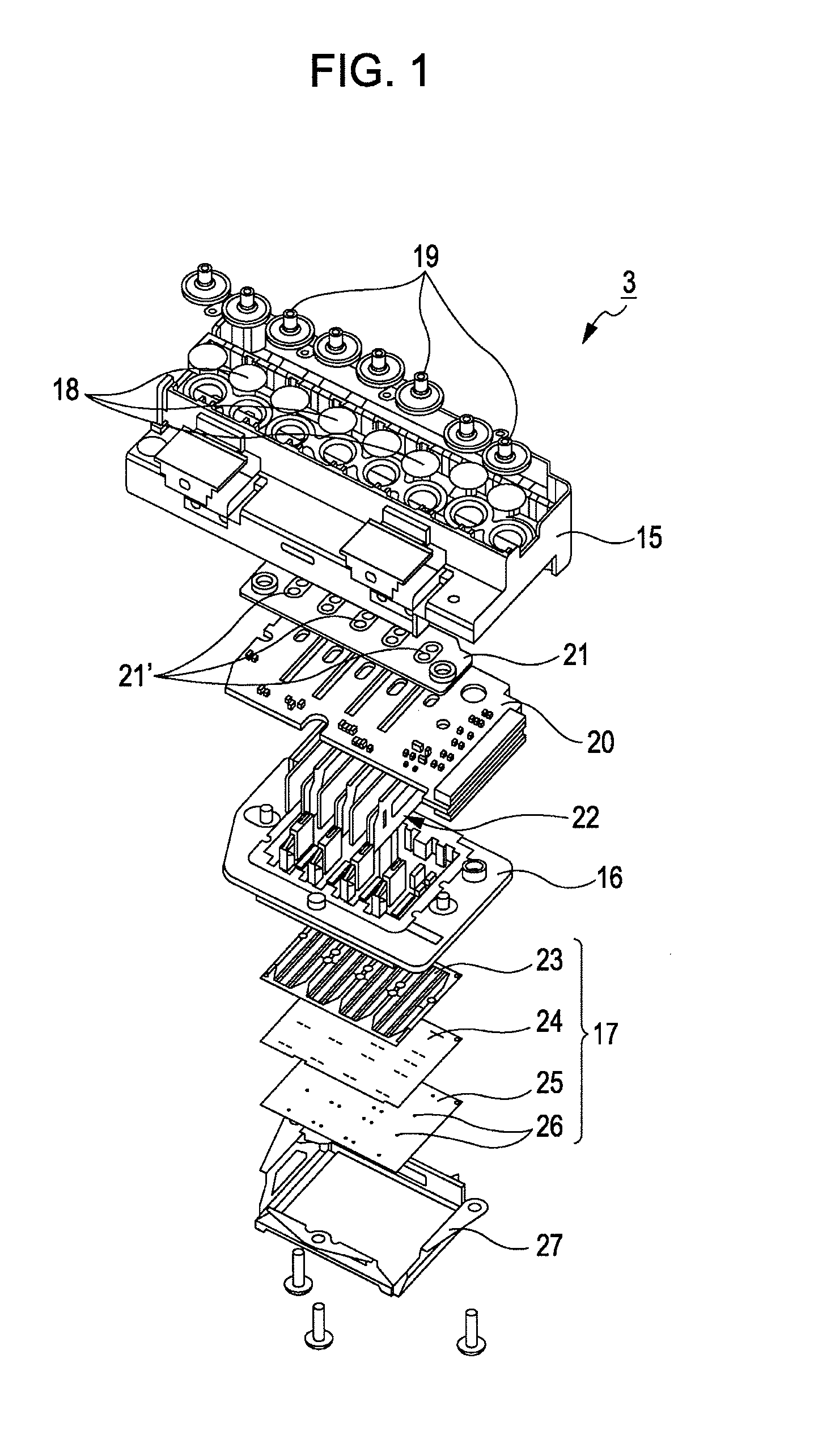

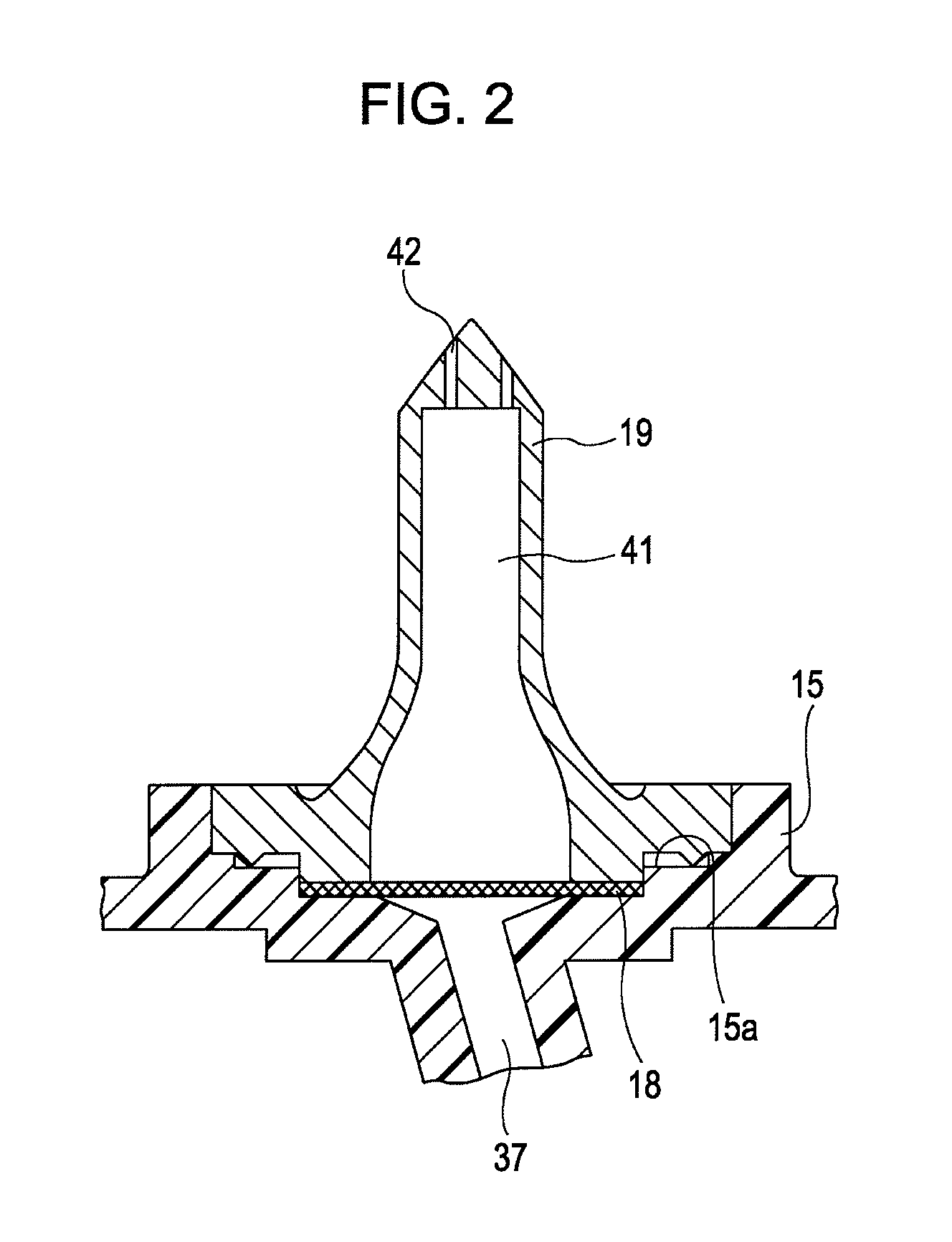

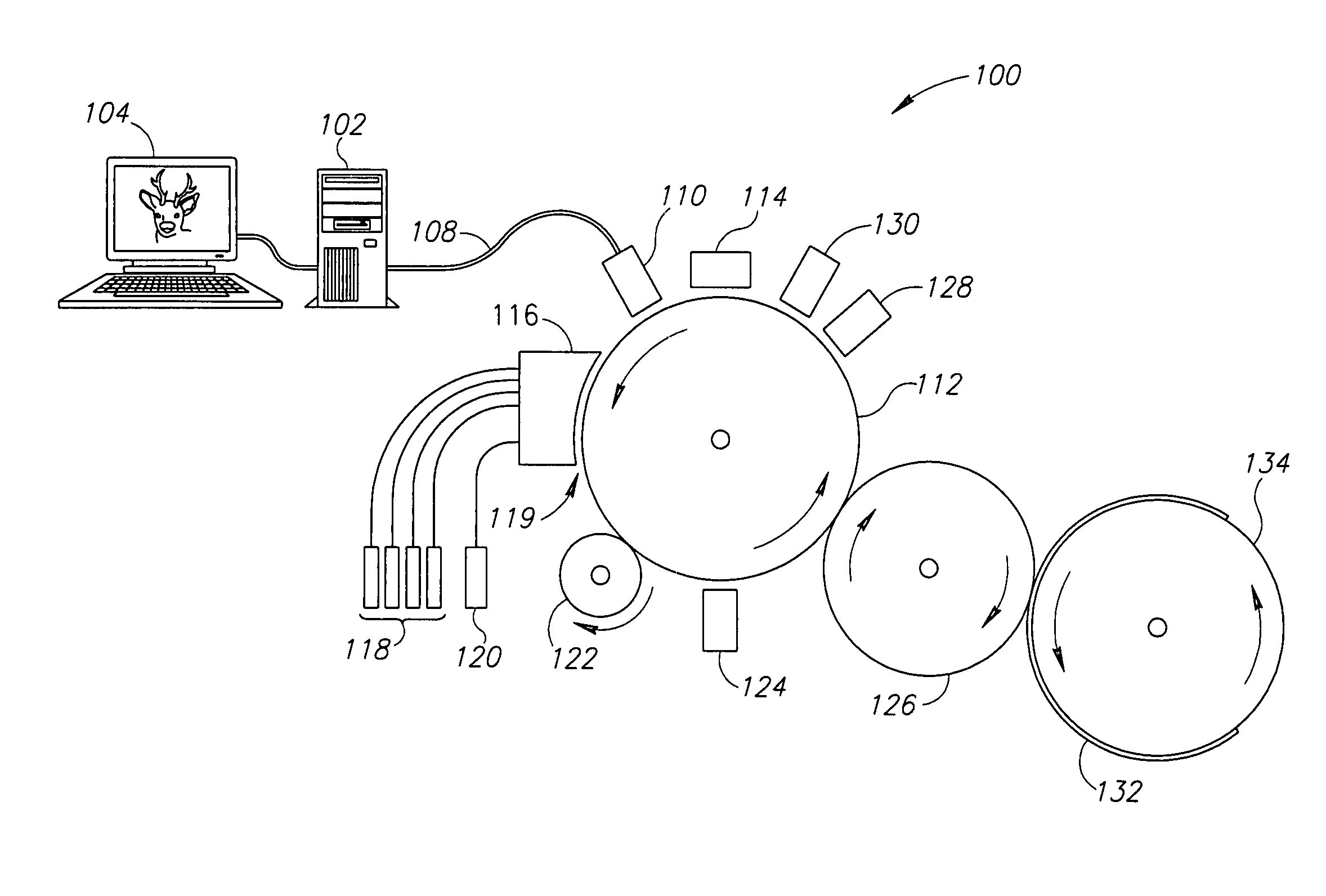

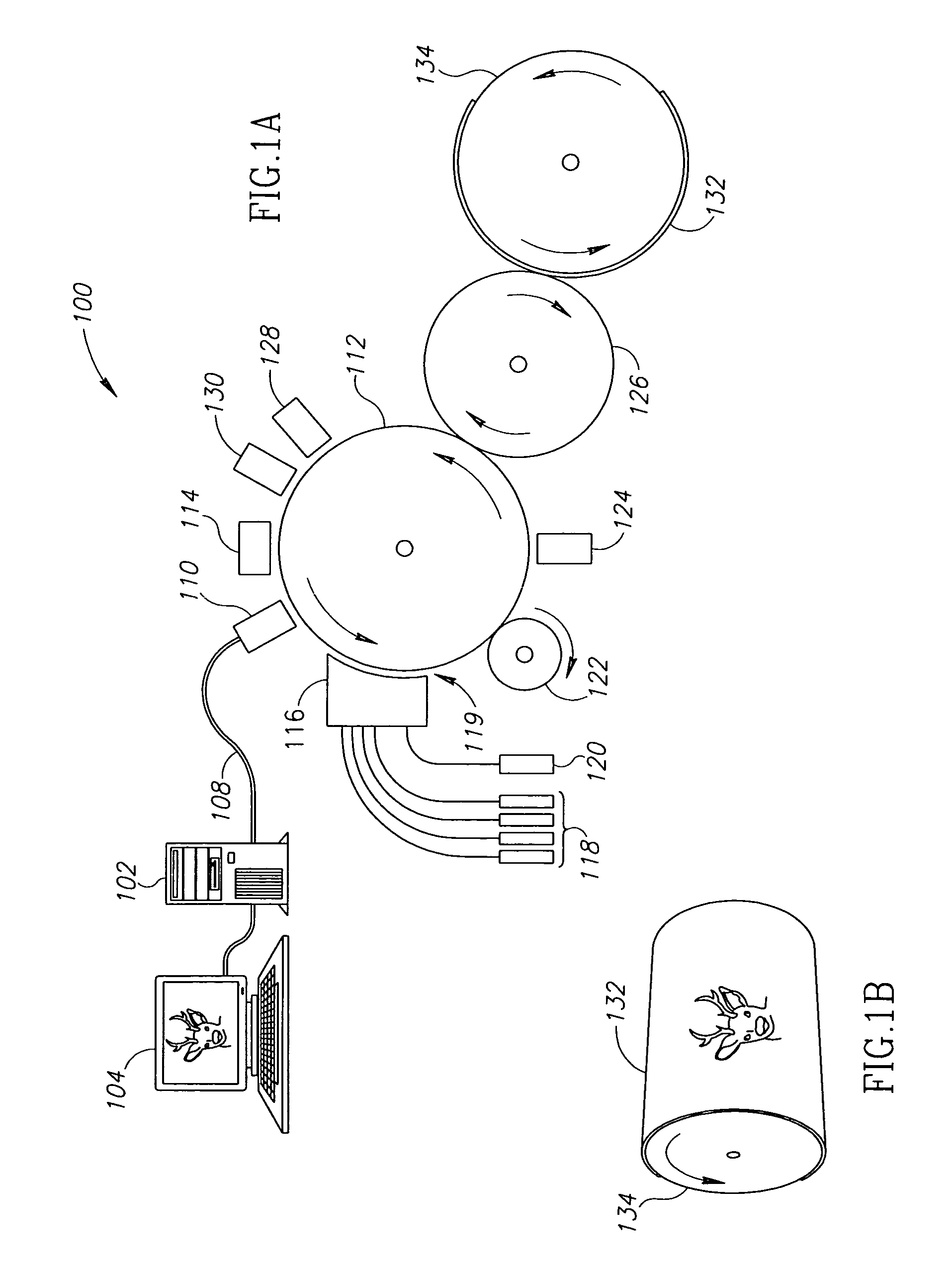

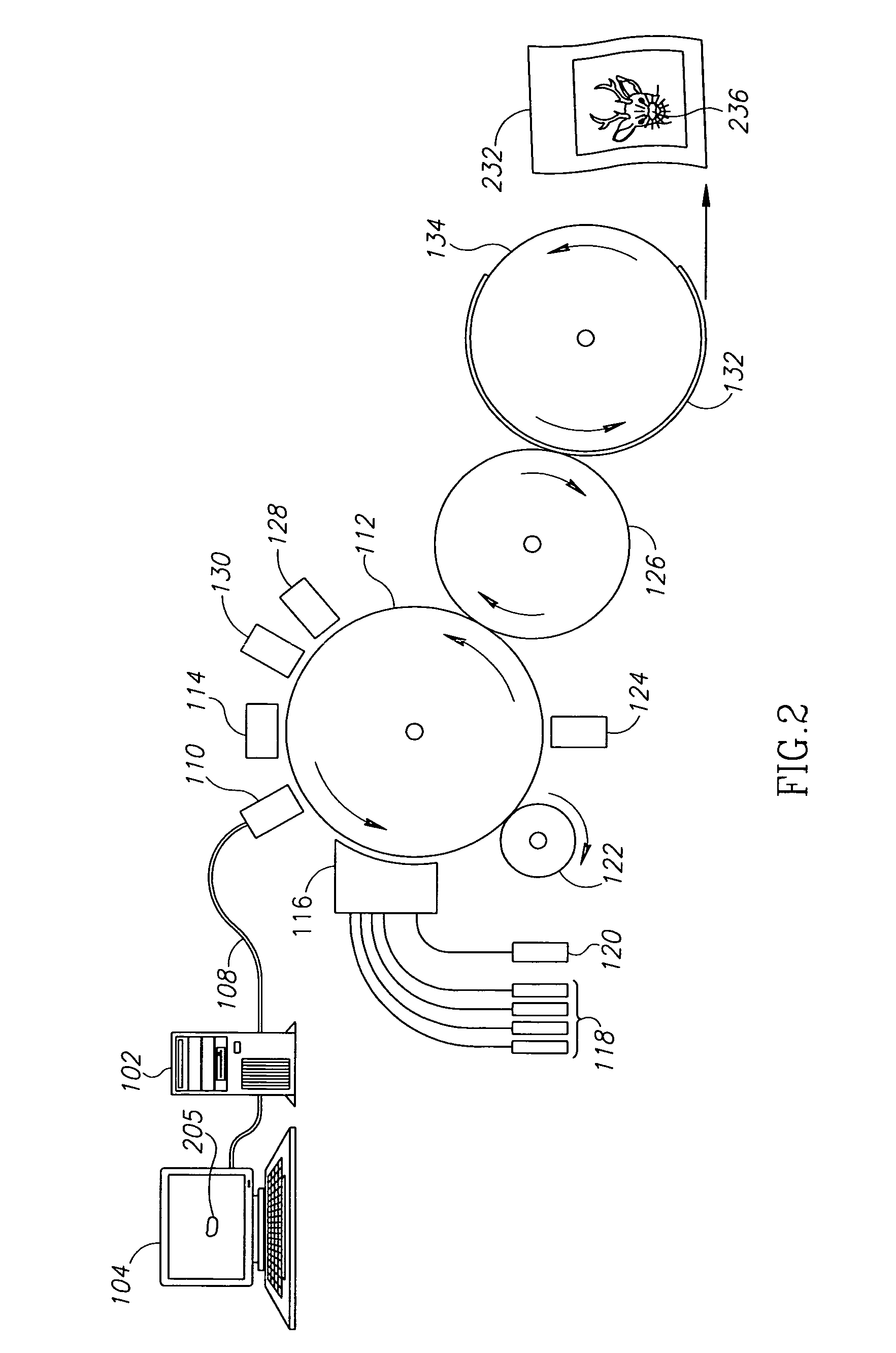

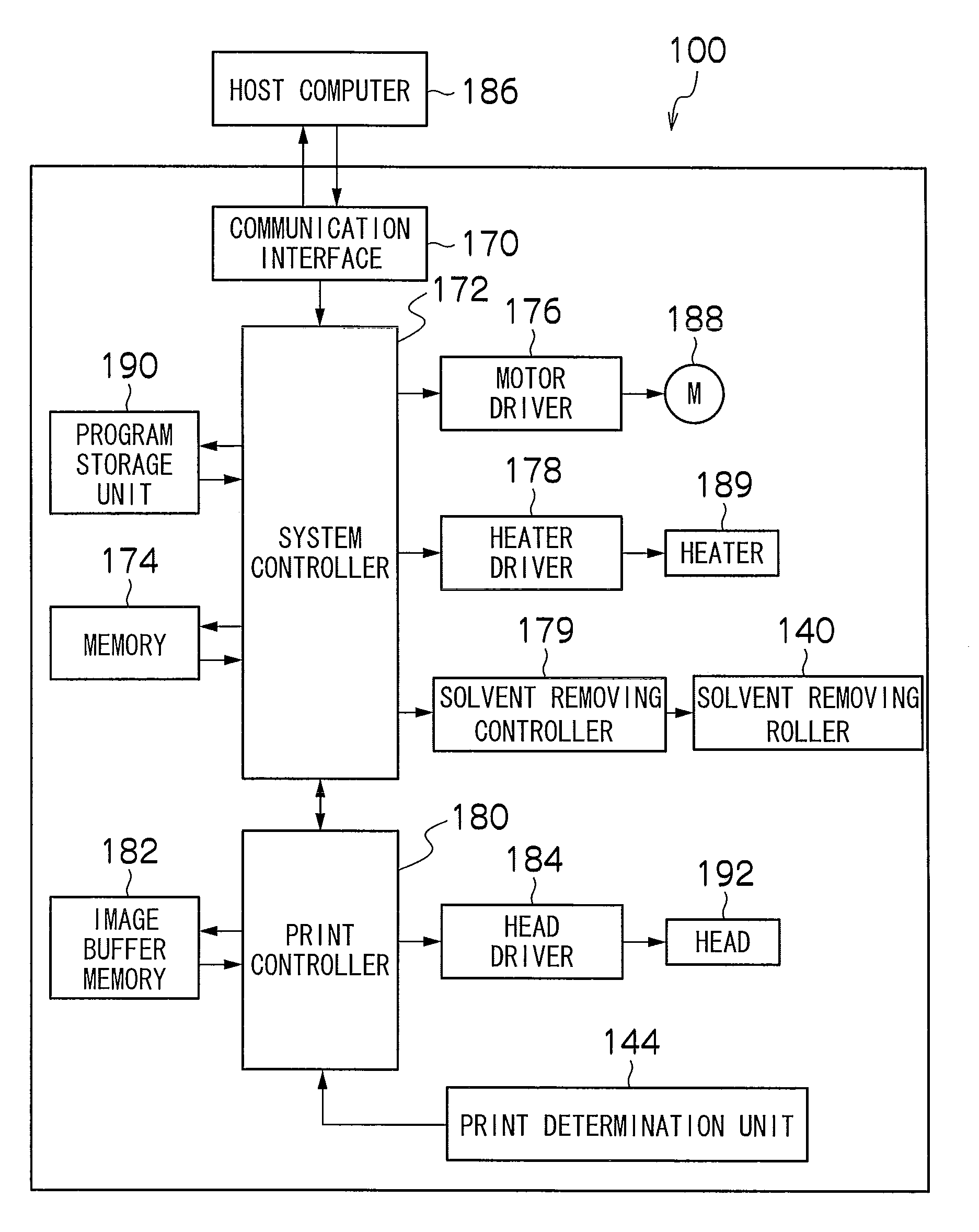

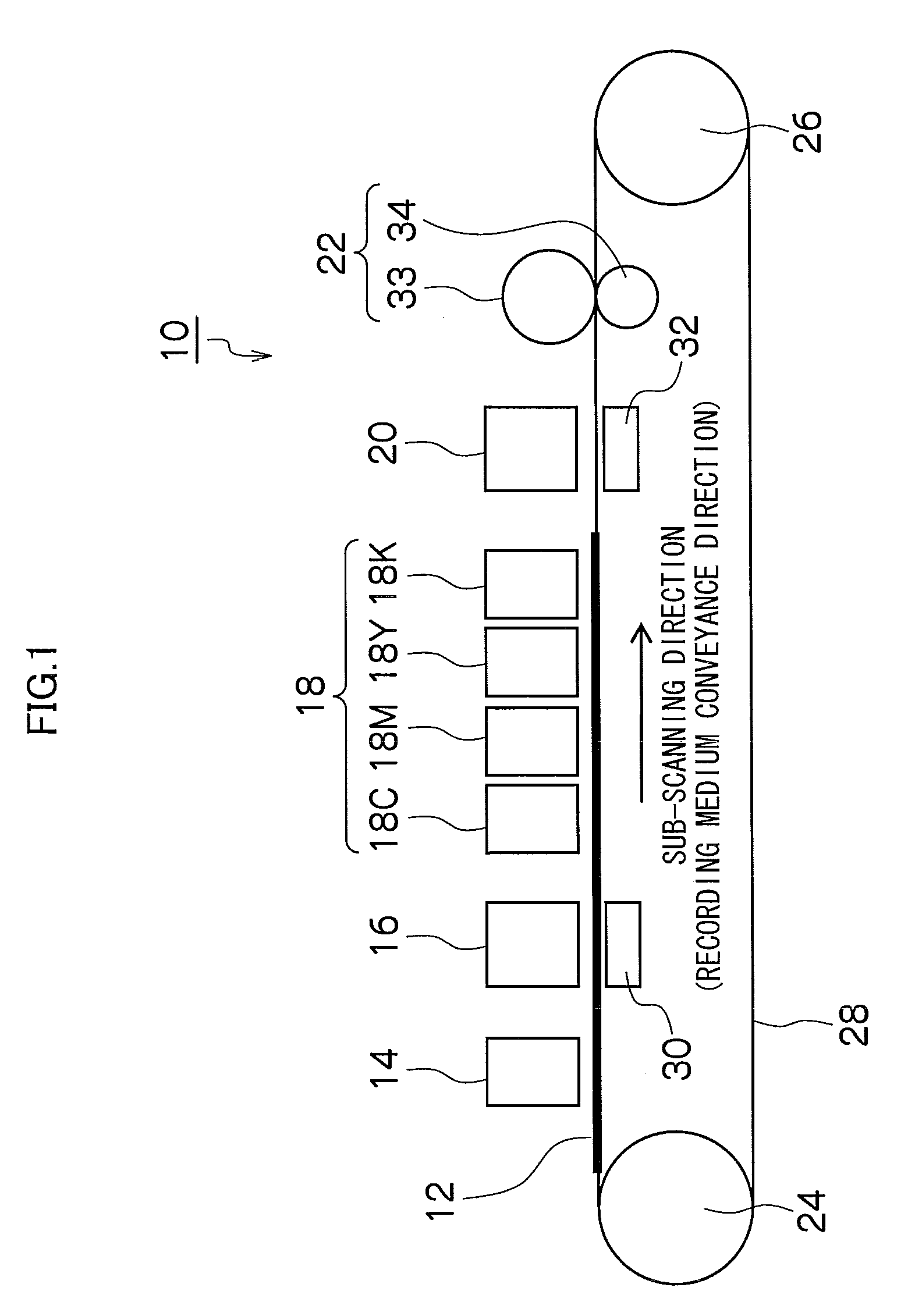

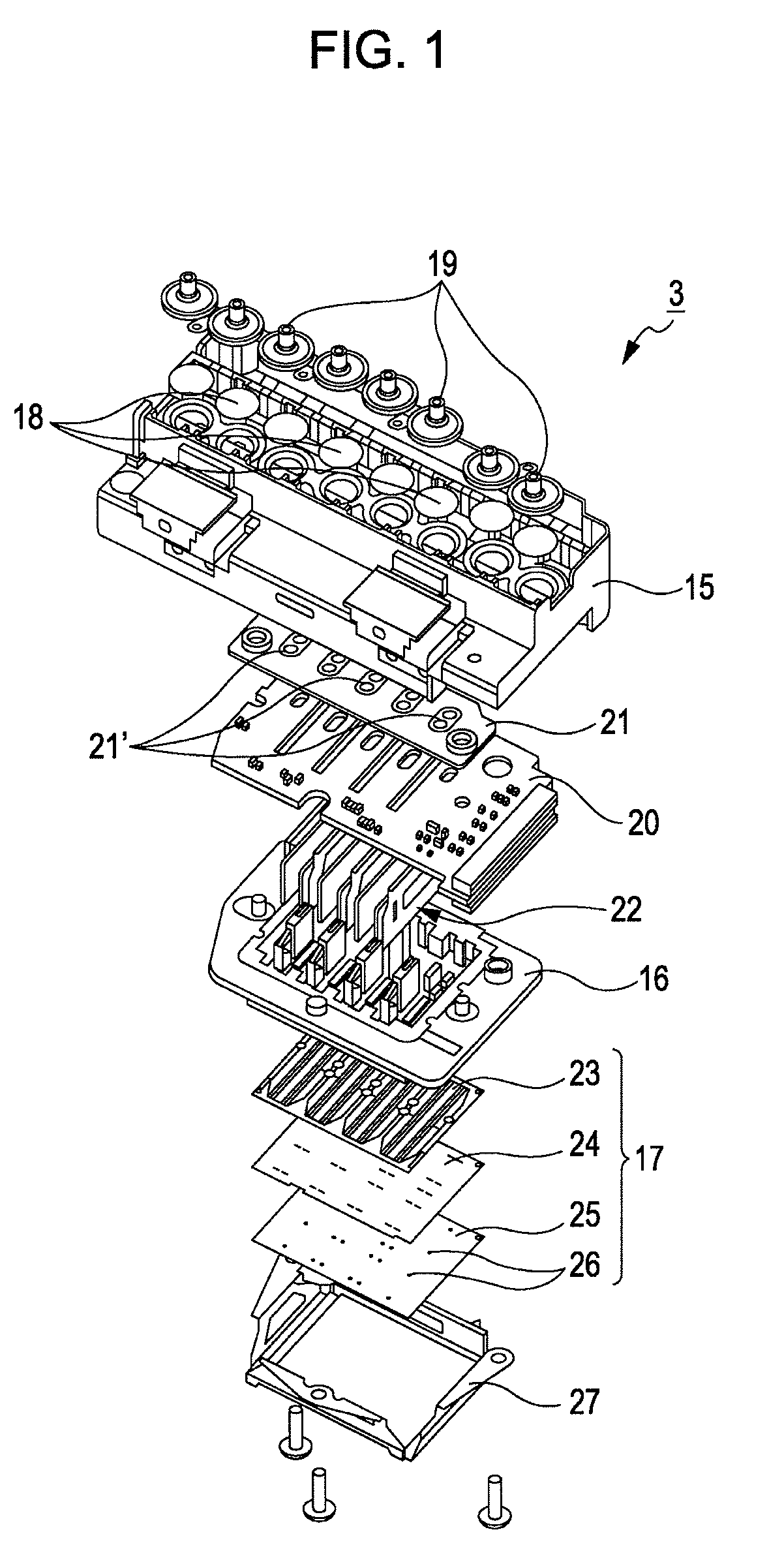

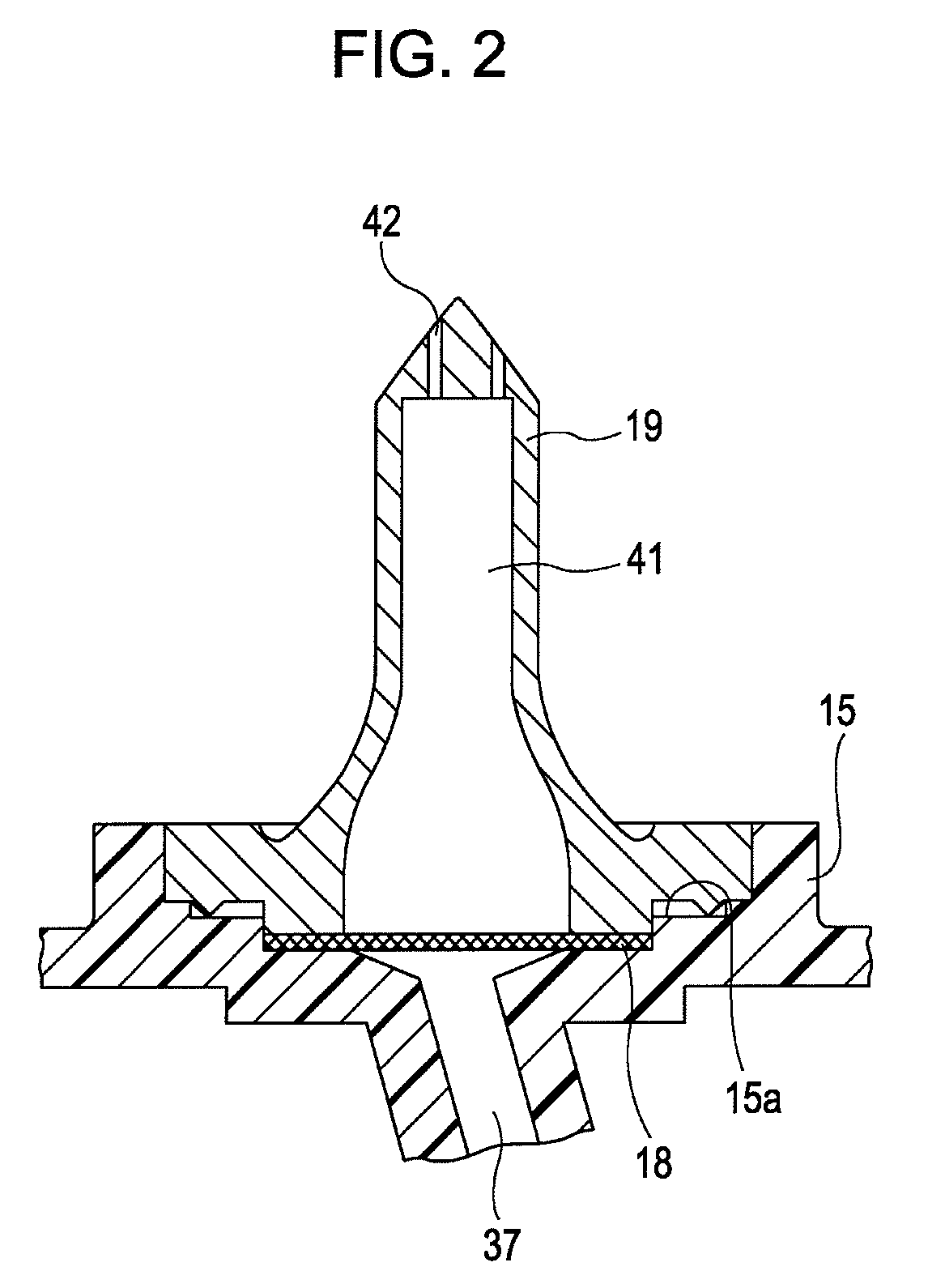

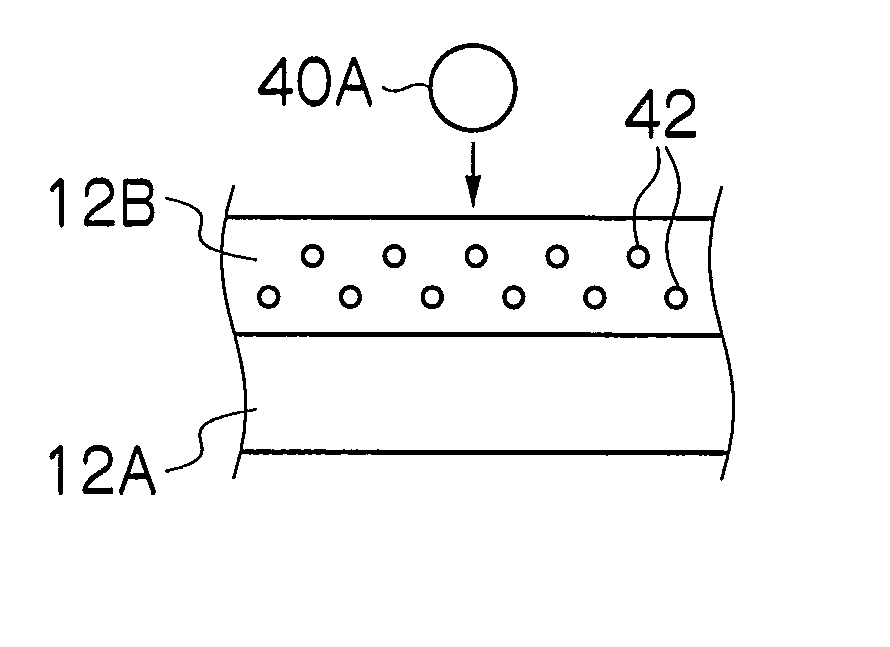

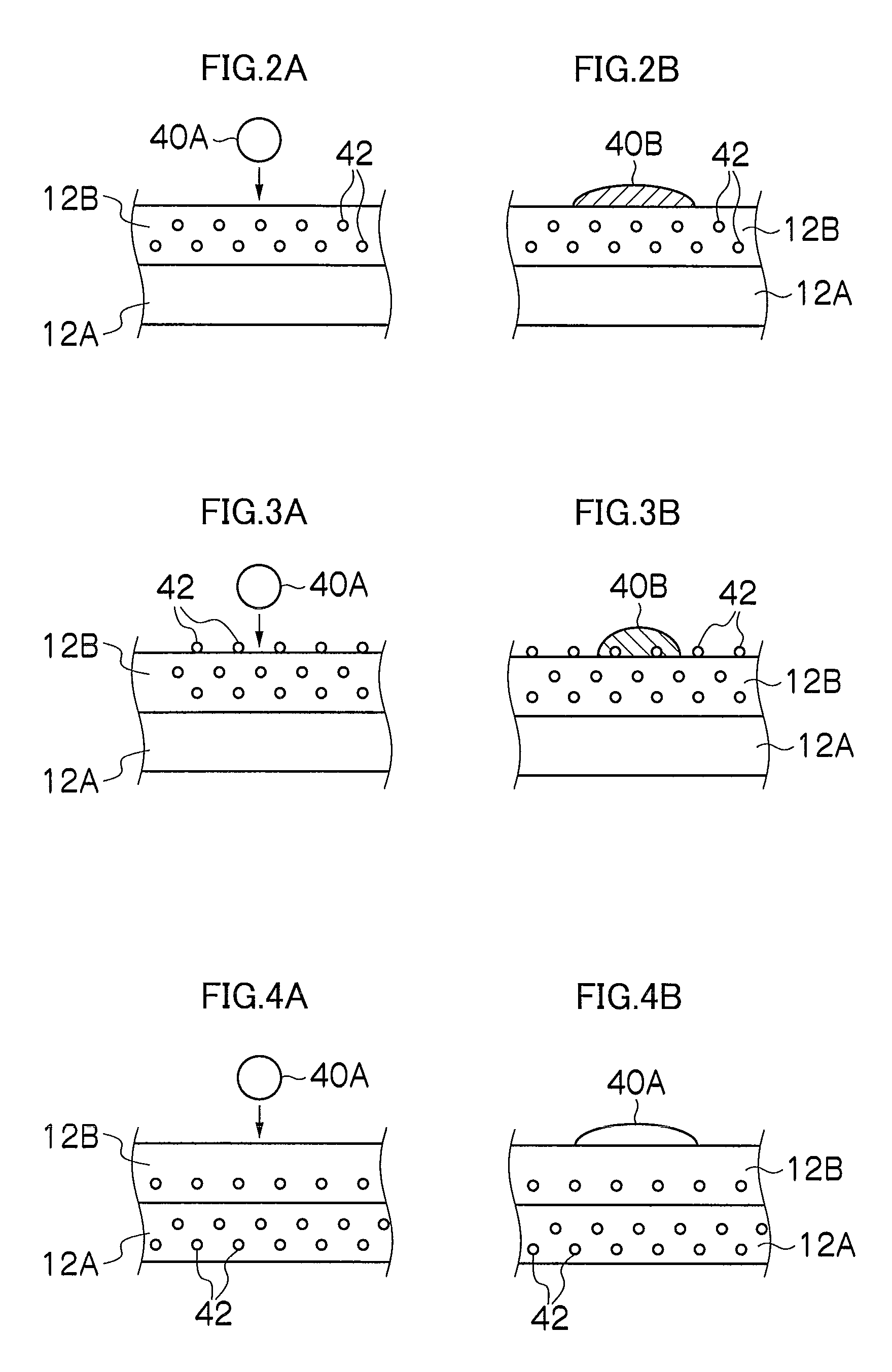

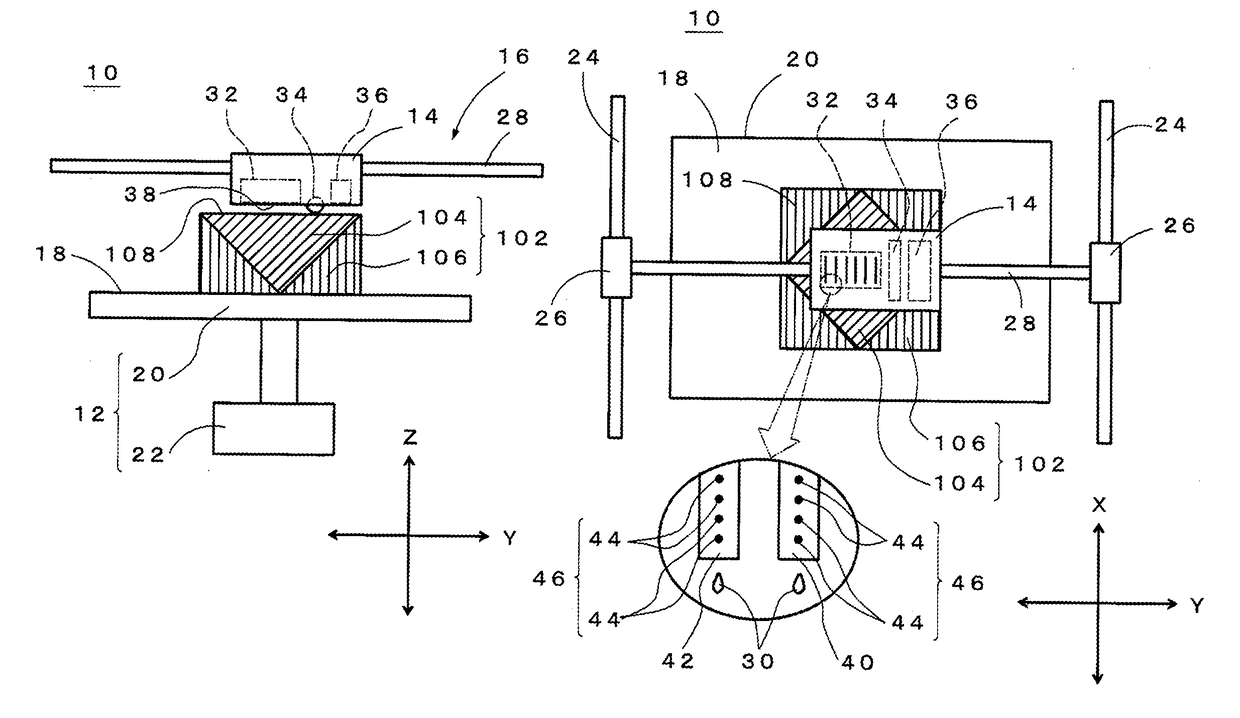

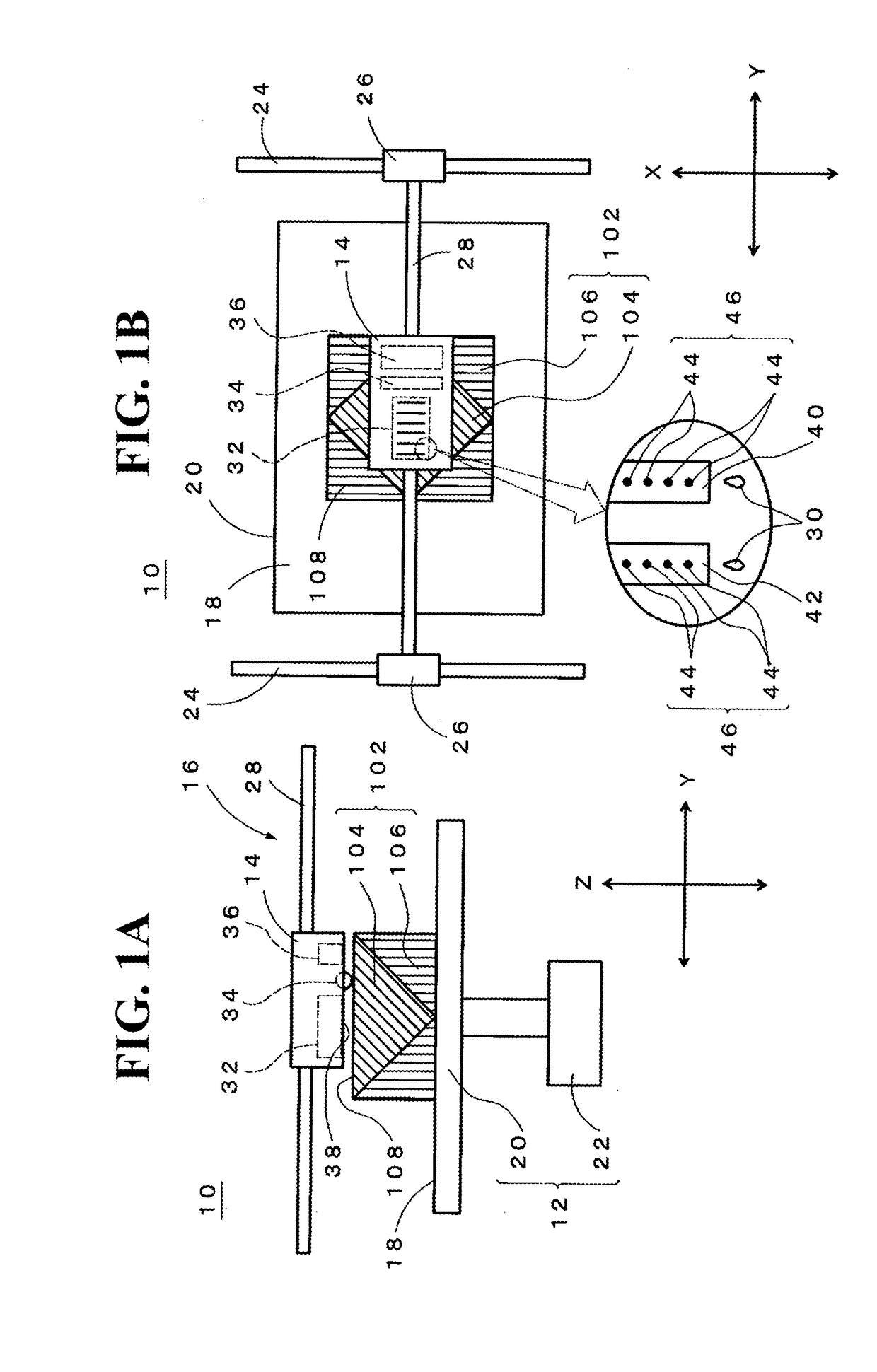

Liquid ejecting apparatus

ActiveUS20140375720A1Reduce in quantitySimple configurationOther printing apparatusLiquid jetSpray nozzle

A liquid ejecting apparatus has a liquid ejecting head capable of ejecting an ink containing thermoplastic resin particles from nozzles to a landing target and a heating unit of heating ink droplets landing on the landing target, in which the heating unit heats the ink droplets at a filming control temperature according to the minimum film forming temperature at which the filming of the surface of the ink droplets starts to thereby control the filming degree of the surface of the ink droplets.

