N,N-dimethylamino ethyl acrylate preparation method

A technology of ethyl dimethylaminoacrylate and ethyl formyl acetate, which is applied in the field of preparation of ethyl N,N-dimethylaminoacrylate, can solve problems such as high raw material prices, difficulty in purchasing, and viscous mother liquor, and reduce the The content of impurities, cheap and easy-to-obtain raw materials, and the effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

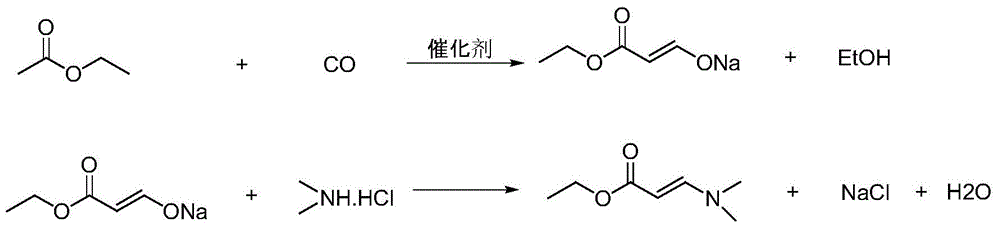

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Add ethyl acetate (88g, 1mol), sodium ethoxide (68g, 1mol) and 440g of mixed solvent (ethyl acetate / ethanol=1:1) into the autoclave, close the autoclave, start stirring, nitrogen replacement , and then filled with 3.0MP carbon monoxide and heated to 40°C. Under this temperature and pressure, react for 4 hours, lower the temperature, release the pressure, and discharge the material to obtain the sodium salt of the intermediate ethyl formyl acetate.

[0033] Step 2: Add the sodium salt of the intermediate formyl ethyl acetate and 176g of mixed solvent (ethyl acetate / ethanol=1:1) into the three-necked flask, start stirring, and add dimethylamine hydrochloride (82g , 1mol), the temperature was controlled at 10°C, after 4 hours of reaction, filtered, the filtrate was concentrated until solvent-free and evaporated to obtain a crude product, rectified, and 86°C (186Pa) fractions were collected to obtain 129g of a colorless liquid. The total yield 90%.

