A kind of preparation method and application of porous carbon reinforced microbial hanging film carrier material

A film-hanging carrier and porous carbon technology, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problems of poor mechanical strength of immobilized particles, long time for microbial film-hanging, and low microbial fixation rate and other problems, to achieve the effects of metabolic activity, strong film resistance to impact load, rich charged atoms, and improved adsorption and mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

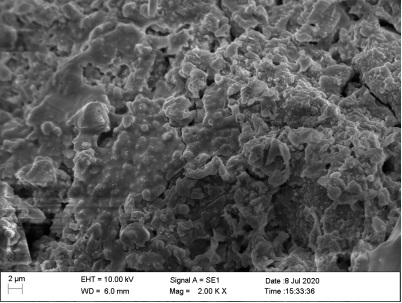

Image

Examples

Embodiment 1

[0042] Example 1 Preparation of Porous Carbon

[0043] 1) Put 1kg of rice straw biochar (10-20 mesh) into 10L hydrochloric acid solution of 0.1 mol / L, wash at 75℃ for 60min, wash until the eluate is neutral, and dry (drying temperature 103 ±2℃, time 4h) to obtain acidified rice straw biochar;

[0044] 2) Mix 1kg of acidified rice straw biochar, 100g of nano-montmorillonite, 100g of hydrated silicate, 50g of polyacrylamide and 300g of amino starch binder to obtain a premix;

[0045] 3) Put 0.3mol FeCl 3 ·6H 2 O, 0.1mol CaCl 2 , 0.2mol LaCl 3 ·7H 2 O is diluted with 110g solvent water and sprayed onto the surface of 100g premix, then the moisture content of the material system is adjusted to 45±2%, and then the material is transferred to the HTLAB high temperature and high pressure reactor (150℃, 6MPa, stirring speed 100r / min), carry out surface functional modification for 3 h, and obtain the surface-modified biomass charcoal;

[0046] 4) The surface-modified biomass car...

Embodiment 2

[0049] Example 2 Preparation of porous carbon microbial hanging film carrier material

[0050] In the reactors whose tops are not closed, the hanging film carrier materials (the FPB of the test group and the PB of the control group obtained in Example 1) were respectively added, and the input amount accounted for 4 / 5 of the total volume of the reactor, and activated sludge (this example) was inoculated. The medium activated sludge comes from the aerobic tank of the sewage treatment plant in Jingkou District, Zhenjiang, and the MLSS of the activated sludge is 5500 mg / L. In the specific implementation, aerobic activated sludge from other sources can also be used).

[0051] The dosage is 15g dry weight sludge per liter of porous carbon material. The porous carbon material is immersed in the activated sludge, injected into the reactor from the top through the nozzle, and the remaining activated sludge flowing out from the bottom is collected, introduced into the recovery tank, and ...

Embodiment 3

[0059] Example 3 Porous carbon hanging film carrier material acclimation of phosphorus-accumulating bacteria and nitrogen and phosphorus removal test in water

[0060]Take aquaculture wastewater as the test sewage, take 100 mL of aquaculture wastewater solution (ammonia nitrogen content is 20 mg / L, TP content is 10 mg / L), placed in a 150 mL conical flask, and 0.2 g of M obtained in Example 3 was added. -FPB (film hanging for 36h), acclimated for 14d at room temperature, 100mL solution of the same solute concentration was added to the system on the 2nd, 4th, 8th and 14th day, respectively, and the changes of ammonia nitrogen and TP content in the system solution were measured for different days. The test results are as follows Figure 4 shown.

[0061] The domestication refers to the enrichment and domestication of phosphorus-accumulating bacteria by using a conventional anaerobic-aerobic alternating environment (see the literature "Li Wei, Sun Huizhi, Wei Wei, et al. 2019, Dom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com