Patents

Literature

60 results about "Pixel value differencing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

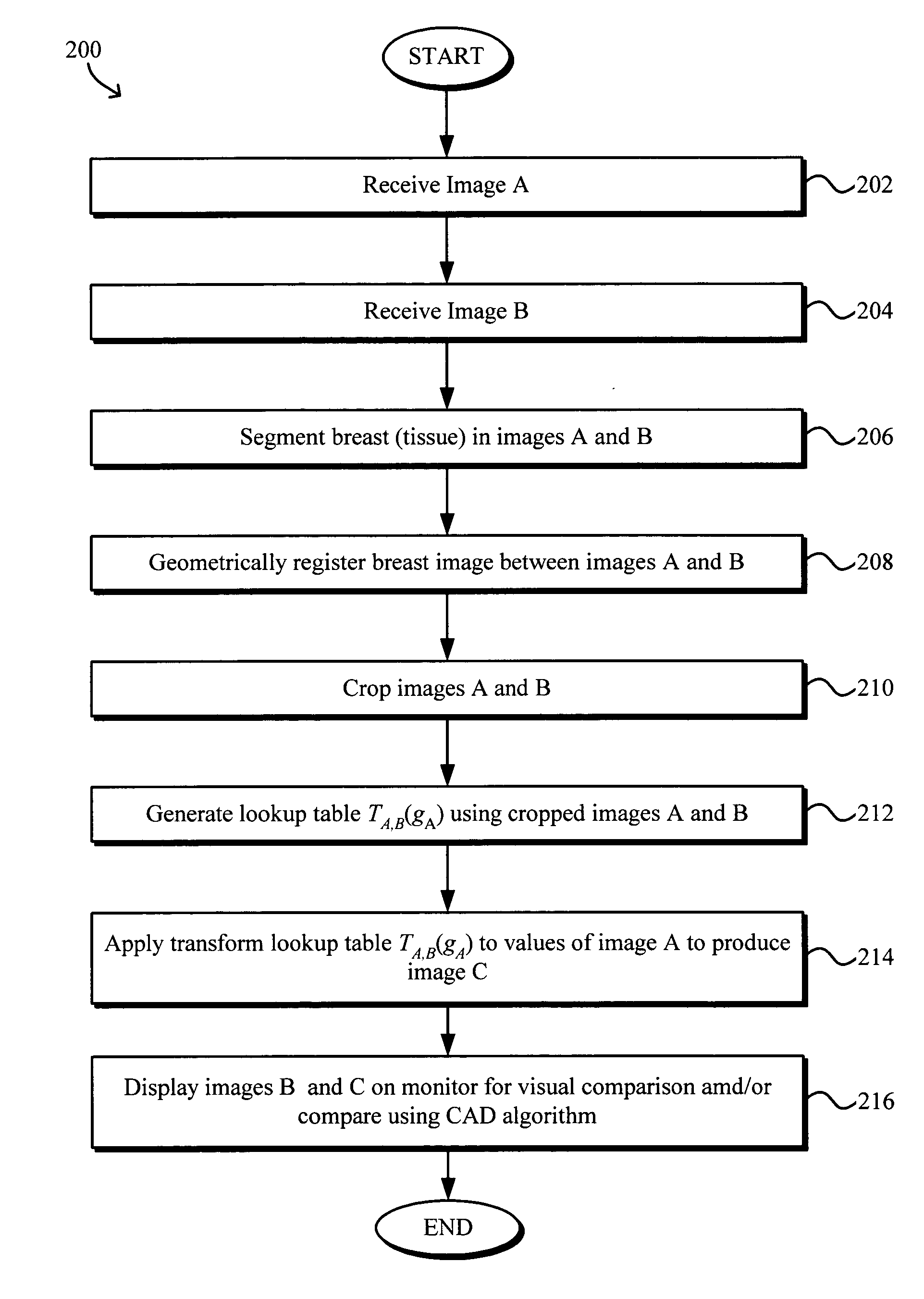

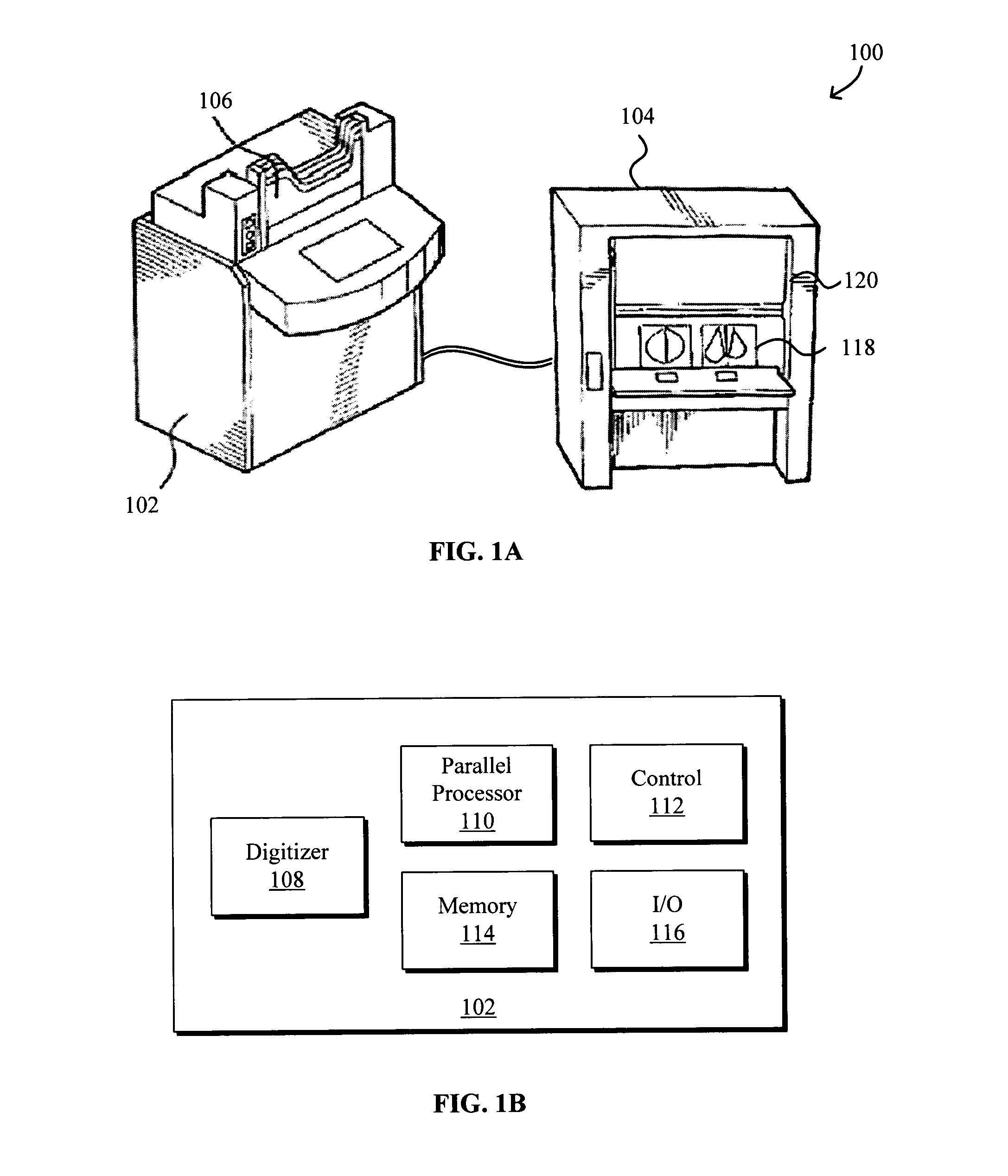

