Integrating technology of water supplying and saving and sewage reusing technology system in petroleum and petrochemical industry

A technology of system integration and reuse of water, applied in flotation water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. Lack of systematic research and other issues to achieve the effects of skilled craftsmanship, lightening the burden on enterprises, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

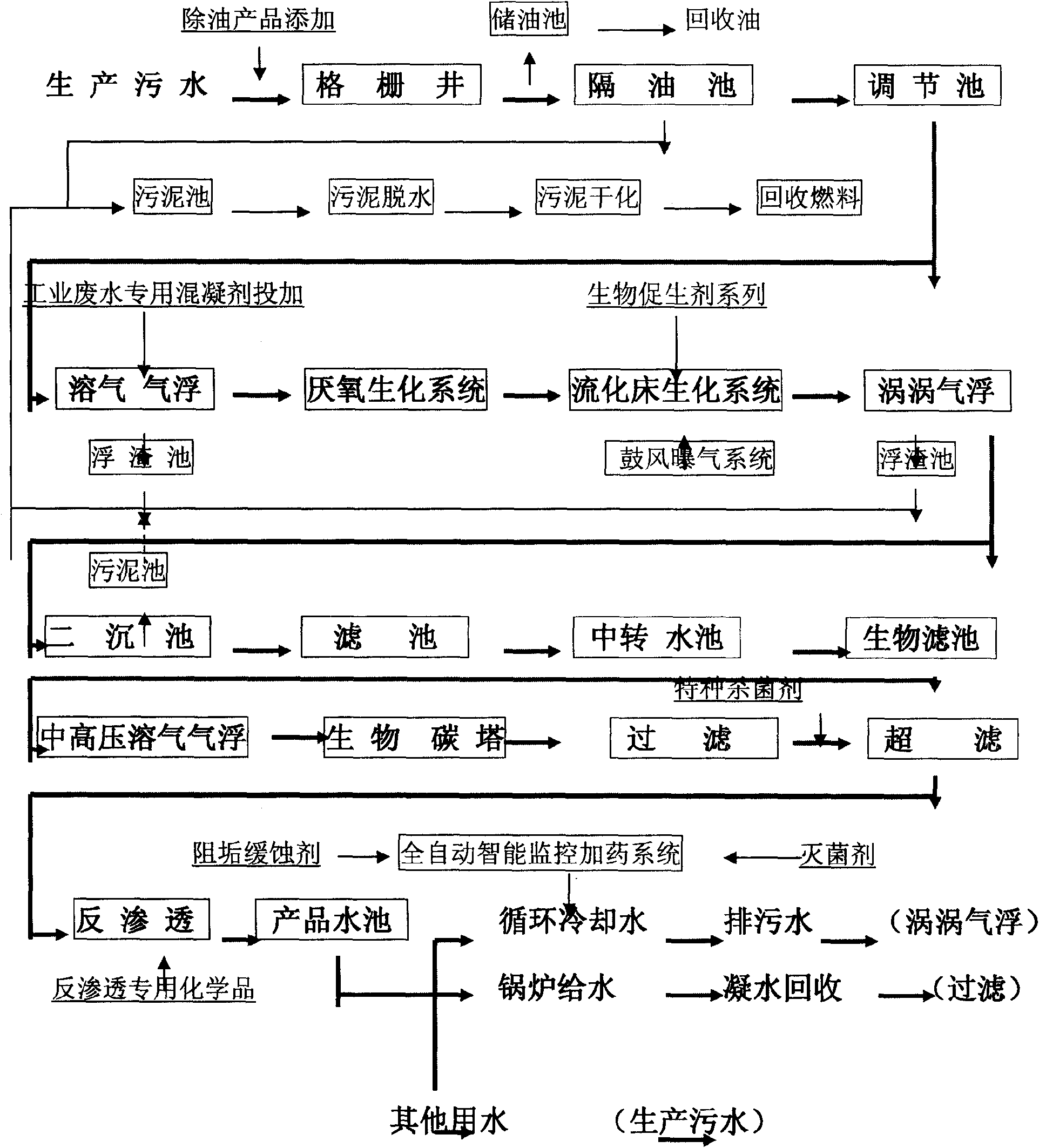

[0028] Technical key point control during system operation:

[0029] Dissolved air flotation, adding high-efficiency special coagulant for industrial wastewater to enhance the coagulation effect and improve the removal of emulsified oil and suspended solids;

[0030] Biochemical treatment is based on incoming water, adding biological growth promoters / antidotes / active phosphorus / nutrients to strengthen the treatment effect and reduce the load for subsequent treatment;

[0031] The bio-carbon tower is an important barrier for filtration and reverse osmosis systems to prevent suspended matter and organic fouling. A medium and high-pressure dissolved air flotation device can be added in front of the bio-carbon tower to remove suspended matter and organic colloids in the water and ensure the normal operation of the bio-carbon tower. .

[0032] To control the reproduction and fouling of the filtered microorganisms, use a special fungicide for the reverse osmosis system. The product...

Embodiment 2

[0035] Increase the concentration ratio of circulating cooling water:

[0036] During the recycling process of cooling water, due to continuous evaporation and concentration, the harmful ions in the water are multiplied. In addition, the cooling tower is exposed to sunlight, wind and rain for many years, and dust and sundries will fall, which will cause corrosion and condensation. Scale biological slime breeding and other hazards.

[0037] Scaling hazard: Refers to the dissolved or suspended inorganic substances in water, which are deposited on the surface of the metal due to factors such as heat. The main components are calcium carbonate and corrosion products. Scale and corrosion inhibitors are used to effectively control the scaling hazard.

