Variable resistance conductive polymer/polyelectrolyte solid composite or mixed film and its preparing method

A technology of conductive polymers and polyelectrolytes, applied in the direction of non-aqueous electrolyte batteries, electrode manufacturing, battery electrodes, etc., can solve the problems of limitations, slow diffusion of doped ions, etc., and achieve improved charging and discharging speed, large contact area, and wide application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1. Preparation of a rapidly adjustable conductive polymer / polyelectrolyte solid composite membrane with sulfonated polyaniline as the conductive polymer

[0040] 7.2ml of aniline (An) monomer was dissolved in 150ml of 3M hydrochloric acid (HCl), and 4g of ammonium persulfate (APS) was dissolved in 40ml of 3M HCl. The two solutions were combined while stirring. After reacting for 3 h, the PAn precipitate was separated by filtration, washed with distilled water, and vacuum-dried at room temperature. Take 2g of PAn product and disperse it in 60ml of 1,2-dichloroethane (DCE), add 4.8g of chlorosulfonic acid and heat to 90°C while stirring. After reacting for 5 h, the precipitate was separated by filtration, washed with DCE and vacuum-dried at room temperature. The product was dispersed in 80ml of distilled water and heated to reflux for 4h to obtain an aqueous solution of sulfonated PAn. Under stirring conditions at 80°C, 4g polyvinylidene fluoride (PVDF), 3g pol...

Embodiment 2

[0042] Example 2. Preparation of a rapidly adjustable conductive polymer / polyelectrolyte solid composite membrane with PAn nanofibers as conductive polymers

[0043] 3ml of aniline (An) monomer was dissolved in 100ml of 3M hydrochloric acid (HCl), and 1.8g of ammonium persulfate (APS) was dissolved in 80ml of 3M HCl. Under stirring, the two solutions were combined. After reacting for 3 h, the PAn precipitate was separated and washed with distilled water, and finally the PAn was dispersed in distilled water, thereby diluting to obtain a PAn nanofiber suspension with a solid content of 3 mg / ml. Transmission electron microscope observation showed that the microstructure of the PAn product was nanofibers with a diameter of about 30nm. Under stirring conditions at 90°C, 6g of polyvinylidene fluoride (PVDF), 5g of polycarbonate (PC), 2.5g of lithium perchlorate (LiClO 4 ) was dissolved in 250 ml of ethyl acetate (EA), thereby obtaining a PE solution.

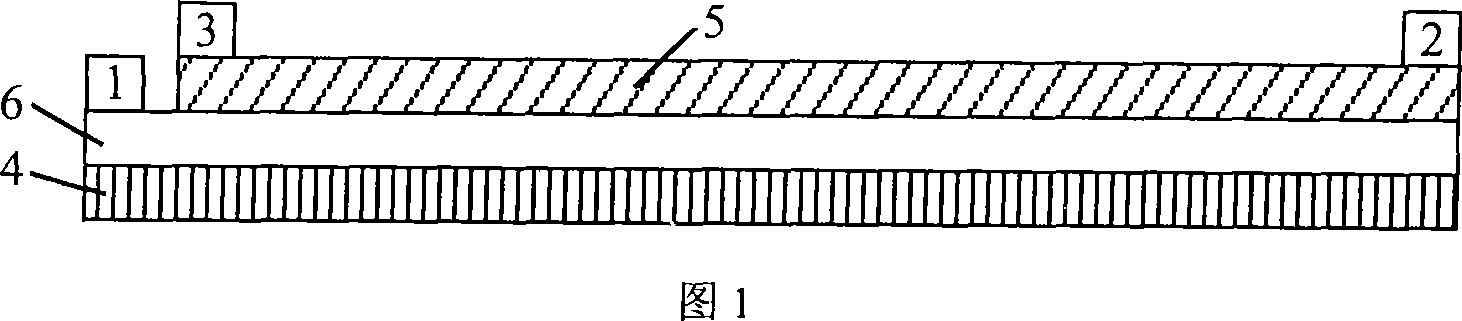

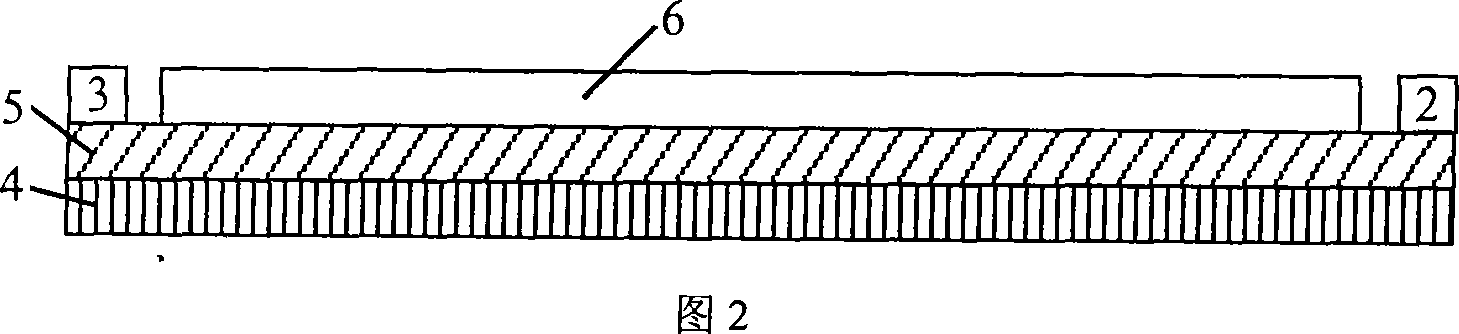

[0044] As shown in Figure 2...

Embodiment 3

[0045] Example 3. Preparation of a rapidly adjustable conductive polymer / polyelectrolyte solid composite membrane with polypyrrole nanofibers as the conductive polymer

[0046] 2.5 ml of pyrrole (Py) monomer was dissolved in 150 ml of 3M hydrochloric acid (HCl), and 2 ml of polyaniline (PAn) nanofiber suspension with a solid content of 8 mg / ml was added thereto to induce the formation of polypyrrole nanofibers. 2.5 g of ammonium persulfate (APS) was dissolved in 60 ml of 3M HCl. Under stirring, the two solutions were combined. After reacting for 12 hours, the polypyrrole (PPy) was precipitated and separated and washed with distilled water, and finally the PPy was dispersed in distilled water, thereby diluting to obtain a PPy nanofiber suspension with a solid content of 6 mg / ml. Transmission electron microscopy observations showed that the microstructure of PPy products was nanofibers with a diameter of 70nm. Under stirring conditions at 85°C, 5g of polyvinylidene fluoride (P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com