Owner:SEIKO EPSON CORP

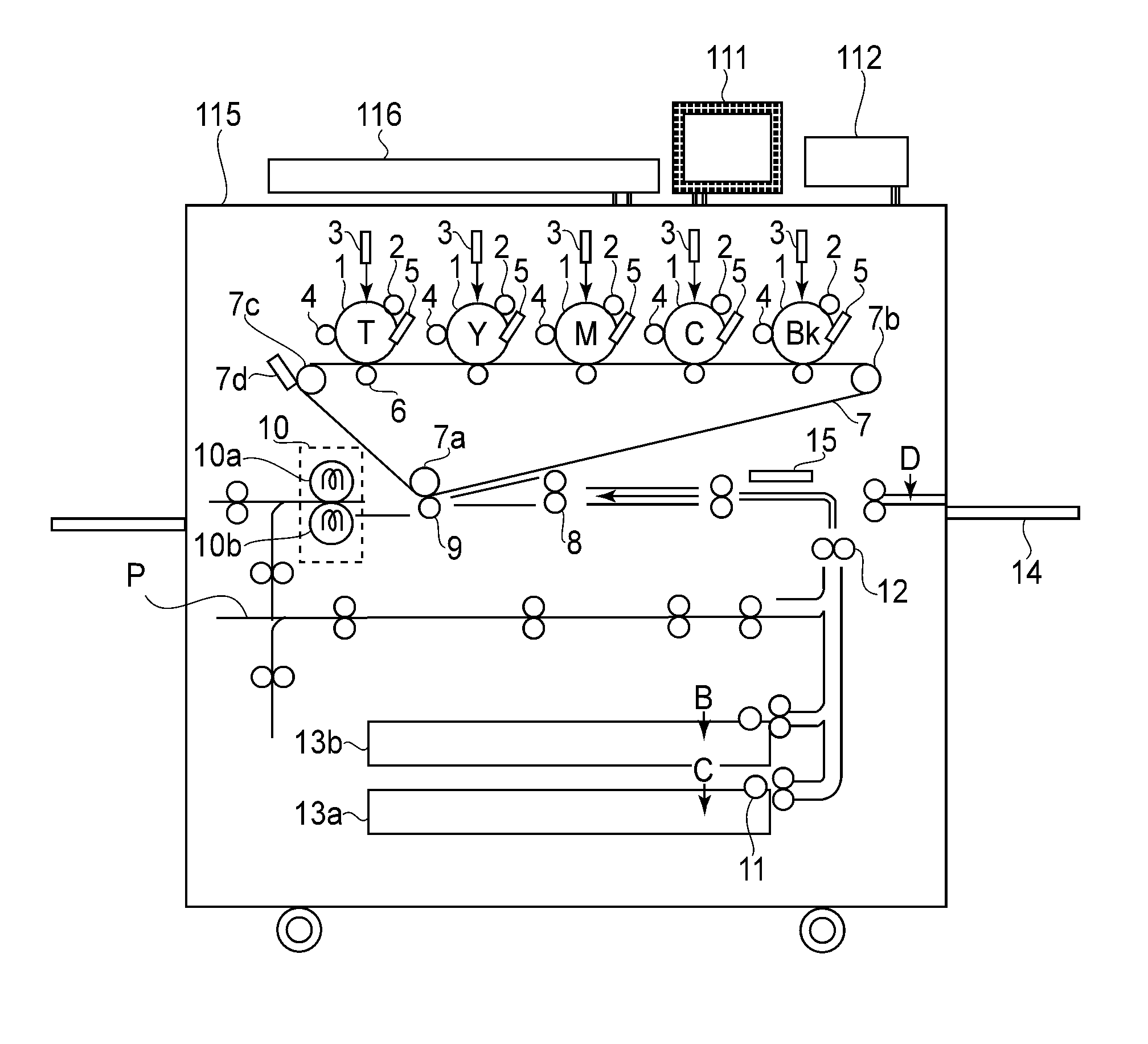

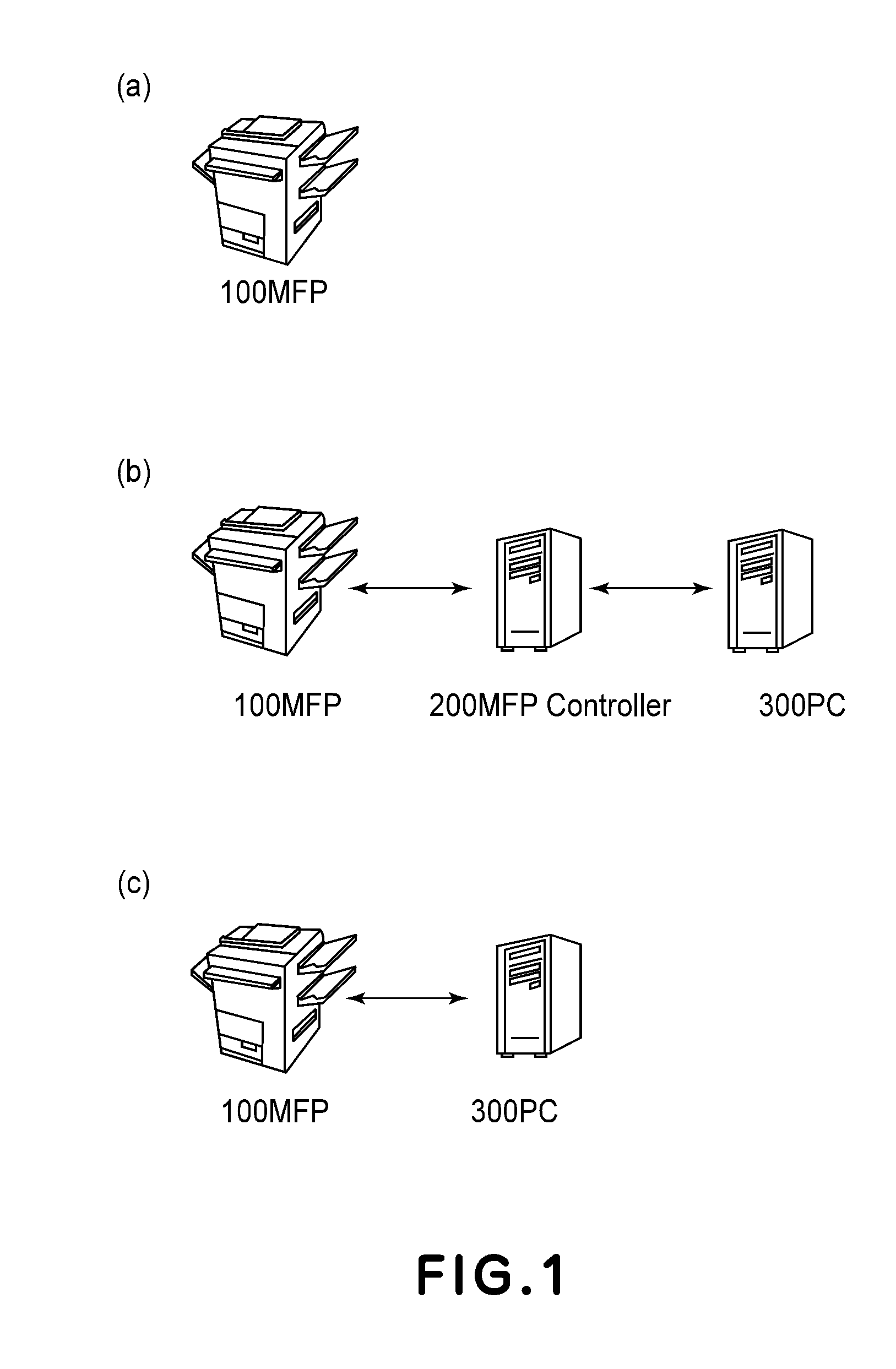

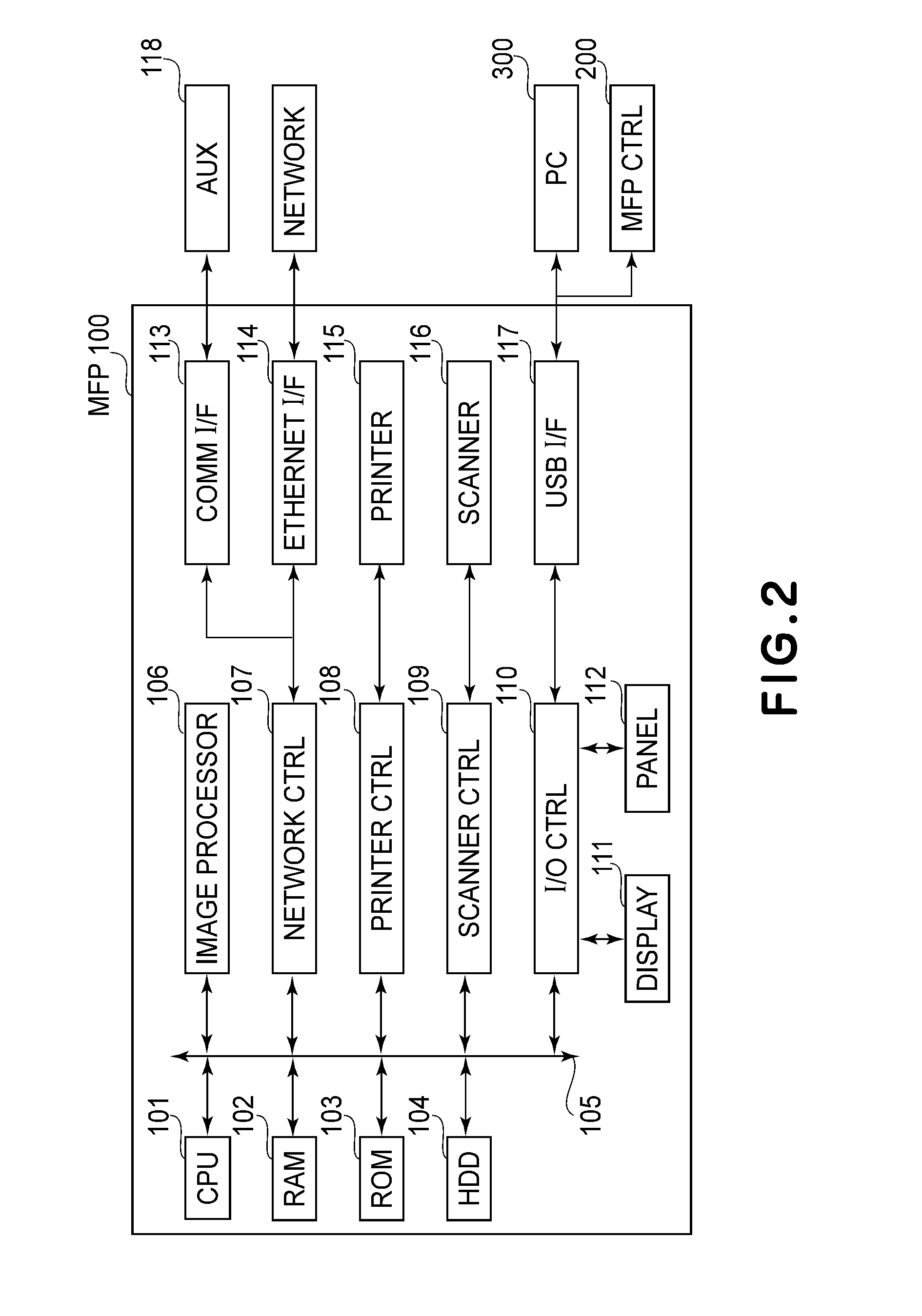

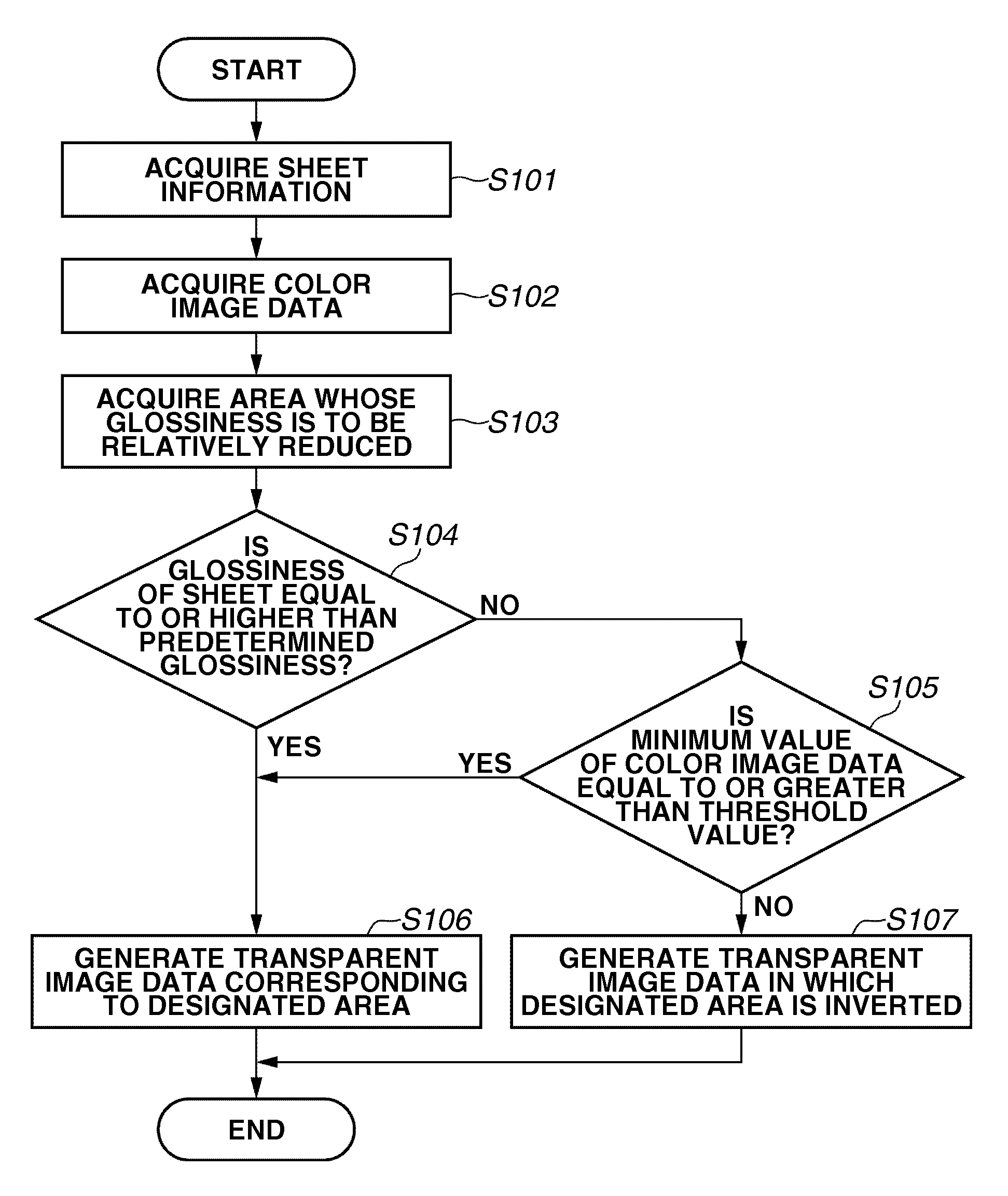

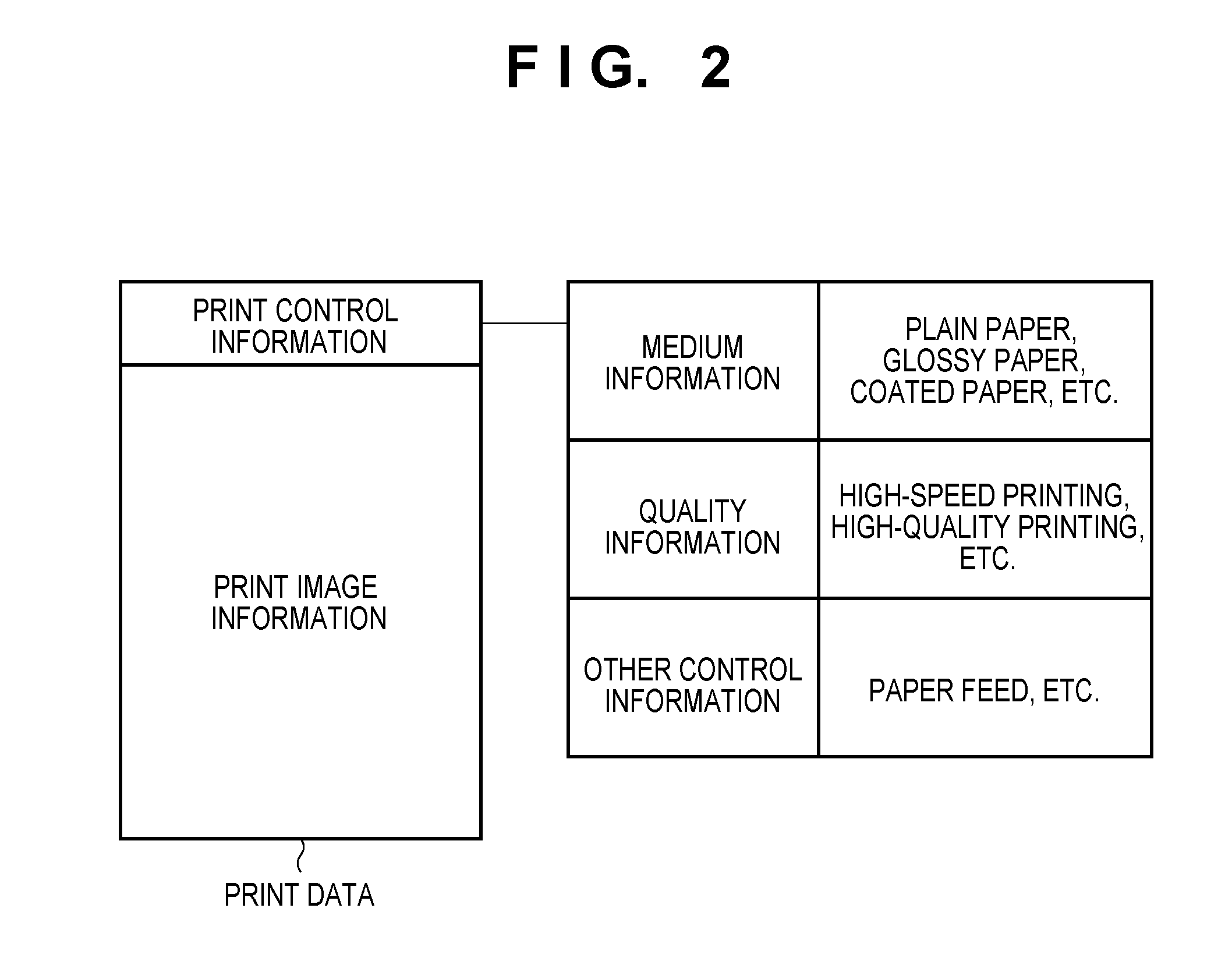

Image processing apparatus, recording medium, and image forming apparatus for lowering print glossiness

InactiveUS8391733B2Making glossiness in a designated area lowerDecrease in glossinessVisual presentation using printersElectrographic process apparatusImaging processingImage formation

Owner:CANON KK

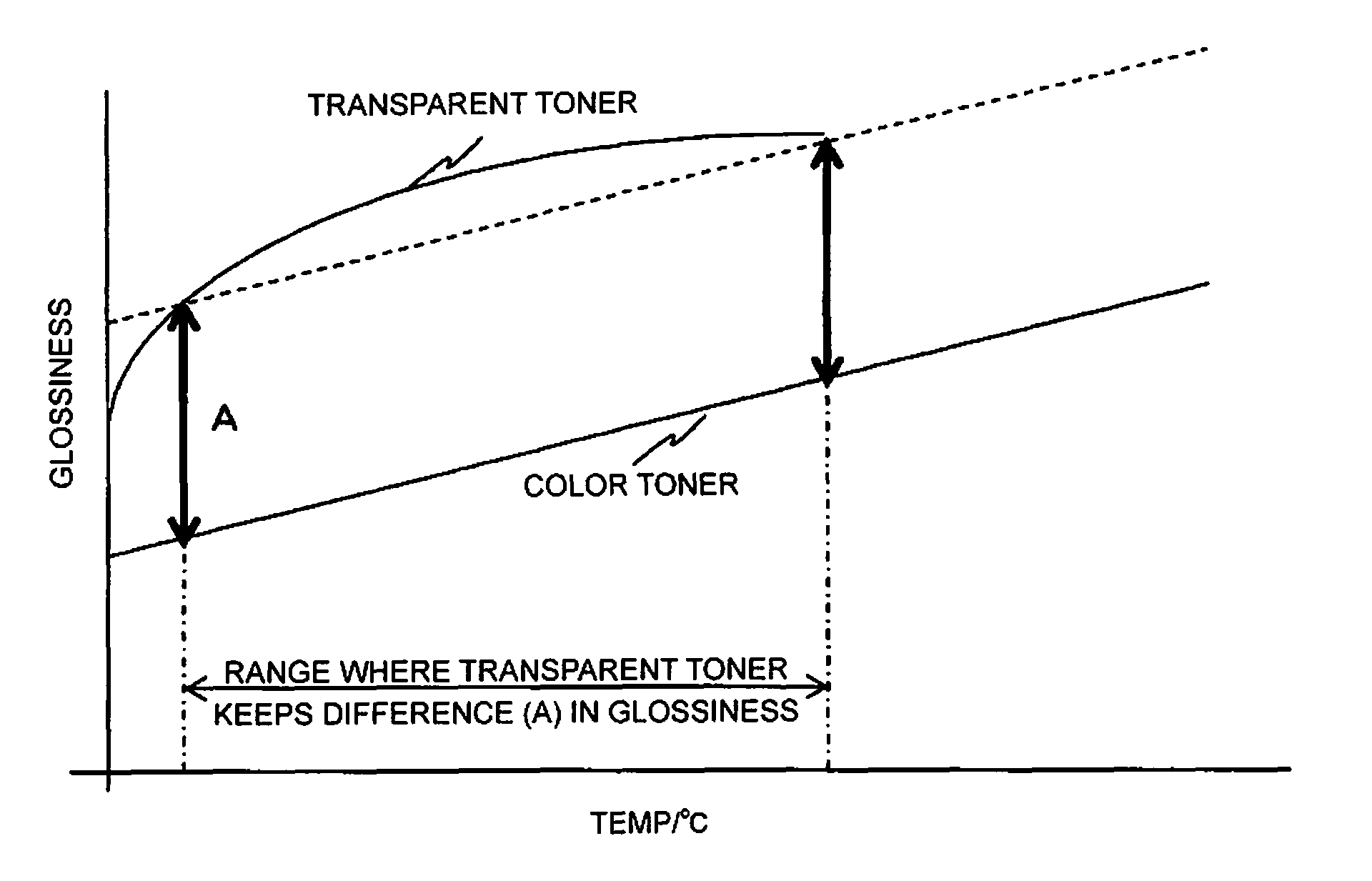

Control apparatus and image forming system for applying a transparent toner in an area where an image is to be formed

InactiveUS8521075B2Decrease in glossinessDegree of glossiness of a sheetElectrographic process apparatusElectrical and Electronics engineeringEngineering

A control apparatus configured to control an image forming system, in forming a transparent toner on a sheet having color toners formed and fixed thereon, applies a transparent toner on an area on which an image can be formed and which is other than an area that a user desires to reduce the glossiness thereof.

Owner:CANON KK

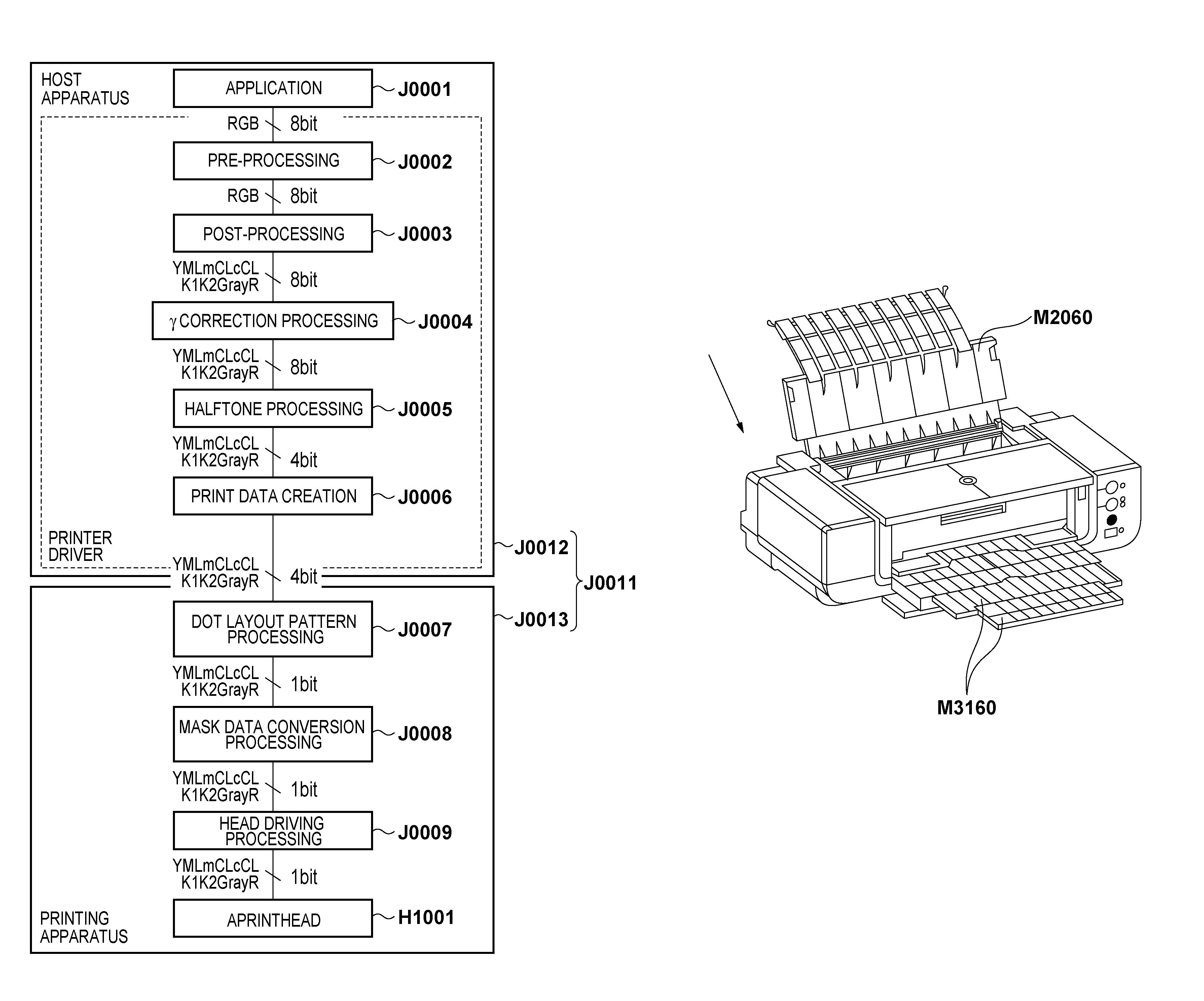

Image processing method and image processing apparatus

ActiveUS20120050356A1Decrease in glossinessImproving gamutOther printing apparatusPictoral communicationImaging processingImaging data

An image processing method includes a conversion step of converting input image data into ink color data corresponding to respective use amounts of one or more types of color inks and a clear ink. In the conversion step, the input image data is converted into ink color data so that the use amount of the clear ink used in ink color data using a black carbon-containing ink becomes equal to or larger than that of the clear ink used in ink color data using no black carbon-containing ink.

Owner:CANON KK

Reduced-moisture-content-solvent ink composition and method for producing the same

ActiveUS20110094411A1Low pigment contentDecrease in glossinessPigmenting treatmentInksOrganic solventWater vapor

A method for producing a reduced-moisture-content-solvent ink composition includes reducing the moisture content of a pigment dispersion containing a metal pigment and a dispersion medium or an ink composition containing the pigment dispersion and an organic solvent by bubbling treatment using an inert gas having a water vapor content of 2.0 mg / L or less.

