Method for producing normal paraffin by hydrogenating fatty acid ester

A fatty acid ester and n-alkane technology, applied in the field of catalysis, can solve the problems of difficulty in realizing large-scale production, reduced n-alkane yield, high production labor intensity, etc., and achieves low labor intensity, improved conversion rate, and reaction temperature. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

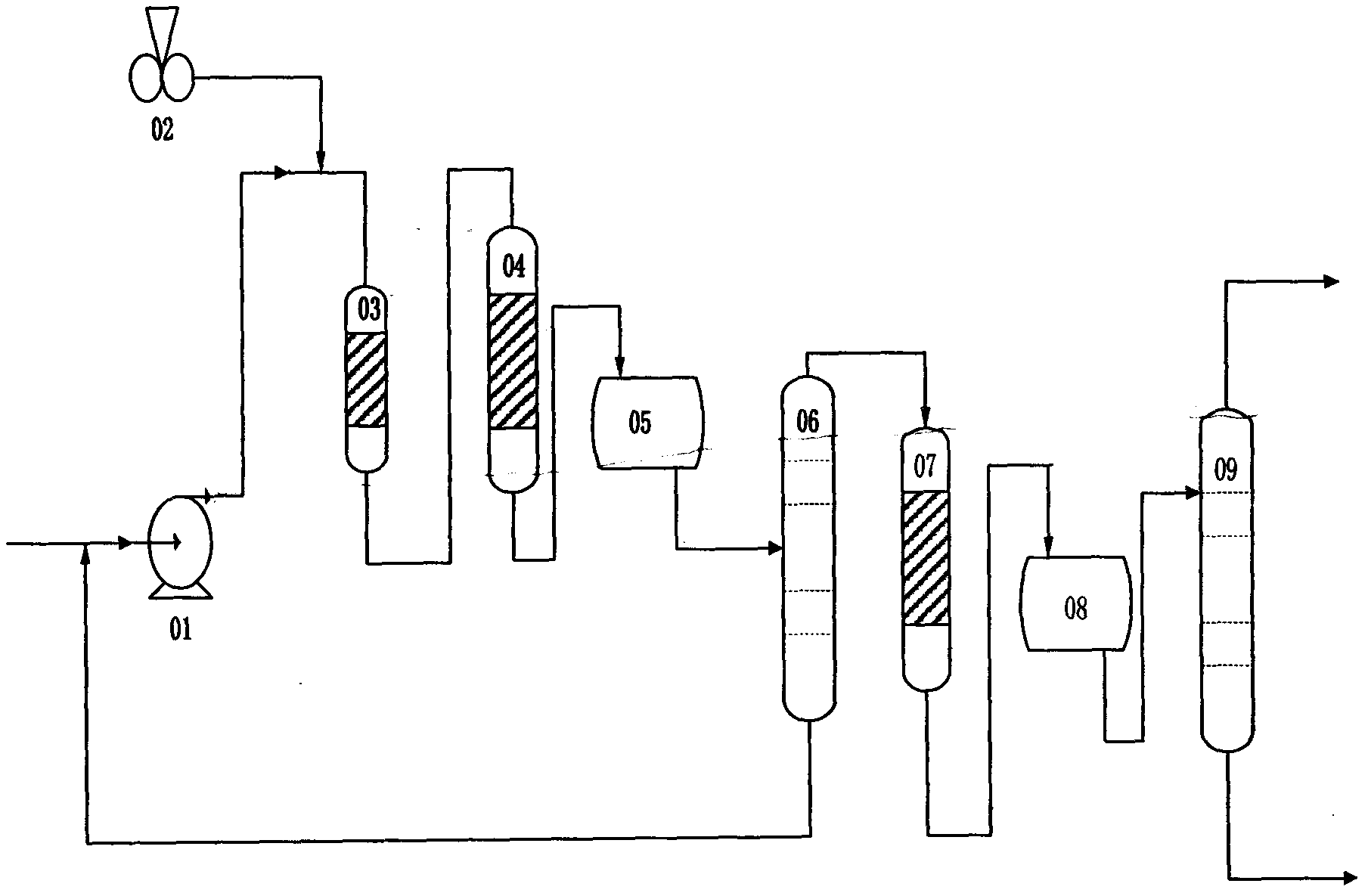

Image

Examples

Embodiment 1

[0036] Hydrodeoxygenation catalyst preparation

[0037] (1) Pseudo-boehmite and magnesium nitrate are mixed in a certain proportion, and at the same time, the modifying additive is dissolved and added in a certain proportion with deionized water, and the carrier is prepared through processes such as kneading-forming-drying-roasting. (2) The active metal is dissolved by complexation, and then the solution is mixed and loaded on the surface of the carrier by co-impregnation, wherein nickel oxide is 10% to 30%, molybdenum oxide is 2.0% to 12.0%, and cobalt oxide is 1.0%. ~10.0%. . (3) The loaded catalyst is dried-calcined to obtain the finished catalyst.

Embodiment 2

[0039] Supplementary Refining Catalyst Preparation

[0040] (1) Aluminum nitrate and zirconium sulfate metal salt are selected to prepare a solution, and sodium hydroxide is used as a precipitant for neutralization and precipitation, and then filtered, washed, dried, and roasted to obtain a composite carrier of alumina and zirconia (2) adopt 15% metal Ni and 1.5% metal Mo were impregnated by equal-volume co-impregnation, dried at 110°C, and then calcined at 400°C to obtain a finished catalyst.

Embodiment 3

[0042] Fatty acid methyl ester (waste oil transesterification product) hydrodeoxygenation

[0043]The gutter oil is treated by primary screening-fractionation, and then transesterified with methanol to obtain fatty acid methyl esters. After mixing fatty acid methyl esters and hydrogen in a certain proportion, they enter the pre-hydrogenation reactor to remove metals and reduce the iodine value of raw materials, and then enter the hydrogenation reactor. The hydrodeoxygenation reactor converts most fatty acid methyl esters. After the hydrodeoxygenation products are separated by the separation system, the light distillate oil enters the supplementary refining unit for further hydrodeoxygenation treatment, so that the content of non-stable substances such as oxides in the product is less than 0.5ppm . The operating conditions of the controlled hydrodeoxygenation catalyst are: the reaction hydrogen partial pressure is 3.0Mpa, the hydrogen oil volume ratio is 700v / v, the reaction in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com