Method for preparing intestine nutritive peptide by using wheat

A technology of wheat protein and intestinal nutrition, which is applied in the preparation method of peptides, food preparation, peptide/protein components, etc., can solve the problems of less than 50% raw material utilization rate, complicated processing technology, and reduced product activity, so as to achieve outstanding intestinal nutrition Efficacy, broaden the scope of application, increase the effect of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

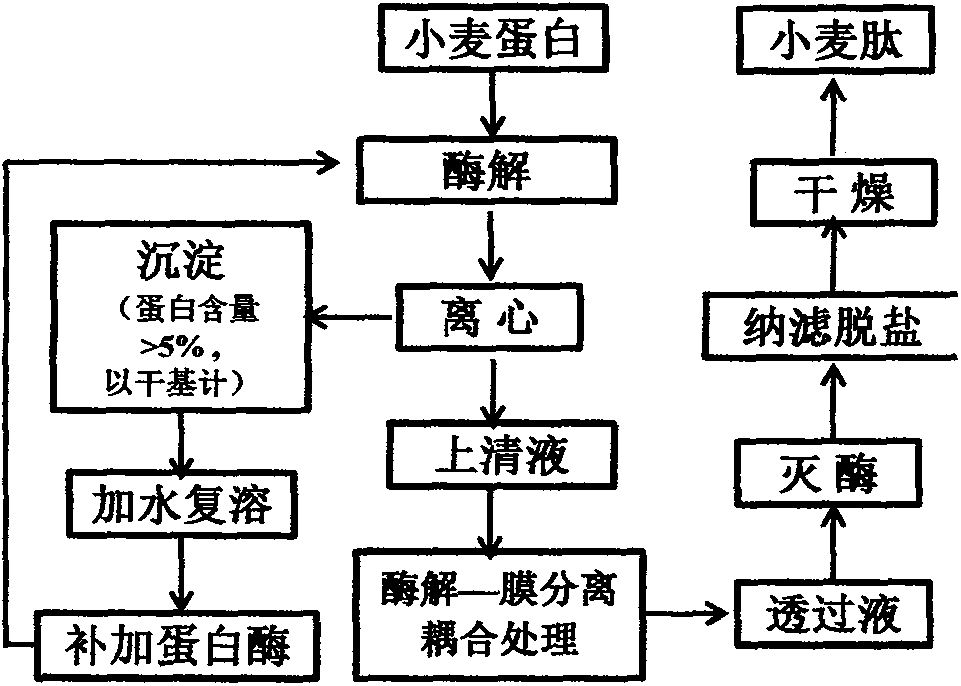

[0033] Embodiment 1: Preparation of high glutamine oligomeric wheat peptide

[0034] (1) Prepare wheat protein feed liquid: blend 100g wheat protein raw material with 0.1g sodium carboxymethyl cellulose, add water until the protein concentration is 10%, stir for 30min to form a uniform suspension;

[0035] (2) Step-by-step enzymatic hydrolysis: adjust the pH value of the feed solution to 7.0±0.5, maintain the temperature at 50±2°C, add 0.5g Protamex TM Carry out enzymatic hydrolysis with protease, and when the degree of hydrolysis reaches 5%, centrifuge the enzymatic solution (3000rpm, 15min) to obtain supernatant 1 and precipitate 1; add water equivalent to 2 / 3 quality of step (1) to redissolve precipitate 1 After that, add 0.5g Protamex TM Protease, continue to enzymatically hydrolyze until the degree of hydrolysis reaches 5%, centrifuge (3000rpm, 15min) to obtain supernatant 2 and precipitate 2; repeat the second step of enzymatic hydrolysis once to obtain supernatant 3 an...