Owner:SEIKO EPSON CORP

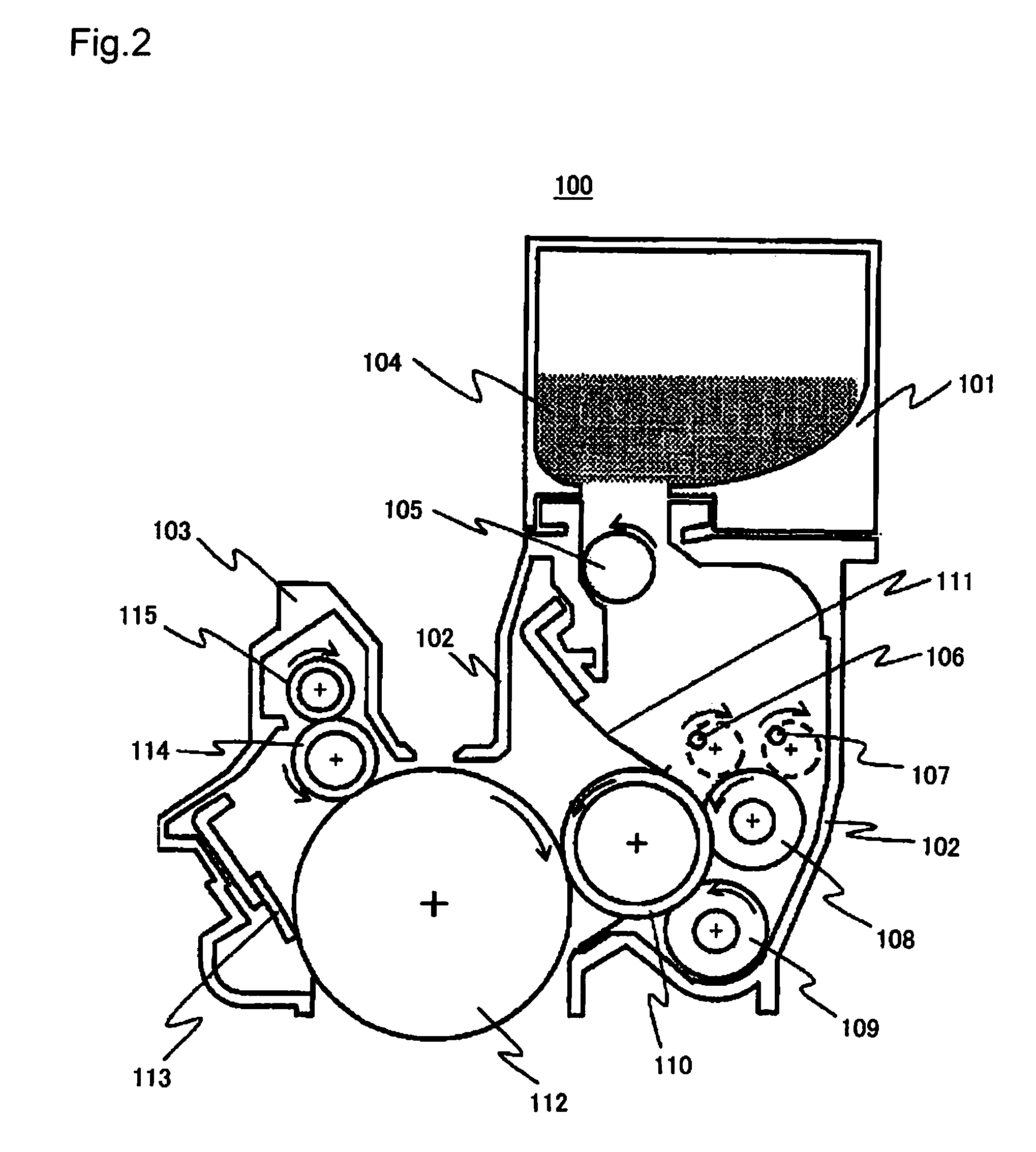

Transparent developer, developer housing, development device, and image formation apparatus

ActiveUS20150072280A1Reduce thicknessChanges the color tone of a printElectrographic process apparatusDevelopersImage formationGlass transition point

A transparent developer has a glass transition point of 63.0° C. to 66.0° C., both inclusive, and a melt temperature, indicative of a softening point by a 1 / 2 method, of 94.3° C. to 97.0° C., both inclusive.

Owner:OKI ELECTRIC IND CO LTD

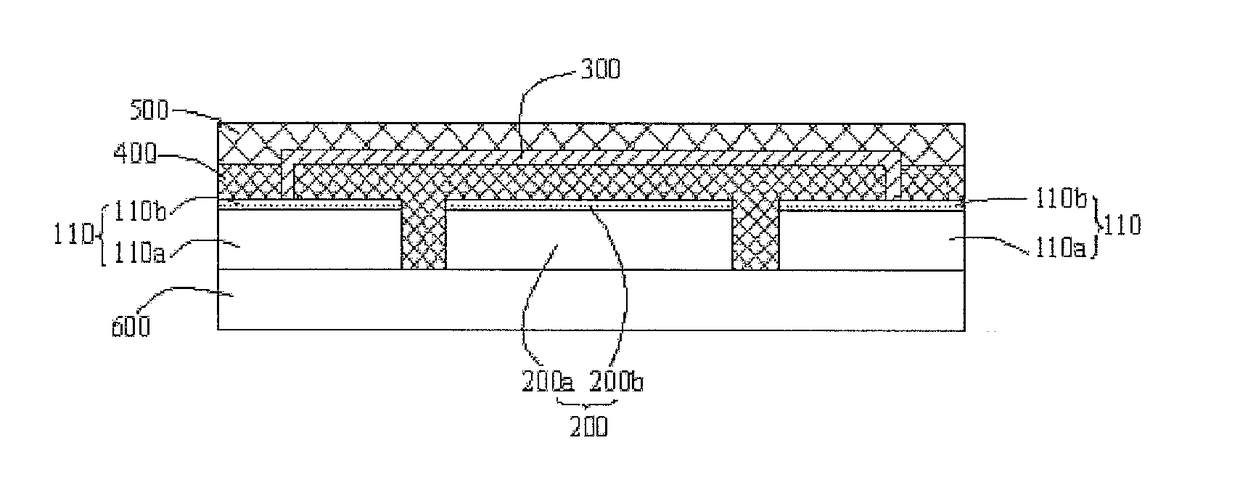

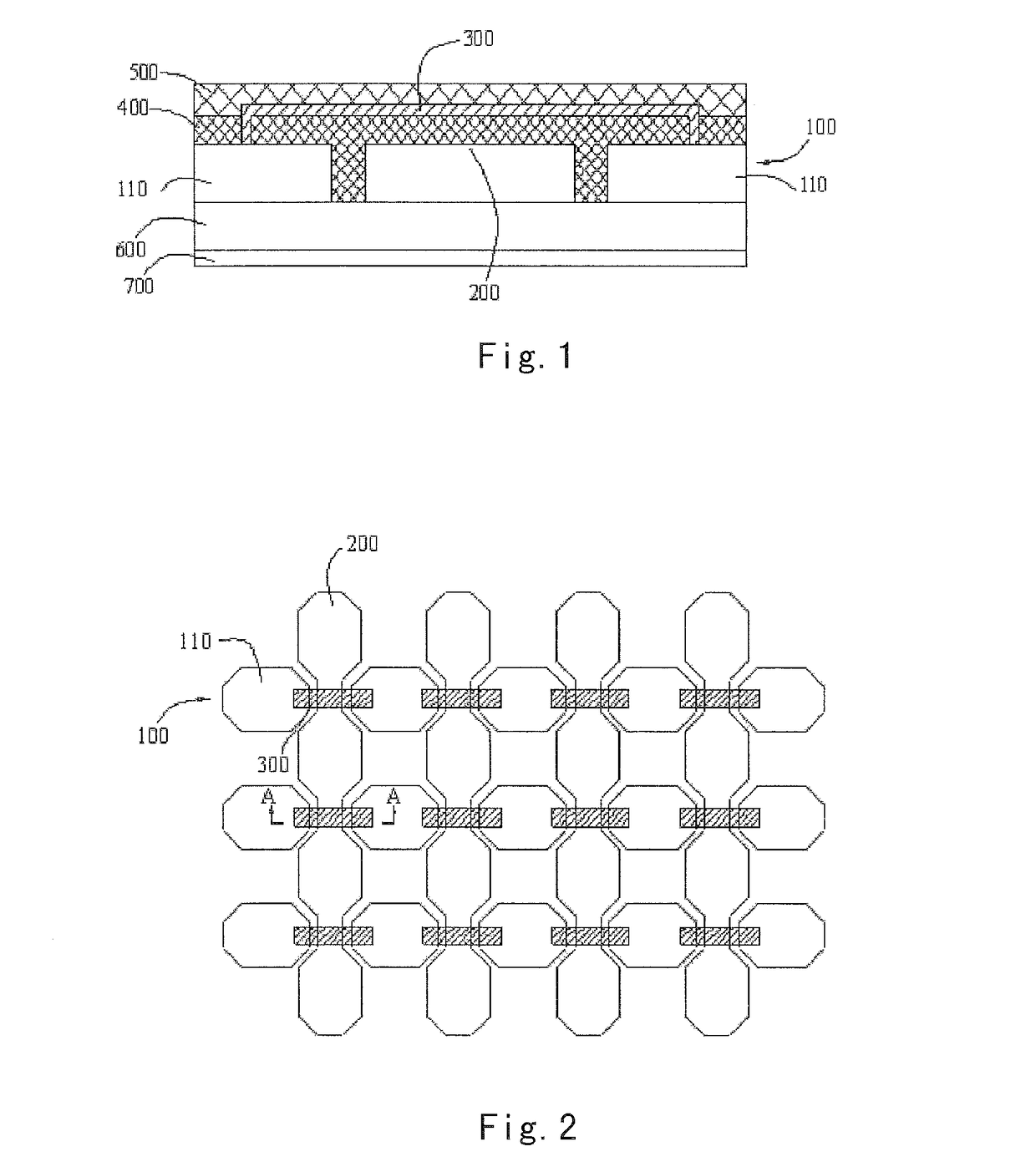

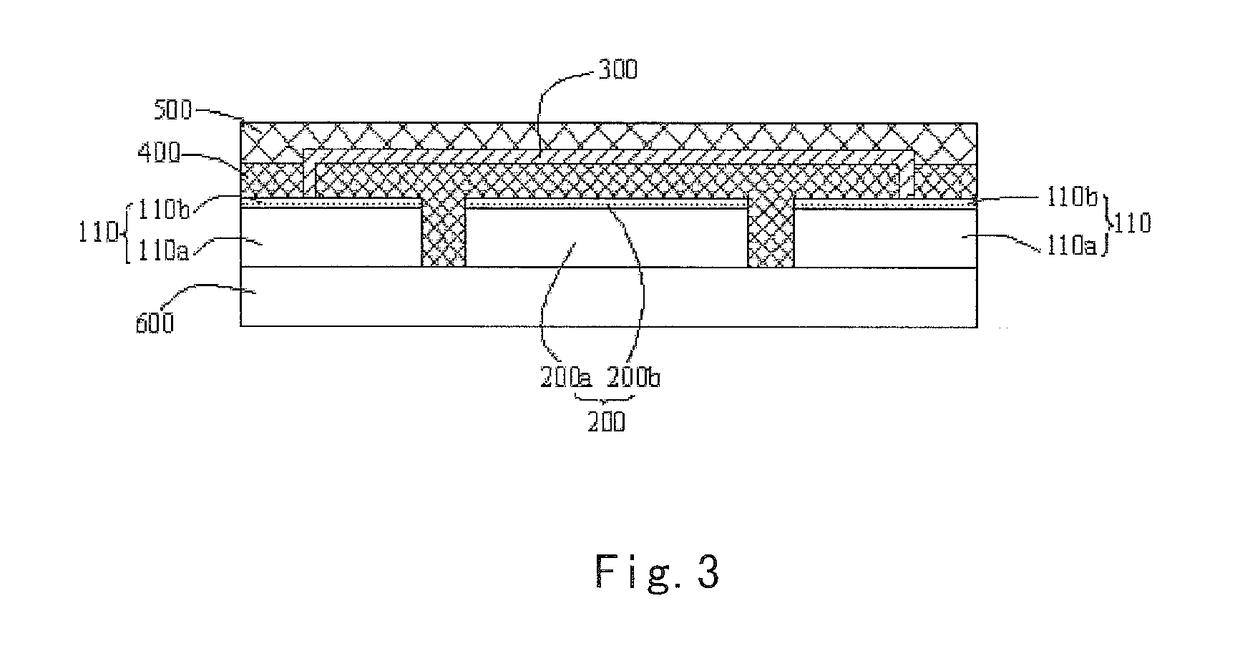

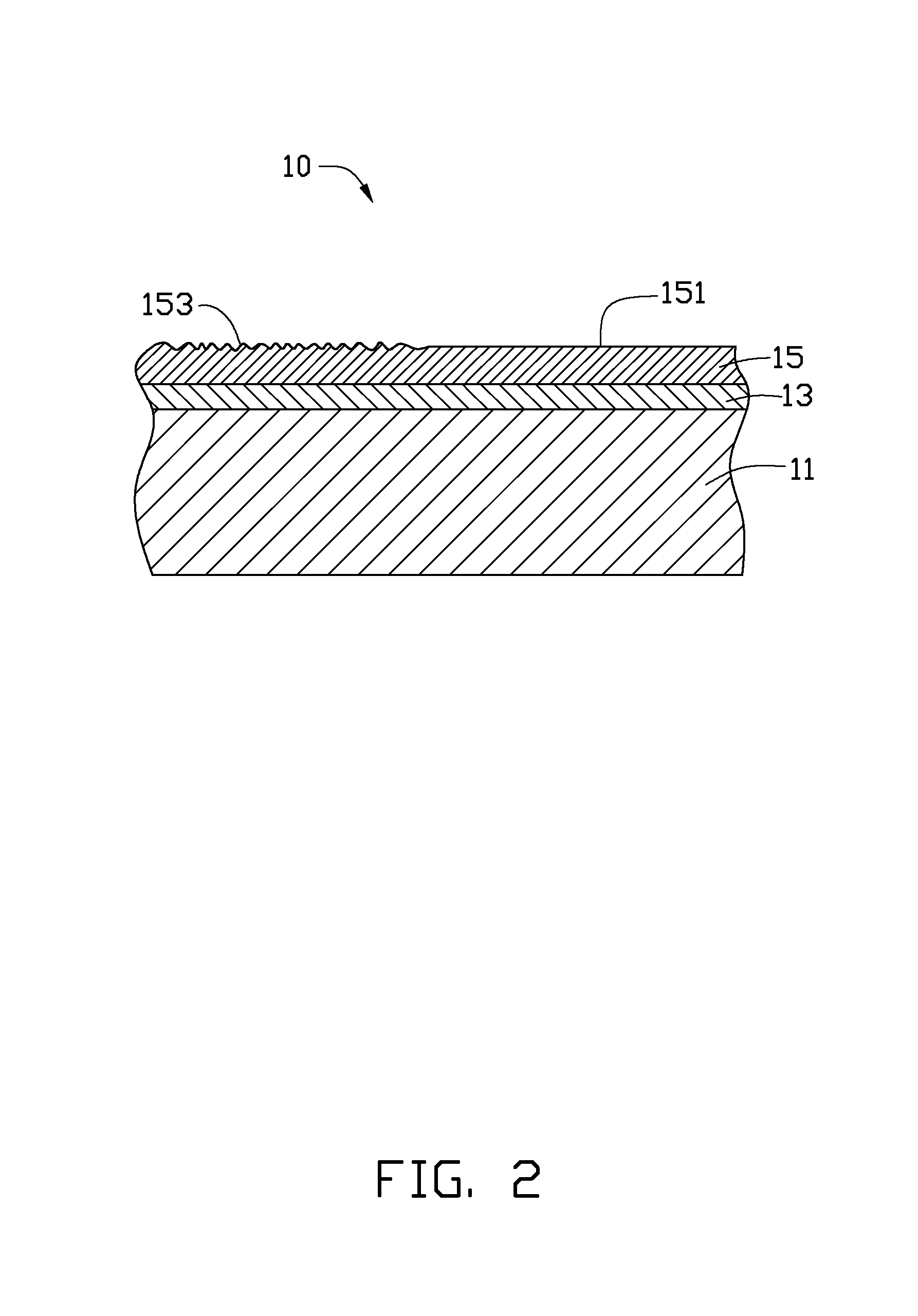

Panel, method for producing the same and display apparatus

ActiveUS20170192585A1Haze ratio is increasedDecrease in glossinessInput/output processes for data processingOptoelectronicsMetal

An embodiment of the present application provides a method for producing a panel. The method includes: providing a transparent substrate including an electrode setting area; forming a transparent electrode layer within the electrode setting area, wherein the transparent electrode layer includes a plurality of transparent electrodes, and each of the transparent electrodes includes a transparent metal oxide layer and a reduced metal layer on the transparent metal oxide layer. Embodiments of the present application also provide a panel and a display apparatus.

Owner:BOE TECH GRP CO LTD +1

Printing of images with selective gloss and toners therefore

InactiveUS8512930B2Optimization rangeDecrease in glossinessDevelopersElectrographic process apparatusPolymer scienceComputer printing

A matte liquid toner suitable for use in a liquid toner printer, comprising a carrier liquid, toner particles comprising a resin and substantially uncolored additive particles of average diameter between 1 and 20 micrometers dispersed in the resin.

Owner:HEWLETT PACKARD DEV CO LP

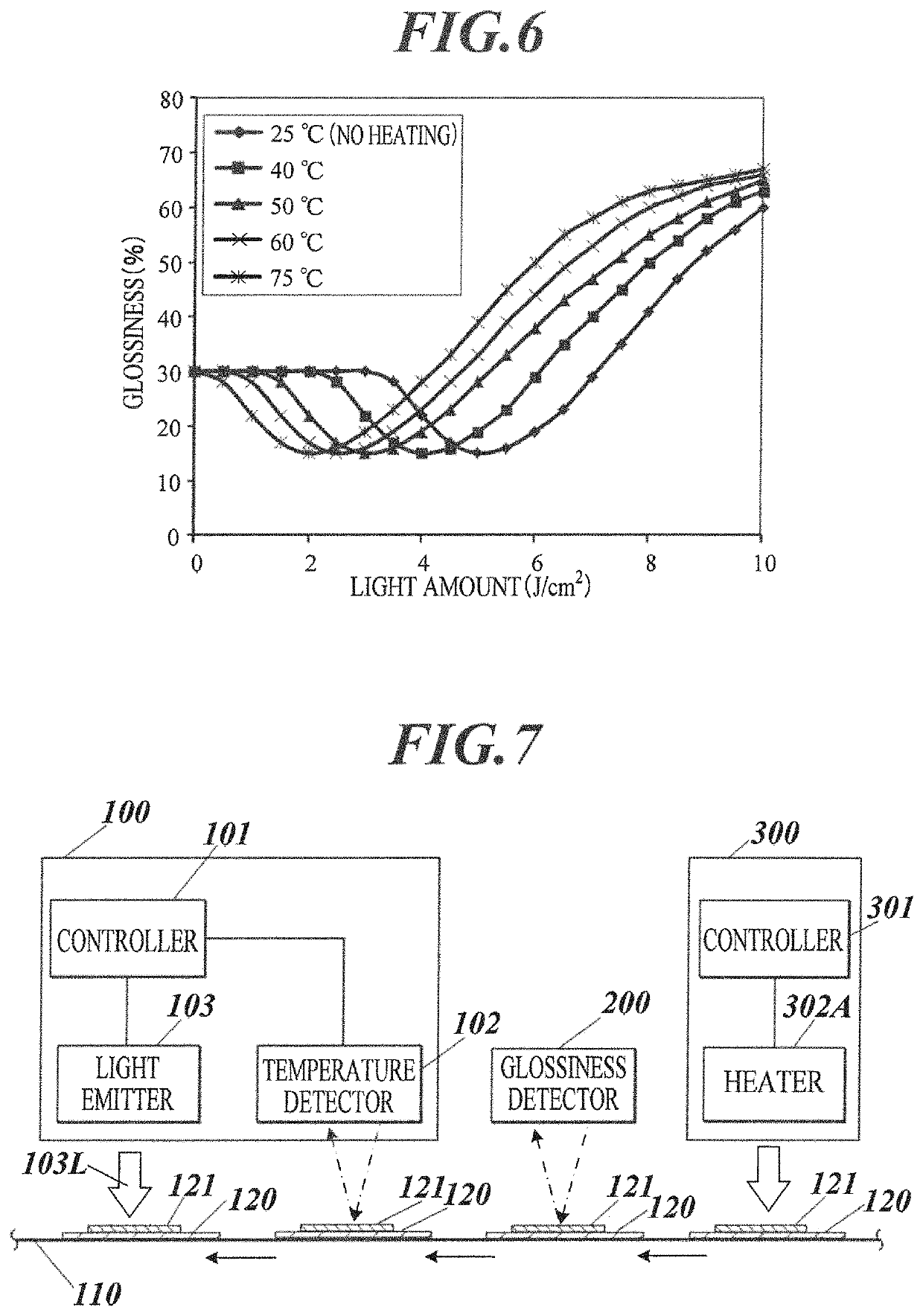

Gloss reduction in image post-processing method, image post-processing apparatus, and image forming apparatus

