Supercritical carbon dioxide (CO2) foaming nucleating agent and preparation method thereof

A technology of foaming nucleating agent and carbon dioxide, which is applied in the production of bulk chemicals, etc., to achieve the effects of simple preparation process, improved nucleation efficiency, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

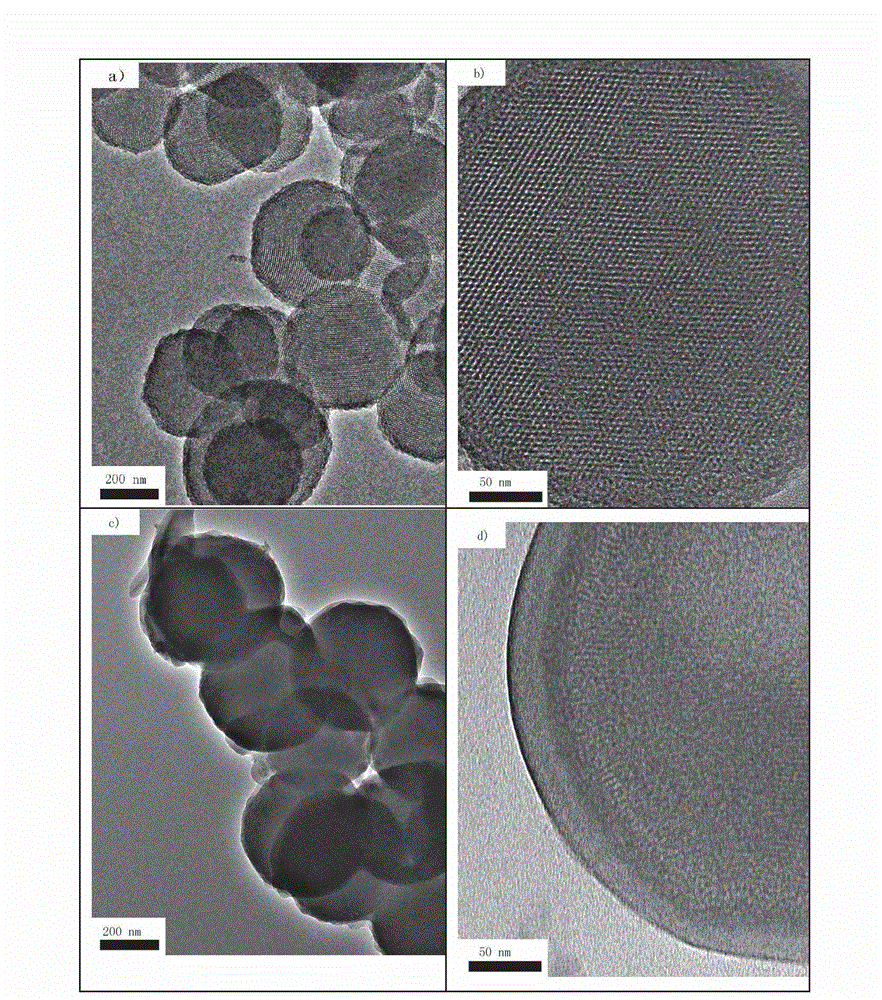

[0034] Synthesize ordered mesoporous silica with CTAB as a template: take 1 g CTAB and 500 mL distilled water, stir well; weigh 0.32g NaOH to adjust the pH to 12; gradually increase the temperature to 80℃, and dissolve the NaOH; 18g positive Ethyl silicate as a silicon source was added dropwise to the system. After the dropping, the hydrolysis reaction was carried out with heat preservation and stirring for 6 hours. The resulting suspension was refluxed and washed with a mixed solvent of concentrated hydrochloric acid and methanol with a volume ratio of 80:500 to remove the template, and the solid was separated and dried. 3g of mesoporous silica (such as figure 1 a) and b)).

[0035] 1g of mesoporous silica and 3g of KH550 were added to 200mL of toluene, and reacted for 24 hours under reflux conditions for modification and modification. After the reaction, the solid was obtained by centrifugation, and the modified powder was obtained after drying. Add 1g of modified powder to 200...

Embodiment 2

[0037] Hydrothermal synthesis of porous titanium dioxide: prepare a hydrochloric acid solution with a pH of 2.0, measure 350ml, add 50ml of glycerin, mix well to obtain a mixed solution with a volume ratio of 7:1, respectively measure 40ml in 10 hydrothermal reactors , Add 600mg of titanium tetrafluoride weighed to each fluorine, stir well; hydrothermally react at 155℃ for 20 hours, after which, take out the reaction solution for centrifugation, wash twice with ethanol, and vacuum dry at 60℃ for 10 hours to obtain the product Porous titanium dioxide.