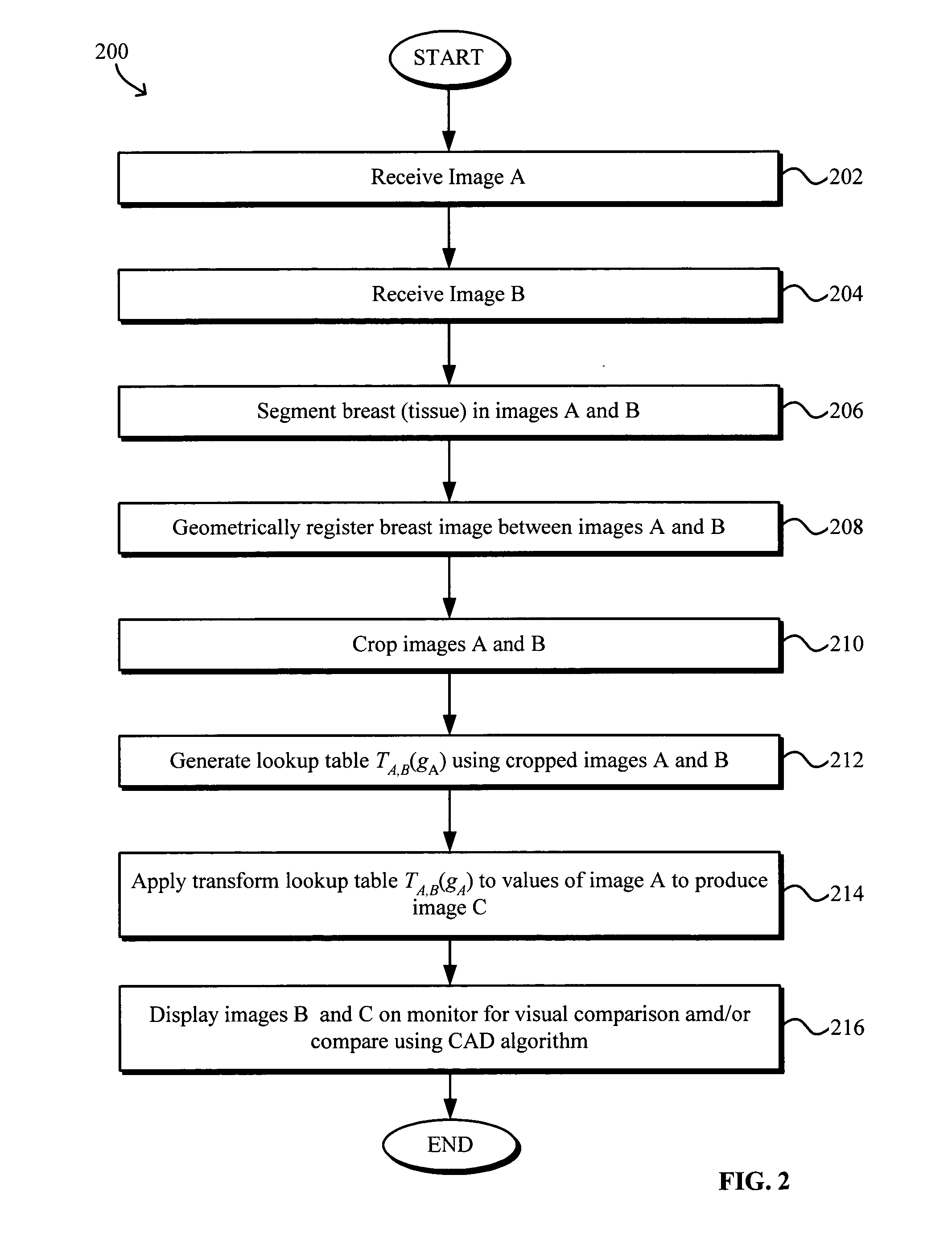

Model-based grayscale registration of medical images

ActiveUS20050013471A1Increase speedImprove reliabilityImage enhancementImage analysisPixel value differenceVisual perception

