Nitride high-entropy ceramic fiber and preparation method and application thereof

A technology of ceramic fiber and nitride, applied in the field of nitride high-entropy ceramic fiber and its preparation, can solve the problems of high-entropy ceramic fiber without nitride, high-entropy ceramic without nitride, powder material easily falling off, etc. The effect of spinning efficiency, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] This example provides a general preparation method for high-entropy ceramic precursors, as follows:

[0056] (1) Obtain metal alkoxides: select transition metal alkoxides containing different types of elements. When M in the metal alkoxides is Hf, Nb, Ta or Mo, the alkoxides are prepared as follows: metal salt MCl n or M(NO 3 ) n Disperse in a solvent, add monohydric alcohol dropwise at -10~5°C, then drop triethylamine, heat to reflux for 1~5h after the dropwise addition, and filter to obtain metal alkoxide solution; among them, metal salt, monohydric alcohol and triethylamine The ratio of ethylamine is 1:(1~2)n:(1~1.5)n; the solvent is n-hexane, n-heptane, toluene, xylene, ethylene glycol dimethyl ether, ethylene glycol diethyl ether, One or more of tert-butyl methyl ether; the monohydric alcohol is selected from one of methanol, ethanol, isopropanol, n-propanol, n-butanol, isobutanol, ethylene glycol methyl ether, and ethylene glycol ether species or several;

[0...

Embodiment 2

[0066] In this embodiment, the following method is used to prepare nitride high-entropy ceramic fibers:

[0067] (1) Preparation of spinnable precursor solution: adopt the method described in Example 1 to prepare a carbide high-entropy ceramic precursor containing Ti, Hf, Ta, Nb, Mo, get 30 g of the high-entropy ceramic precursor, and polymerize Vinylpyrrolidone 10g, ethanol 150g, mixed and stirred to obtain a tan uniform solution;

[0068] (2) Spinning and collection: using compressed air as the gas source, the precursor solution obtained in step (1) is stretched into nanofibers by using an air spinning device, the spinning air pressure is 0.09MPa, and the feed rate is 30mL / h , the receiving distance is 40cm;

[0069] (3) Debinding: place the nanofiber cotton collected in step (2) in a heat treatment device, raise the temperature to 600°C at a heating rate of 1°C / min under a nitrogen atmosphere, and keep it warm for 2 hours to obtain debinding fibers ;

