A kind of bifunctional catalyst for oxygen evolution and oxygen reduction reaction and preparation method thereof

A bifunctional catalyst, oxygen evolution technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc. The problems of large-scale preparation of cost and low bifunctional catalytic performance can achieve the effect of efficient bifunctional catalysis, high bifunctional catalytic performance and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

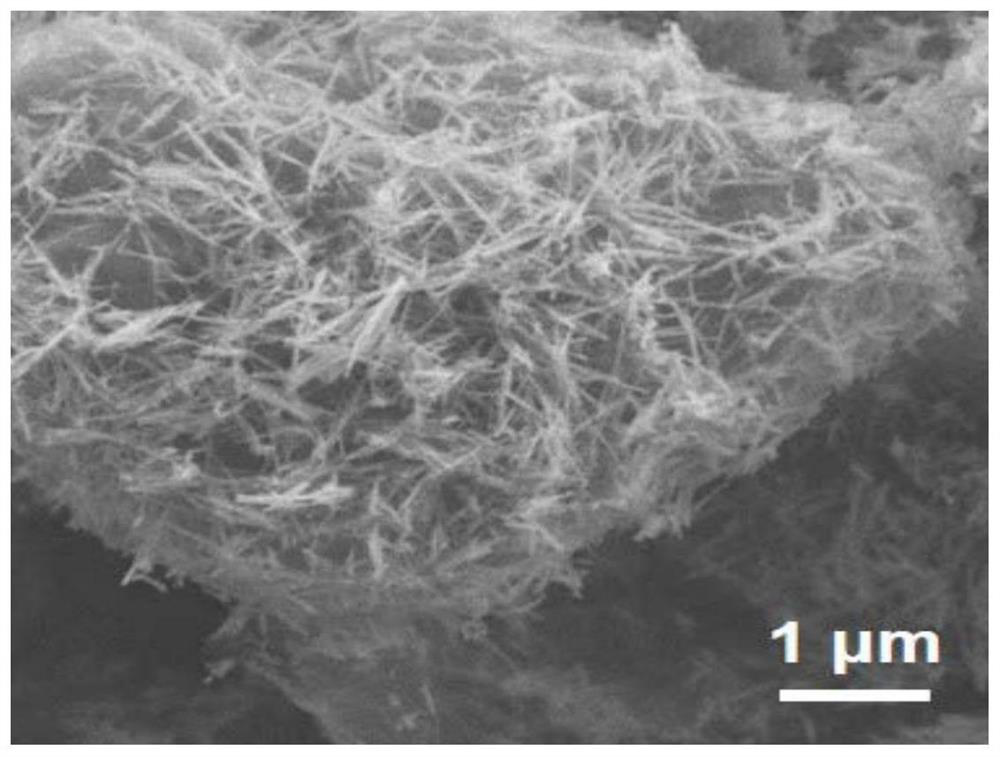

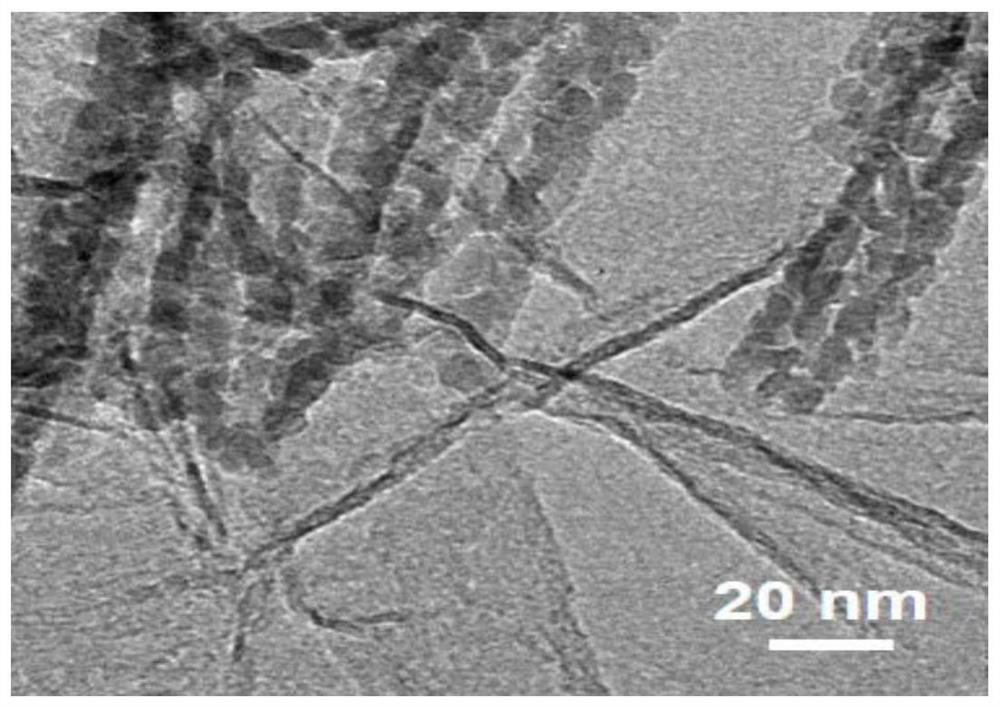

Image

Examples

preparation example Construction

[0026] A method for preparing a dual-functional catalyst for oxygen evolution and oxygen reduction reaction provided by the invention comprises the following steps:

[0027]1) Fully disperse the nano-carbon material, five-membered heterocyclic ring, polyaldehyde and complexing agent in an organic solvent, then add acid and oxidant and stir until mixed evenly, wherein the mass ratio of nano-carbon material to five-membered heterocyclic ring is 1 :1-10:1, the ratio of the amount of substance of the five-membered heterocycle and polyaldehyde is 1:0.1-1:10, the ratio of the amount of the substance of the five-membered heterocycle and the complexing agent is 1:0.5-1: 20; the nano-carbon material adopts one or more of graphite, graphene, carbon nanotube, carbon fiber and carbon black; the five-membered heterocycle is one or both of pyrrole, furan and thiophene; the The polyaldehyde is 3 carbons or more than 3 carbons, and has more than two aldehyde functional groups; the complexing ...

Embodiment 1

[0031] Example 1: Using graphene, pyrrole, and terephthalaldehyde as substrates to prepare bifunctional catalysts containing cobalt-iron oxides

