Hydrophobic monomer for synthesizing temperature sensitive polymer oil-displacing agent and preparation method thereof

A temperature-sensitive polymer and hydrophobic monomer technology, applied in the direction of hydrocarbon production from oxygen-containing organic compounds, drilling compositions, chemical instruments and methods, etc., can solve the problem of loss of hydrophobic effect, removal of hydrophobic groups, water-soluble Improve the ability of temperature resistance and salt resistance, strengthen the hydrophobic effect, and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Synthesis of p-n-butylacetophenone

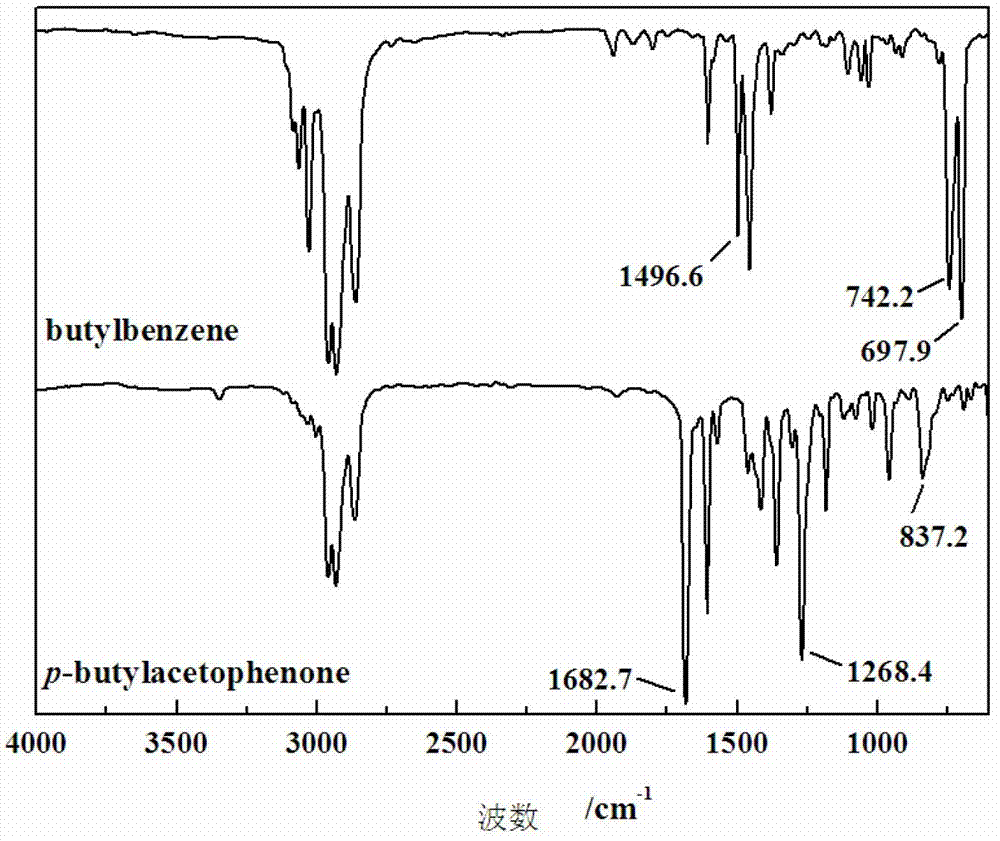

[0032] In a 500ml three-neck flask equipped with magnetic stirring, add 56.75g (0.44mol) of anhydrous aluminum trichloride to 200ml of dichloromethane at 0°C to dissolve for 30min, then slowly add 22.45g ( 0.22mol) acetic anhydride solution, continue to stir at 0°C for 15min, then slowly dropwise add 13.4g (0.1mol) n-butylbenzene solution dissolved in 25ml of dichloromethane for 30min, rise to room temperature and react for 5h. The mixture after the reaction is completed is poured onto 375ml of crushed ice, and the separated organic solution part is washed 2 times with 125ml of 10wt% hydrochloric acid solution, 125ml of saturated sodium carbonate solution, and 125ml of saturated sodium chloride solution. Methylene chloride is removed by rotary evaporation in vacuum after drying over magnesium sulfate water, and the liquid product p-n-butylacetophenone is obtained. figure 1 .

