Lignocellulose-degrading composite microbial system and culture method and application thereof

A technology of lignocellulose and composite bacteria, applied in the direction of microorganism-based methods, methods using microorganisms, biochemical equipment and methods, etc., can solve problems such as low degradation speed and single microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

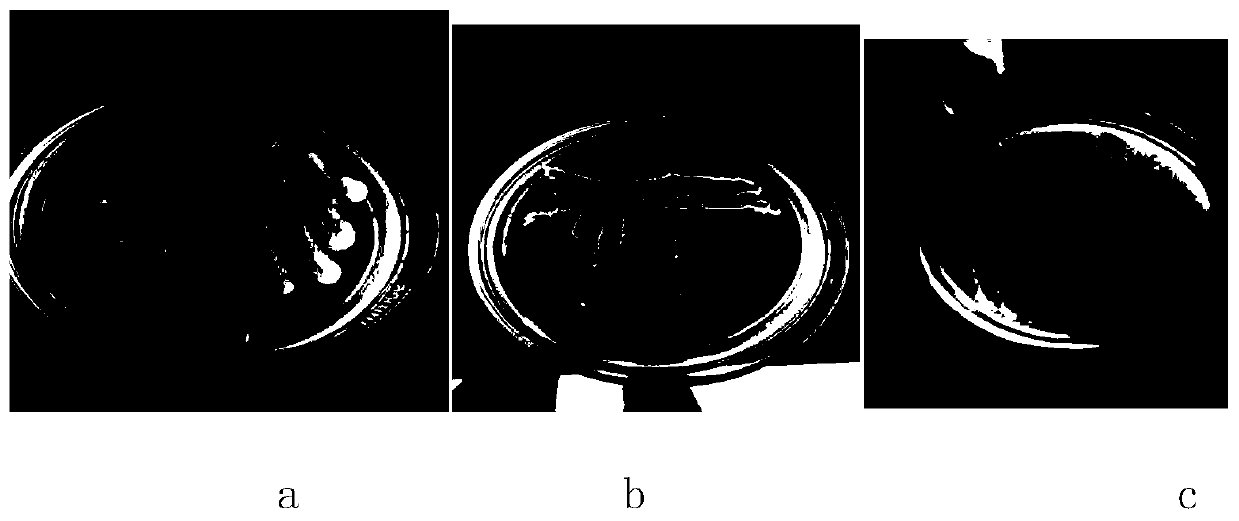

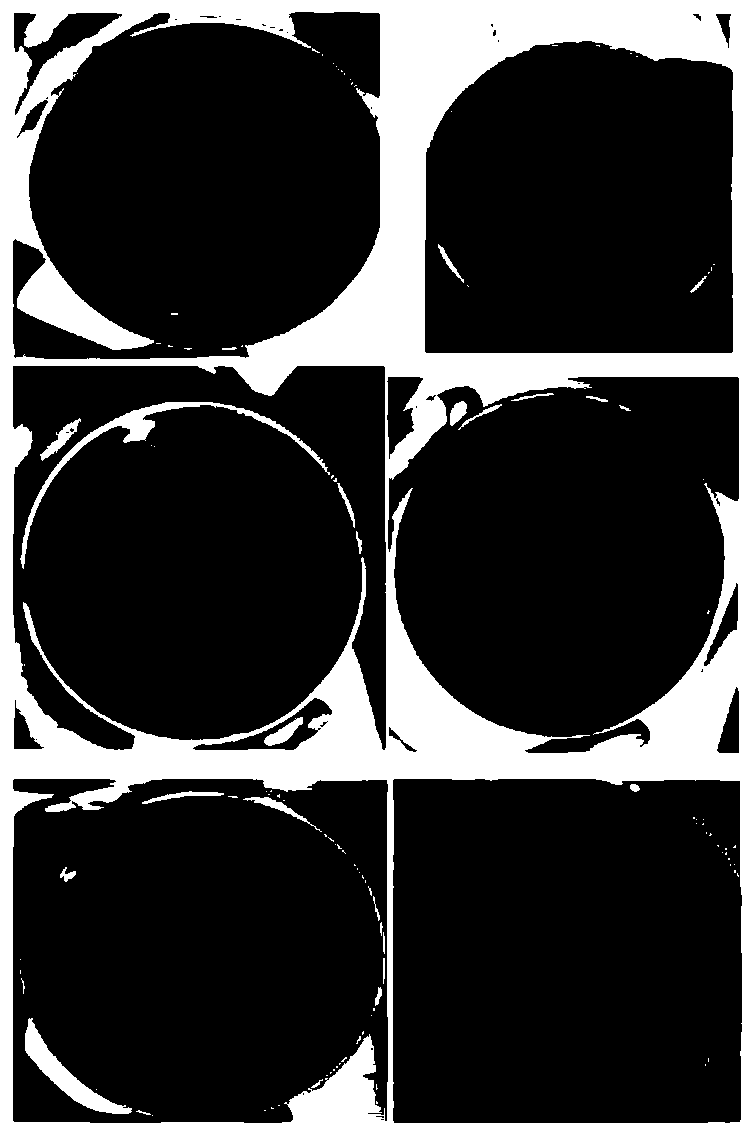

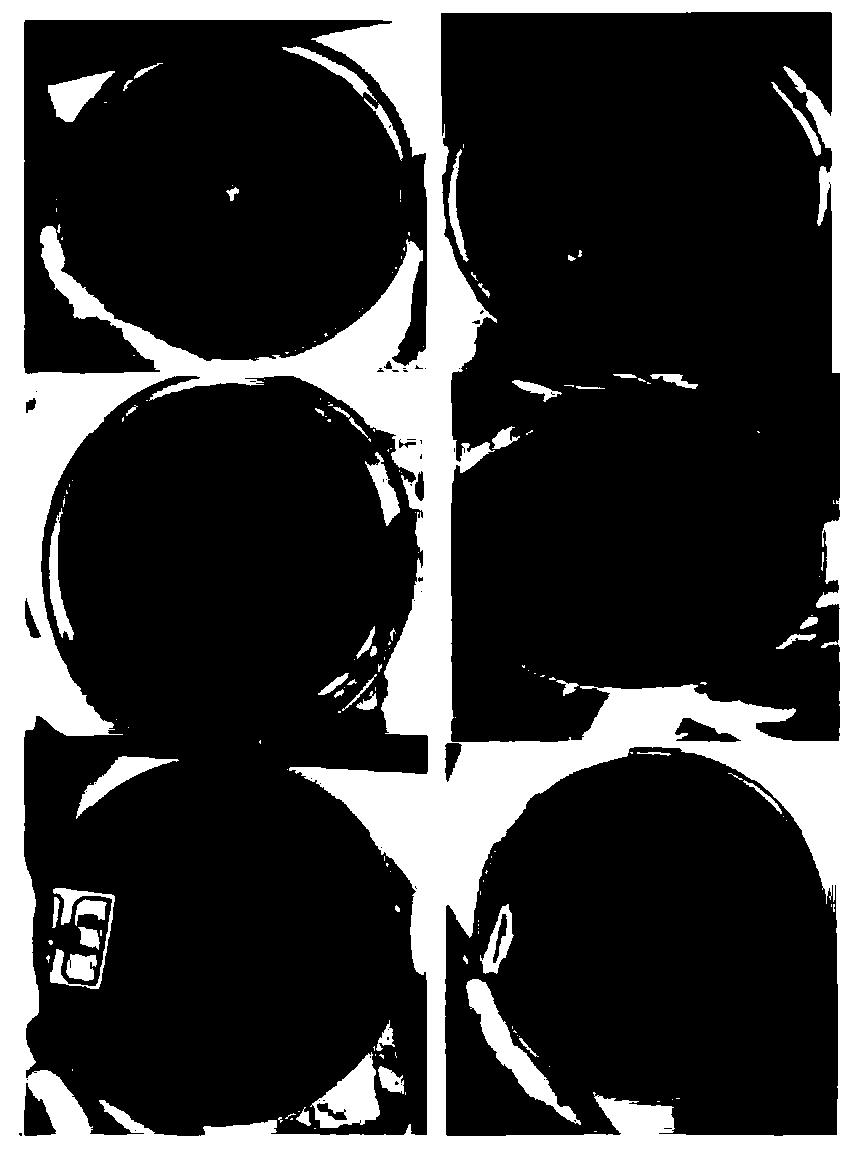

Image

Examples

Embodiment 1

[0131] This embodiment mainly involves the screening of highly efficient biomass cellulose degrading bacteria, and the construction of a composite bacterial system, mainly including:

[0132] 1. Test plan

[0133] 1.1 Sample processing and preliminary screening

[0134] 1.1.1, sample processing

[0135] Accurately weigh 10.0 g of the straw sample, add it into a 250 mL Erlenmeyer flask containing 90 mL of sterile saline and glass beads, shake it on a constant temperature shaker at 37 ° C, and mix the sample thoroughly for 3 hours for later use.

[0136] 1.1.2. Primary screening

