A kind of sugar chain polymer modified microsphere material and preparation method and application thereof

A technology of polymers and microspheres, which is applied in the analysis of materials, material separation, instruments, etc., can solve the problems of cumbersome steps, time-consuming, virus inactivation, etc., and achieve the advantages of easy enrichment or separation, effective capture of viruses, and avoiding hydrolysis Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] The present invention provides the preparation method of the sugar chain polymer modified microsphere material according to the technical solution, comprising the following steps:

[0077] Acrylamide, nitrogen-(4-trimethylsilyl-3-butyne) acrylamide and chain transfer agent are mixed, and RAFT polymerization is carried out under the action of an initiator to obtain acrylamide copolymer with silane-protected side chain alkynyl groups The chain transfer agent is an end-group biotin-functionalized trithioester chain transfer agent or an end-group desthiobiotin-functionalized trithioester chain transfer agent;

[0078] performing deprotection reaction on the acrylamide copolymer of the silane-protected side chain alkynyl group to obtain the acrylamide copolymer of the end group biotinylated side chain alkynyl group or the acrylamide copolymer of the dethiobiotinylated side chain alkynyl group;

[0079] The acrylamide copolymer of the end-group biotinylated side-chain alkynyl...

Embodiment 1

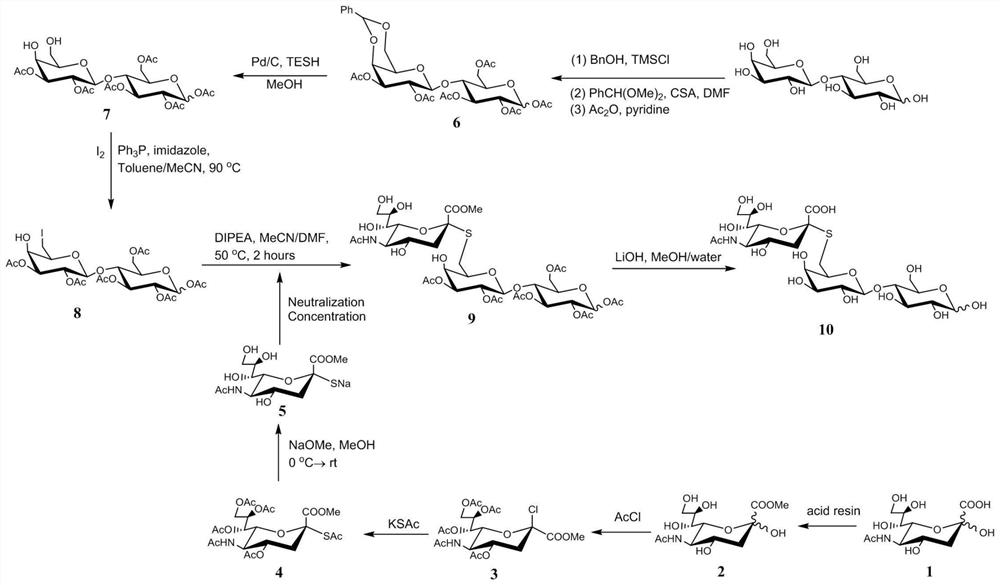

[0137] Non-natural sialic acid oligosaccharide S-6'-sialyllactose (ie, corresponding to the compound numbered No. 3 in Table 2) according to figure 1 The synthetic route shown is prepared, including the following steps:

[0138] Add acidic resin to the methanol solution (3 g / 100 mL) of sialic acid (compound 1) to control the pH value of the system at 3-5, stir at room temperature (25°C) until all dissolved, continue stirring overnight, and remove the acidic resin by filtration , the obtained filtrate was concentrated to obtain compound 2;

[0139] In an ice-water bath (0°C), compound 2 (2.0g), acetyl chloride (20mL), methanol (3mL) and acetic acid (10mL) were added to the pressure vessel, and the reaction was sealed and stirred for 36h at room temperature; the resulting product system was Concentrate to obtain compound 3;

[0140] The obtained compound 3 was dissolved in dry dichloromethane (30 mL), then potassium thioacetate (4 g) was added, and the mixture was stirred over...

