Advanced treatment method for PTA petrochemical wastewater

A petrochemical wastewater, advanced treatment technology, applied in the field of water treatment, can solve the problems of high operating cost, large amount of sludge, large amount of solid waste and hazardous waste, etc., to save land resources, increase calorific value, and occupy a small area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

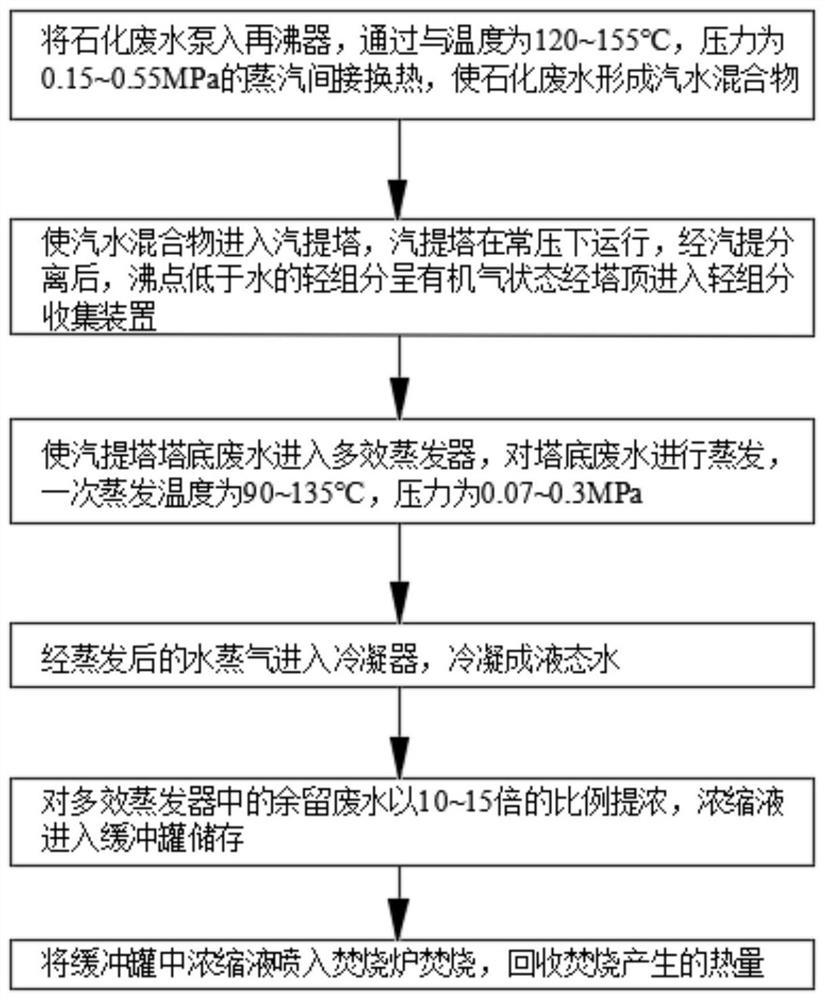

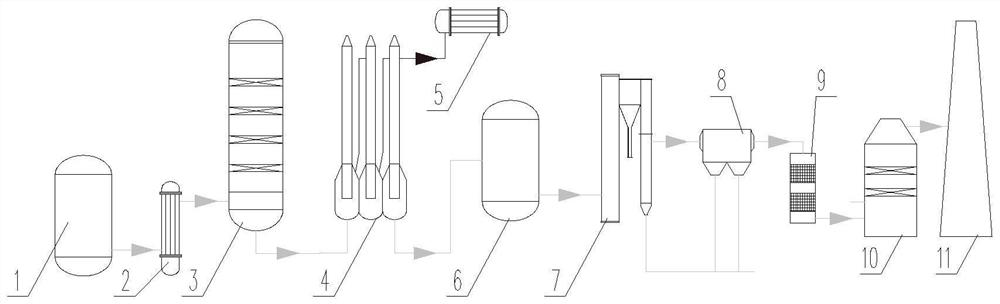

[0069] A method for advanced treatment of PTA petrochemical wastewater, combining Figure 1-3 , the specific implementation of the present invention will be described.

[0070] Put the petrochemical wastewater into the wastewater storage tank 1 for storage, and pump it into the reboiler 2. In the reboiler 2, the petrochemical wastewater passes through indirect heat exchange with steam at a temperature of 120~155°C and a pressure of 0.15~0.55MPa to become mixed with steam and water. Enter the stripper 3 after the state. In the stripping tower 3, after being stripped and separated, the light components with a boiling point lower than water are in the state of organic gas and enter the light component collection device through the top of the tower to realize recycling. The temperature at the top of the stripping tower was controlled at 50°C. The waste water in the bottom of the stripping tower 3 enters the multi-effect evaporator 4. The multi-effect evaporator 4 operates under ...