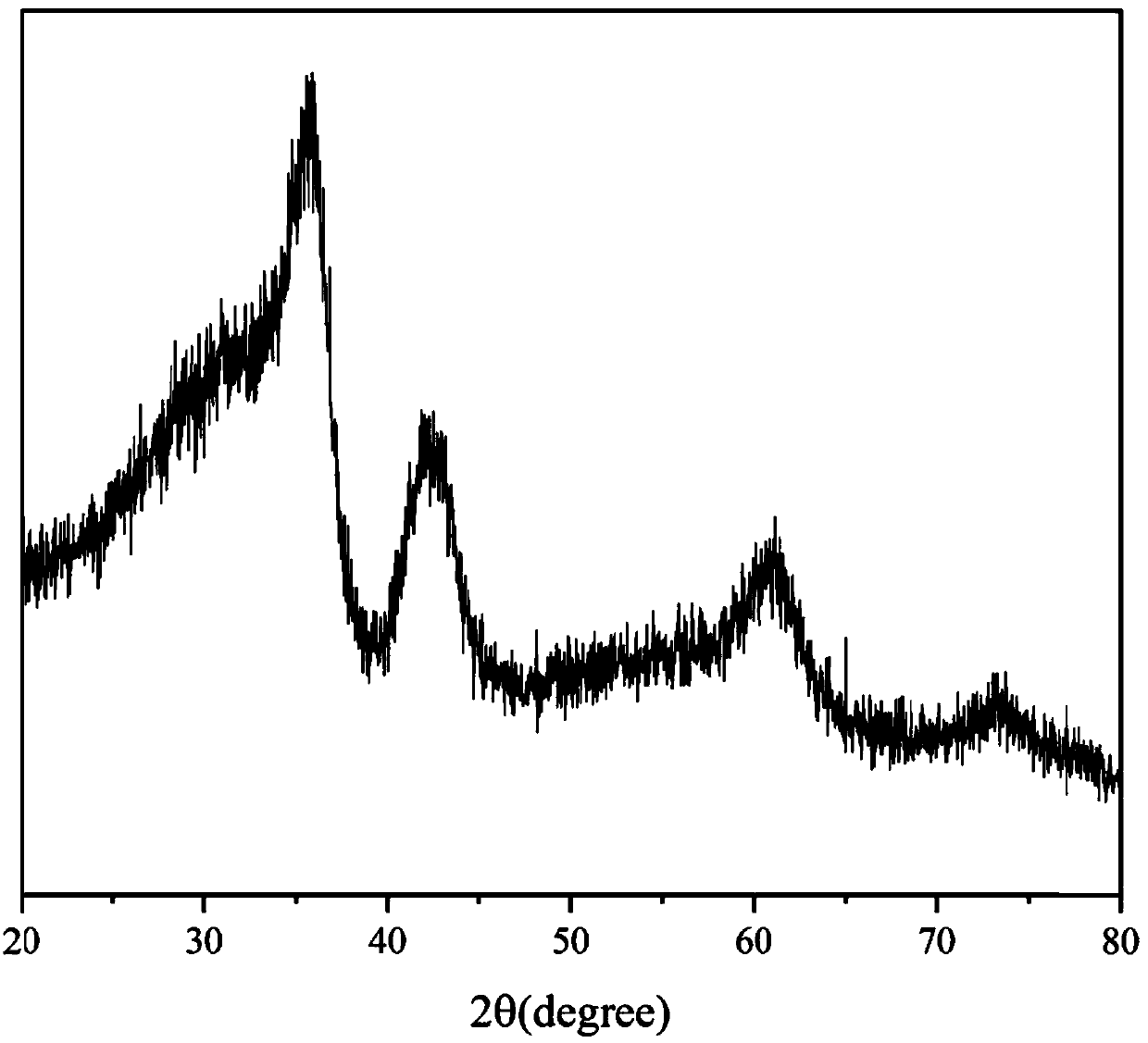

[0070](4) Nitridin...

Embodiment 3

[0073] In this embodiment, the following method is used to prepare nitride high-entropy ceramic fibers:

[0074] (1) Preparation of spinnable precursor solution: adopt the method described in Example 1 to prepare a carbide high-entropy ceramic precursor containing Ti, Hf, Ta, Nb, Mo, get 30 g of the high-entropy ceramic precursor, and polymerize Vinyl butyral 10g, n-propanol 285g, mixed and stirred to obtain a tan uniform solution;

[0075] (2) Spinning and collection: using compressed nitrogen as the gas source, the precursor solution obtained in step (1) was stretched into nanofibers by using an air spinning device, the spinning pressure was 0.06MPa, and the feed rate was 30mL / h , the receiving distance is 40cm;

[0076] (3) Debinding: place the nanofiber cotton collected in step (2) in a heat treatment device, raise the temperature to 600°C at a heating rate of 1.5°C / min under an argon atmosphere, and keep it warm for 2 hours to obtain debinding fiber;