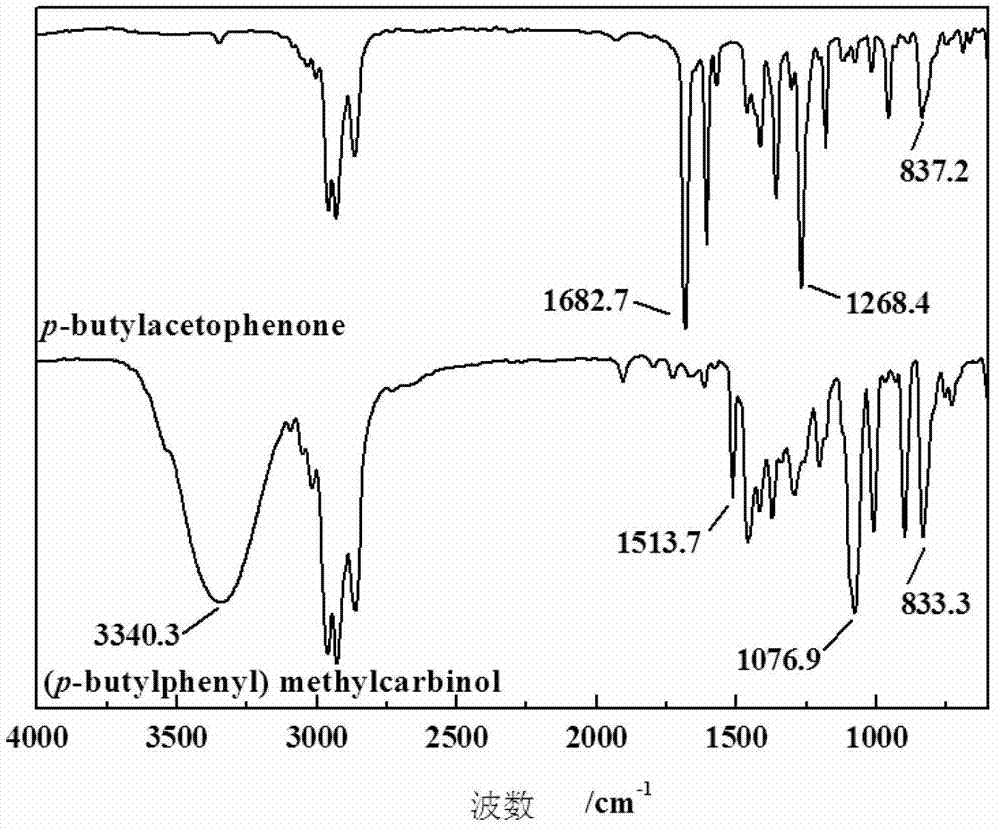

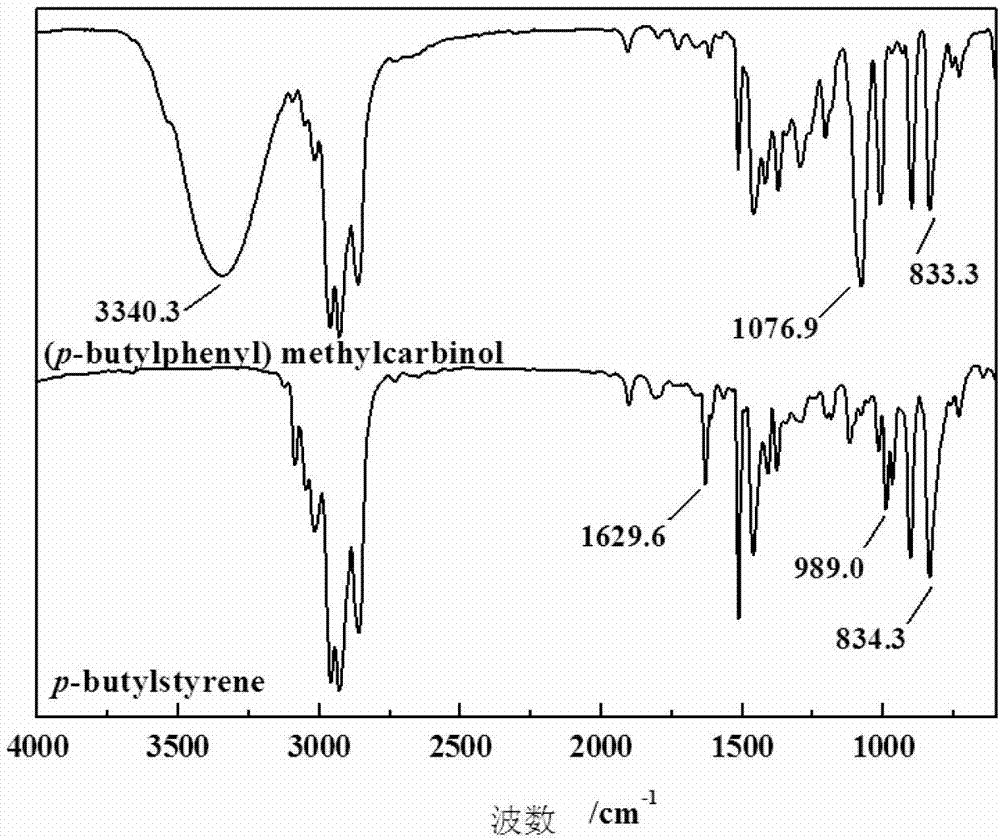

[0033] (2) Synthesis of 1-methyl-n-butylbenzyl alco...

Embodiment 2

[0038]First, acrylamide: N, N diethylacrylamide: p-n-butyl styrene = 79:20:1 monomer molar ratio, sequentially added to the three-necked flask, dissolved in deionized water to obtain a monomer solution, the monomer The total mass accounts for 30% of the total mass of the monomer solution, and then 1.5% of the total mass of the monomer is added with sodium dodecylsulfonate and 1% of the oxidation-reduction initiator system (the mass ratio of potassium persulfate: sodium sulfite is 1:1 ). Control the stirring speed at 100 rpm, the reaction temperature at 45°C, react for 10 hours, wash the product with acetone three times, and then dry it at 80°C to obtain the temperature-sensitive polymer flooding oil with n-butyl styrene agent. The synthesized temperature-sensitive polymer is configured as a 0.8% deionized aqueous solution. When the temperature exceeds 50°C (phase transition temperature), the viscosity rises sharply from 98.5mpa.s. to 256.9mpa.s., showing strong thermal thicke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com