[0038] Corrosion hazard: Corrosion caused by circulating cooling water is mainly caused by dissolved oxygen corrosion. Corrosion of water pipelines and water cooling equipment reduces service life and prevents the occurrence of anti-ru...

Embodiment 3

[0047] Drug identification and use

[0048] Determine the best control parameters through water quality analysis, simulation test, flocculation, static scale inhibition rate, rotating corrosion coupon, dynamic simulation test, microbial test, etc.

[0049] Control parameters:

[0050] Add coagulant

[0051] It is determined to select a special coagulant for industrial wastewater in the dissolved air flotation section, and the dosage is 30-50mg / L.

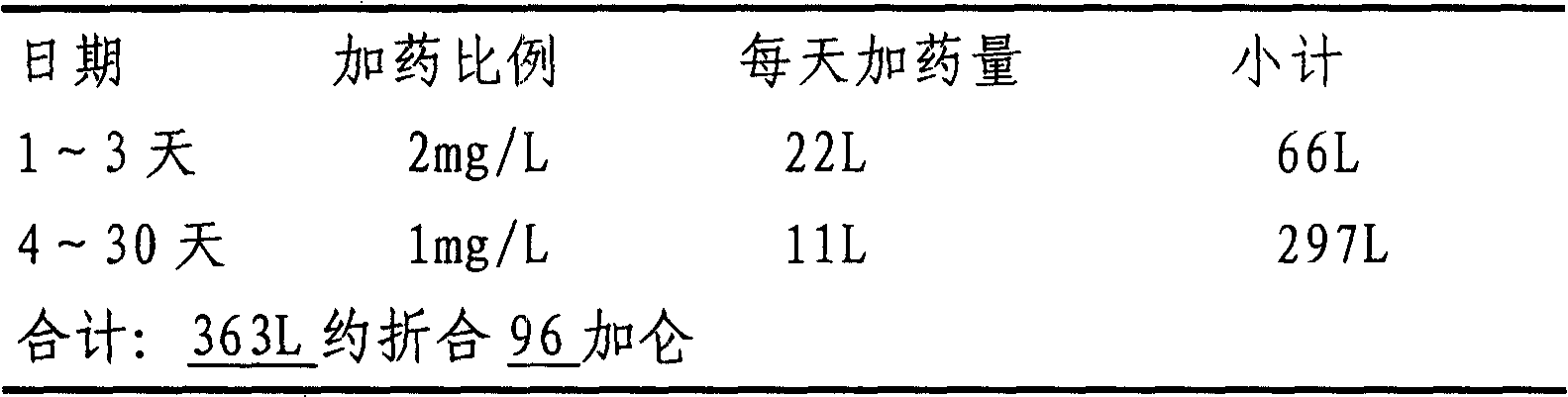

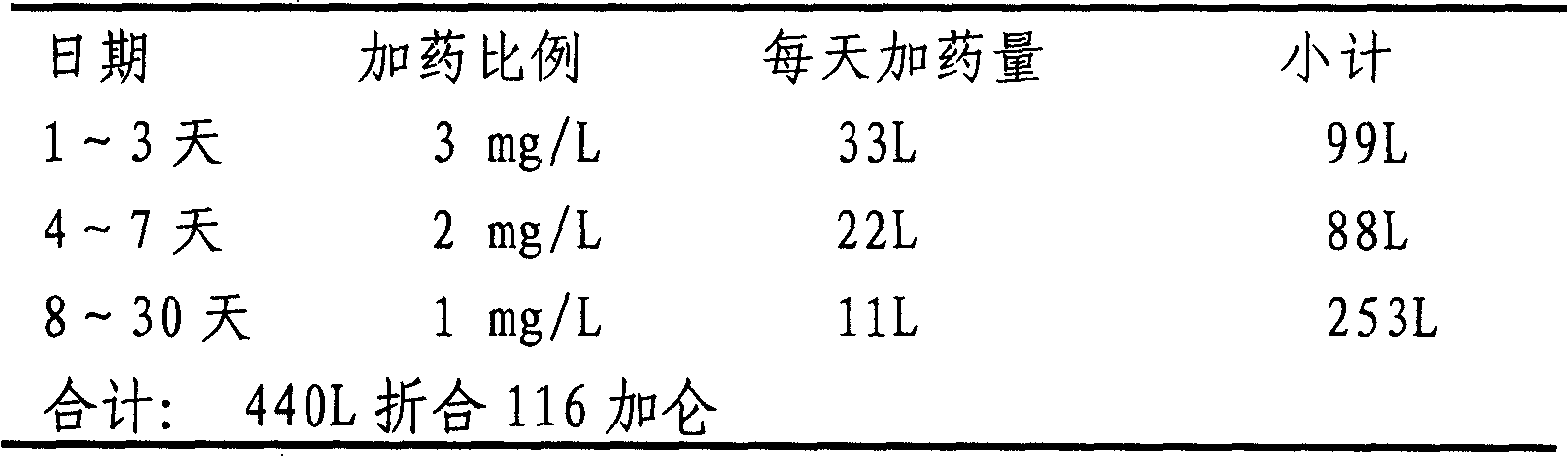

[0052] Dosing biopromoter

[0053] Make sure to add bio-growth-promoting agent (BE) in the biochemical section, and the dosage depends on the water situation, generally 0.5-4mg / L. The addition of bio-growth promoter can promote the metabolic function of microorganisms in the biological treatment system to reach the highest level, accelerate the reproduction of microorganisms, promote the formation of good bacteria gelatinous groups, and improve the efficiency of microorganisms in treating organic pollutants. Effectively improve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com