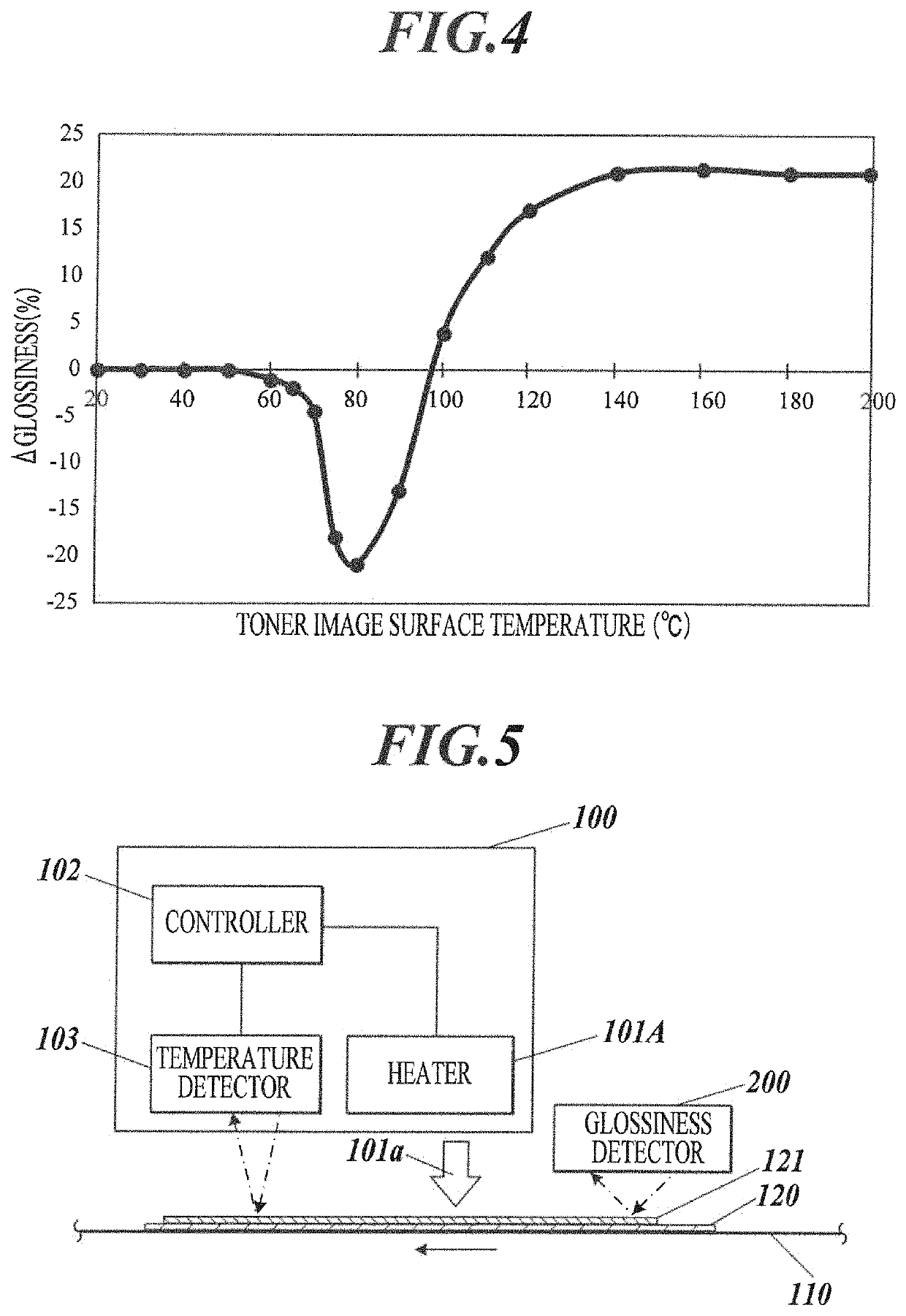

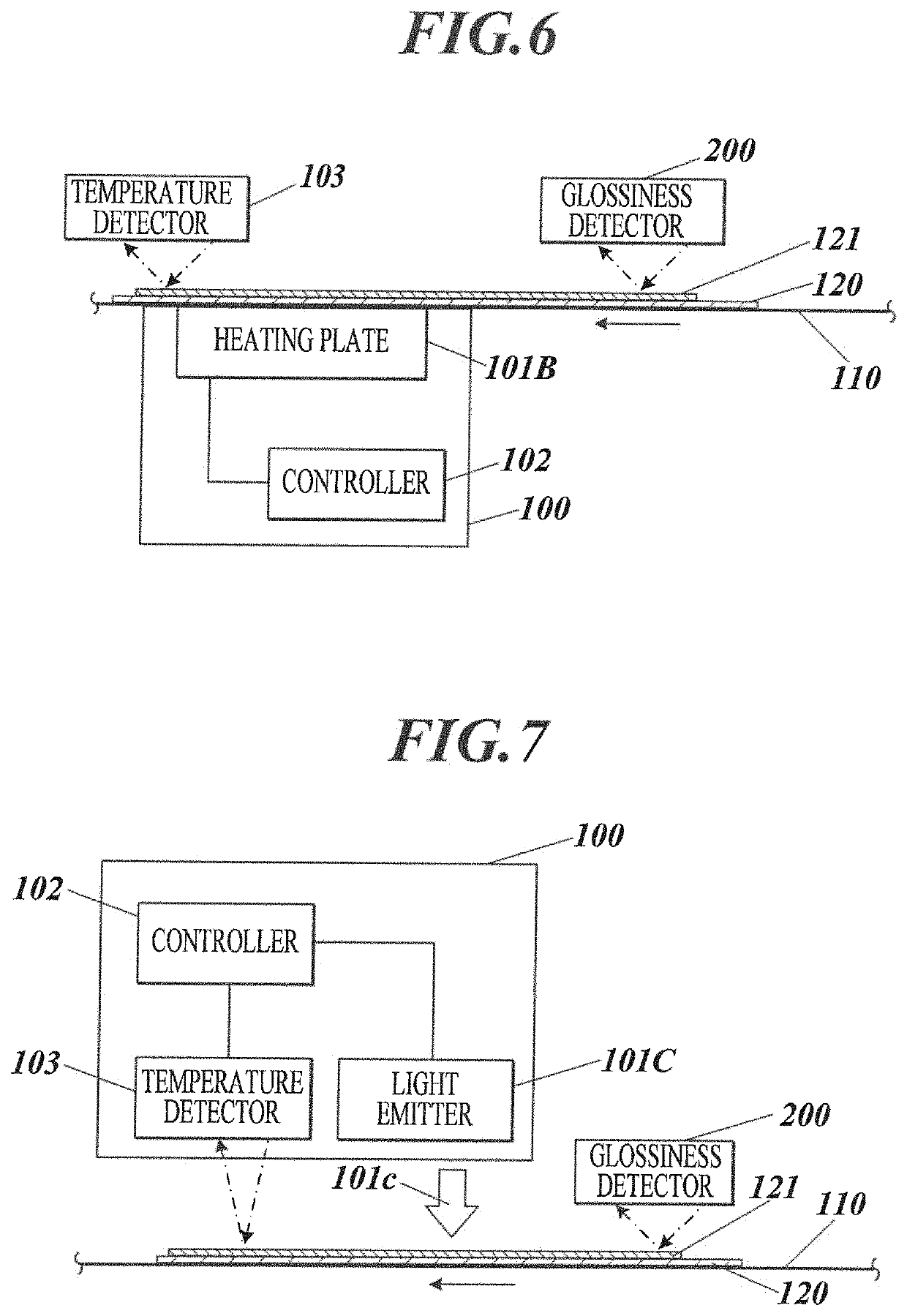

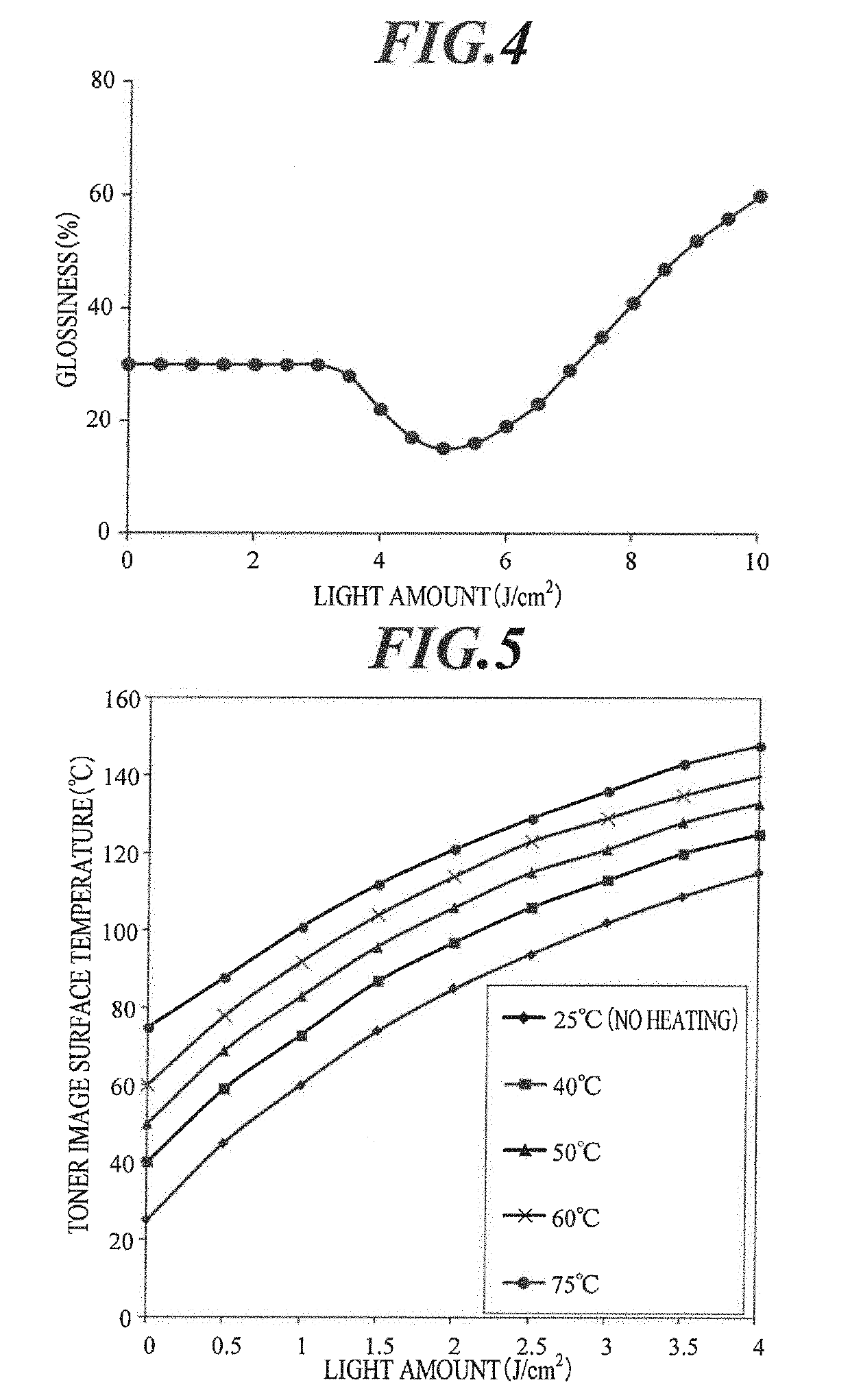

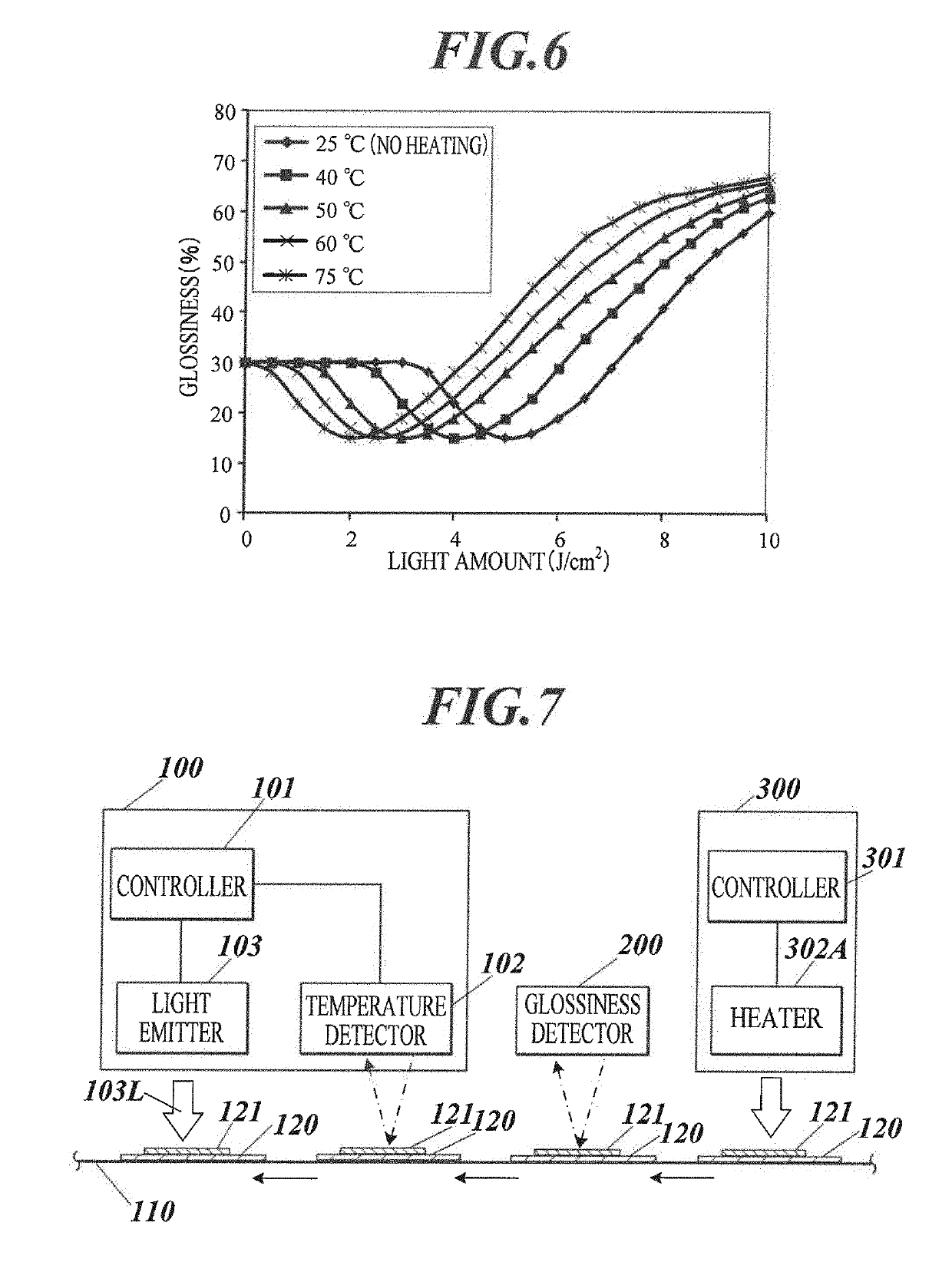

ActiveUS10663902B2Glossiness can be adjustedNo influence fixabilityElectrographic process apparatusImage formationEngineering

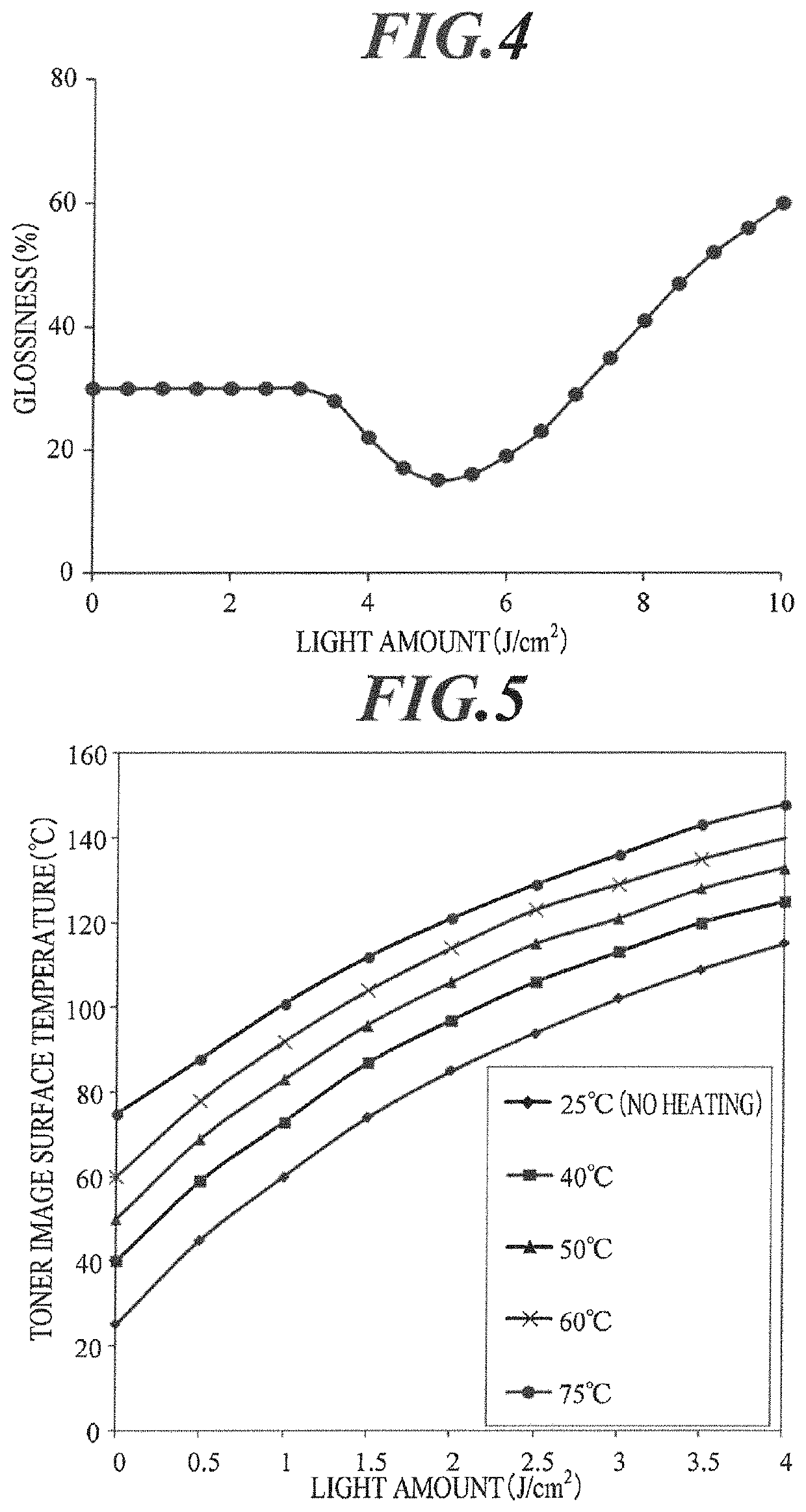

There is disclosed an image post-processing method for adjusting glossiness of a fixed toner image. The image post-processing method includes a glossiness control step of, with a non-contact heating device, heating a toner image fixed to a recording medium so as to reduce glossiness of the toner image. The non-contact heating device is configured to heat the toner image fixed to the recording medium to a temperature which reduces the glossiness of the fixed toner image.

Owner:KONICA MINOLTA INC

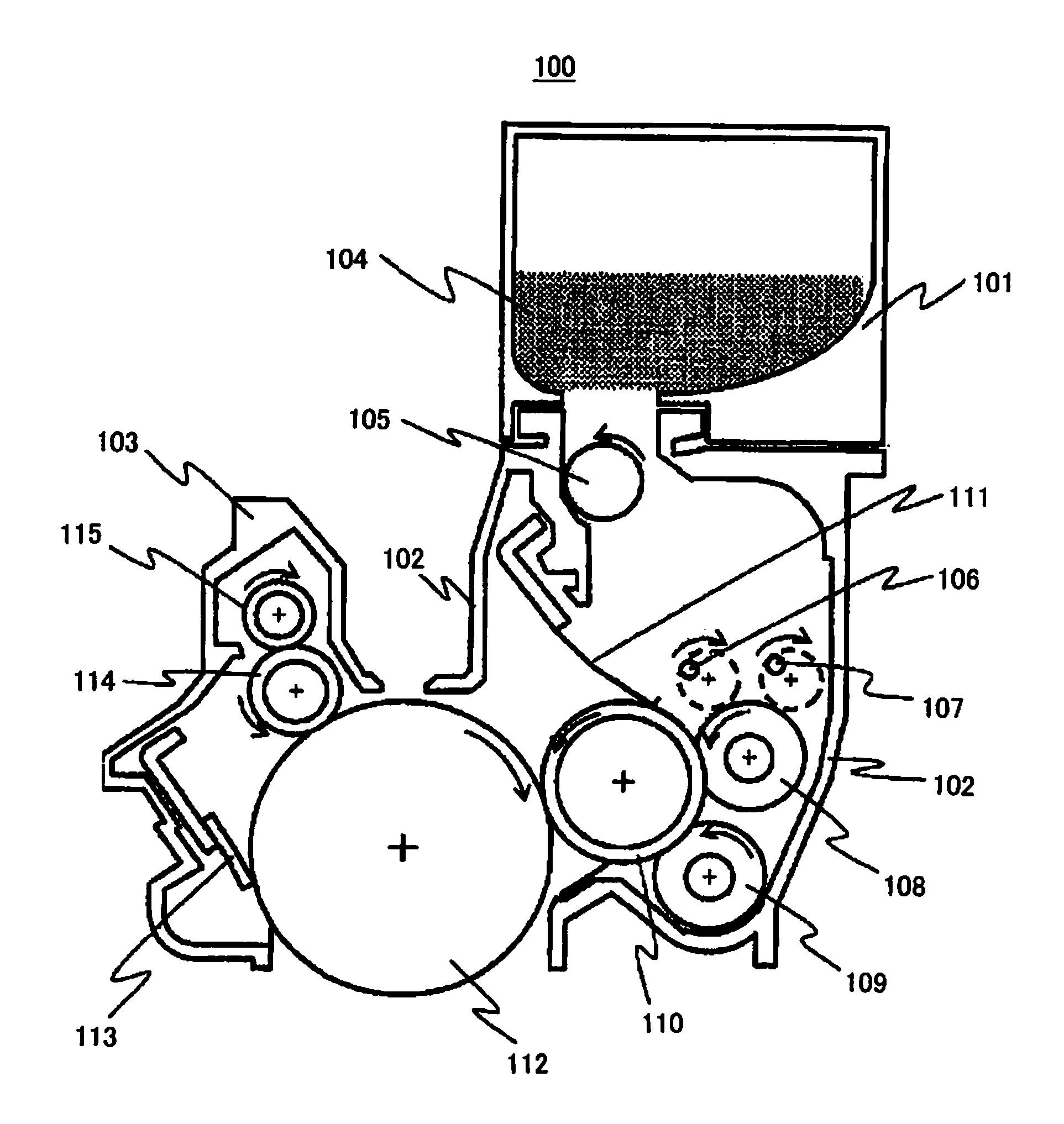

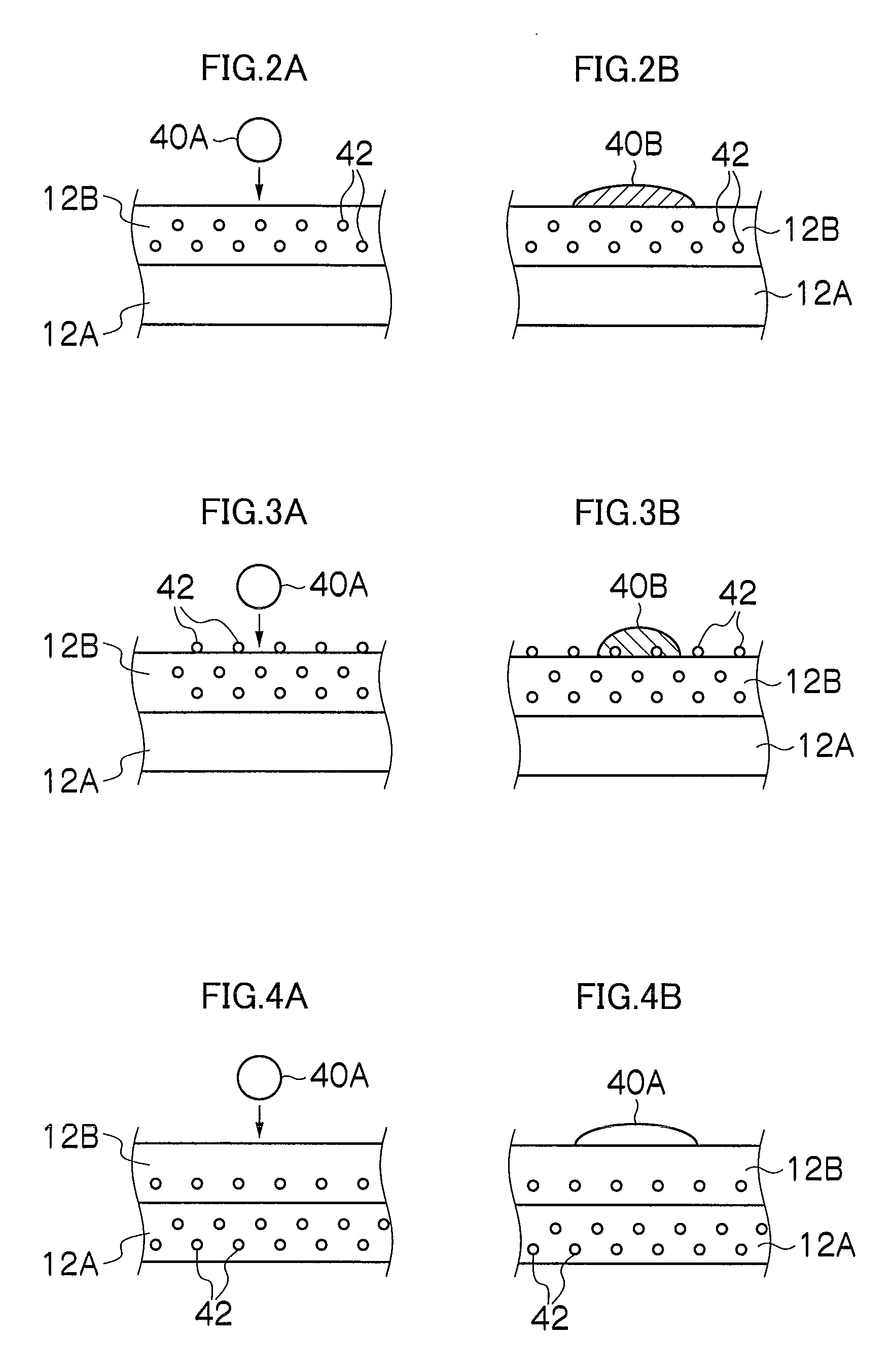

Inkjet recording method and apparatus

ActiveUS20090322805A1Reduce the overall diameterAvoid it happening againDuplicating/marking methodsOther printing apparatusPaper sheetEngineering

The inkjet recording method includes: a treatment liquid deposition step of depositing a treatment liquid containing an aggregating agent onto a surface of a coating layer of a coated paper having a base paper layer and the coating layer coating the base paper layer; and an ink deposition step of depositing ink onto the surface of the coating layer on which the treatment liquid has been deposited. In the ink deposition step, the ink is deposited onto the surface of the coating layer in a state where an effective pH of the aggregating agent on the surface of the coating layer is not lower than 1.67 and not higher than 7.0, and an effective pH of the aggregating agent in the coating layer is not lower than 0.1 and not higher than 1.7.

Owner:FUJIFILM CORP

Ink composition and printed article

InactiveUS20120156451A1Low transparencyDecrease in glossinessLayered productsDuplicating/marking methodsWaxTransmittance

The ink composition contains a glitter pigment and wax. In the case where an aqueous solution containing the wax of 0.1 weight % is prepared, the wax serves to satisfy the following relationship: a transmittance of at least 50% and less than 100% with respect to light having a wavelength of 450 nm; a transmittance of at least 60% and less than 100% with respect to light having a wavelength of 550 nm; a transmittance of at least 70% and less than 100% with respect to light having a wavelength of 650 nm; or a transmittance of at least 70% and less than 100% with respect to light having a wavelength of 750 nm.

