Method for preparing light highly-conductive hot carbon nano composite material

A composite material, high thermal conductivity technology, applied in the field of carbon nanomaterials, can solve the problems of long production cycle, the influence of density and purity on thermal conductivity, and high raw material requirements, to improve high temperature thermal conductivity, excellent product repeatability, and preparation technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

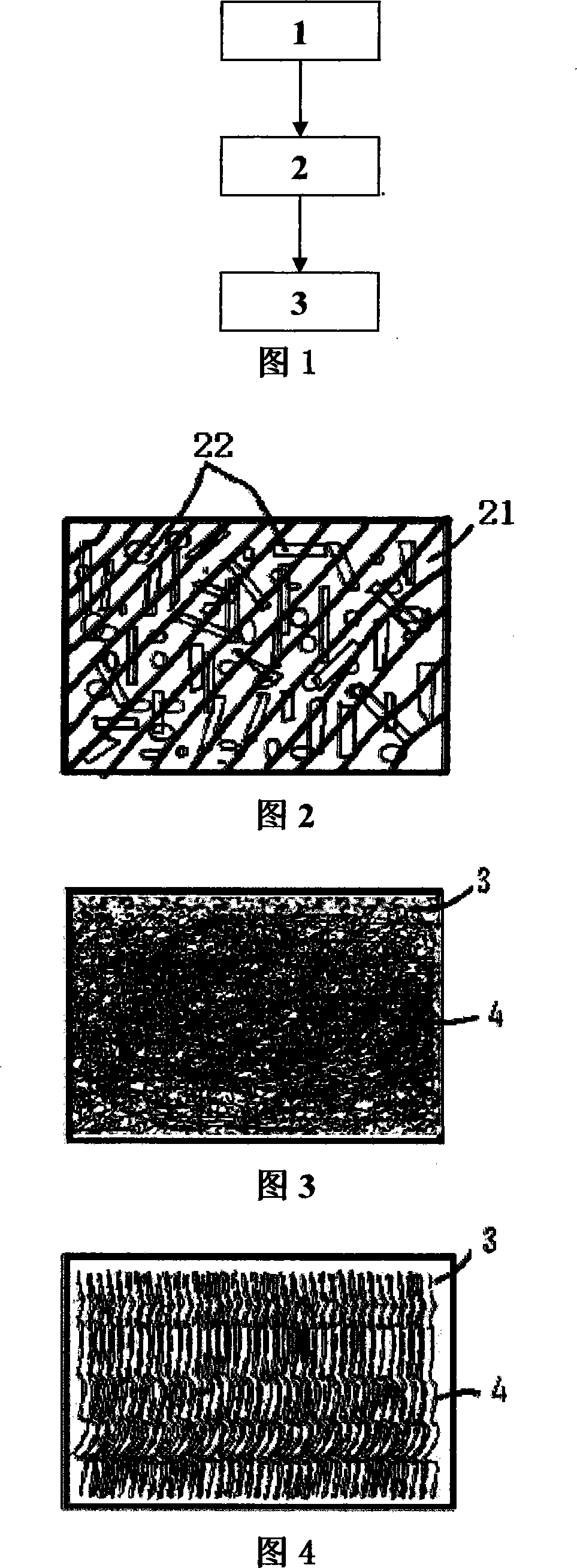

[0019] Preparation of bulk carbon nanotube composites by blending method:

[0020] Prepare 20g of carbon nanotube powder by electric arc method or laser method, and then soak it in hydrochloric acid or nitric acid or sulfuric acid solution with a concentration of 6mol / L for 24 hours to purify carbon nanotubes; then take 15g of carbon nanotube powder after cleaning, filtering and drying Tube; The mesophase pitch is diluted to a concentration of 12.5wt% with carbon tetrachloride;

[0021] Use wet ball milling to mix carbon nanotubes: choose a satellite ball mill, the ball mill tank is a steel tank, the grinding balls are 5 large steel balls, 20 small steel balls, the outer diameter of the large steel ball is 10mm, the outer diameter of the small steel ball is 6mm, and the total mass is 151.1g ; The ball milling speed is 100 rpm; the ball milling time is 0.5 hours;

[0022] Take out the ball-milled mixture, pour it into 20ml of acetone, and then remove the large particles in the...

Embodiment 2

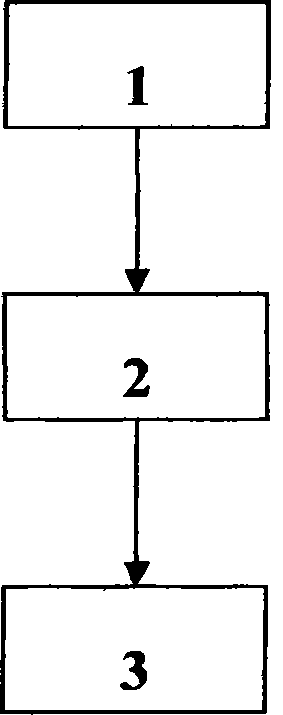

[0028] Preparation of aligned carbon nanotube composite film by injection method:

[0029] Quartz glass or silicon substrate, using nickel-chromium alloy film as the catalyst layer, preparing aligned carbon nanotube film by plasma enhanced chemical vapor deposition method, and then purifying carbon nanotube by oxidation method, the temperature is 300 °C, and the time is 0.5 hour; The high carbon resin is diluted with alcohol to a concentration of 25wt%;

[0030] Place the aligned carbon nanotube film with the substrate in a closed container, and inject the high-carbon resin solution under pressure: pressure 4Mpa;

[0031] Put the impregnated aligned carbon nanotube film into an oven and bake at 30°C for 0.5 hours;

[0032] Graphitization treatment: Vacuum furnace, under argon atmosphere, increase the temperature to 300°C, keep for 20 minutes, raise the temperature to 800°C, keep the temperature for 30 minutes; then raise the temperature to 1800°C, keep for 20 minutes;

[003...

Embodiment 3

[0035] Preparation of sheet-like nano-carbon fiber composites by impregnation method:

[0036] Pure nickel sheet or copper-nickel sheet is used as the substrate, and the carbon nanotube / fiber thick film is prepared by thermal chemical vapor deposition, with a thickness of 1-2 mm and a certain degree of flexibility; dilute the high-carbon polymer to a concentration of 10wt %;

[0037] Peel off the carbon nanotube / fiber thick film from the substrate and leave it in a 10wt% high-carbon polymer solution for 24-40 hours;

[0038] Put the impregnated aligned carbon nanotube film into an oven and bake at 30°C for 0.5 hours;

[0039] Graphitization treatment: Vacuum furnace, under hydrogen environment, increase the temperature to 300°C, keep for 20 minutes, raise the temperature to 800°C, keep for 30 minutes, then raise the temperature to 1800°C, keep for 20 minutes;

[0040] In the case of hydrogen circulation, the temperature is naturally cooled and taken out to obtain a light-wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com