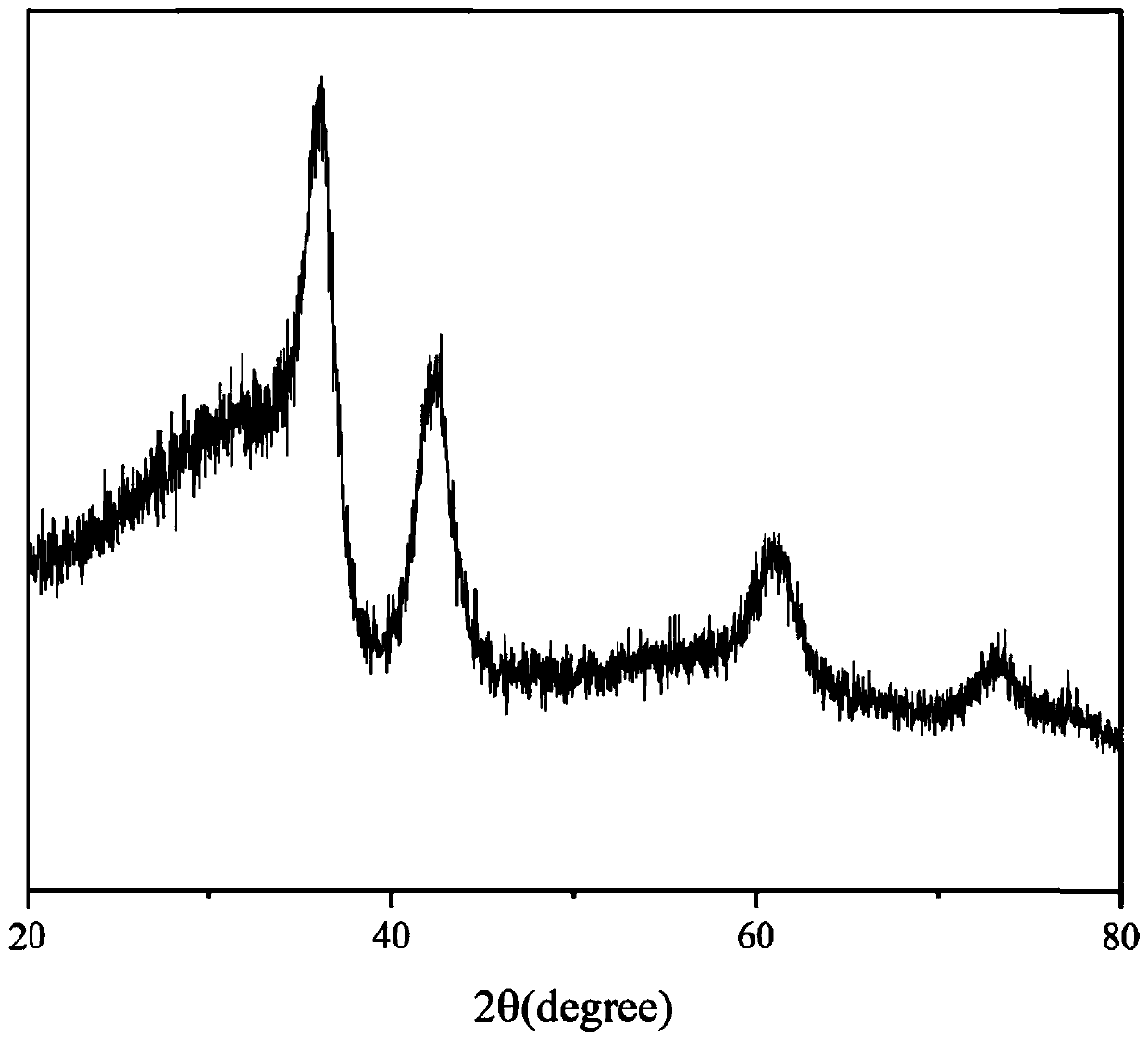

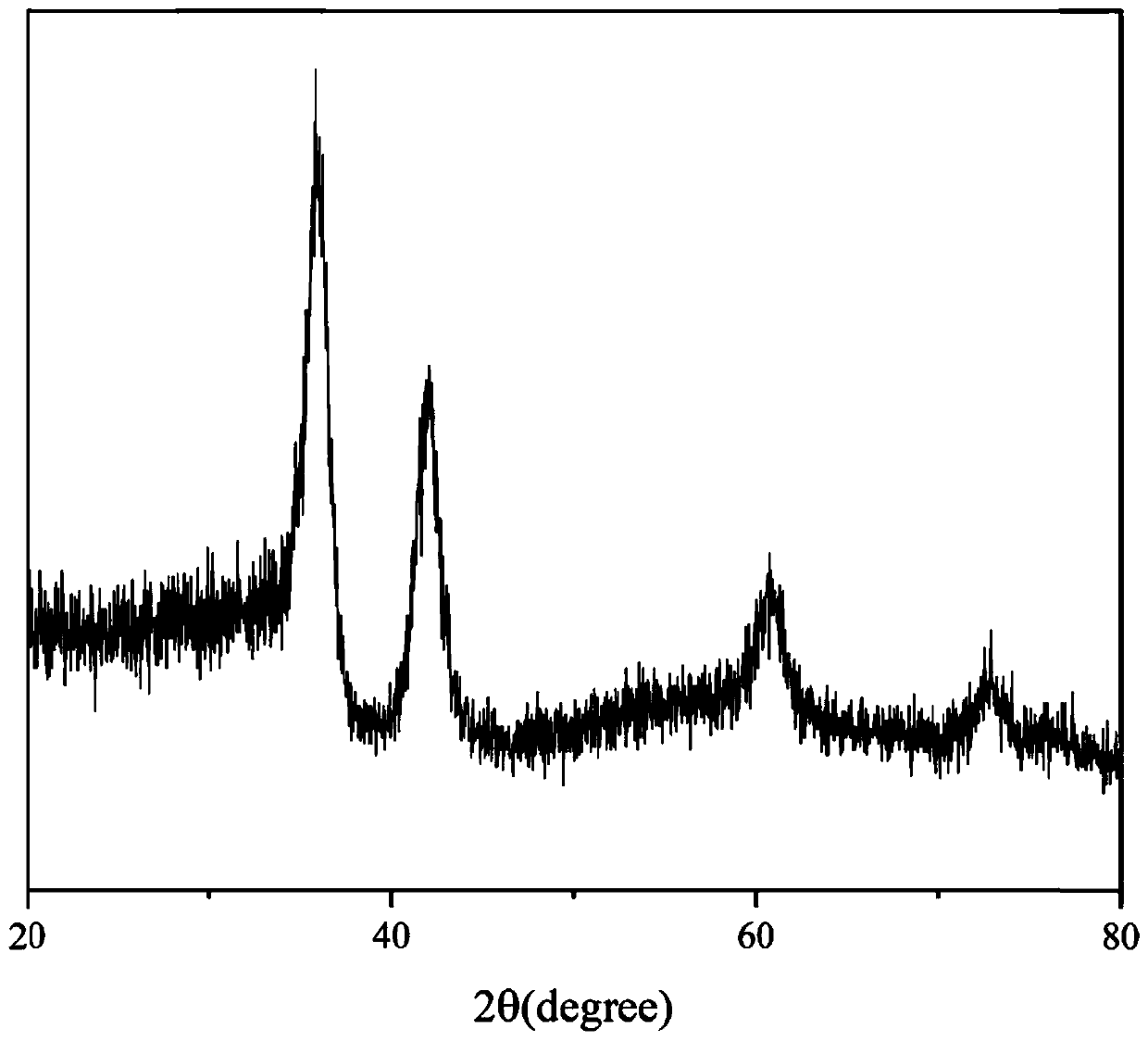

[0077] (4) Nitri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com