Preparation of compound enzyme rich in acidic pectinase as well as strain and application of compound enzyme

A technology of acid pectinase and compound enzyme, which is applied in the field of compound enzyme, can solve the problem of single enzyme system, achieve the effect of reducing feed-to-egg ratio, increasing egg production rate, and good application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

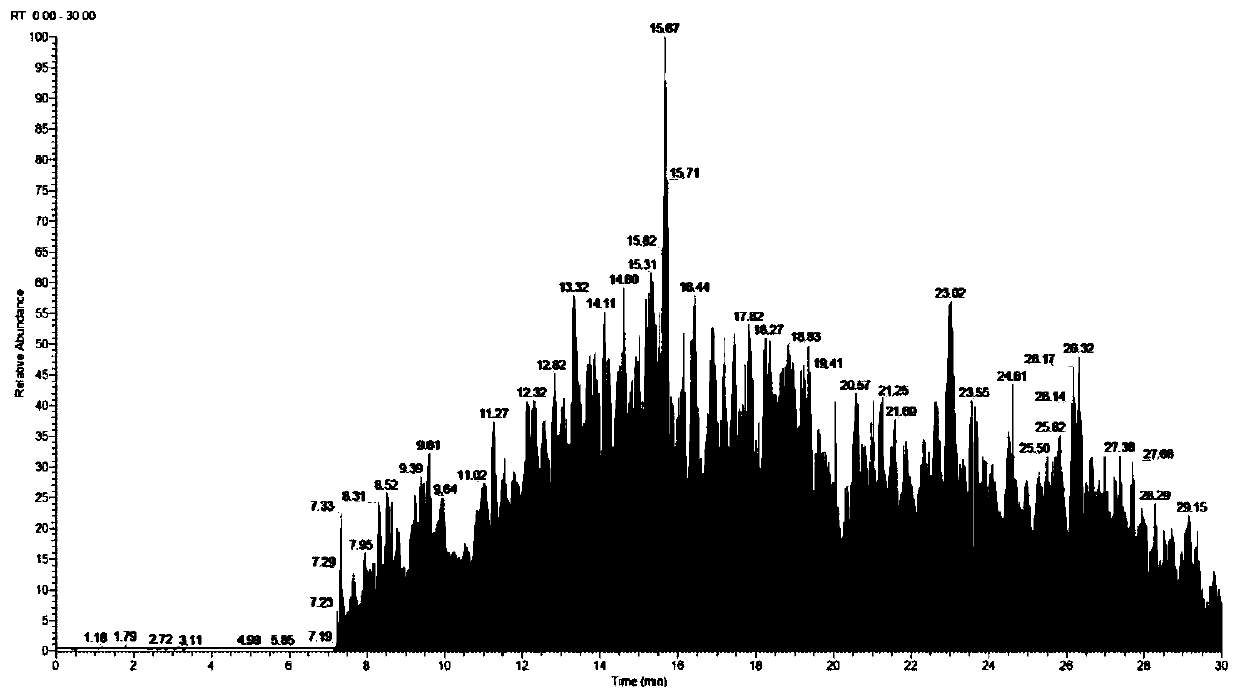

Image

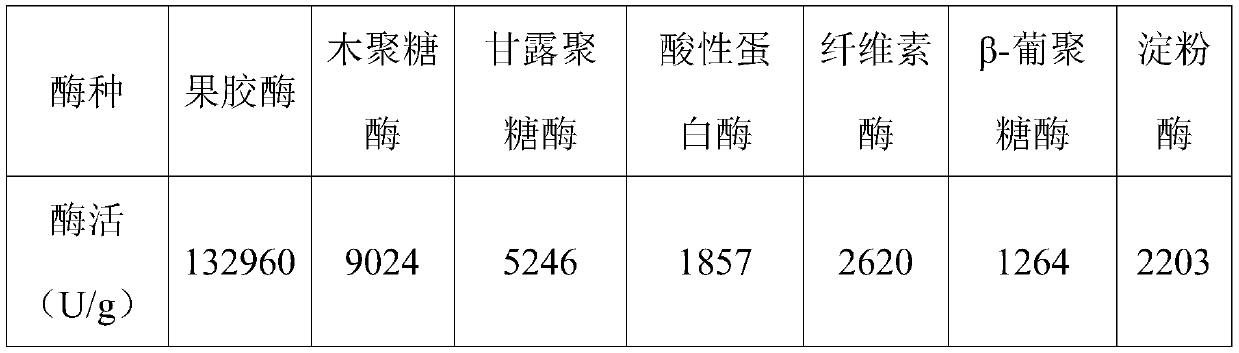

Examples

Embodiment 1

[0046] A preparation of a compound enzyme rich in acid pectinase, the specific preparation method is as follows:

[0047] 1 slant culture

[0048] Streak inoculation of Aspergillus niger BAK200345 on the slanted solid medium of the sterilized primary test tube, and culture at 25-35°C for 4-8d. Its culture medium is Cha's medium: 3% sucrose, 0.3% sodium nitrate, 0.1% dipotassium hydrogen phosphate, 0.05% magnesium sulfate, 0.05% potassium chloride, 0.001% ferrous sulfate, 1.2-1.8% agar powder, 121 Sterilize at ℃ for 20min.

[0049] 2 shake flask cultures

[0050] Scrape the first-stage test tube slant seeds obtained in step 1 of the 1-2 rings and culture them in the liquid medium of the second-stage shake flask, and the liquid volume of the shake flask is 100-150mL / bottle. Cultivate for 2-6 days at a temperature of 25-35° C. and a shaker rotation speed of 160-200 rpm to obtain a secondary shake flask seed liquid. The formula of the culture medium is: bran 2-6%, peptone 1-5%...

Embodiment 2

[0061] The slant medium in embodiment 1 is replaced with the following medium;

[0062] Glucose 2%, potato juice 20%, agar powder 1.2-1.8%, sterilized at 121°C for 20min.

[0063] or,