Embodiment 2

[0074] A method for advanced treatment of PTA petrochemical wastewater, combining figure 1 , 4 and 5, the specific implementation of the present invention is described.

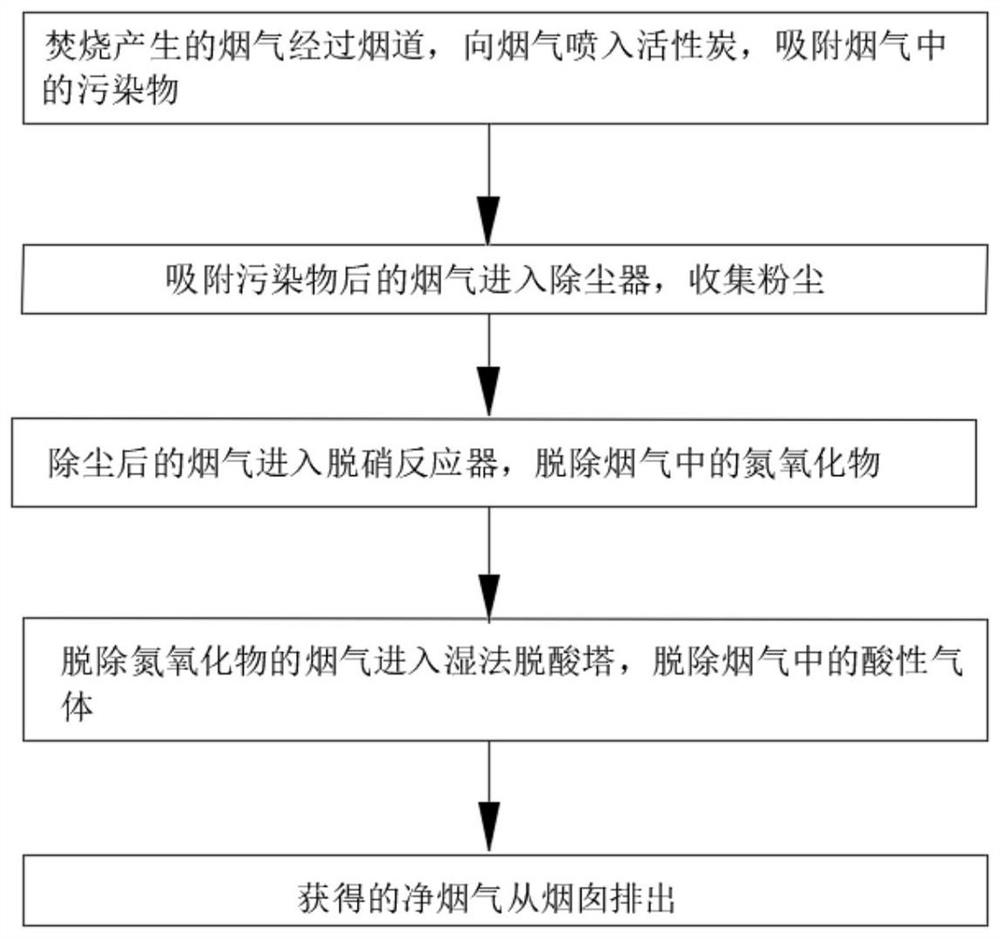

[0075] Process flow of incinerator 7 and before and figure 1 The same, but the difference is that the flue gas produced by incineration passes through the flue and is sprayed into activated carbon to absorb pollutants such as dioxin, cobalt, and mercury in the flue gas; the desulfurization agent sodium hydroxide is sprayed into the flue gas to remove acid gas. Then the flue gas enters the semi-dry deacidification tower 8, and the deacidification agent calcium hydroxide slurry is sprayed into the semi-dry deacidification tower 8. After removing the acid gas, the flue gas enters the dust collector 9 to collect dust. The flue gas after dust removal enters the denitrification reactor 10, and the nitrogen oxides in the flue gas are removed by low-temperature SCR reaction, and the clean flue gas that meets the e...

Embodiment 3

[0077] technical plan by Figure 1-5 During implementation, the incinerator used is a slurry fuel combustion method. According to the different components in the wastewater, this incinerator can be defined as an alkali incinerator and a hazardous waste incinerator. During the incineration process, it can simultaneously burn waste gas. Meet the requirements of various parameters in the incineration process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com