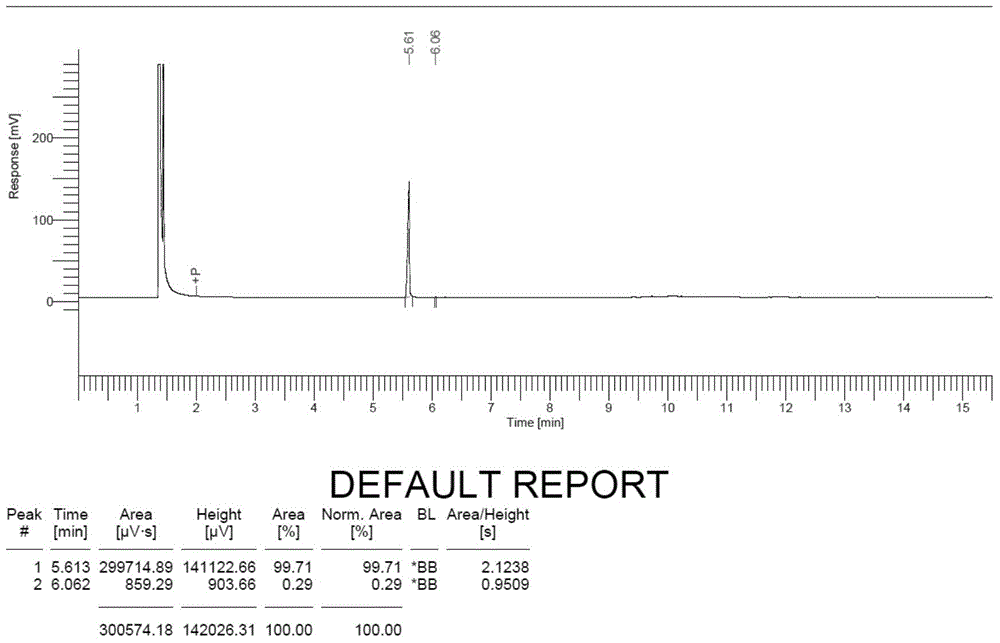

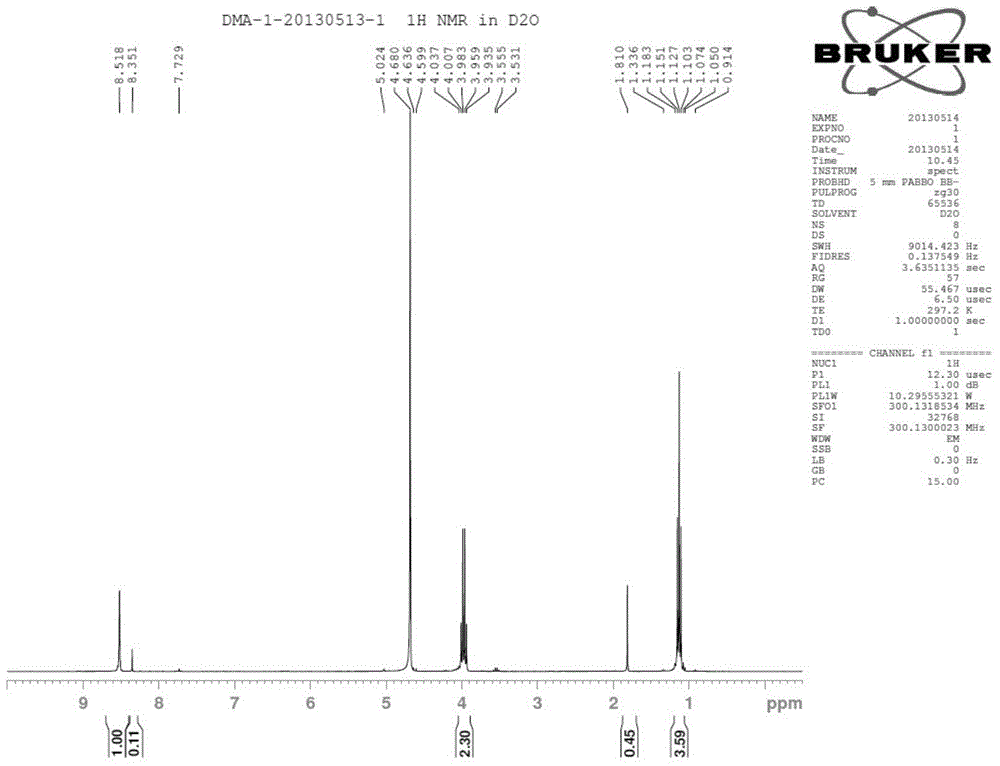

[0034] The ex...

Embodiment 2

[0040] Step 1: Add ethyl acetate (70g, 0.79mol), sodium ethoxide (652g, 0.952mol) and 210g of mixed solvent (ethyl acetate / ethanol=1.5:1) into the autoclave, close the autoclave, start stirring, Replace with nitrogen, then fill with 2.0MP carbon monoxide, and raise the temperature to 50°C. Under this temperature and pressure, react for 3 hours, lower the temperature, release the pressure, and discharge the material to obtain the sodium salt of the intermediate ethyl formyl acetate.

[0041]Step 2: Add the sodium salt of the intermediate formyl ethyl acetate and 210 g of a mixed solvent (ethyl acetate / ethanol = 1.5:1) into a three-necked flask, start stirring, and add dimethylamine hydrochloride in batches at 20°C ( 71g, 0.87mol), the temperature was controlled at 20°C, after 3 hours of reaction, filtered, the filtrate was concentrated until solvent-free and evaporated to obtain a crude product, rectified, and 86°C (186Pa) fractions were collected to obtain 102g of colorless li...

Embodiment 3

[0045] Step 1: Add ethyl acetate (90g, 1.02mol), sodium ethoxide (139g, 2mol) and 540g of mixed solvent (ethyl acetate / ethanol=2.2:1) into the autoclave, close the autoclave, start stirring, nitrogen Replacement, and then filled with 3.0MP carbon monoxide, the temperature was raised to 60°C. Under this temperature and pressure, react for 8 hours, lower the temperature, release the pressure, and discharge the material to obtain the sodium salt of the intermediate ethyl formyl acetate.

[0046] Step 2: Add the sodium salt of the intermediate formyl ethyl acetate and 450g of mixed solvent (ethyl acetate / ethanol=2.2:1) into the three-necked flask, start stirring, and add dimethylamine hydrochloride in batches at 40°C ( 128g, 1.58mol), the temperature was controlled at 40°C, after 6 hours of reaction, filtered, the filtrate was concentrated until solvent-free and evaporated to obtain a crude product, rectified, and 86°C (186Pa) fractions were collected to obtain 132g of a colorless...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com