Preparation method of lactic ester

A lactate and carbohydrate technology, applied in the chemical industry, can solve the problems of short reaction time and high concentration of reactant sugar, and achieve the effects of low cost, high catalytic activity and improved product conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The invention provides a method for preparing lactic acid esters. Carbohydrates, transition metal salts, alcohols and water are mixed, and the mixed solution is stirred and reacted at a temperature of 200-260°C and a pressure of 4-15 MPa to obtain The lactic acid ester and the transition metal salt are acidic, the alcohol is a low-carbon alcohol with 1-4 carbon atoms, and the carbohydrate is a hydrolyzed carbohydrate including monosaccharide.

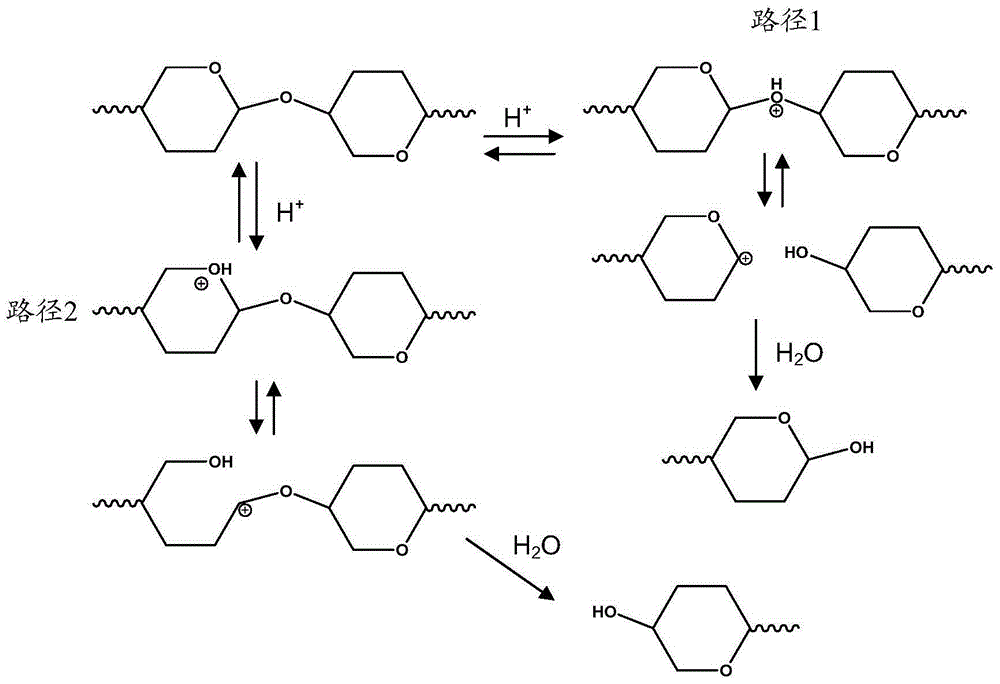

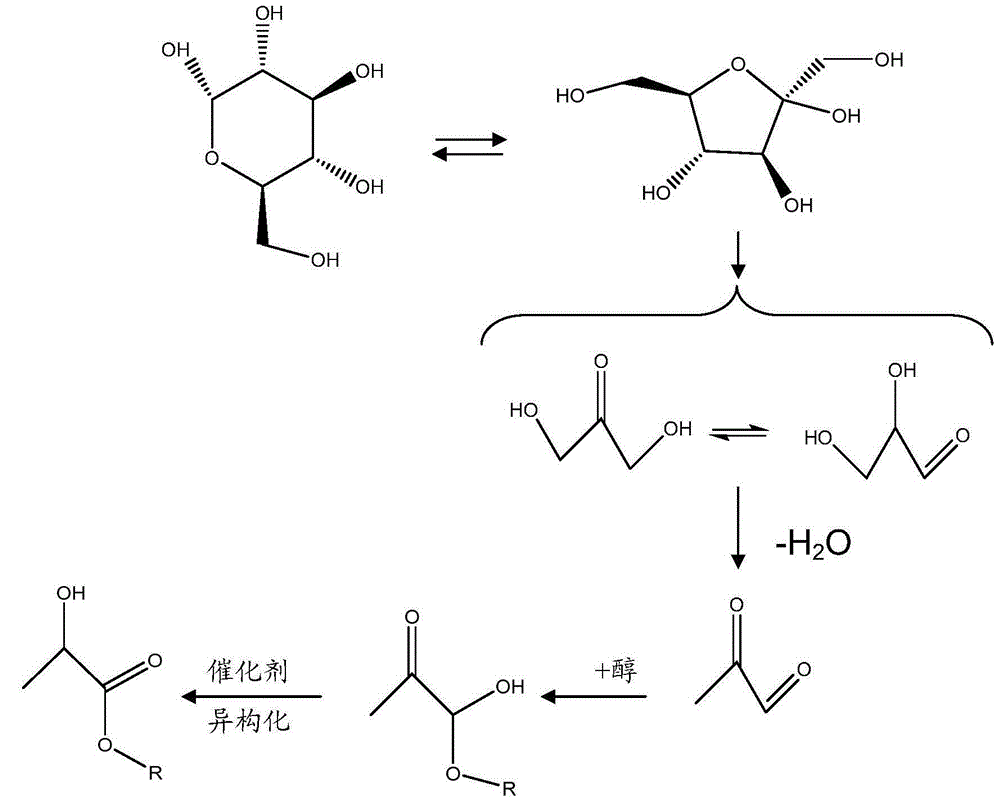

[0017] The reaction mechanism of the present invention is: the depolymerization reaction occurs on macromolecules such as cellulose, and macromolecules form small molecular substances through depolymerization. When the raw material is cellulose, the fiber macromolecule first undergoes a hydrolysis reaction to obtain monosaccharides, and then undergoes a series of reactions such as ring opening, isomerization, and esterification to finally obtain lactate. The main factors affecting the preparation of lactate are temperature, press...

Embodiment 1

[0041] A method for preparing lactic acid esters in this example comprises mixing carbohydrates, transition metal salts, alcohols, and water, and stirring and reacting the mixed liquid at a temperature of 200°C and a pressure of 4 MPa to obtain the milk ester, the solid-to-liquid ratio of the mass of the carbohydrate