Owner:SEIKO EPSON CORP

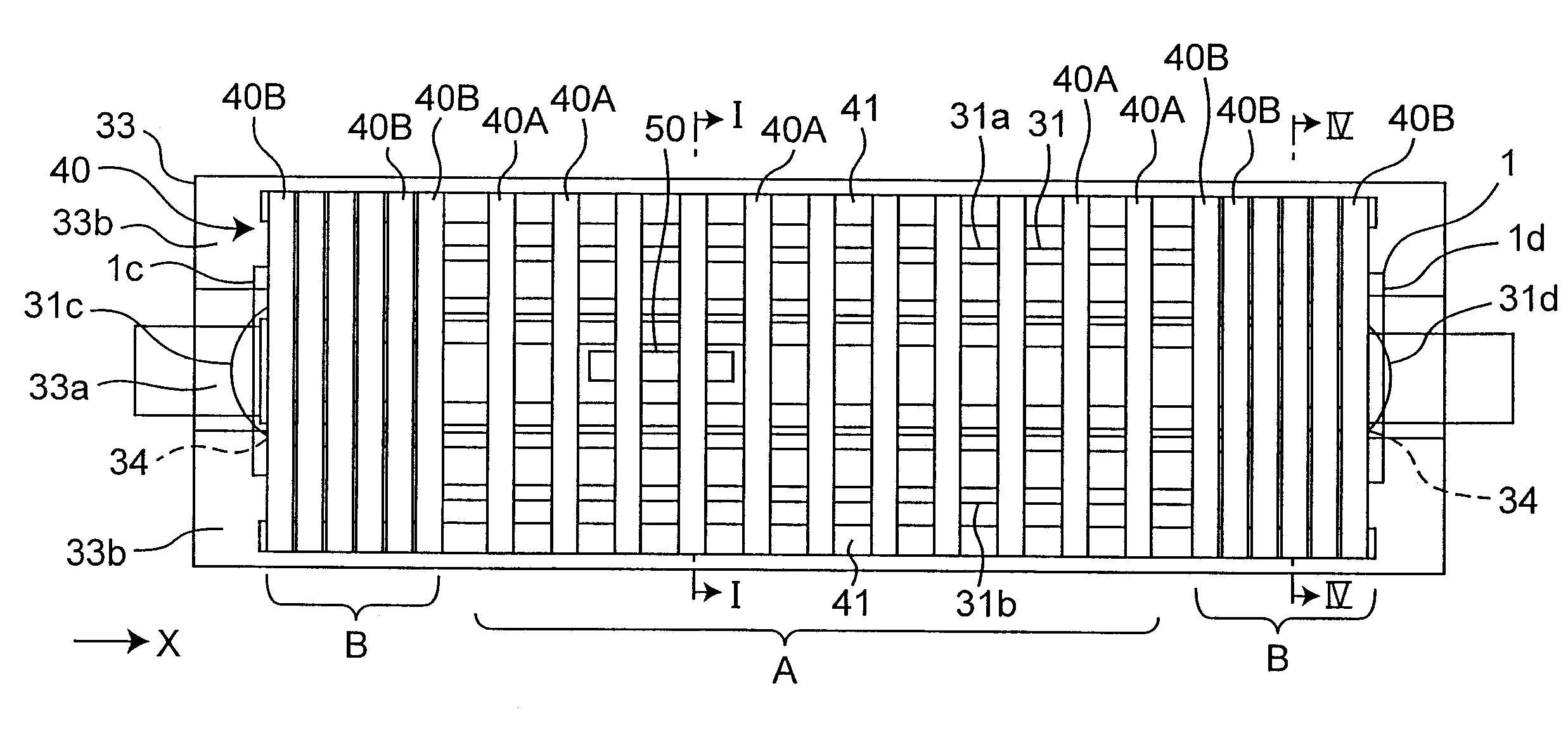

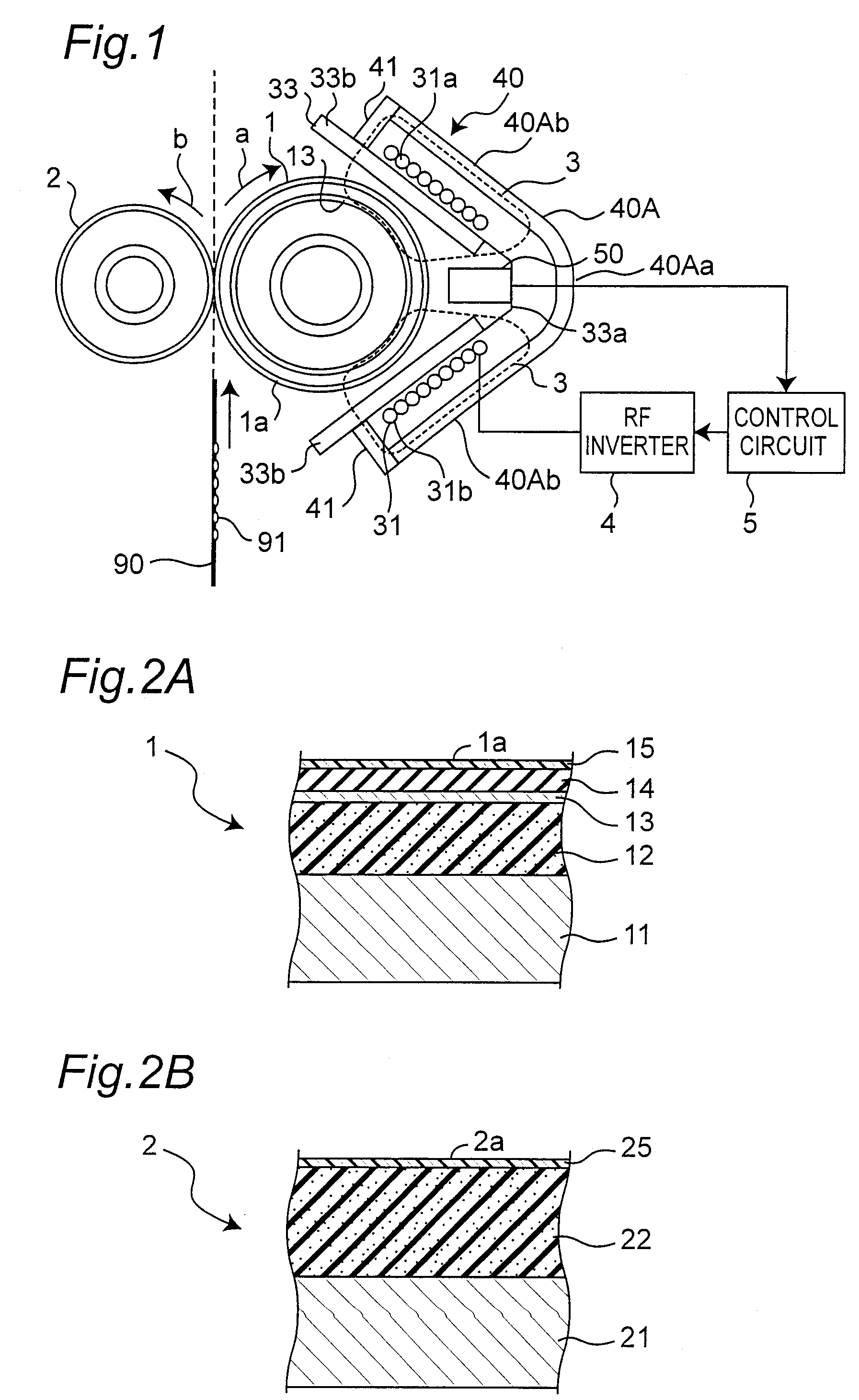

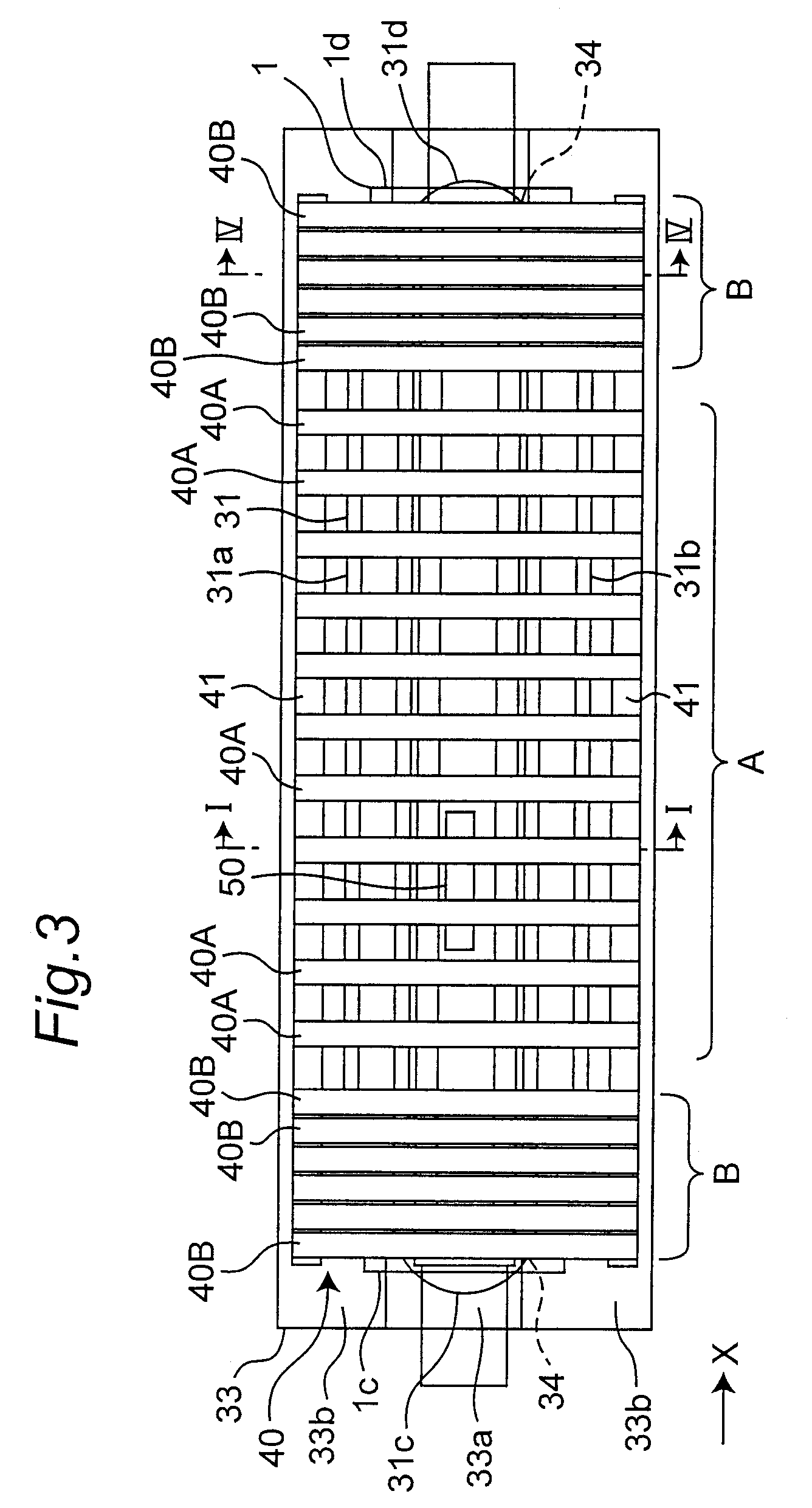

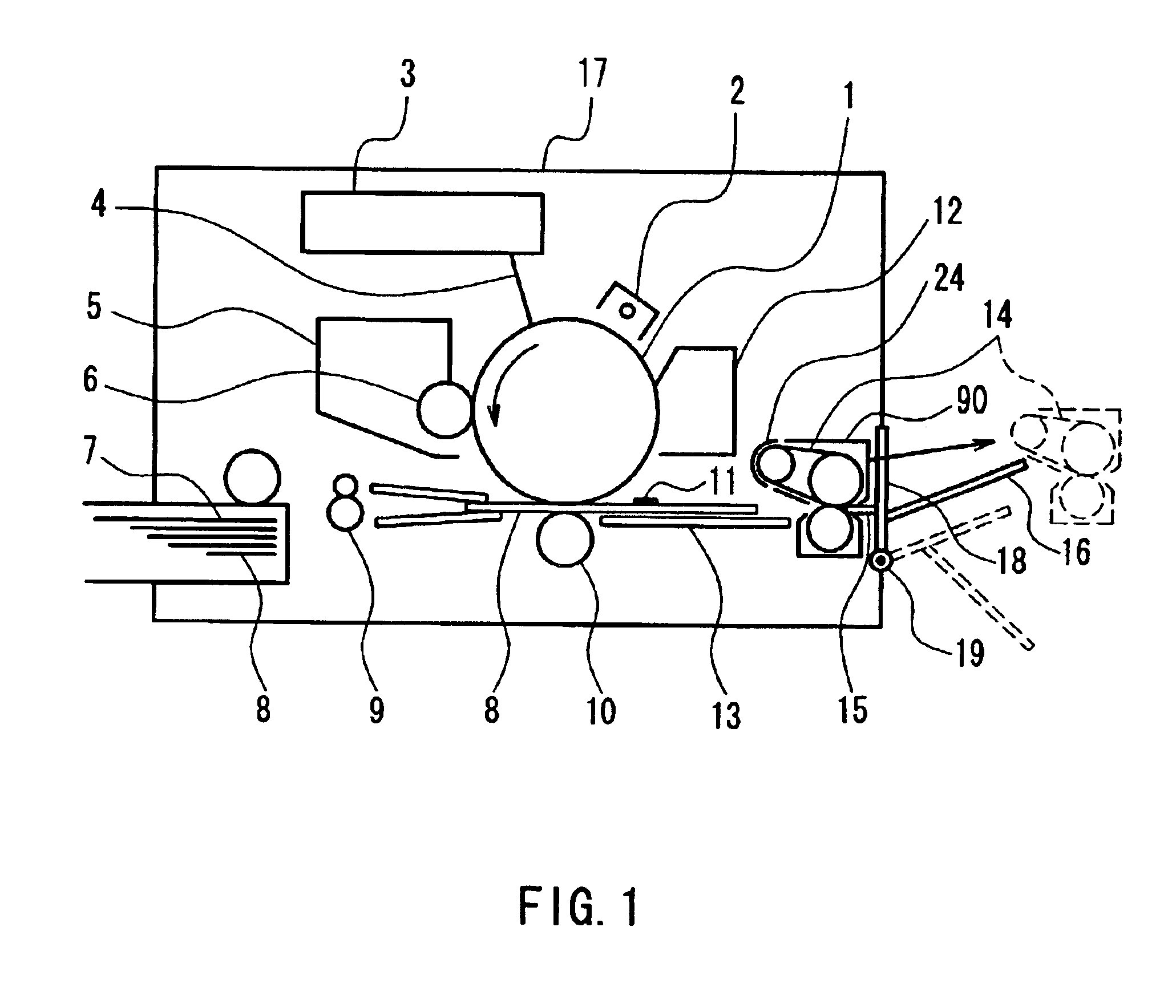

Fixing device

InactiveUS7756459B2Decrease in glossinessAccelerate the temperature dropElectrographic process apparatusEngineeringMechanical engineering

Owner:KONICA MINOLTA BUSINESS TECH INC

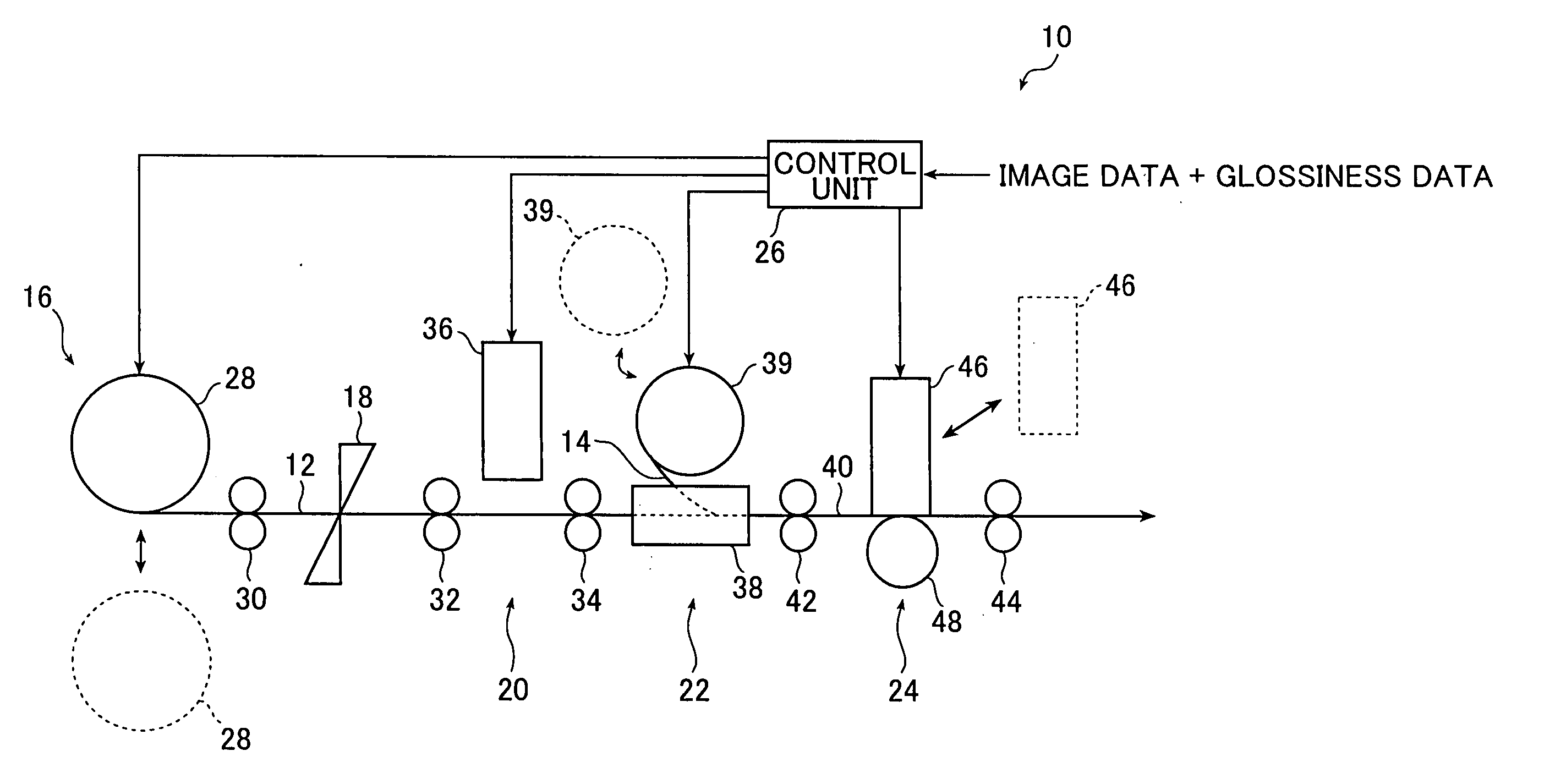

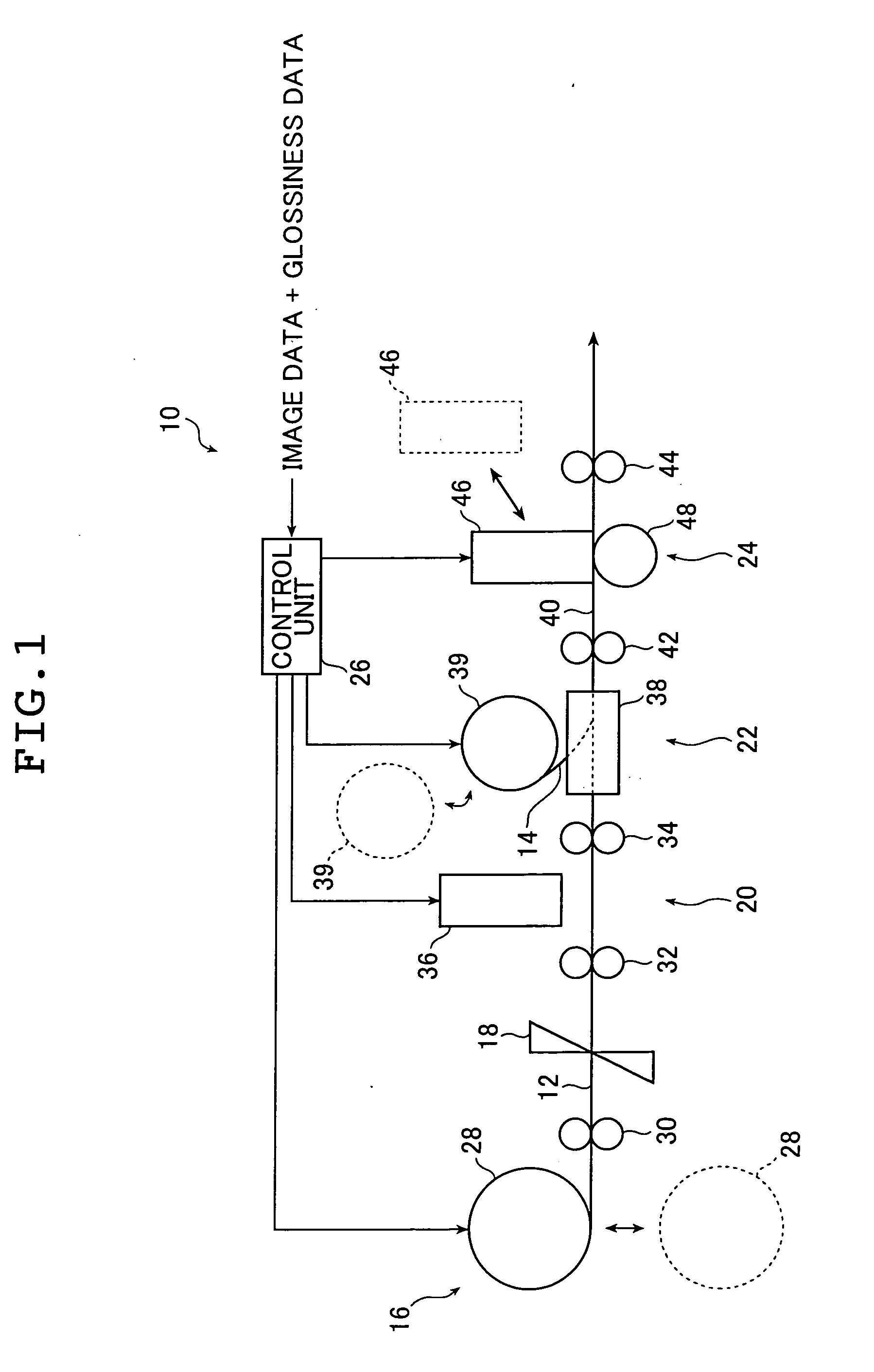

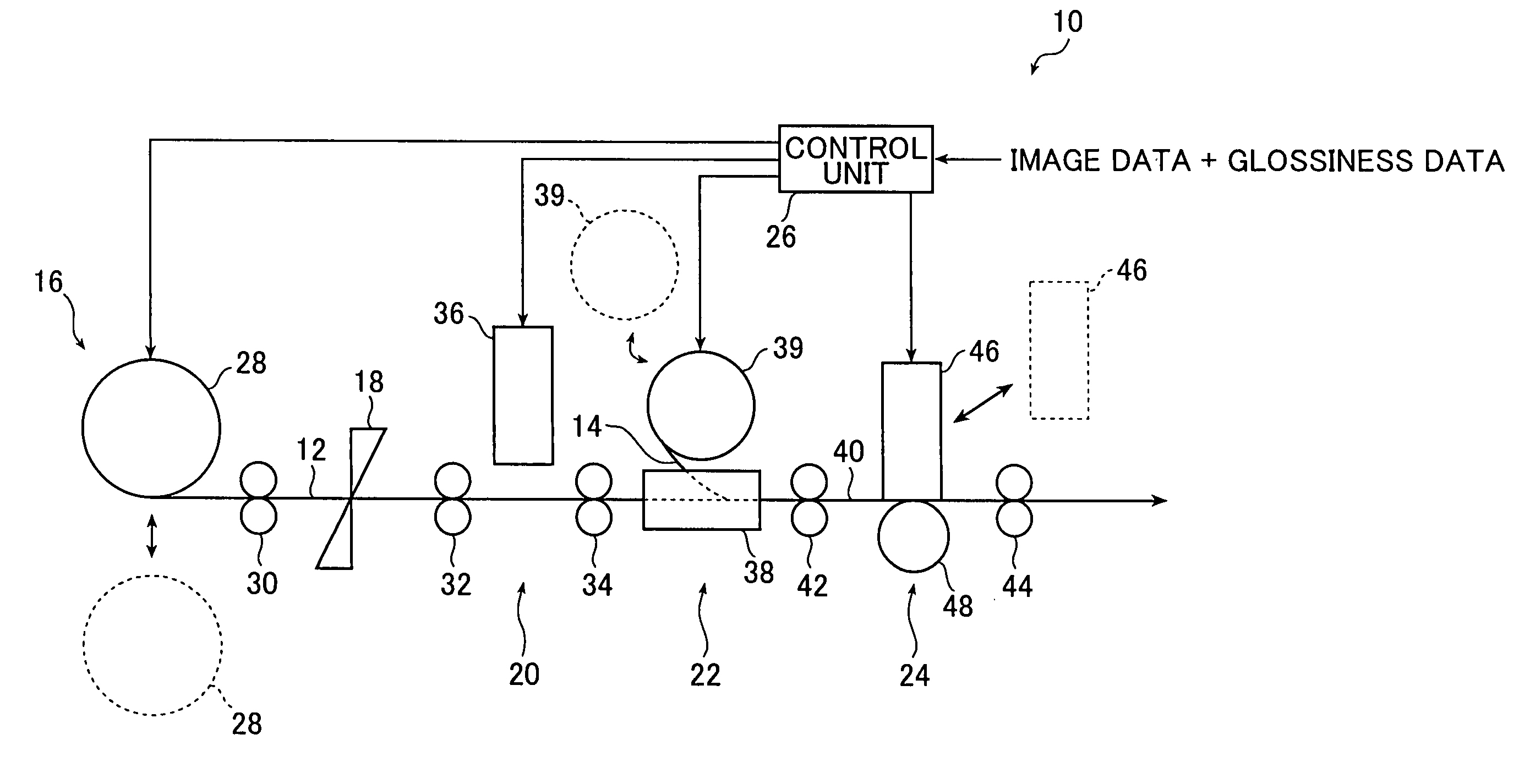

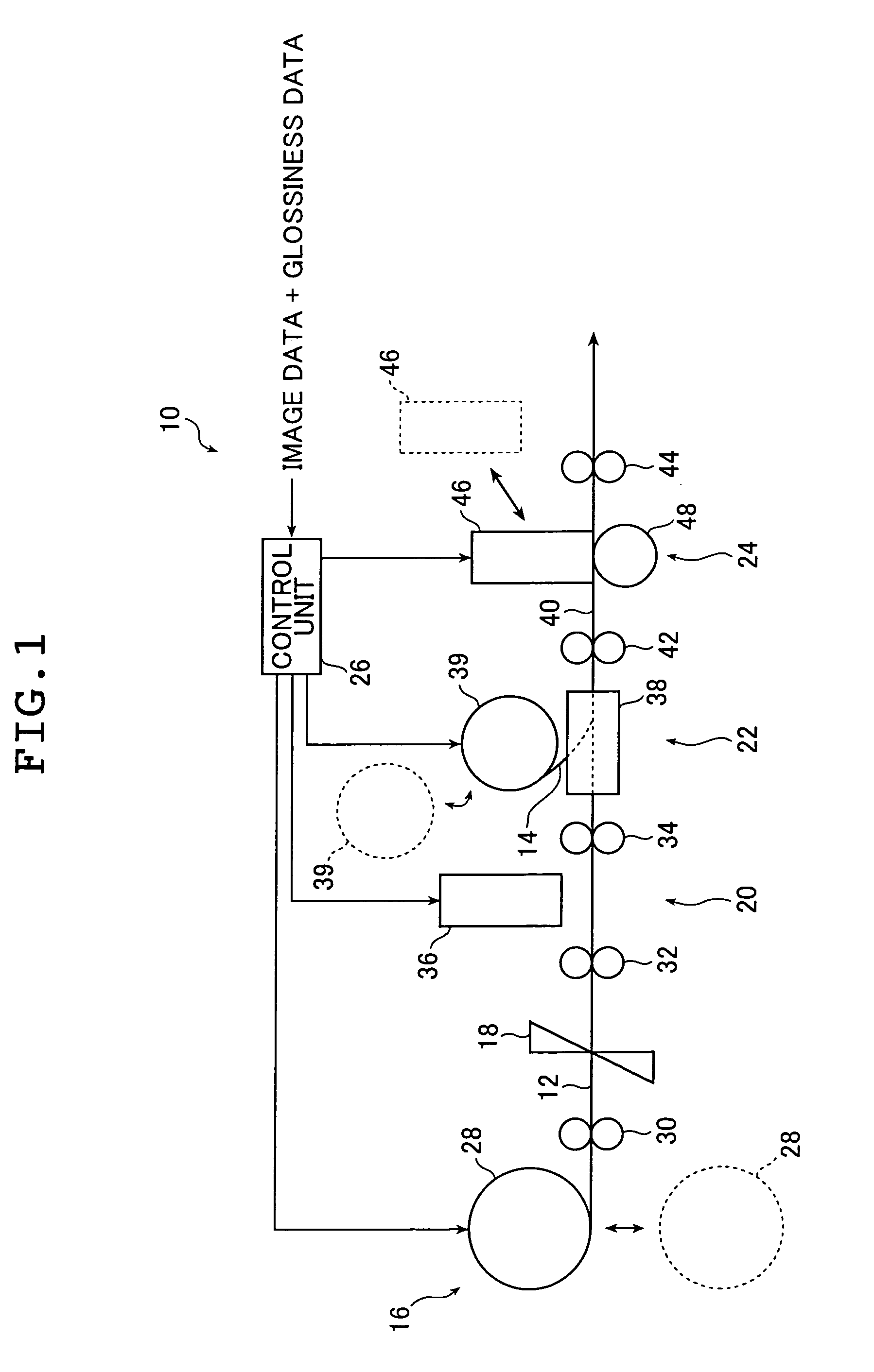

Image forming method and image forming apparatus

InactiveUS20050058955A1Reduces in glossinessImprove viewabilityRecording apparatusX-ray/infra-red processesImage recordingSurface processing

The image forming method includes a recording step of recording an image on an image recording layer of an image recording medium according to image data, a material setting step of setting a coating film to be provided on the image recording layer according to glossiness data indicating glossiness of the image reproduced by the image data, a condition setting step of determining a condition of a surface processing of the coating film by considering the set coating film and according to the glossiness data, and a processing step of performing the surface processing of the coating film in accordance with the determined surface processing condition.

