Bioactive shell-core multiplelayer microstructure nanometer powder and its preparation method

A bioactive, nano-powder technology, applied in prosthesis, medical science and other directions, can solve the problems of poor biological activity, long time for bone defect regeneration and repair, unstable bioactive factors, etc. It is easy to achieve nanometer size and layer structure. The effect of easy control of release rate and excellent safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

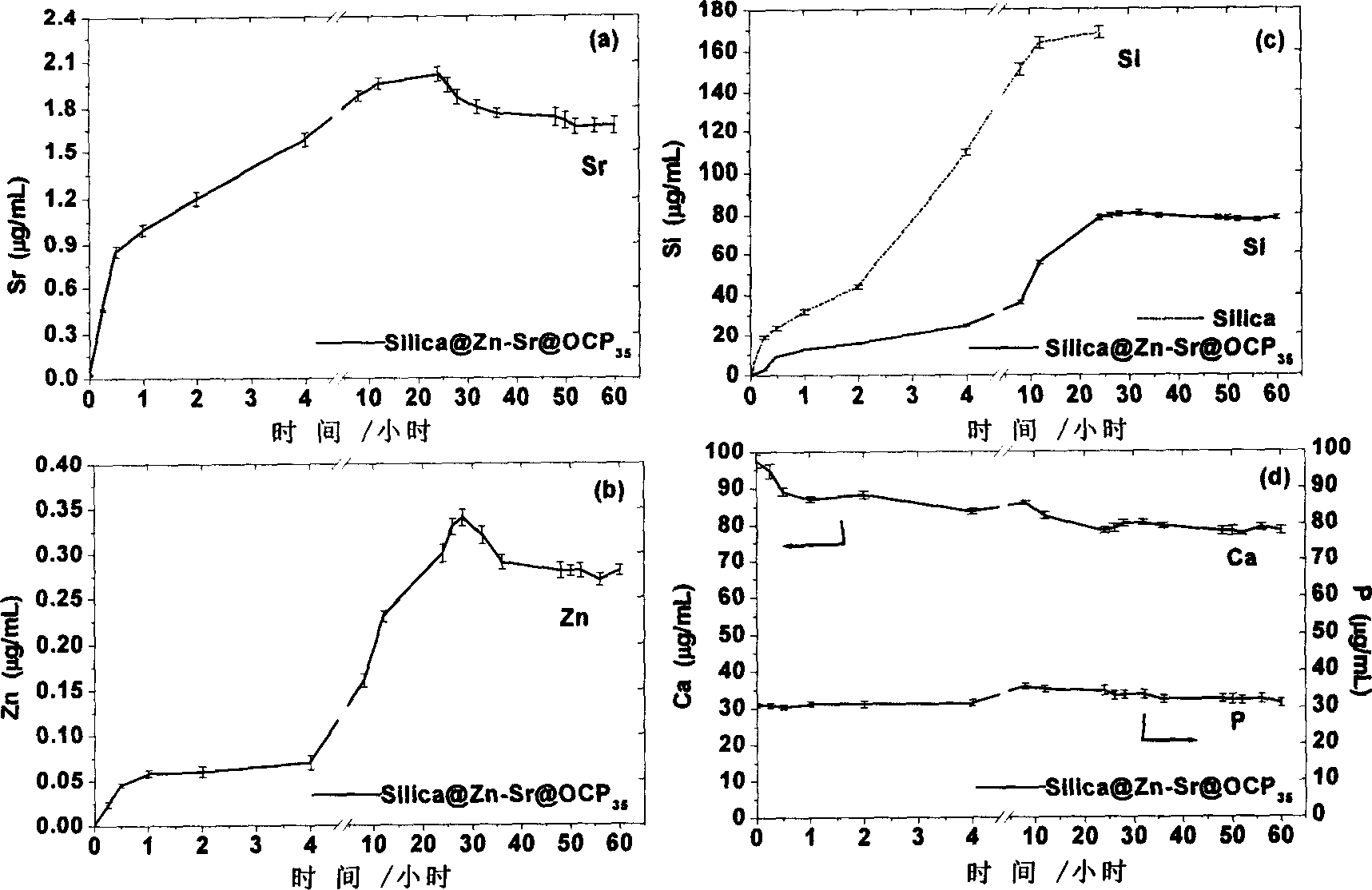

[0036] Example 1 Preparation of Silica@Zn-Sr@OCP 35 Nano powder

[0037] (1) Preparation of gel nanosphere powder:

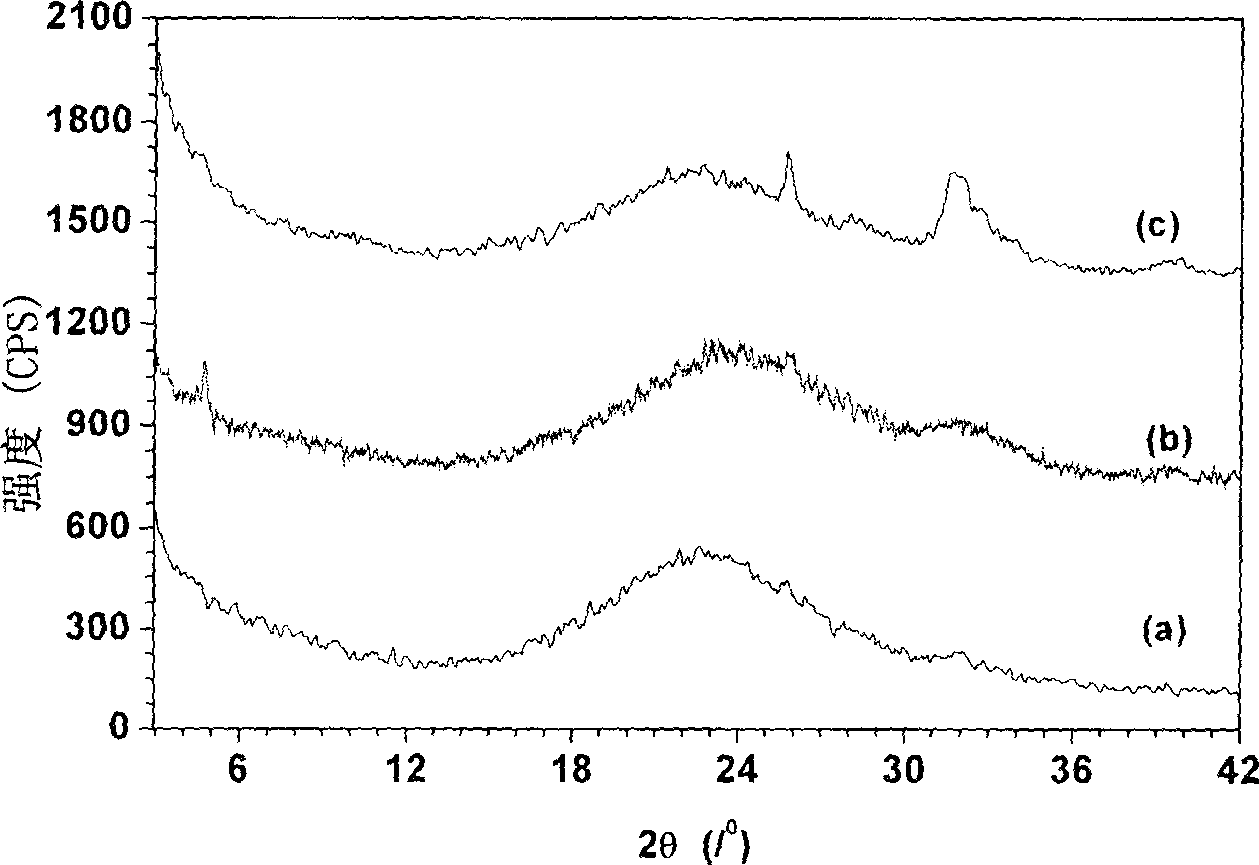

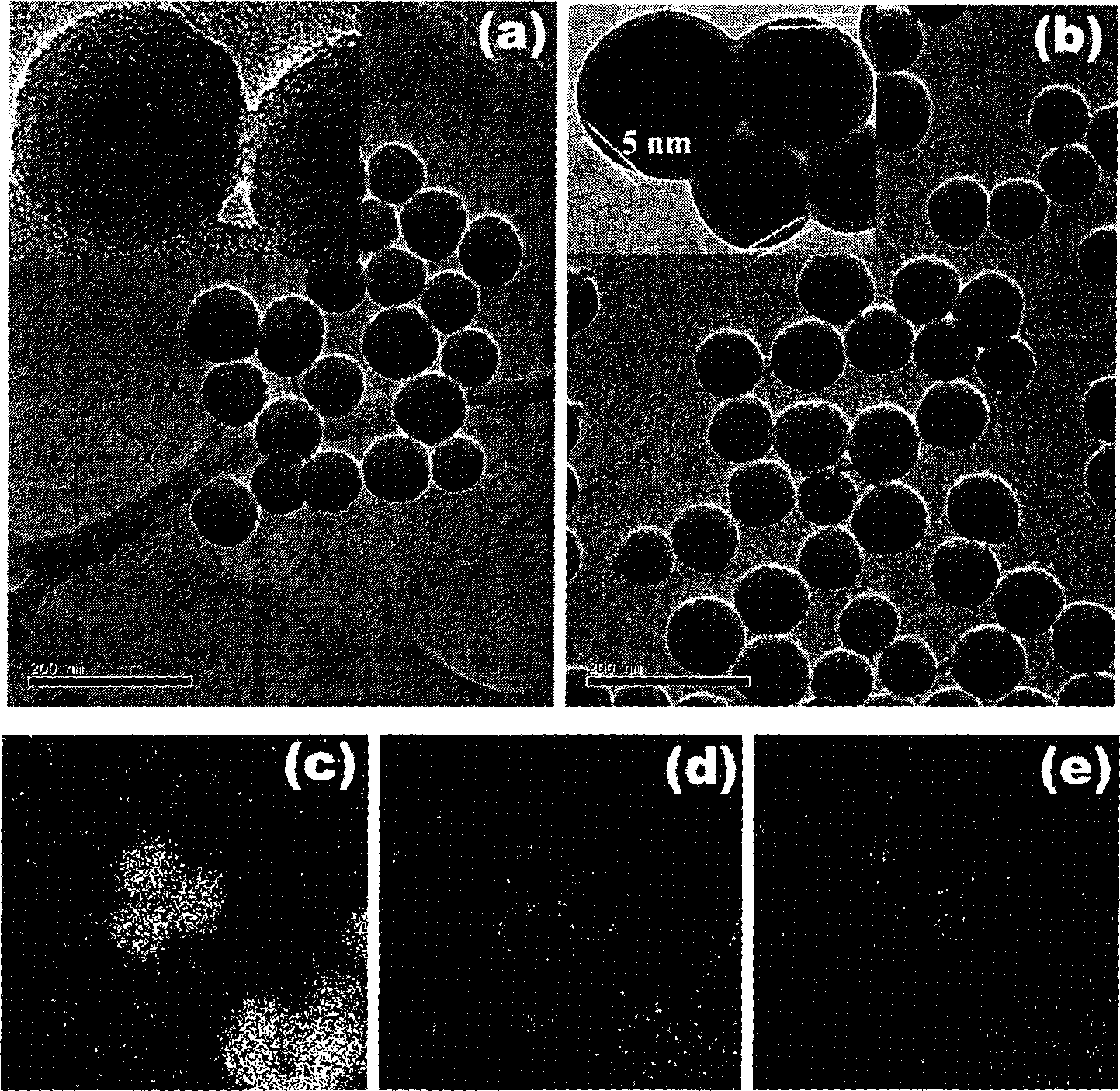

[0038] In 17.8mL absolute ethanol medium, add 0.72mL ammonia water and 0.58mL deionized water successively under the condition of magnetic stirring, then add 0.9mL tetraethyl orthosilicate to the above mixed solution, and put the silica sol solution at 25°C Stirring was continued for 6 hours. Then, adopt centrifugal filtration method (4000rpm) to carry out solid-liquid separation, ultrasonically disperse and wash with deionized water, and centrifuge again to remove unhydrolyzed and polymerized silica sol, and dry under vacuum at 60°C for 24 hours to obtain silica gel nanospheres ( Such as figure 1 a spectrum and figure 2 a photo).

[0039] (2) Gel nanosphere layer-layer assembly of zinc and strontium ions:

[0040] Add 240mg of silica gel nanospheres to 5.0mL of ionized water, ultrasonically disperse, add 200mL of zinc nitrate aqueous solution with a conc...

Embodiment 2

[0043] Example 2 Preparation of Silica@Zn@OCP 40 Nano powder

[0044] (1) Preparation of gel nanosphere powder:

[0045] Operate with step (1) in Example 1.

[0046] (2) Gel nanosphere layer-layer assembly of zinc ions:

[0047] Add 120mg of Silica nanospheres to 2.5mL of ionized water, ultrasonically disperse, add 100mL of zinc nitrate aqueous solution with a concentration of 5mmol / L, adjust the pH value to 8.2, and stir rapidly for 6 hours. Zinc ions are adsorbed on the surface of Silica nanospheres, and centrifugally filtered. Then, add the nano-powder with zinc ions adsorbed to 5mL of absolute ethanol medium, ultrasonically disperse, add 0.2mL of ammonia water, 0.2mL of deionized water and 0.08mL of ethyl orthosilicate under the condition of magnetic stirring, and the The suspension was stirred at 35°C for 6 hours, and filtered by centrifugation. Repeat the above steps for adsorption and wrapping three times to obtain multilayer nanospheres with zinc ions wrapped in si...

Embodiment 3

[0050] Example 3 Preparation of Silica@Sr@OCP 40 Nano powder

[0051] (1) Preparation of gel nanosphere powder:

[0052] Operate with step (1) in Example 1.

[0053] (2) Preparation of gel nanosphere layer-layer assembly of strontium ions and Silica@Sr@OCP:

[0054]Zinc nitrate aqueous solution is changed into strontium nitrate aqueous solution in the embodiment 2 step (2), and the adjustment pH value is 8.2 and the adjustment pH value is 9.6 instead, and other operations are with step (2) and (3) in the embodiment 2, can Preparation of bioactive nanopowder Silica@Sr@OCP which is coated with hydrated calcium hydrogen phosphate and encapsulated silica gel nanospheres and assembled with strontium ions 40 (40 represents the molar ratio of Silica to OCP).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com