Numerical image processing of two or more medical images to provide grayscale registration thereof is described, the numerical image processing algorithms being based at least in part on a model of medical image acquisition. The grayscale registered temporal images may then be displayed for visual comparison by a clinician and / or further processed by a computer-aided diagnosis (CAD) system for detection of medical abnormalities therein. A parametric method includes spatially registering two images and performing gray scale registration of the images. A parametric transform model, e.g., analog to analog, digital to digital, analog to digital, or digital to analog model, is selected based on the image acquisition method(s) of the images, i.e., digital or analog / film. Gray scale registration involves generating a joint pixel value histogram from the two images, statistically fitting parameters of the transform model to the joint histogram, generating a lookup table, and using the lookup table to transform and register pixel values of one image to the pixel values of the other image. The models take into account the most relevant image acquisition parameters that influence pixel value differences between images, e.g., tissue compression, incident radiation intensity, exposure time, film and digitizer characteristic curves for analog image, and digital detector response for digital image. The method facilitates temporal comparisons of medical images such as mammograms and / or comparisons of analog with digital images.

Owner:HOLOGIC INC

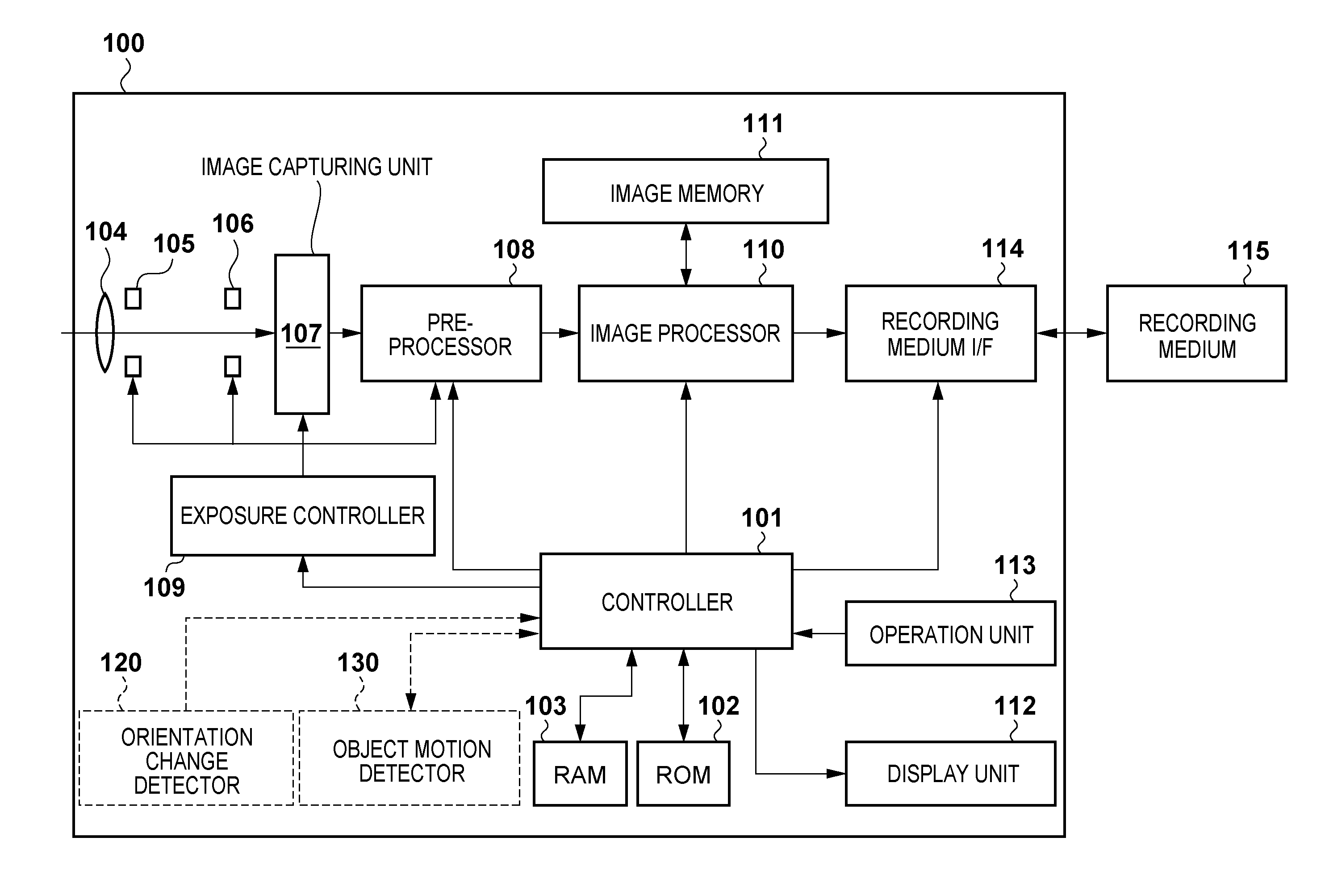