Owner:FUJIFILM HLDG CORP

Flaky fine powder, production thereof, and cosmetic

InactiveUS6923974B2Decrease in glossinessImprove slipperinessCosmetic preparationsBiocideSilica particleSilicic acid

Owner:JGC CATALYSTS & CHEM LTD

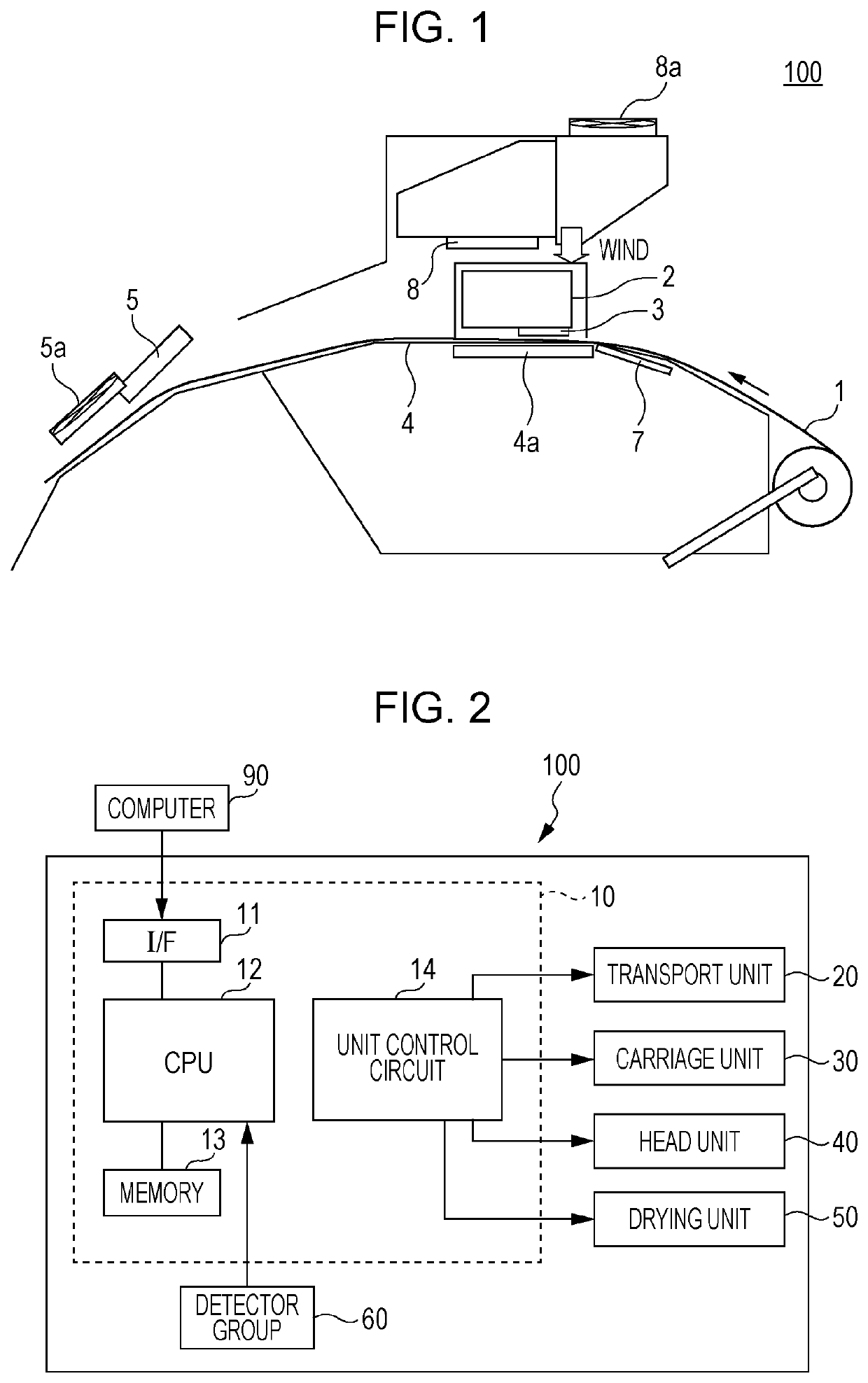

Image post-processing method, image post-processing apparatus and image forming apparatus

ActiveUS20190187606A1No influence fixabilityGlossiness can be adjustedElectrographic process apparatusTemperature controlImage post processing

There is disclosed an image post-processing method for adjusting glossiness of a fixed toner image. The method includes a glossiness control step and a temperature control step. The glossiness control step is a step of, to a toner image formed of a toner containing a light absorbing compound and fixed to a recording medium, emitting glossiness control light so as to reduce or increase glossiness of the toner image. The temperature control step is a step of heating the toner image immediately before the light is emitted to the toner image such that the toner image has a surface temperature which is at least 20° C. lower than a softening temperature of the toner. The glossiness control light has a maximum emission wavelength in a wavelength range in which the compound absorbs light and is made to at least reduce the glossiness of the toner image.

Owner:KONICA MINOLTA INC

Reduced-moisture-content-solvent ink composition and method for producing the same

ActiveUS8192538B2Decrease in glossinessLow pigment contentPigmenting treatmentInksOrganic solventWater vapor

A method for producing a reduced-moisture-content-solvent ink composition includes reducing the moisture content of a pigment dispersion containing a metal pigment and a dispersion medium or an ink composition containing the pigment dispersion and an organic solvent by bubbling treatment using an inert gas having a water vapor content of 2.0 mg / L or less.

Owner:SEIKO EPSON CORP

Ink composition

InactiveUS20110172342A1Excellent in metallic gloss and discharge stabilityMaintain viscosityDuplicating/marking methodsInksOrganic solventPoly(methyl methacrylate)

Provided is an ink composition including a metallic pigment, a metallic-pigment-fixing resin component containing poly(methyl methacrylate), and an organic solvent, but not including poly(isobutyl methacrylate).

Owner:SEIKO EPSON CORP

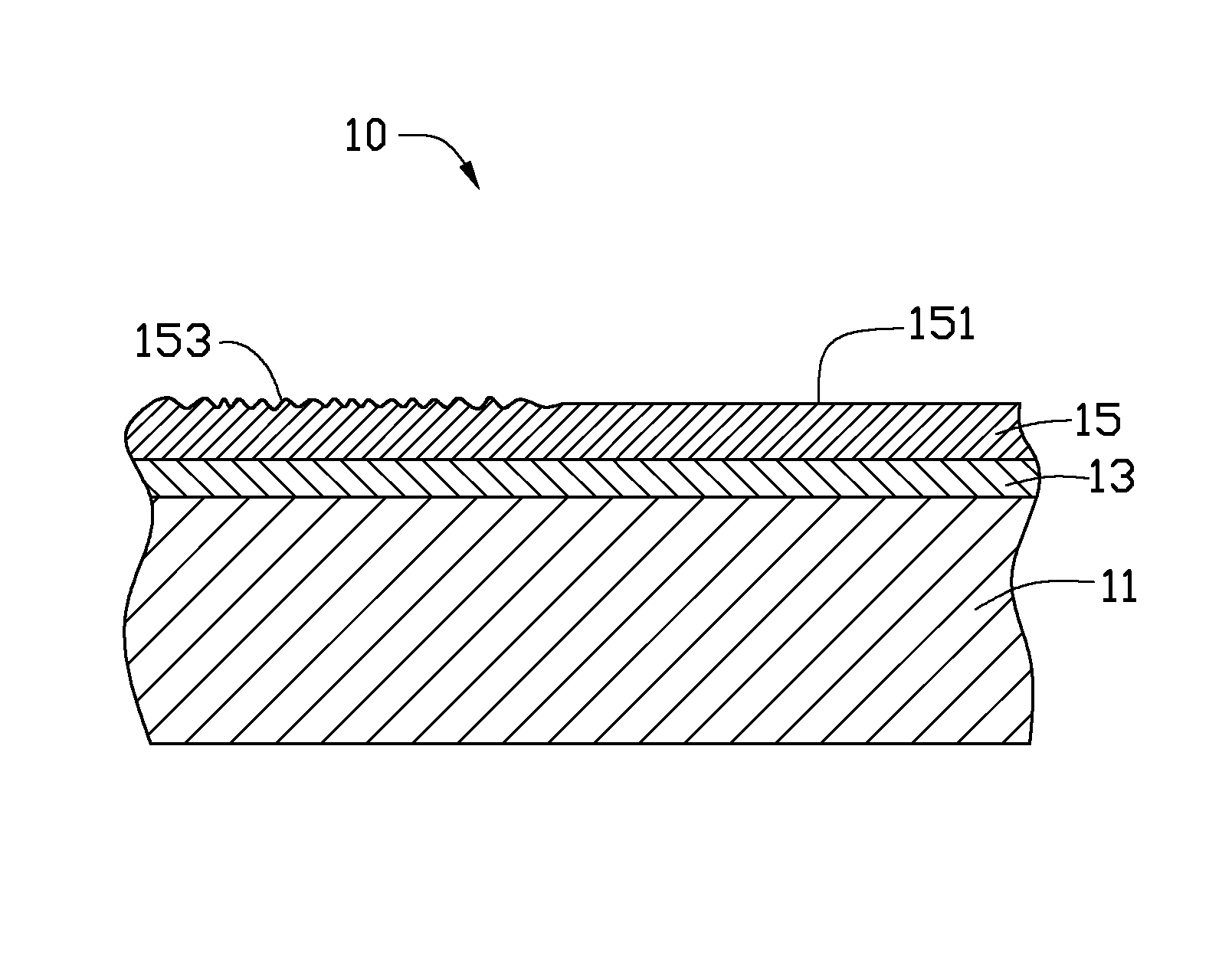

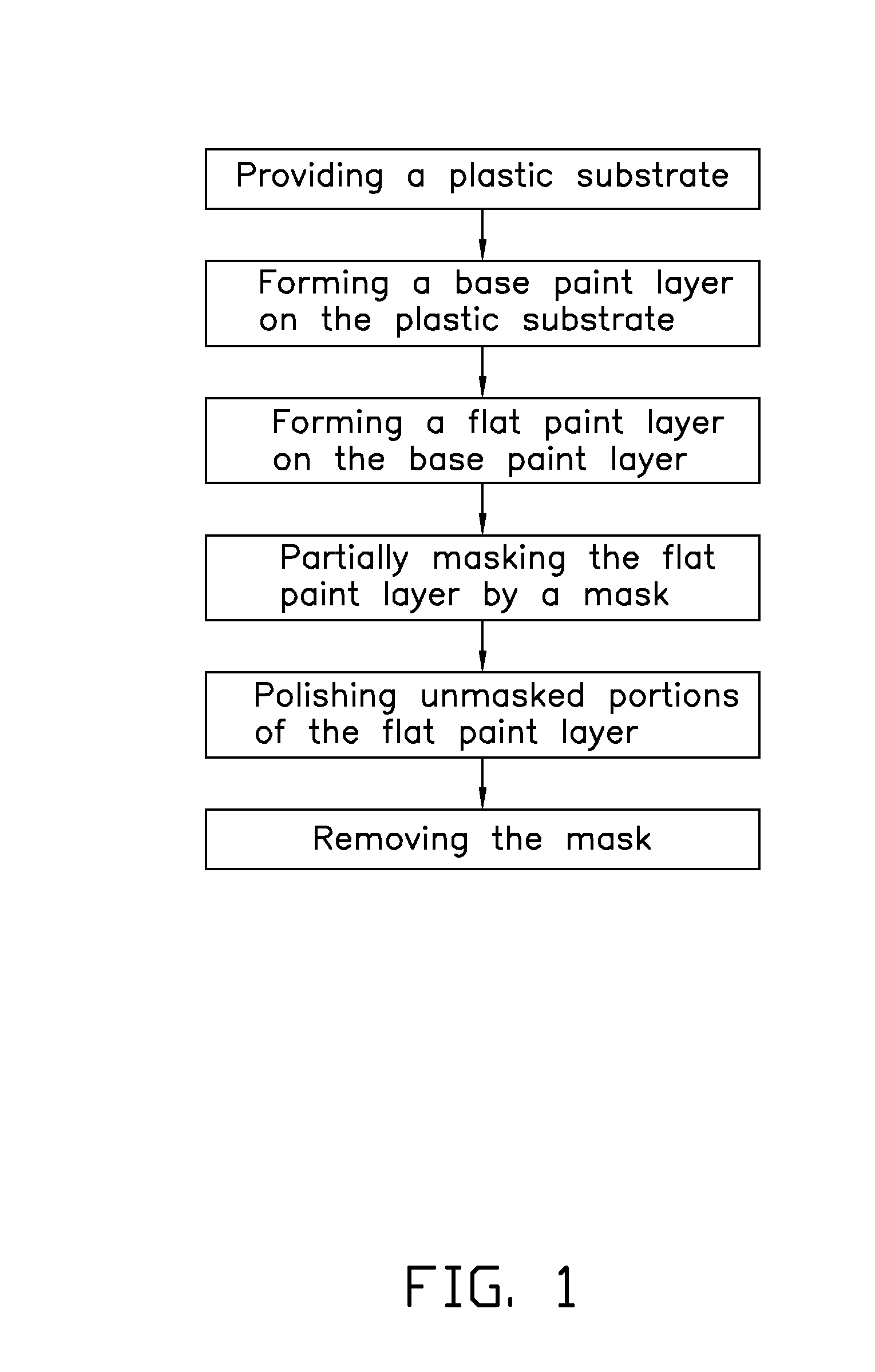

Method for surface treating plastic products and plastic products made thereby

InactiveUS20130288028A1Decrease in glossinessEasy to attractSynthetic resin layered productsPretreated surfacesPresent methodEngineering

A method for surface treating plastic products includes providing a plastic substrate; forming a base paint layer on the plastic substrate; forming a flat paint layer on the base paint layer, the flat paint layer made of a flat paint and having an initial specular gloss at 60° geometry of about 5-10; partially masking the flat paint layer; and polishing unmasked portions of the flat paint layer to achieve a specular gloss at 60° geometry of about 80-90. A plastic product made by the present method is also described.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

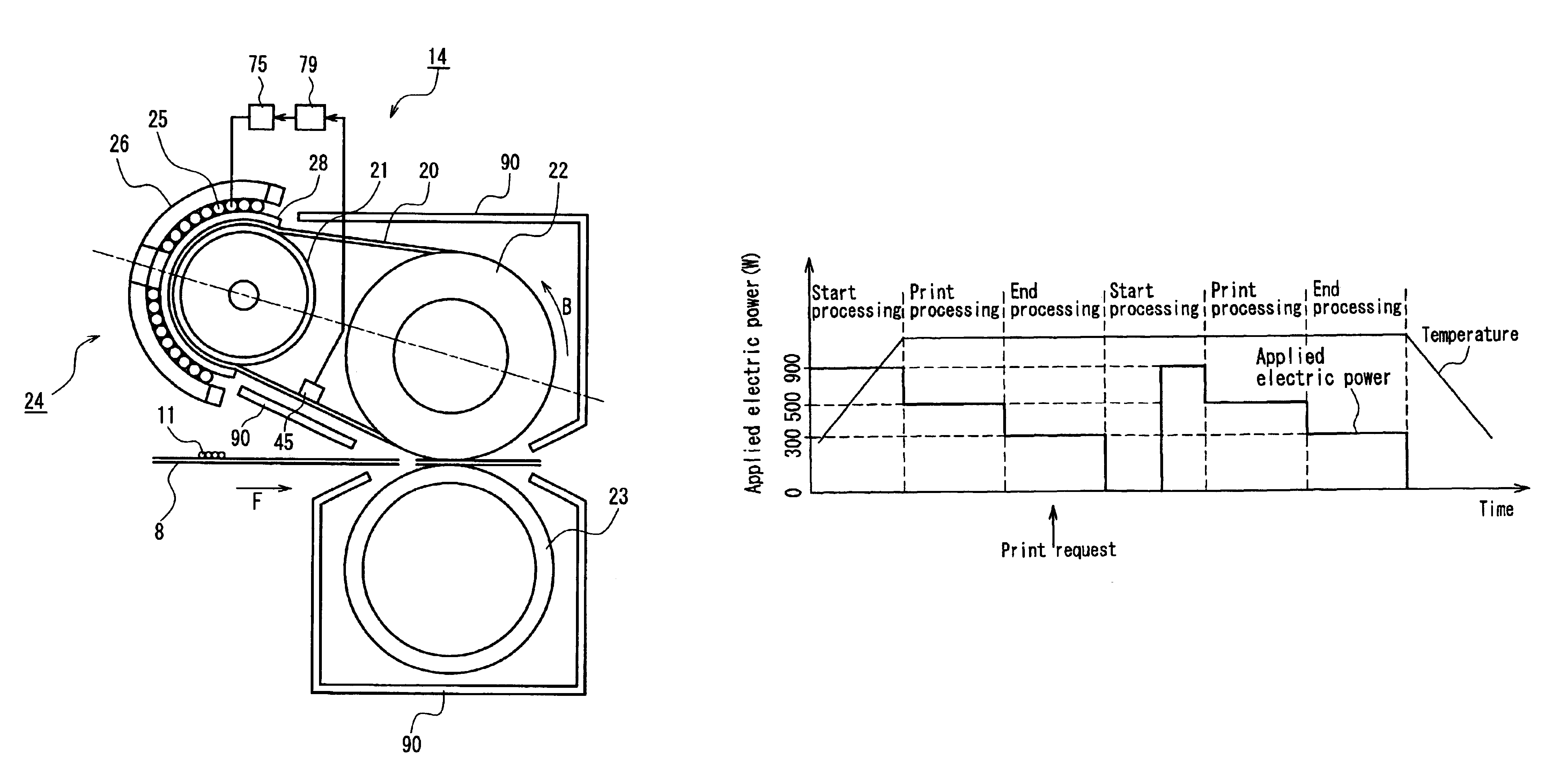

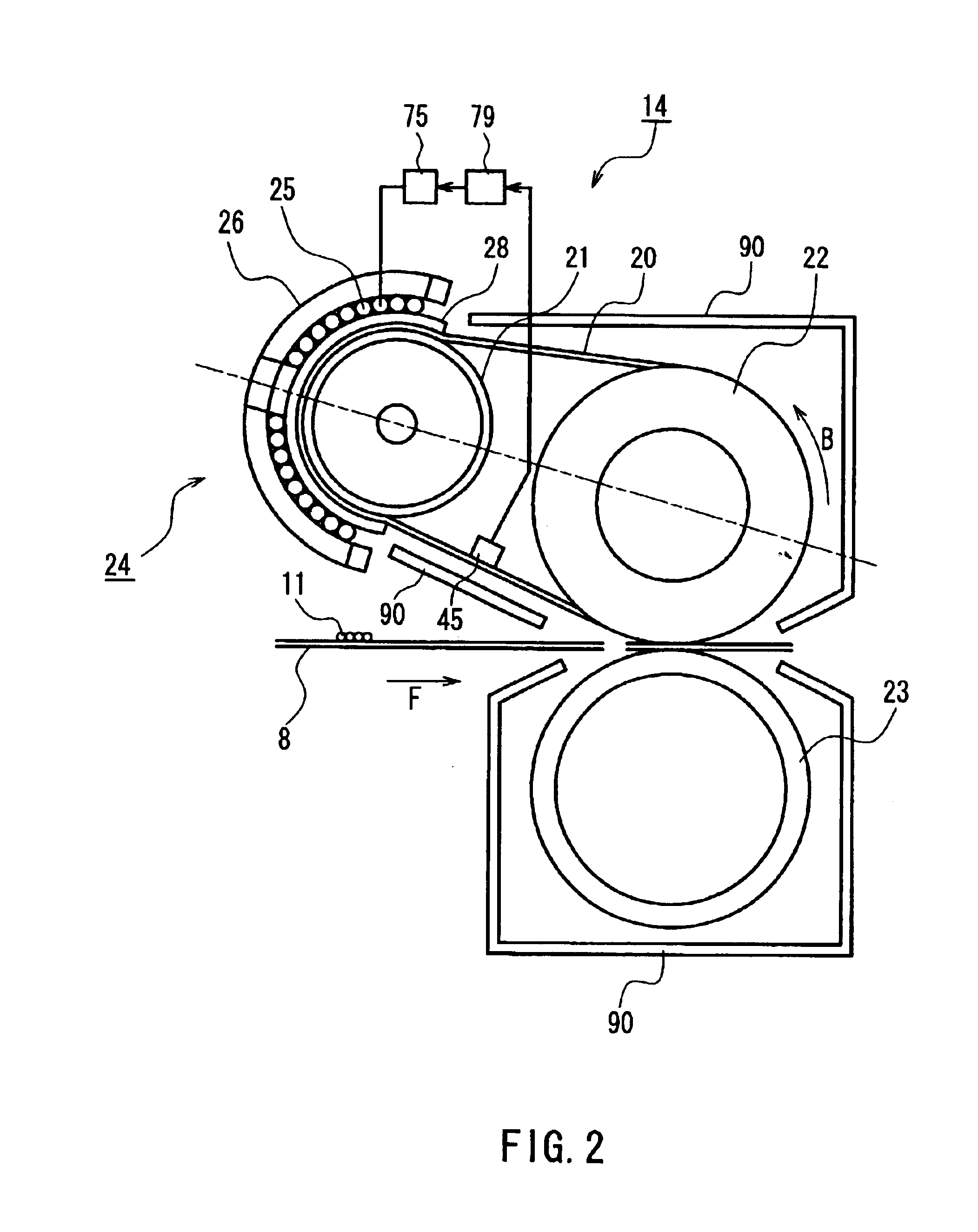

Image heating device, image forming apparatus, image copying machine, and method for controlling temperature

InactiveUS6934483B2Decrease in glossinessIncrease temperatureElectrographic process apparatusTemperature controlImage formation

A fixing device as an image heating device is provided, by which a difference in glossiness is not caused in a recording medium in the axial direction of a pressure roller. When a print request is issued during the end-processing sequence, an electric power applied to a magnetization coil via an exciting circuit is dropped to 0 by controlling means during the start-processing sequence, and after an appropriate interval, the heating with full power is restarted by the controlling means. By so doing, the decrease in temperature at both ends of a fixing belt and a heat-generating roller in the axial direction can be compensated.

Owner:PANASONIC CORP

Inkjet recording method and apparatus

ActiveUS8162423B2Reduce the overall diameterAvoid it happening againDuplicating/marking methodsOther printing apparatusCoated surfaceEngineering

Owner:FUJIFILM CORP

Image processing method and image processing apparatus

ActiveUS8511790B2Decrease in glossinessImproving the black OD and the gamutOther printing apparatusPictoral communicationData transformationComputer science

An image processing method includes a conversion step of converting input image data into ink color data corresponding to respective use amounts of one or more types of color inks and a clear ink. In the conversion step, the input image data is converted into ink color data so that the use amount of the clear ink used in ink color data using a black carbon-containing ink becomes equal to or larger than that of the clear ink used in ink color data using no black carbon-containing ink.

Owner:CANON KK

Image post-processing method and apparatus for emitting a glossiness control light, and image forming apparatus

ActiveUS10705474B2Glossiness can be adjustedNo influence fixabilityElectrographic process apparatusImage formationEngineering

There is disclosed an image post-processing method for adjusting glossiness of a fixed toner image. The method includes a glossiness control step and a temperature control step. The glossiness control step is a step of, to a toner image formed of a toner containing a light absorbing compound and fixed to a recording medium, emitting glossiness control light so as to reduce or increase glossiness of the toner image. The temperature control step is a step of heating the toner image immediately before the light is emitted to the toner image such that the toner image has a surface temperature which is at least 20° C. lower than a softening temperature of the toner. The glossiness control light has a maximum emission wavelength in a wavelength range in which the compound absorbs light and is made to at least reduce the glossiness of the toner image.

