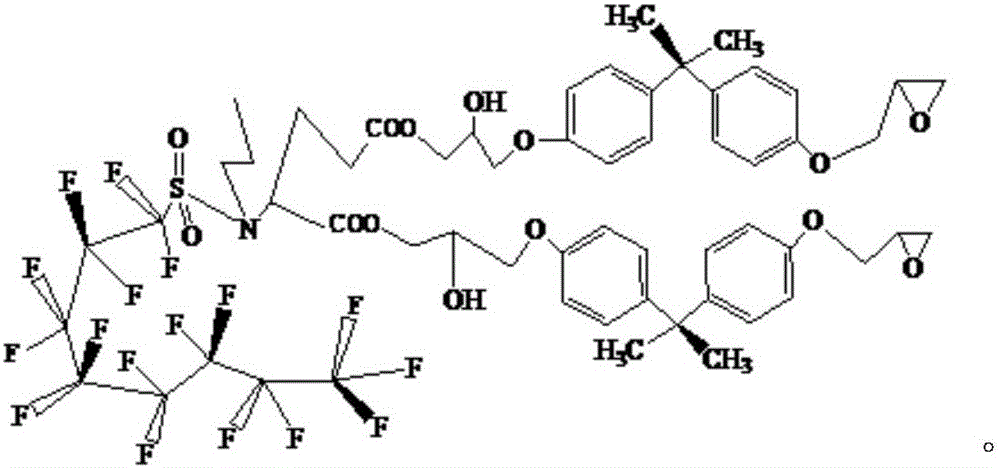

Fluorination bisphenol-type glycidyl ether and preparing method and application thereof

A glycidyl ether, fluorinated bisphenol type technology, applied in the field of fine chemical coatings, can solve the problems of unsatisfactory corrosion protection of metal substrates, unfavorable social and economic sustainable development, consumption of non-renewable resources, etc., to improve electrical conductivity or Salt spray resistance, good tribological properties, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