Embodiment 2

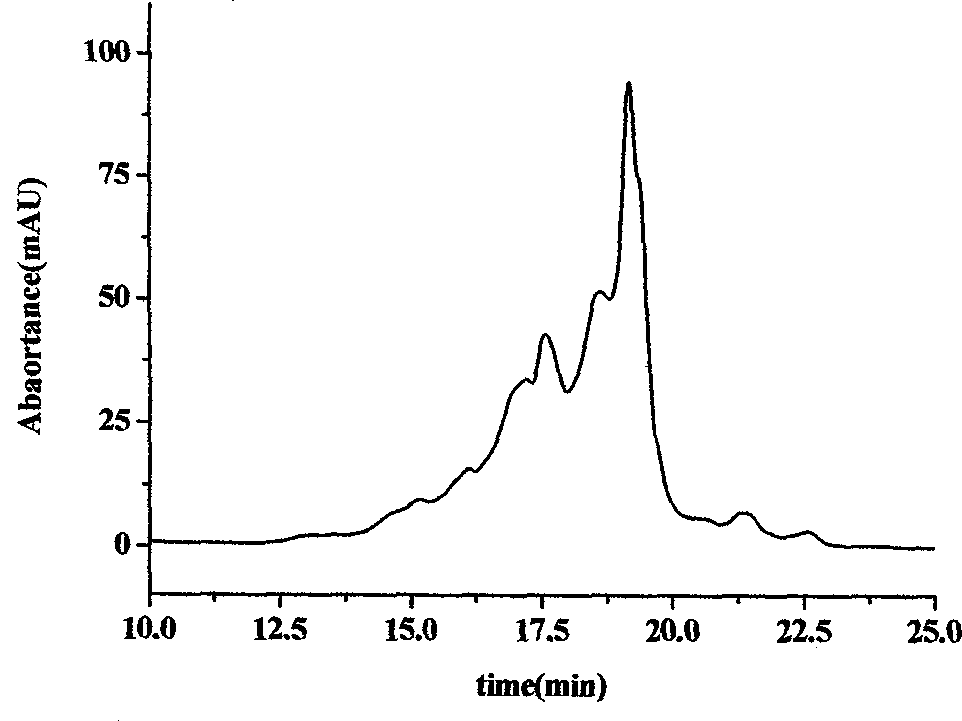

[0038] Example 2: Analysis of Wheat Glutamine Peptide Basic Components and Molecular Weight Distribution

[0039] The analysis results of the basic components of wheat glutamine peptides are shown in Table 1.

[0040] Element Protein (N×5.79) Fat starch Ash Content%(dry basis) 85.3 0.1 9.8 2.6

[0041] The molecular weight distribution of wheat glutamine peptides was analyzed by high performance gel filtration chromatography, and the chromatographic conditions were as follows:

[0042] Chromatographic column: TSKgel2000SWXL (300mm×7.8mm)

[0043] Mobile phase: acetonitrile / water / TFA=45 / 55 / 0.1(V / V)

[0044] Detection wavelength: UV220nm

[0045] Flow rate: 0.5ml / min

[0046] Column temperature: 30°C

[0047] Cytochrome C (MW12500Da), aprotinin (MW6500Da), bacitracin (MW1450Da), ethanamide-ethanamide-arginine (MW451Da) and ethanamide-ethanamide-ethylamine Acid (MW189Da) is made relative molecular mass calibration curve as standard substance, ...

Embodiment 3

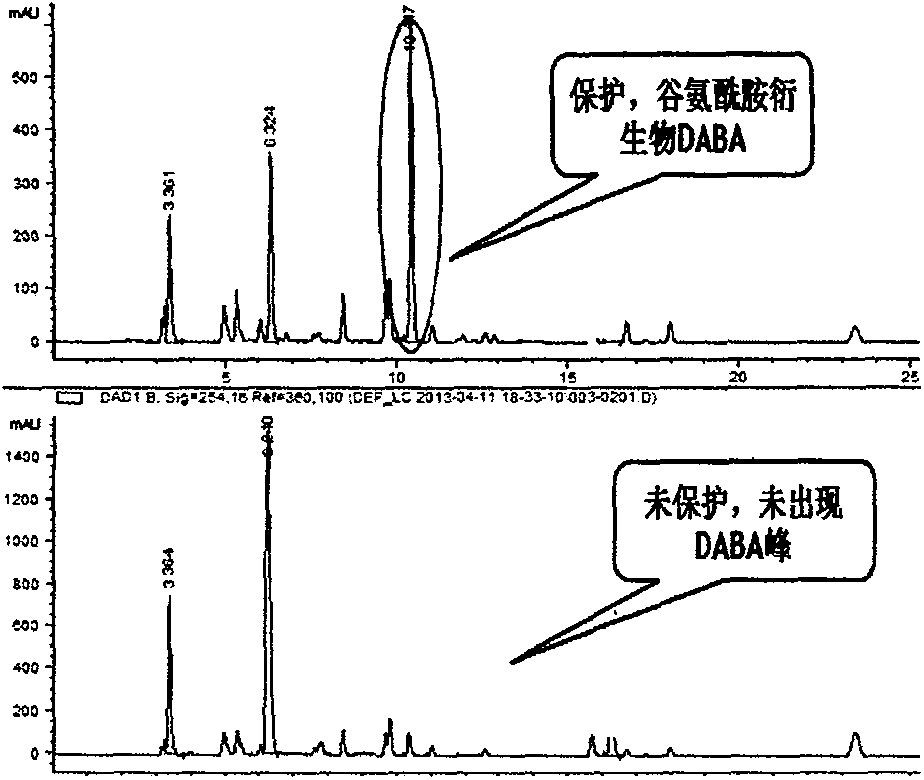

[0049] [0038] Embodiment 3: Determination of effective glutamine content in wheat glutamine peptide

[0050] BTI was used to protect the glutamine at the non-nitrogen end of the glutamine peptide, and then treated with acid hydrolysis. After pre-column derivatization with PITC, the content of glutamine at the non-nitrogen end of the peptide chain was detected by high performance liquid chromatography. The standard used is Gly-Gln, and the standard curve equation is: y=1582x-950.3 (R 2 =0.998). The liquid chromatograms of the samples before and after BTI protection are shown in Figure 3. After calculation, the effective glutamine content is 30.19%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com