Owner:KONICA MINOLTA INC

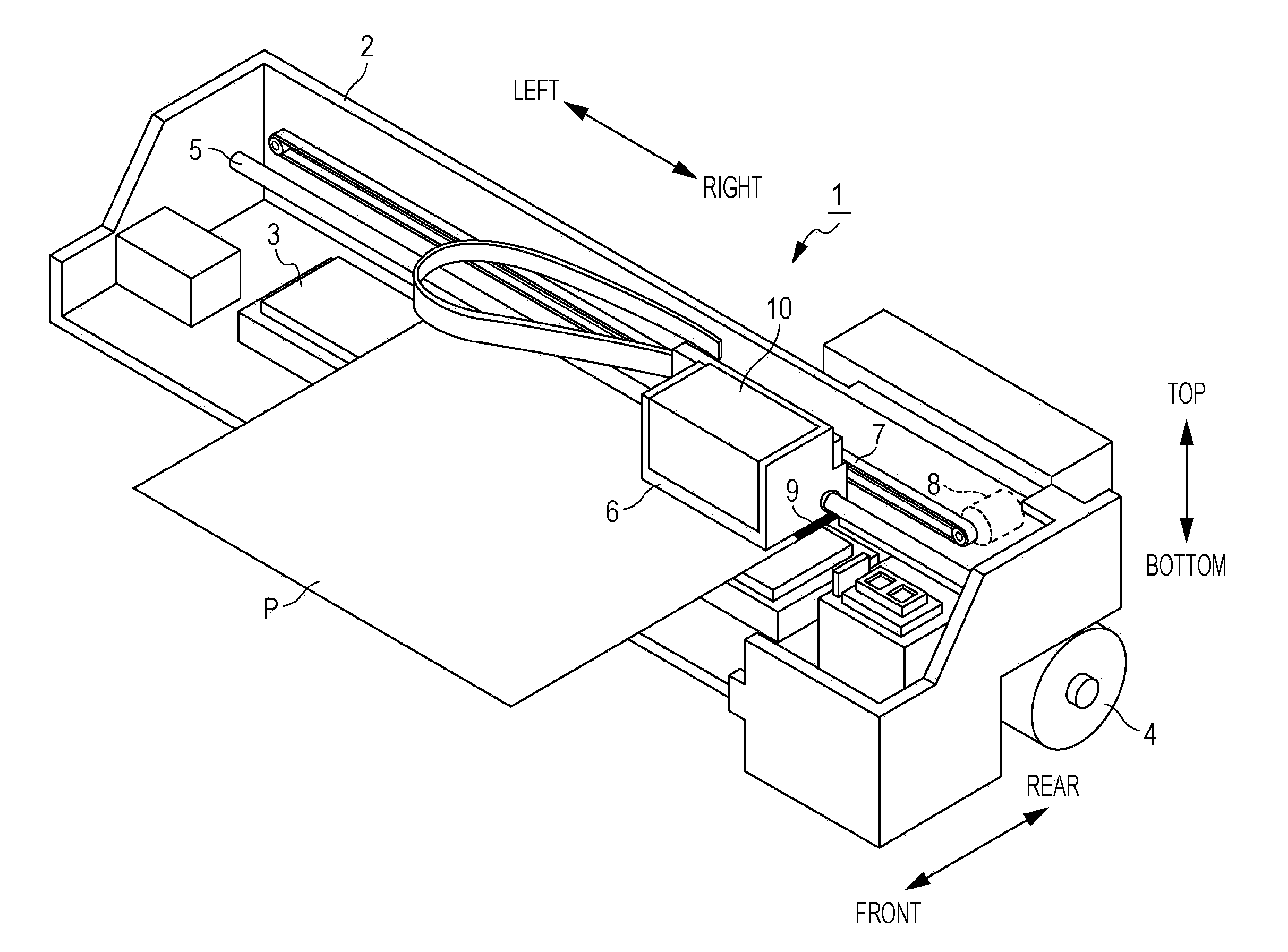

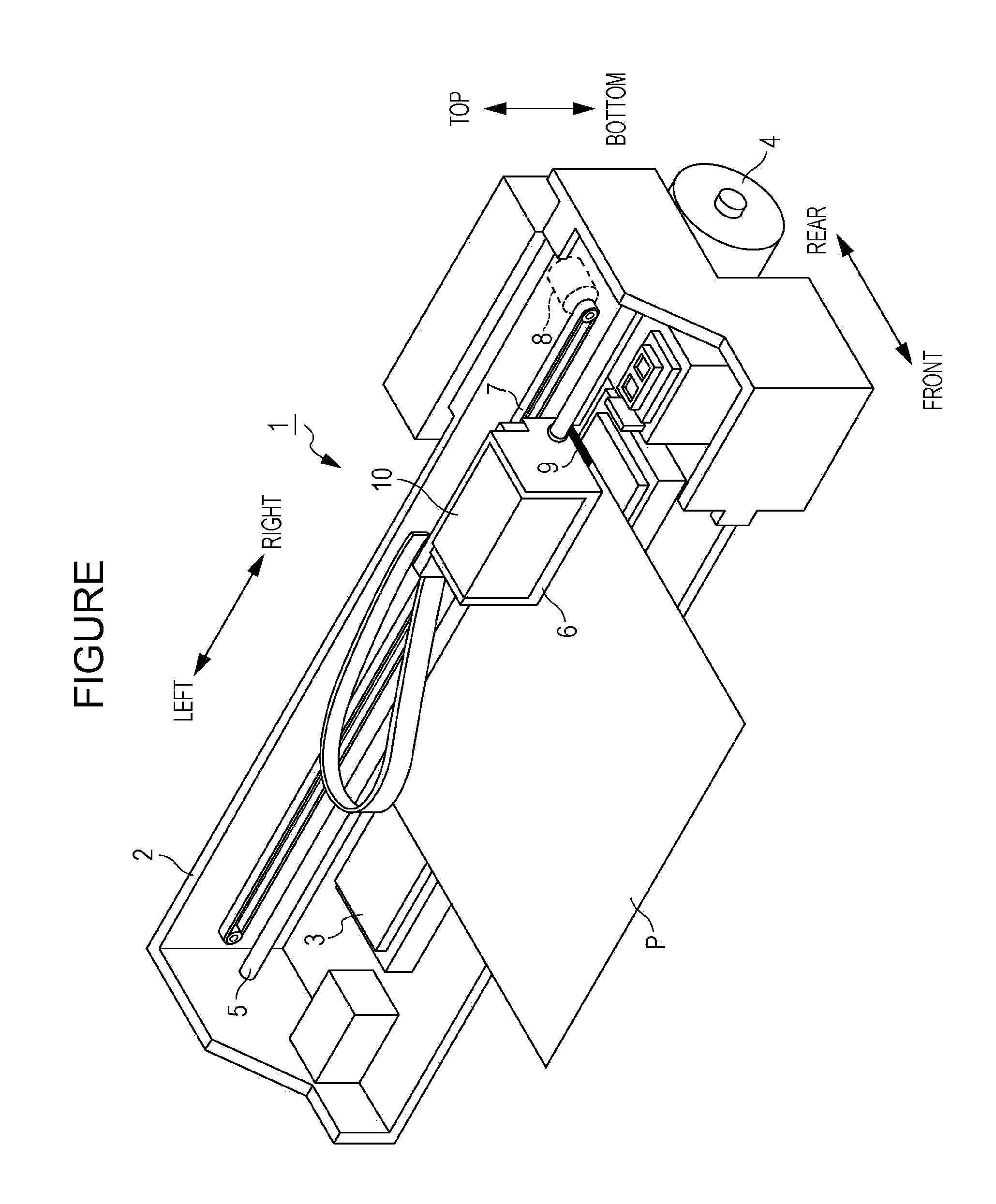

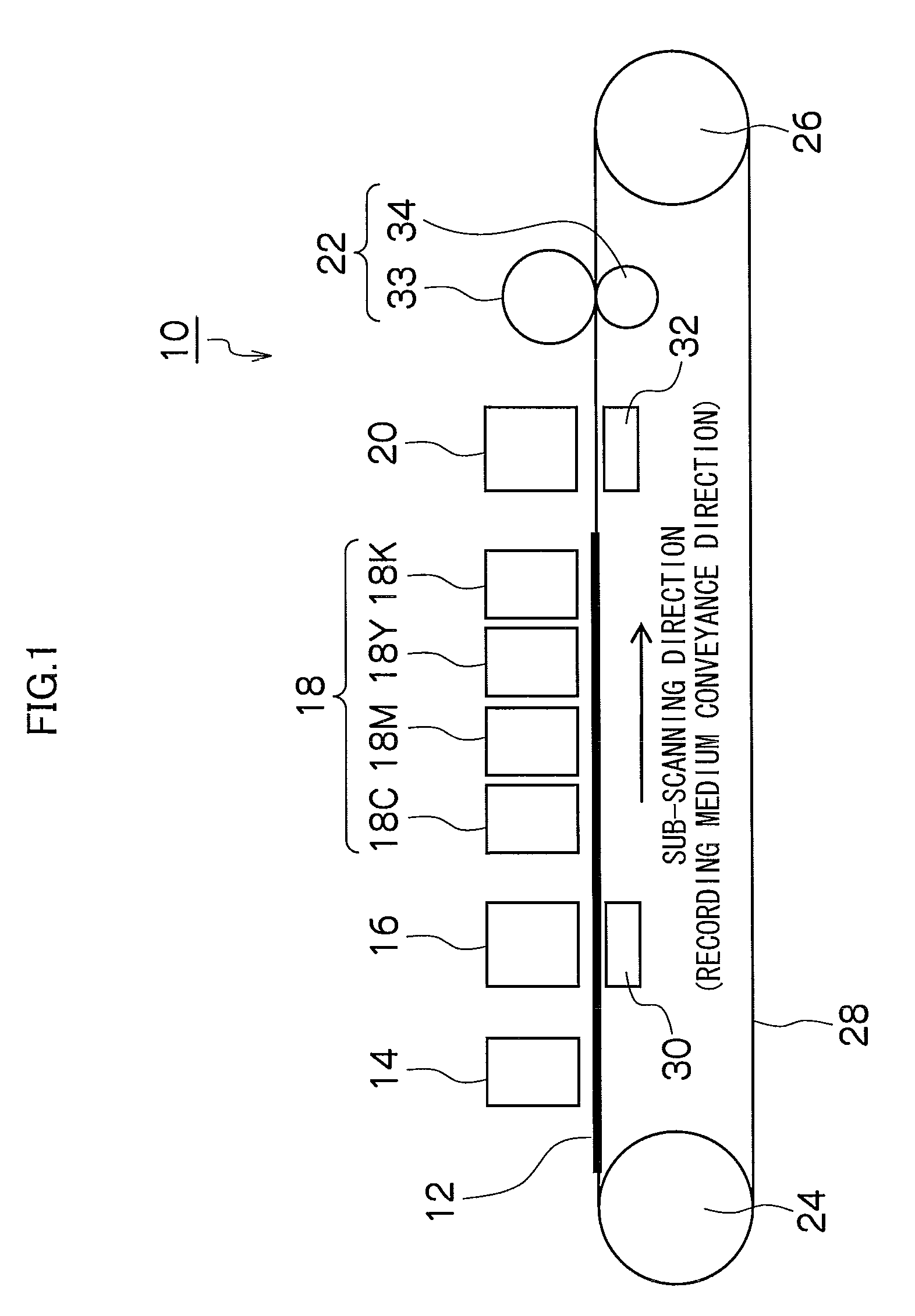

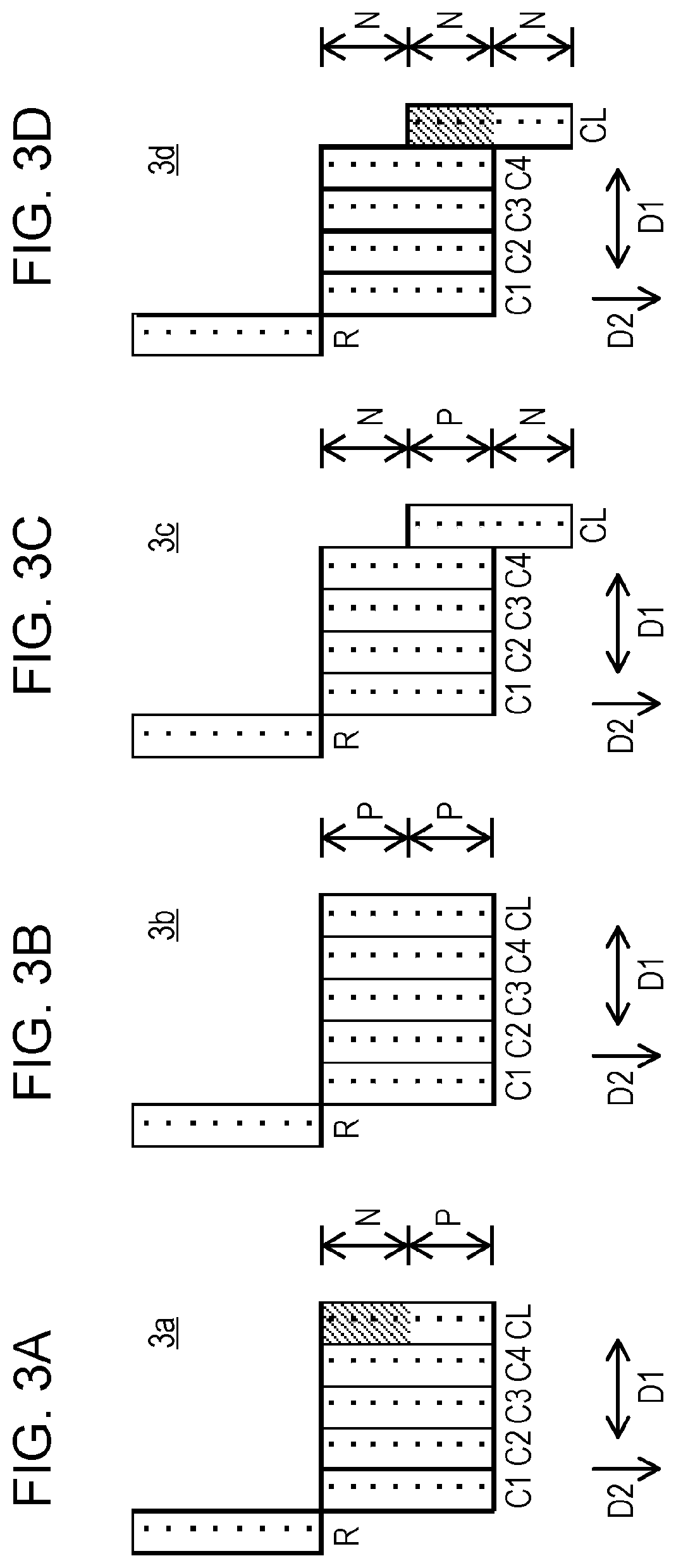

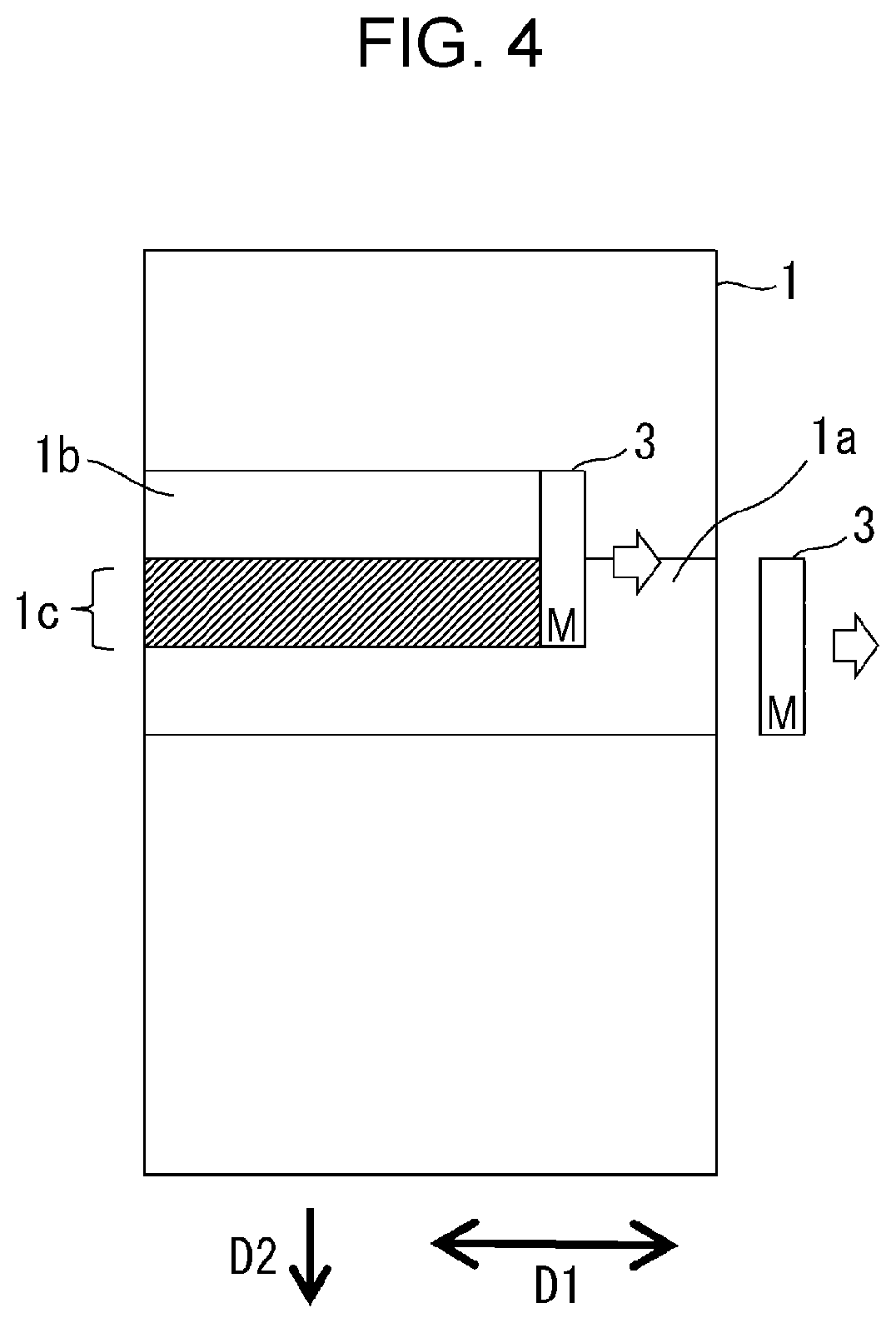

Ink jet recording method and recording apparatus

ActiveUS11059988B2Decrease in glossinessDuplicating/marking methodsInksEngineeringMechanical engineering

An ink jet recording method is provided for a low or non-absorbable recording medium using a solution containing a colored ink, a clear ink, and an aggregating agent for aggregating constituents in the colored ink. The method includes: causing the solution containing the aggregating agent to adhere to the recording medium; and a main scanning in which the colored and the clear inks are ejected while relative positions of an ink jet head and the recording medium are changed to a main scanning direction, and a sub-scanning in which the relative positions of the ink jet head and the recording medium are changed to a sub-scanning direction. The main scanning involves a region where a recording region in which the colored ink is ejected in the main scanning and a recording region in which the clear ink is ejected in the main scanning overlap one another.

Owner:SEIKO EPSON CORP

Transparent developer, developer housing, development device, and image formation apparatus

ActiveUS9213252B2Reduce thicknessChanges the color tone of a printElectrographic process apparatusDevelopersImage formationGlass transition point

A transparent developer has a glass transition point of 63.0° C. to 66.0° C., both inclusive, and a melt temperature, indicative of a softening point by a 1 / 2 method, of 94.3° C. to 97.0° C., both inclusive.

Owner:OKI ELECTRIC IND CO LTD

Image forming method and image forming apparatus

InactiveUS7044594B2Decrease in glossinessEnhance the imageRecording apparatusX-ray/infra-red processesImage recordingImage formation

Owner:FUJIFILM HLDG CORP

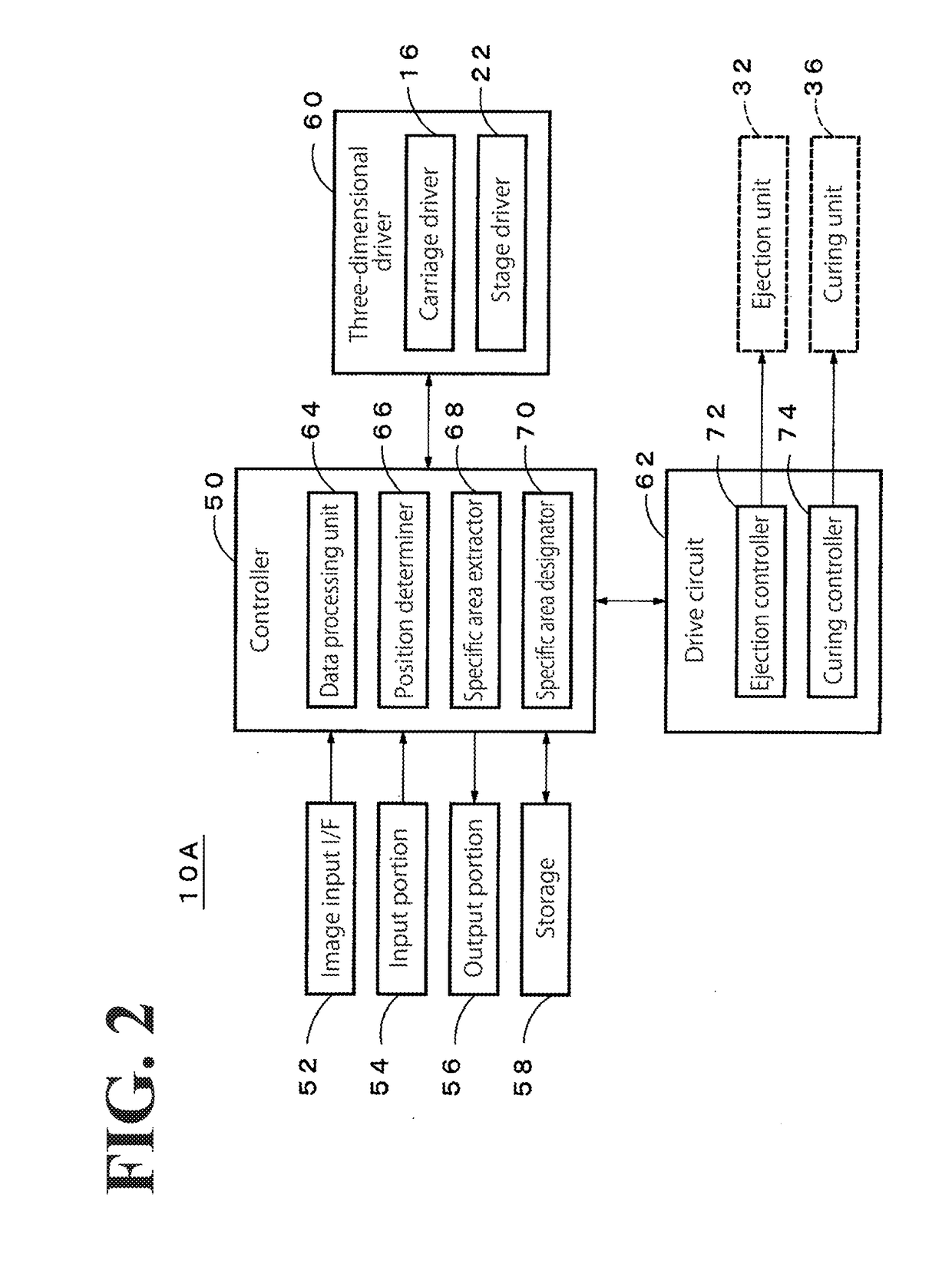

Three-dimensional object forming apparatus, three-dimensional object forming method, formation intermediate product, and three-dimensional object

InactiveUS20180200951A1Good quality finishDifference in surface roughnessManufacturing driving means3D object support structuresEngineeringMechanical engineering

A three-dimensional-object forming apparatus generates a three-dimensional object such that from a formation intermediate product obtained by sequentially depositing unit layers each including a build material and / or a support material on a work surface, a support made of the support material is removed. The three-dimensional-object forming apparatus includes a position determiner and a roughener. The position determiner determines a position of the build material and a position of the support material to make a partial surface contact between the three-dimensional object and the support. The roughener roughens a specific area defined by an outer surface among outer surfaces of the build material located at the position determined by the position determiner. The outer surface is parallel with the work surface.

Owner:MIMAKI ENG

Weather-resistant hard coat composition for metal, cured product, and coated metal substrate

PendingUS20220017777A1Excels in hardnessExcels in resistanceSynthetic resin layered productsPretreated surfacesPolymer scienceWeather resistance

The purpose of the present invention is to provide a weather-resistant hard coat composition for a metal, the composition being capable of efficiently forming a coating film excelling in weather resistance, scratch resistance, and flexibility. The present invention provides: a weather-resistant hard coat composition for a metal, the composition containing a polyorganosilsesquioxane having a constituent unit represented by Formula (1); a cured product thereof; and a coated metal substrate having a metal substrate and a coating film formed on at least one surface of the metal substrate. The coating film is a layer of a cured product of the weather-resistant hard coat composition for a metal. [In Formula (1), R1 represents a group containing an active energy ray-curable functional group.][R1SiO3 / 2] (1)

Owner:DAICEL CHEM IND LTD

Polyester film and method of manufacturing polyester film

ActiveUS10850547B2Good glossinessHigh whitenessDuplicating/marking methodsSynthetic resin layered productsPolyesterPolymer science

Provided are a polyester film and a method of manufacturing the polyester film. A polyester film has a base film and at least one image receiving layer which is disposed on at least one surface of the base film, the base film contains a polyester and titanium oxide particles, the mass-based content of the titanium oxide particles in the base film satisfies Formula 1 on the assumption that the thickness of the base film is T μm, a surface roughness standard deviation Rq is 0.01 μm to 0.12 μm, a cross section in a thickness direction orthogonal to a plane direction of the base film has voids whose average area per void is 0.01 μm2 / void to 0.10 μm2 / void, and a surface roughness standard deviation Rq of an outermost surface of the image receiving layer is 0.01 μm to 0.1 μm.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com