[0064] Bran juice 2-5%, beef extract 1-3%, peptone 0.5%-2%, dipotassium hydrogen phosphate 0.1-0.6%, magnesium sulfate 0.2-0.4%, agar powder 1.2-1.8%, sterilized at 121°C for 20min .

[0065] The rest of the conditions remain unchanged.

[0066] The solid medium in embodiment 1 is replaced with the following medium;

[0067] Bran 80-85%, soybean meal 5-10%, corn flour 5-10%, ammonium chloride 1-2%, magnesium sulfate 0.05%-0.1%, calcium carbonate 0.5%-1%, dipotassium hydrogen phosphate 0.2% -0.3%, initial moisture 60%-65%, sterilized at 121°C for 40min.

[0068] or,

[0069] Bran 80-90%, soybean meal 5-10%, palm meal powder 5-10%, ammonium sulfate 1-2%, magnesium sulfate 0.05%-0.1%, manganese sulfate 0.01-0.02%, calcium carbonate 1%-2% , Dipotassium hydrogen phosphate 0.2%-0.3%, initial m...

Embodiment 3

[0073] A preparation of a compound enzyme rich in acid pectinase, the specific preparation method is as follows:

[0074] 1 slant culture

[0075] Streak inoculation of Aspergillus niger strain CGMCC No.19614 on the slanted solid medium of the sterilized primary test tube, and culture at 25-35°C for 6-10d. Its culture medium is Cha's medium: 3% sucrose, 0.3% sodium nitrate, 0.1% dipotassium hydrogen phosphate, 0.05% magnesium sulfate, 0.05% potassium chloride, 0.001% ferrous sulfate, 1.2-1.8% agar powder, 121 Sterilize at ℃ for 20min.

[0076] 2 Erlenmeyer flask culture

[0077] In the ultra-clean workbench, scrape the slant spores of the primary test tube cultivated in step 1 into a glass bead bottle filled with 150-200mL sterile water (containing 100-500μL Tween-80), shake and mix well to make the spores fully Suspended in sterile water. Then inoculate 1-3mL / bottle of solid seeds on the solid medium of the secondary Erlenmeyer flask for cultivation. Cultivate at 28-35°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com