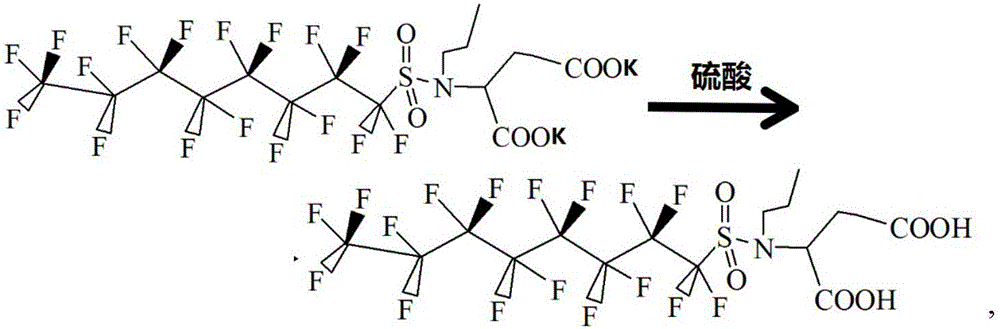

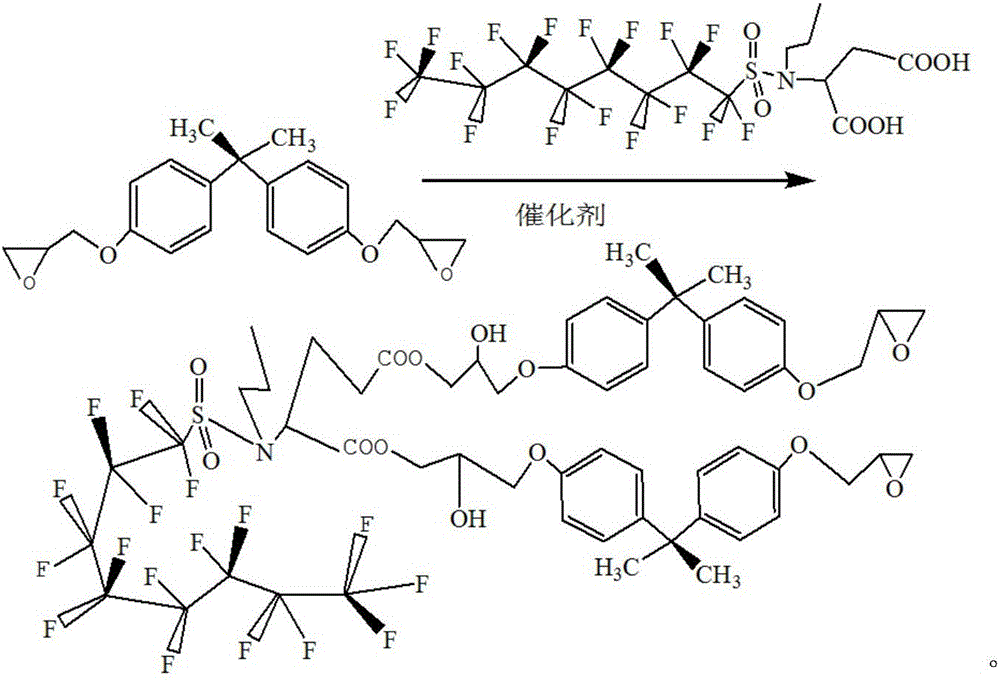

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of fluorine-modified polysiloxane graphene coating, its steps are as follows:

[0042] (1) Weigh 41.0 g of epoxy bisphenol A resin, 2.0 g of graphene, 1.0 g of KH560 coupling agent, and 10.0 g of glass flakes according to the proportioning ratio. After mixing, heat to 50° C. in a water bath for dissolution to obtain a mixed resin.

[0043] (2) Add 5.0g of phenyl glycidyl ether, 5.0g of fluorinated bisphenol glycidyl ether, 0.5g of fumed silica, 0.6g of BYK-190 dispersant, and 0.6g of BYK-331 leveling agent to the above mixed resin in sequence 0.3g of BYK-020 defoamer, 0.3g of BYK-020 defoamer, 3.2g of propylene glycol methyl ether, 0.8g of butylene phthalate, 30.0g of barium sulfate, and 6g of titanium dioxide; high-speed dispersion in a mixer at 2000r / min, after 30min , for grinding.

[0044] (3) Grinding to a fineness of 30 microns, and cooling down to room temperature naturally to obtain component A.

[0045] (4) Mix the cashew nut shell oil mo...

Embodiment 2

[0050] A preparation method of fluorine-modified polysiloxane graphene coating, its steps are as follows:

[0051] (1) Weigh 38.0 g of epoxy bisphenol A type epoxy resin, 2.0 g of graphene, 1.5 g of KH560 coupling agent, and 10.0 g of glass flakes according to the proportion, mix and heat to 55°C for dissolution to obtain a mixed resin.

[0052](2) Add 5.5g of phenyl glycidyl ether, 7.5g of fluorinated bisphenol glycidyl ether, 0.5g of fumed silica, 0.6g of BYK-190 dispersant, and 0.6g of BYK-331 leveling agent to the above mixed resin. 0.3g of BYK-020 antifoaming agent, 3.4g of propylene glycol methyl ether, 0.6g of butylene phthalate, 10g of aluminum tripolyphosphate, 5g of rutile titanium dioxide, and 15g of mica powder. Stir in a mixer at high speed Disperse at 2000r / min, and grind after 30min.

[0053] (3) Grinding to a fineness of 30 microns, and cooling down to room temperature naturally to obtain component A.

[0054] (4) Mix the cashew nut shell oil modified amine e...

Embodiment 3

[0057] A preparation method of fluorine-modified polysiloxane graphene coating, its steps are as follows:

[0058] (1) Weigh 40.0 g of epoxy bisphenol A type epoxy resin, 4.0 g of graphene, 1.5 g of KH560 coupling agent, and 11.0 g of glass flakes according to the proportion, mix and heat to 60°C for dissolution to obtain a mixed resin.

[0059] (2) Add 2.0g of butyl glycidyl ether, 6.0g of fluorinated bisphenol glycidyl ether, 0.5g of fumed silica, 0.6g of BYK-190 dispersant, and 0.6g of BYK-331 leveling agent to the above mixed resin. 0.3g of BYK-020 antifoaming agent, 0.3g of BYK-020 defoamer, 3.4g of propylene glycol methyl ether, 0.6g of butylene phthalate, and 32.5g of barium sulfate; high-speed stirring and dispersing in a mixer at 2000r / min, after 30min, grinding .

[0060] (3) Grinding to a fineness of 30 microns, and cooling down to room temperature naturally to obtain component A.

[0061] (4) Mix the cashew nut shell oil-modified amine epoxy curing agent of compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com