[0137] a) Dilute the collected samples step by step 10 times with sterile water to 10 -6 、10 -7 and 10 -8 After doubling, take 0.1mL and spread it on the cellulose Congo red selective medium, repeat the coating on 3 plates for each concentration, culture at 28°C, observe regularly, and pick the strains with clear transparent circles around the colonies;

[0138] b) Purify the picked strains by st...

Embodiment 2

[0209] In this example, the complex bacterial strain constructed by the high-efficiency biomass cellulose degrading bacteria screened out in Example 1 is used to prepare the complex bacterial enzyme preparation, and the process flow is as follows Figure 11 As shown, it mainly includes the process of strain cultivation, fermentation process, extraction, separation and purification of enzymes, finished enzymes, testing and packaging.

[0210] Process operation points

[0211] 1. Bacteria culture

[0212] The compound strains of selected fungi, bacteria and actinomycetes are amplified and cultured on the corresponding medium. Specific steps:

[0213] 1.1) Clean the inclined surface with sterile physiological saline, shake well, put it into a sterile flask and shake well;

[0214] 1.2) Inoculate the oblique culture in the seed bottle, cultivate the bacteria at 30°C and 180r / rain for 12 hours to obtain the seed liquid, and cultivate the mold at 28°C and 220r / rain for 48 hours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com