to the total volume of the alcohol and water is 1:1, the volume ratio of the alcohol to water is 20:1, the transition metal salt is acidic, and the alcohol It is a low-carbon alcohol with 1-4 carbon atoms, and the carbohydrate is a hydrolyzed carbohydrate including monosaccharide. The alcohol is selected from one or more of methanol, ethanol, n-propanol, isopropanol, n-butanol and isobutanol. The carbohydrates are selected from one or more of plant cellulose, artificial fiber pulp, starch, sucrose, fructose and glucose. The metal in the transition metal salt is selected from one or more of titanium, platinum, nickel, zirconium, chromium, tungsten, zinc, iron and ...

Embodiment 2

[0043] A method for preparing lactic acid esters in this example comprises mixing carbohydrates, transition metal salts, alcohols, and water, and stirring the mixed solution at a temperature of 260°C and a pressure of 15 MPa to obtain the milk ester, the solid-to-liquid ratio of the mass of the carbohydrate to the total volume of the alcohol and water is 1:60, the volume ratio of the alcohol to water is 1:20, the transition metal salt is acidic, and the alcohol It is a low-carbon alcohol with 1-4 carbon atoms, and the carbohydrate is a hydrolyzed carbohydrate including monosaccharide. The alcohol is selected from one or more of methanol, ethanol, n-propanol, isopropanol, n-butanol and isobutanol. The carbohydrates are selected from one or more of plant cellulose, artificial fiber pulp, starch, sucrose, fructose and glucose. The metal in the transition metal salt is selected from one or more of titanium, platinum, nickel, zirconium, chromium, tungsten, zinc, iron and copper, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com