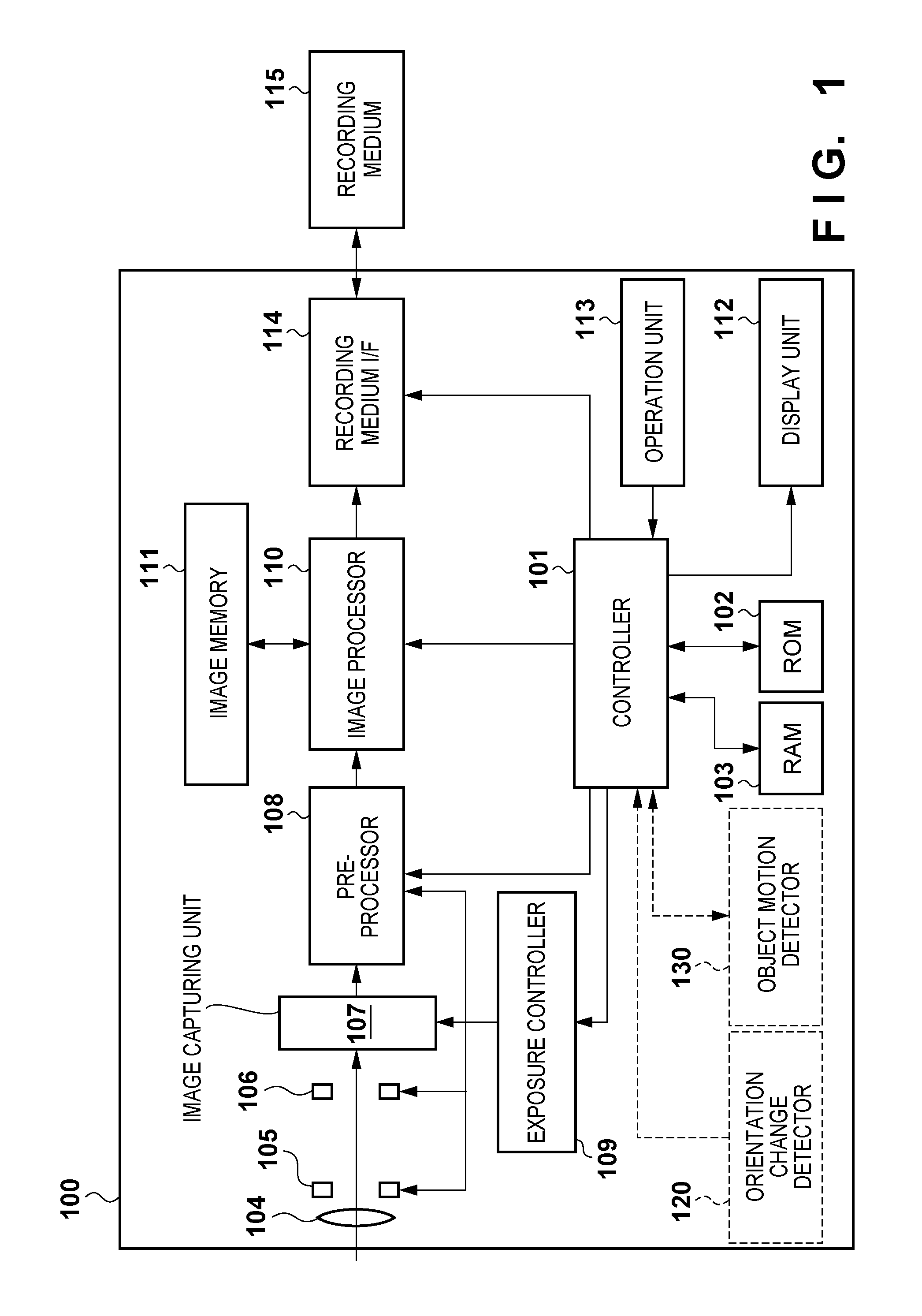

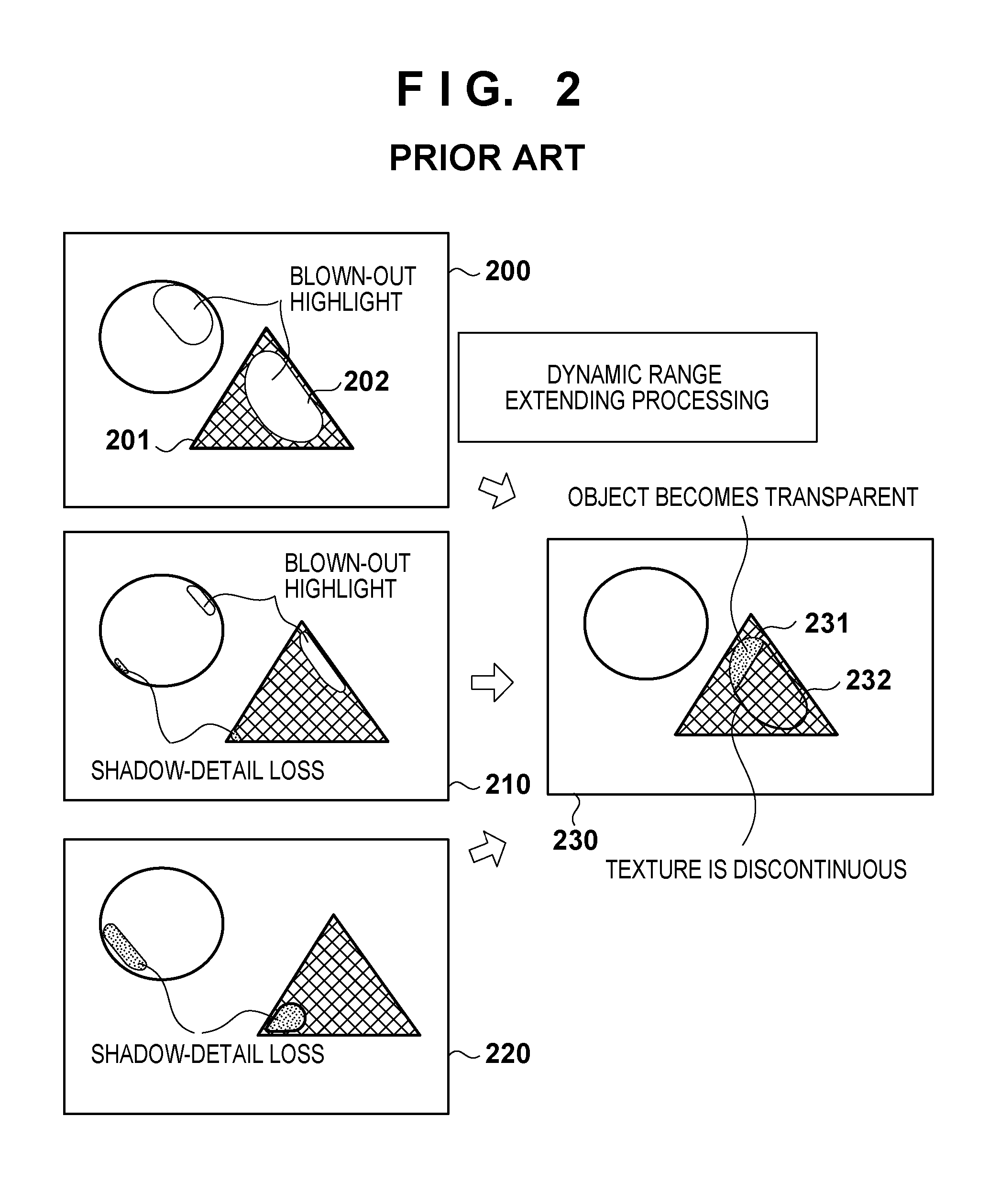

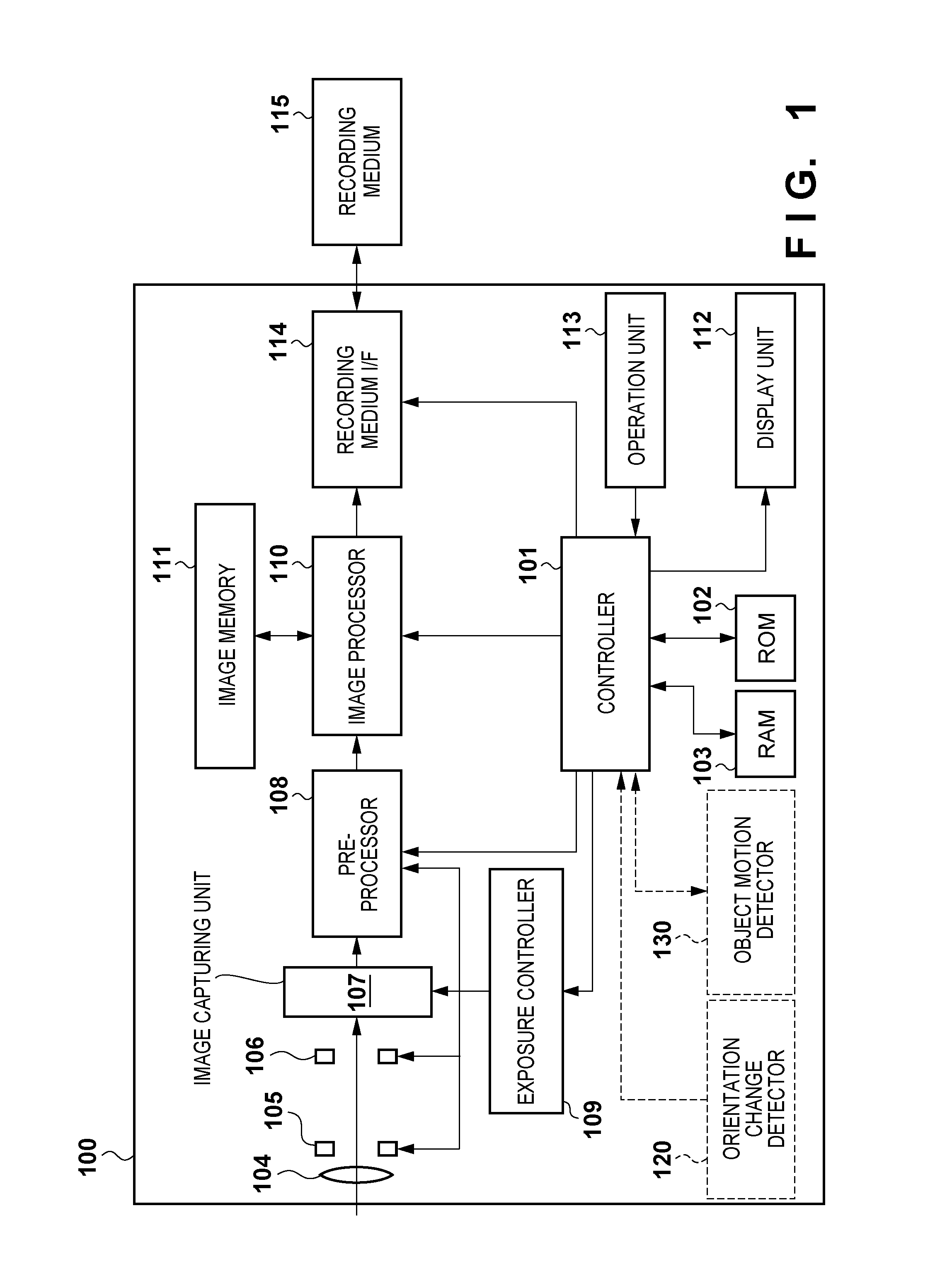

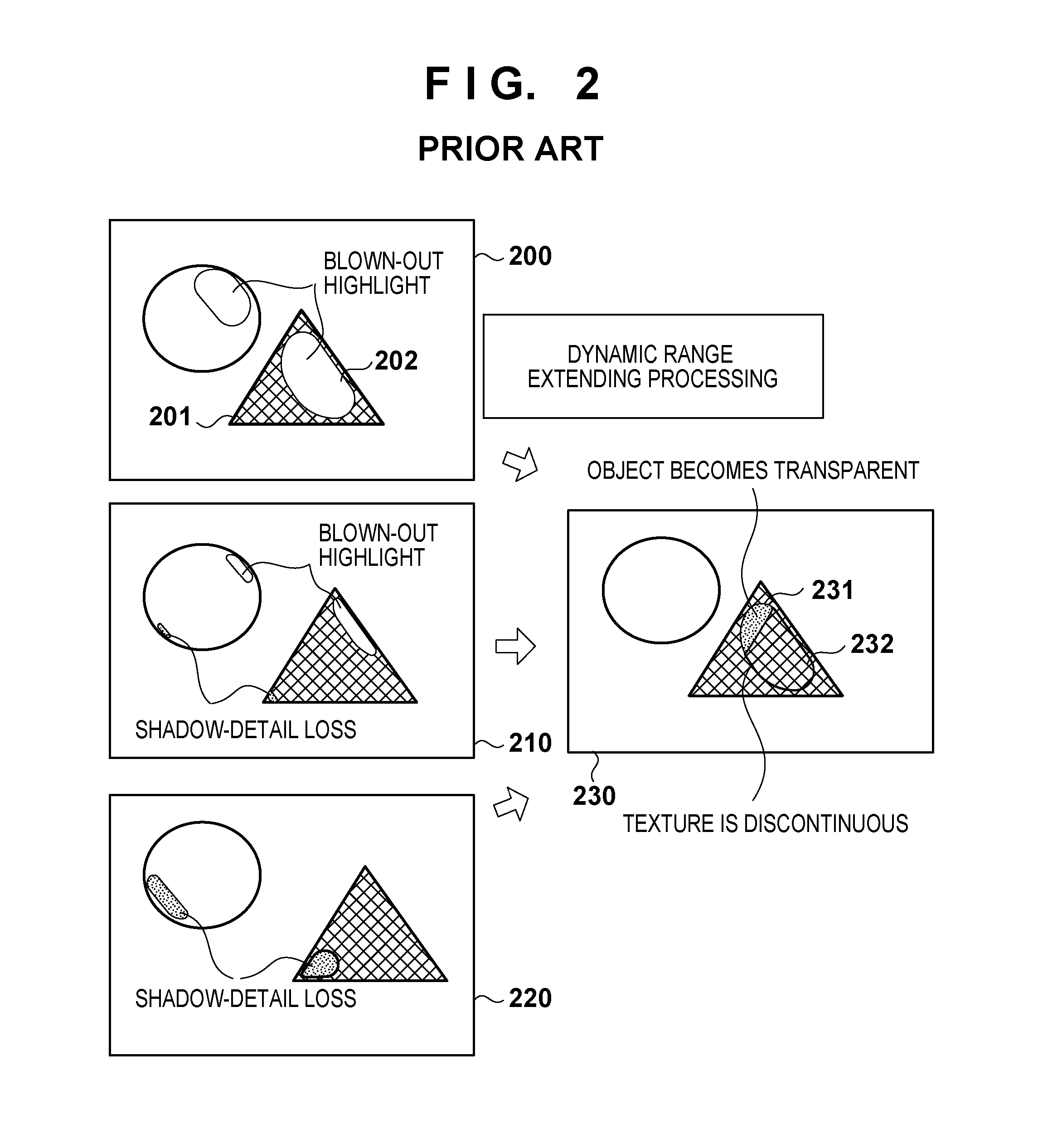

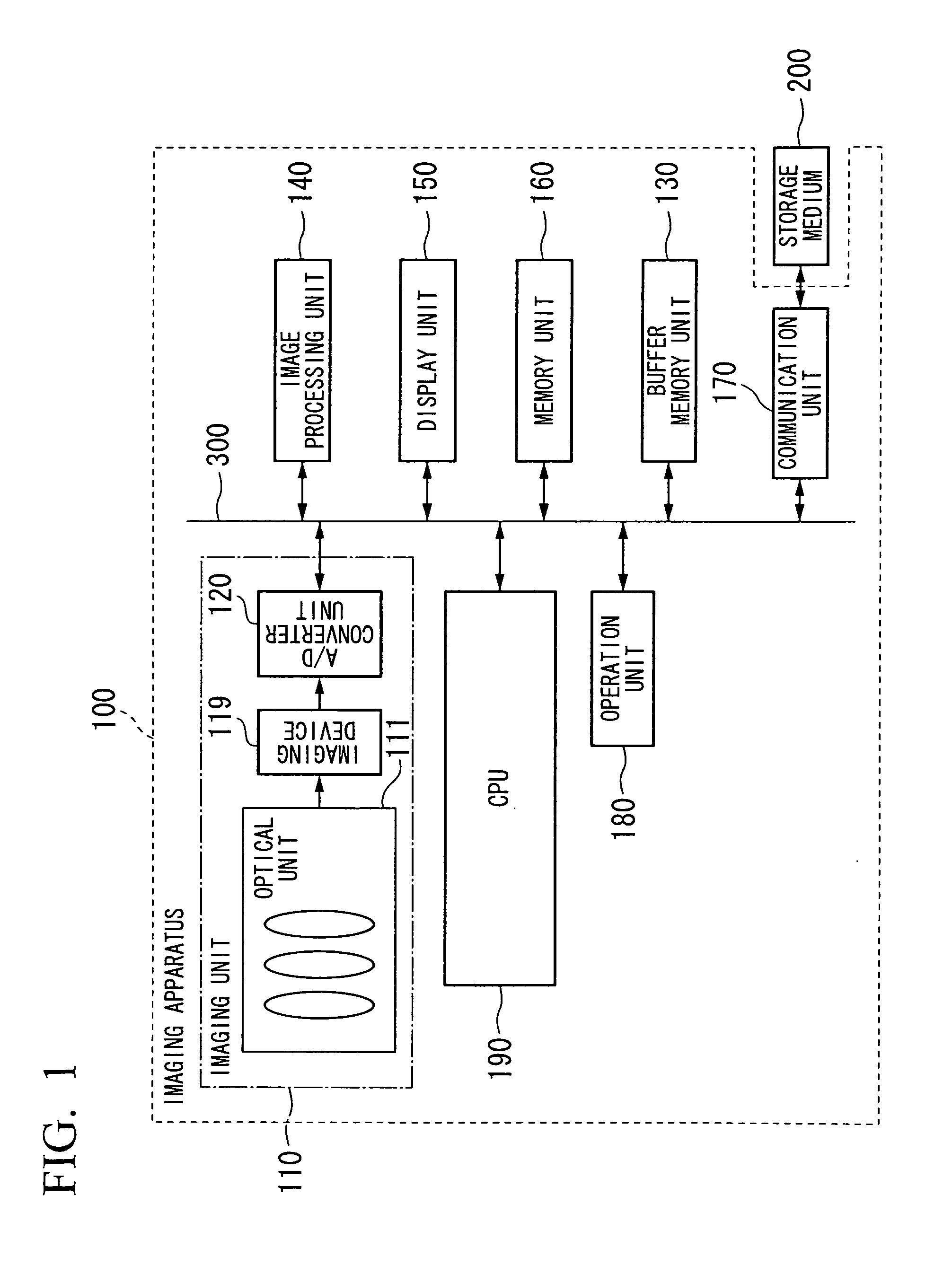

Image processing apparatus and control method thereof

InactiveUS20120249830A1Avoids image discontinuityImage enhancementTelevision system detailsImaging processingPixel value difference