Embodiment 2

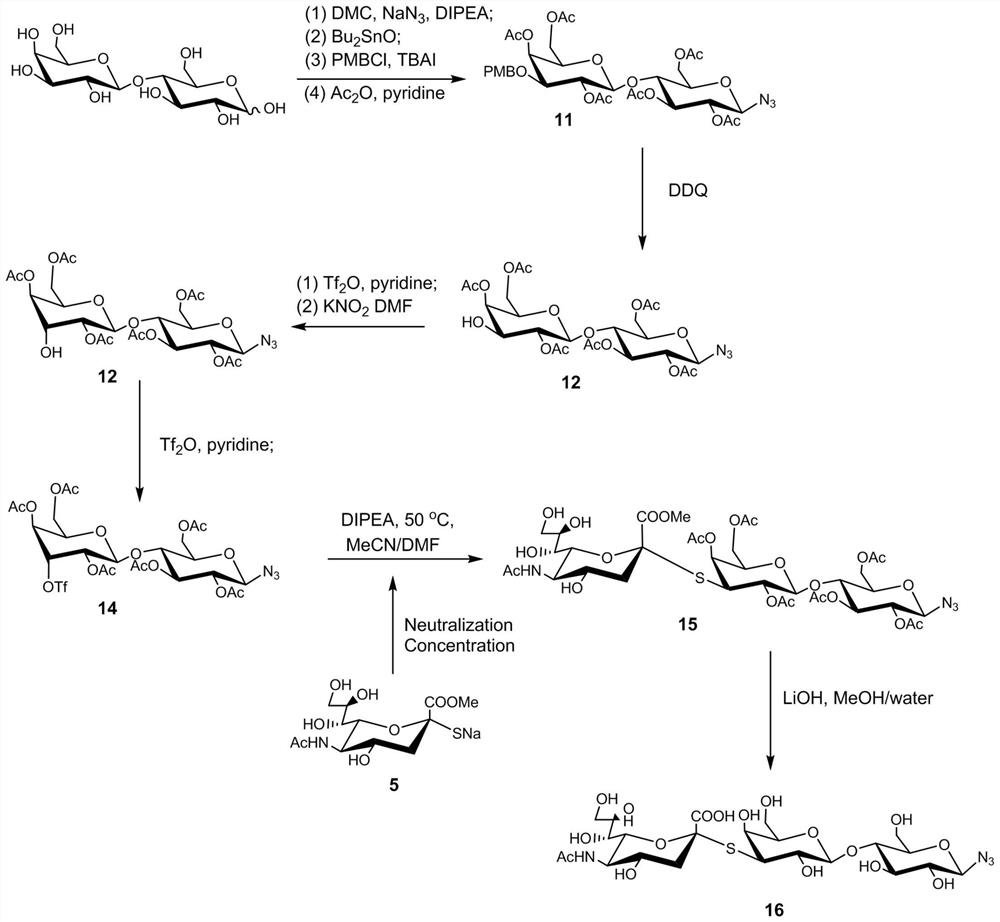

[0148] Reducing terminal azide sialic acid oligosaccharide was prepared based on sialyllactose (specifically, the compound No. 1 in Table 2, the compound No. 5 or the compound No. 3 prepared in Example 1) was prepared , including the following steps:

[0149] Sialyl lactose (0.65 g), 2-chloro-1,3-dimethylimidazolinium chloride (DMC, 0.52 g), triethylamine (2.0 mL) and sodium azide (0.67 g) were mixed, Under the condition of ice-water bath (0°C), the azide reaction of the water-phase end group was carried out for 1.5 h to introduce the azide group at the reducing end of sialyllactose; the obtained product system was concentrated, and the obtained residue was mixed with N,N- Dimethylformamide (20 mL) was mixed, and unreacted sodium azide was removed by filtration; the filtrate was concentrated, the obtained residue was dissolved in water (20 mL), the obtained system was washed with dichloromethane, and the aqueous phase was collected, Purified by cation exchange resin (IR-120) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com