Preparation method for doped-element-free black oxide film of titanium surface

A black oxidation, non-doping technology, applied in the direction of surface reaction electrolytic coating, electrolytic coating, coating, etc., can solve the problems that affect the appearance and use of products, easily cause inhalation, percutaneous absorption, and difficult to prepare oxide film layers, etc. , to achieve the effects of low equipment and operating costs, good biocompatibility, and good economic applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Sand blasting treatment: refer to the conventional method, use sand with a certain mesh number to perform sand blasting treatment on the surface of the titanium parts, so that the surface roughness of the titanium parts is Ra≥0.4μm;

[0042] 2) Degreasing and cleaning: Use PWC-401 alkaline cleaning agent to ultrasonically clean the surface of the titanium parts after sandblasting at a cleaning temperature of 60-80 °C for 10-20 minutes to remove machining and cutting oils on the surface of the titanium parts ;

[0043] 3) Pickling: Use a mixed solution of 100-150ml / L hydrofluoric acid (concentration ≥ 40%) and 20-40ml / L nitric acid (concentration 65-68%) to clean the surface of the titanium parts after degreasing and cleaning. Bubbling pickling for 20-30s to remove surface oxides and achieve the purpose of uniform and activating the surface;

[0044] 4) DC anodizing treatment: at room temperature, place the pickled titanium piece in the anolyte, use it as an anode, a...

Embodiment 2

[0051] In this embodiment, the anolyte and the DC anodizing treatment are as follows:

[0052] The anolyte contains 3% formic acid, 2% acetic acid, 1g / 100ml citric acid, 4g / 100ml oxalic acid, 2g / 100ml salicylic acid, 1% hydrochloric acid, 2.5% nitric acid and 0.2g / 100ml manganese sulfate.

[0053] The method of DC anodizing treatment: initial voltage 10V treatment for 1min→15V treatment for 1min→20V treatment for 1min→25V treatment for 1min→30V treatment for 1min→35V treatment for 1min→40V treatment for 1min→45V treatment for 1min→50V treatment for 1min→55V treatment 1min→60V treatment for 1min→65V treatment for 1min→70V treatment for 1min→75V treatment for 1min→80V treatment for 1min→85V treatment for 1min→90V treatment for 1min→95V treatment for 1min→100V treatment for 1min→105V treatment for 1min→110V treatment for 1min→115V treatment for 1min→ 120V treatment for 1min; step-by-step boosting a total of 22 times, the cumulative voltage loading time is 23min.

[0054] All the...

Embodiment 3

[0059] In this embodiment, the anolyte and the DC anodizing treatment are as follows:

[0060] The anolyte contains 5% formic acid, 1% acetic acid, 3g / 100ml citric acid, 5g / 100ml oxalic acid, 1g / 100ml salicylic acid, 3% hydrochloric acid, 3% nitric acid and 0.1g / 100ml manganese sulfate.

[0061] The method of DC anodizing treatment: initial voltage 10V treatment for 2min→20V treatment for 2min→30V treatment for 2min→40V treatment for 2min→50V treatment for 2min→60V treatment for 2min→70V treatment for 2min→80V treatment for 2min→85V treatment for 2min→90V treatment 2min→95V treatment for 2min→100V treatment for 2min→105V treatment for 2min→110V treatment for 2min→120V treatment for 2min; a total of 14 times of step-by-step boosting, and the cumulative voltage loading time was 30min.

[0062] All the other are with embodiment 1.