[0038] 0.5 g of porous titanium dioxide and 1 g of KH550 were added to 200 mL of toluene and reacted for 24 hours under reflux conditions for modification and modification. After the reaction, the solid was obtained by centrifugation, and the modified powder was obtained after drying. Add 1g of modified powder to 300mL of dichloromethane and 20mL of triethylamine after dewatering. After stirring evenly, add 9mL of 2-bromoisobutyryl...

Embodiment 3

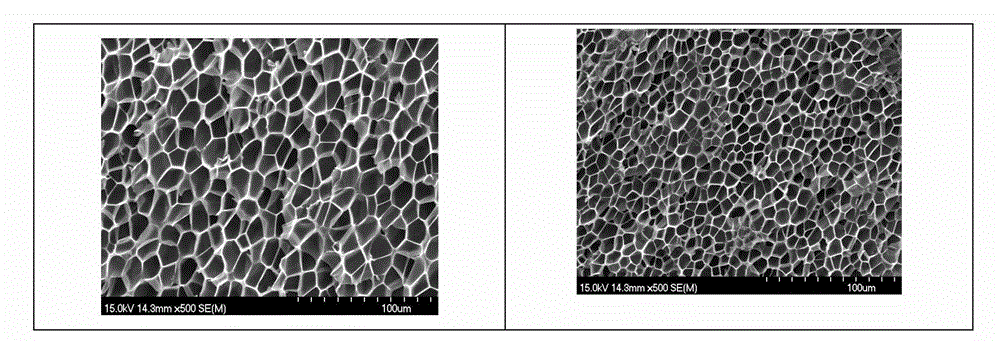

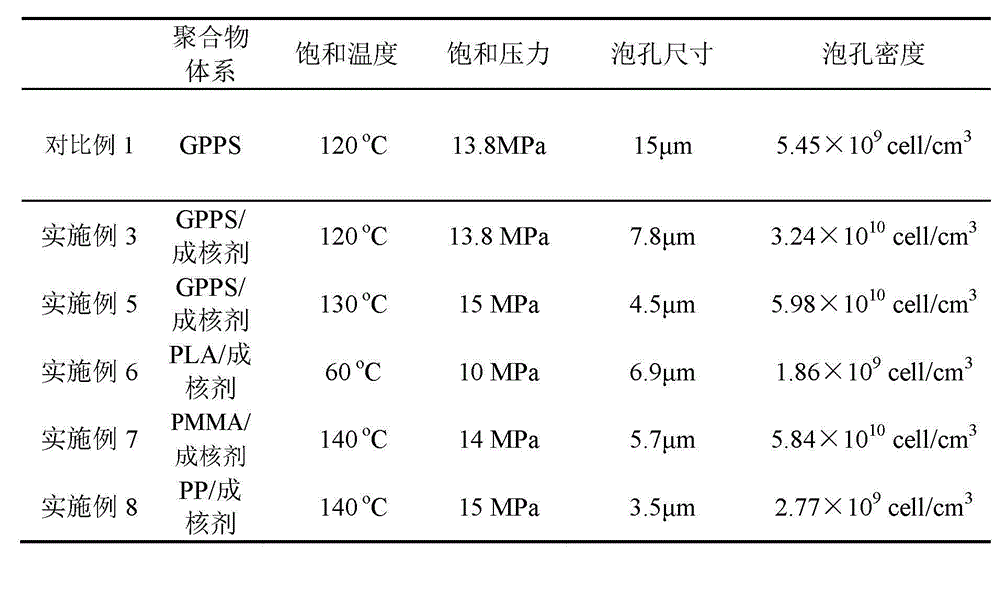

[0042] Take 0.15g of the nucleating agent prepared in Example 1 and 4.85g of GPPS, disperse and dissolve them in 25mL DMF, precipitate the precipitate with 300mL methanol, and filter the filter cake at 120 o Vacuum drying at C, the dried sample is mixed uniformly under the twin-screw extrusion of the micro mixer, at 200 o C extrudes the material, and obtains a spline after drawing. Spline is made into 5mm*5mm foam samples for supercritical CO 2 Foaming experiment. Place the sample in the autoclave and use supercritical CO first 2 Flush the system with fluid, purge the air, and heat up the system to 120 after sealing the device o Saturation temperature of C, injected CO 2 Saturate the fluid to a saturation pressure of 13.8 MPa for 10 hours, then quickly release the pressure and place it in an ice water room to cool and shape it to obtain a polymer foam material. Frozen and brittle the foamed material with liquid nitrogen and perform scanning electron microscopy analysis, such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell size | aaaaa | aaaaa |

| Cell size | aaaaa | aaaaa |

| Cell size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com