[0032] 1) Add graphene, pyrrole, terephthalaldehyde and cobalt acetate to a 250mL flask, fully disperse in 50mL methanol, then add 5mL trifluoroacetic acid and 5mL nitrobenzene and stir for 5 minutes to mix evenly, wherein the mass of graphene and pyrrole The ratio of pyrrole and terephthalaldehyde is 1:1, the ratio of pyrrole and terephthalaldehyde is 1:0.1, and the ratio of pyrrole and cobalt acetate is 1:0.5;

[0033] 2) The mixture in the above step 1 was reacted at a temperature of 140° C. for 30 minutes. Naturally cool to room temperature after the reaction, filter the reacted product, wash with chloroform, and dry at 60°C to obtain an intermediate product of nitrogen porphyrin organic skeleton;

[0034] 3) Add the obtained nitrogen porphyrin organic skeleton intermediate product, cobalt nitrate, iron nitrate and urea in a 250...

Embodiment 2

[0036] Example 2: Using graphite, pyrrole, furan, and succinic dialdehyde as a substrate to prepare a bifunctional catalyst containing magnesium-aluminum hydroxide

[0037] 1) Add graphite, pyrrole, furan, succinic dialdehyde and manganese acetate to a 250mL flask, fully disperse in 50mL ethanol, then add 5mL formic acid and 5mL dinitrobenzene and stir for 5 minutes to mix evenly, wherein the mass ratio of graphite to pyrrole is 5:1, the ratio of the amount of substance of pyrrole and succinic dialdehyde is 1:1, the ratio of the amount of substance of pyrrole and manganese acetate is 1:5, and the ratio of the amount of substance of pyrrole and furan is 1:1;

[0038] 2) React the mixture in the above step 1 at a temperature of 40° C. for 1 hour. Naturally cool to room temperature after the reaction is completed, filter the reacted product, wash with chloroform, and dry at 80°C to obtain an intermediate product of an organic skeleton of oxygen porphyrin;

[0039] 3) Add the obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com