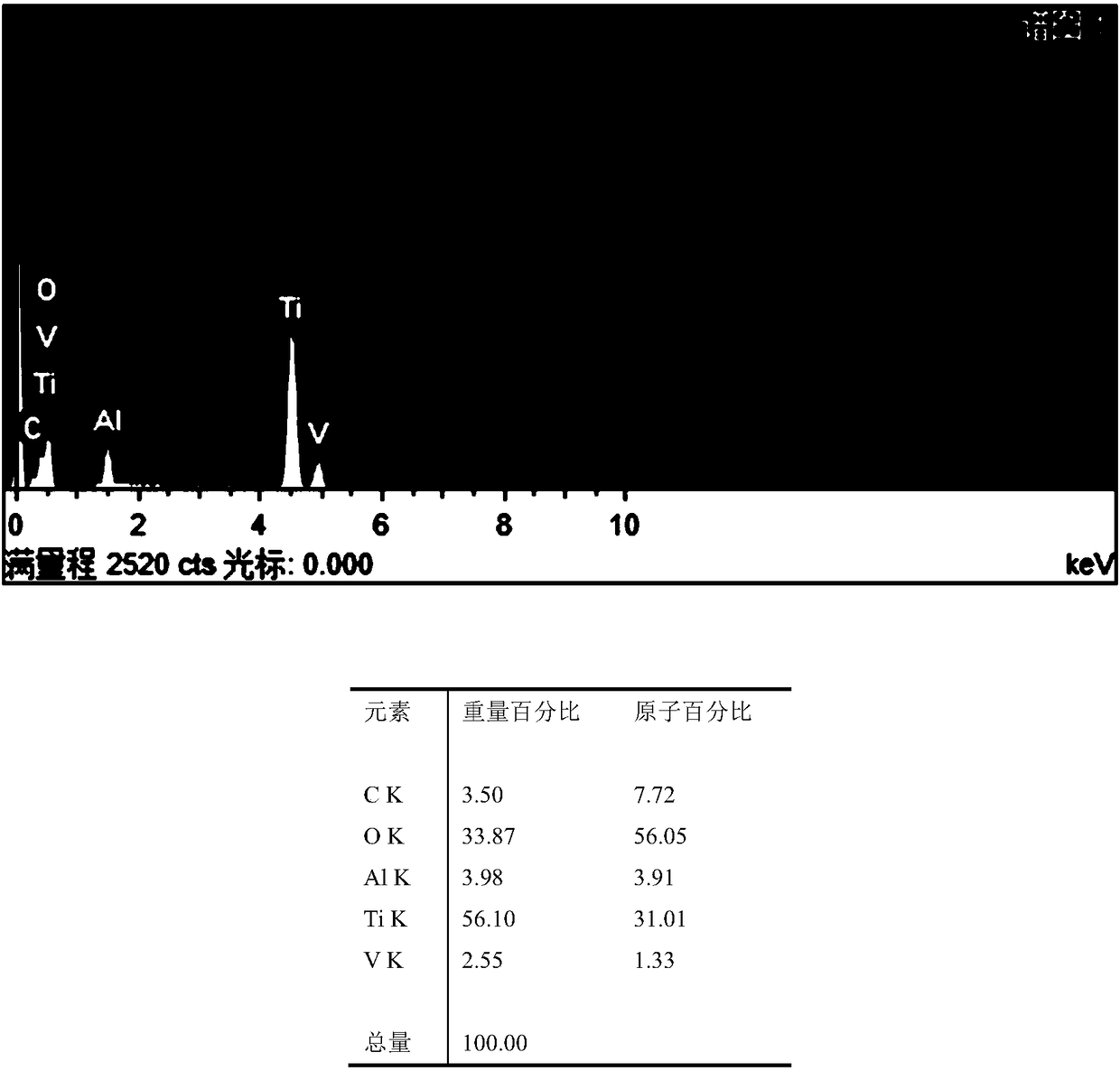

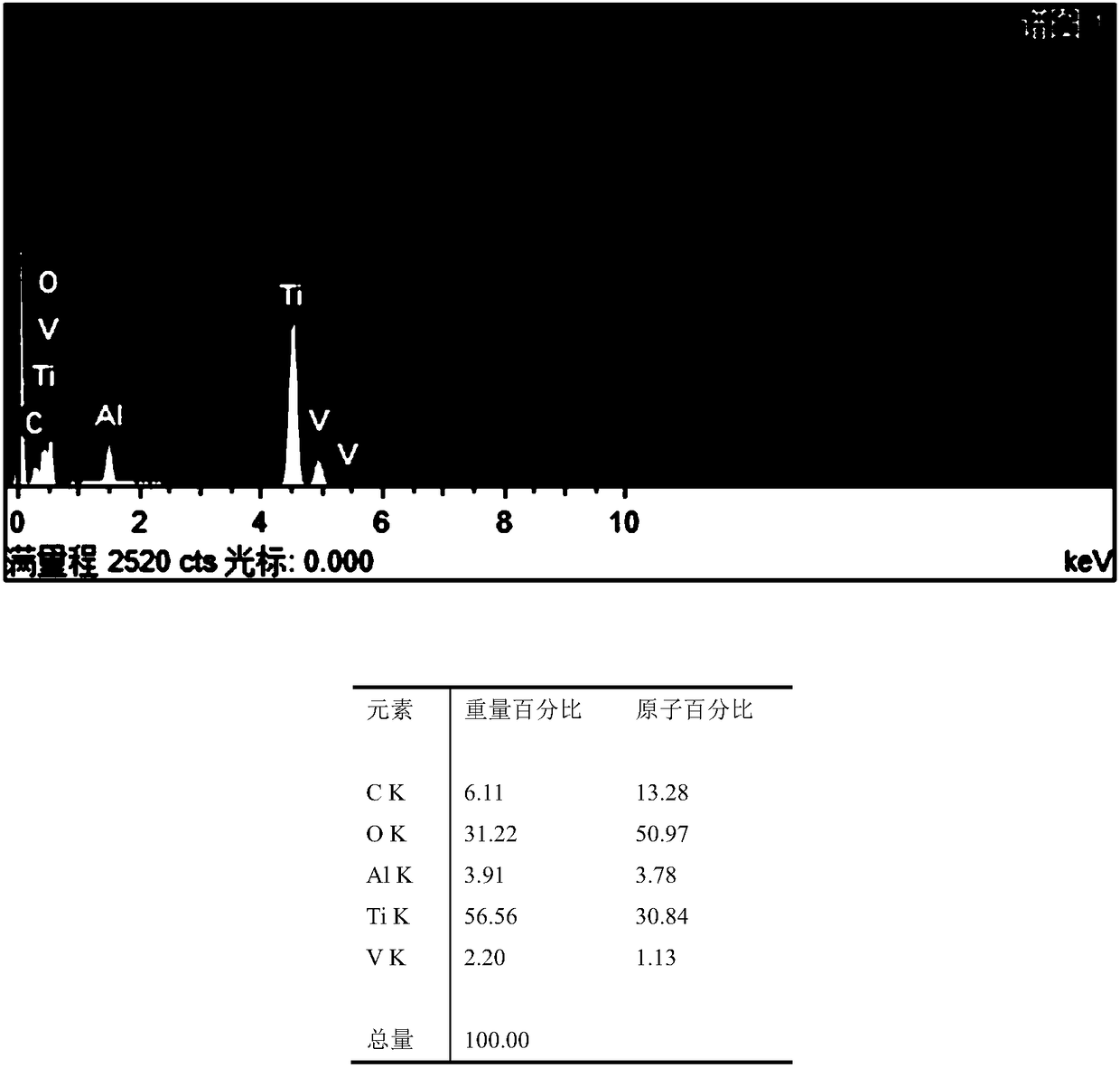

[0063] After the DC anodizing treatment is completed, a black sample is obtained, that is, a black oxide film without doping other elements is forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com