Phenolic resin modified ceramic diaphragm and application thereof

A technology of phenolic resin and ceramic diaphragm, applied in the field of electrochemistry, can solve the problems of positive and negative contact short circuit, application that cannot meet the high safety of the battery, and degradation of the mechanical properties of the diaphragm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Prepare the ceramic diaphragm:

[0055] 95 parts by mass of aluminum oxide inorganic powder with a particle diameter of about 300nm, 3 parts by mass of styrene-butadiene rubber, 2 parts by mass of sodium carboxymethyl cellulose, and the second solvent is a water / ethanol mixture with a volume ratio of 1:1 , prepared into a ceramic slurry with a solid content of 10%, coated on the surface of a single-layer commercial polyethylene (PE) diaphragm, and dried to remove the second solvent to obtain an aluminum oxide ceramic diaphragm.

[0056] Preparation of phenolic resin modified ceramic diaphragm:

[0057] In terms of weight percentage, the preparation contains 5% formaldehyde, 8% phenol, 1% sodium hydroxide, 0.5% barium hydroxide, 1.2% resorcinol, 0.13% sodium petroleum sulfonate, and 0.15% sodium cetyl sulfonate. % of the first solution of water / ethanol volume ratio 2:1. Soak the above aluminum oxide ceramic diaphragm in the mixed solution and react with 75°C for 1h, th...

Embodiment 2

[0059] Synthetic phenolic resin:

[0060] In terms of mass percentage, react a mixed solution containing 15% of acetaldehyde, 10% of phenol, 3% of hydrochloric acid, and 72% of solvent (volume ratio of water and isopropanol 1:2) at 65°C for 1.5h, and then at 95°C React for 5 hours, separate, wash and dry to obtain phenolic resin.

[0061] Preparation of phenolic resin modified ceramic diaphragm:

[0062]5 parts by mass of the phenolic resin synthesized above, 2 parts by mass of gelatin, 2 parts by mass of polyvinyl alcohol, 1 part by mass of hexamethyltetramine, 0.1 part by mass of toluenesulfonic acid, 0.1 part by mass of sodium dodecylbenzenesulfonate, 89.8 parts by mass of silicon dioxide with a particle diameter of about 200nm and water and isopropanol are formulated into a phenolic resin ceramic slurry with a solid content of 15% in a volume ratio of 1:1.5, and the above-mentioned phenolic resin ceramic slurry is coated on a single-layer surface of a commercial polyethy...

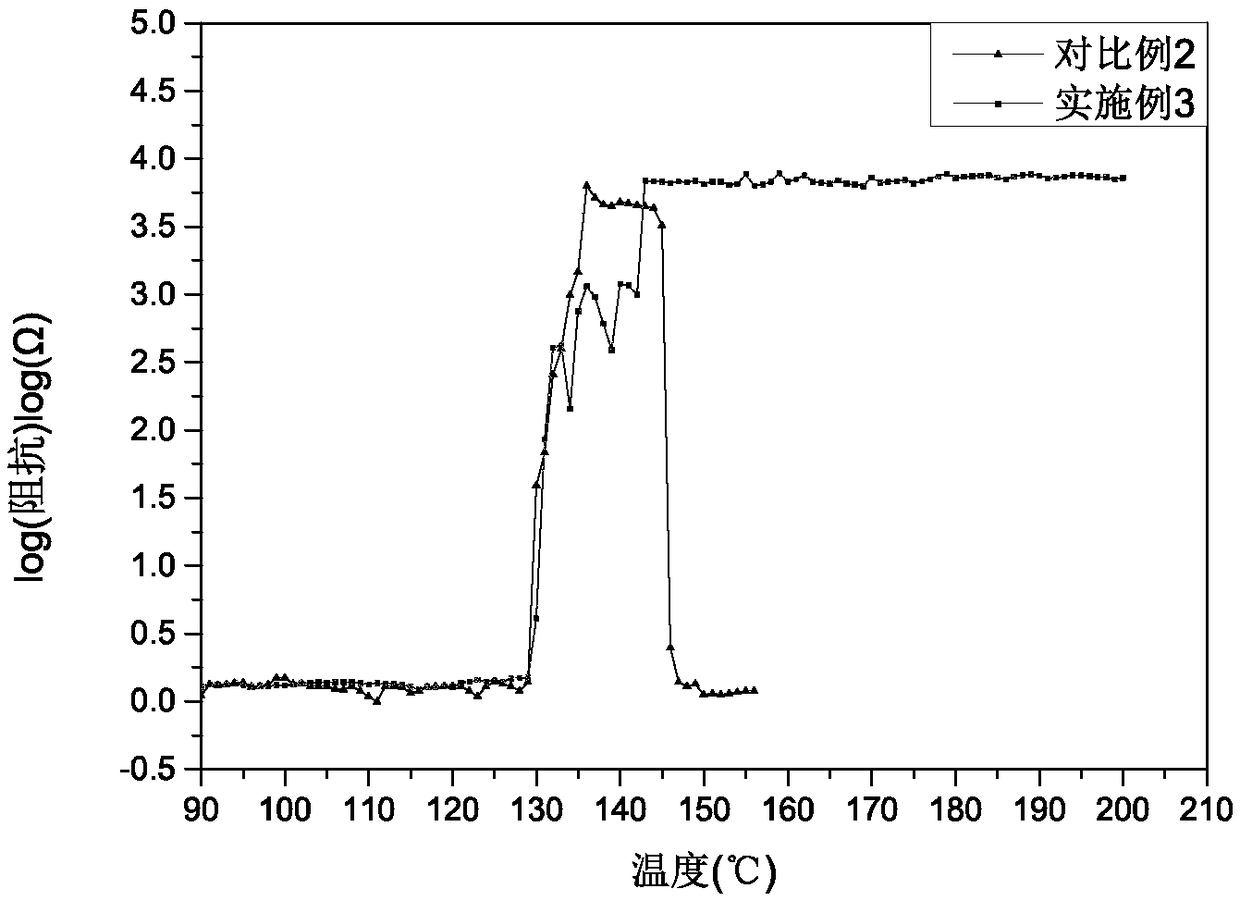

Embodiment 3

[0064] Prepare the ceramic diaphragm:

[0065] 90 parts by mass of magnesium oxide inorganic powder with a particle diameter of about 500nm, 5 parts by mass of styrene-butadiene rubber, 5 parts by mass of sodium carboxymethylcellulose, and the second solvent is a water / acetone mixture with a volume ratio of 2:1, and prepare A ceramic slurry with a solid content of 12% is coated on the double-layer surface of a commercially available polypropylene (PP) diaphragm, and dried to remove the second solvent to obtain a magnesium oxide ceramic diaphragm.

[0066] Preparation of phenolic resin modified ceramic diaphragm:

[0067] In terms of weight percentage, the preparation contains 6% furfural, 5% xylenol, 1% barium hydroxide, 0.5% calcium hydroxide, 1% resorcinol, 0.1% sodium petroleum sulfonate, cetyl sulfonic acid Sodium 0.1% Water / acetone 2:1 by volume as the second solvent. Soak the above-mentioned magnesium oxide ceramic diaphragm in the mixed solution and react with 65°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com