Owner:CANON KK

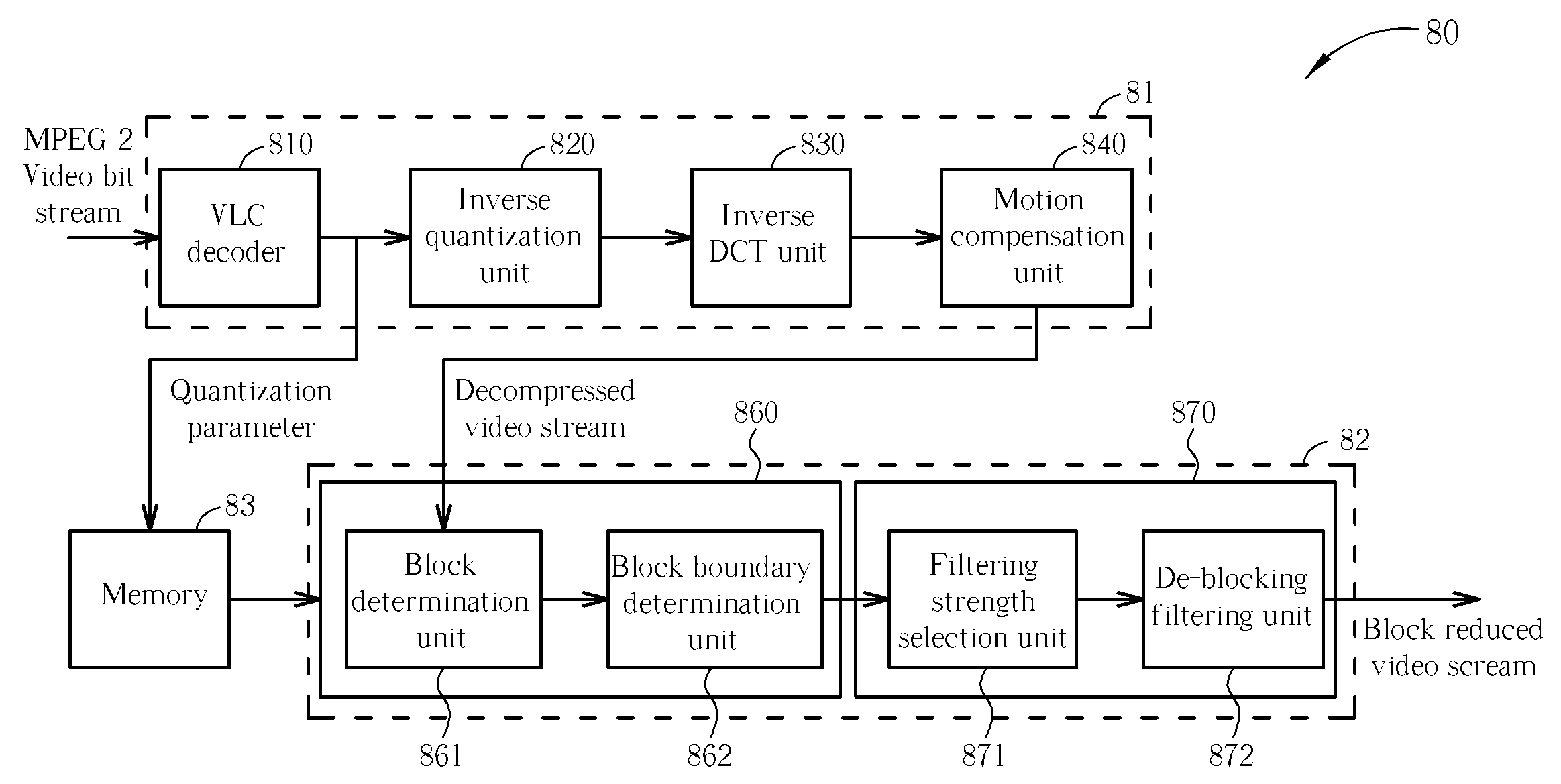

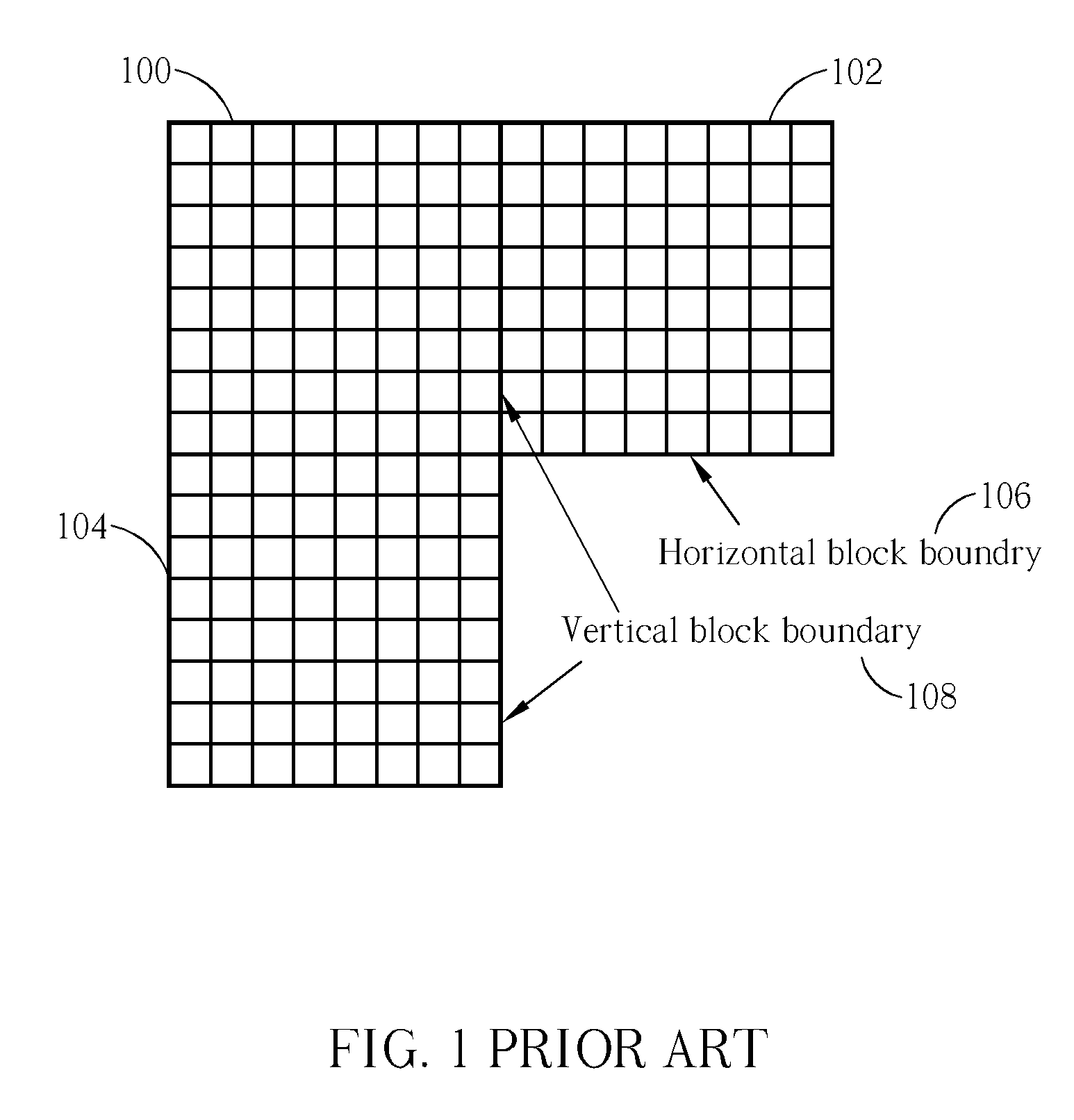

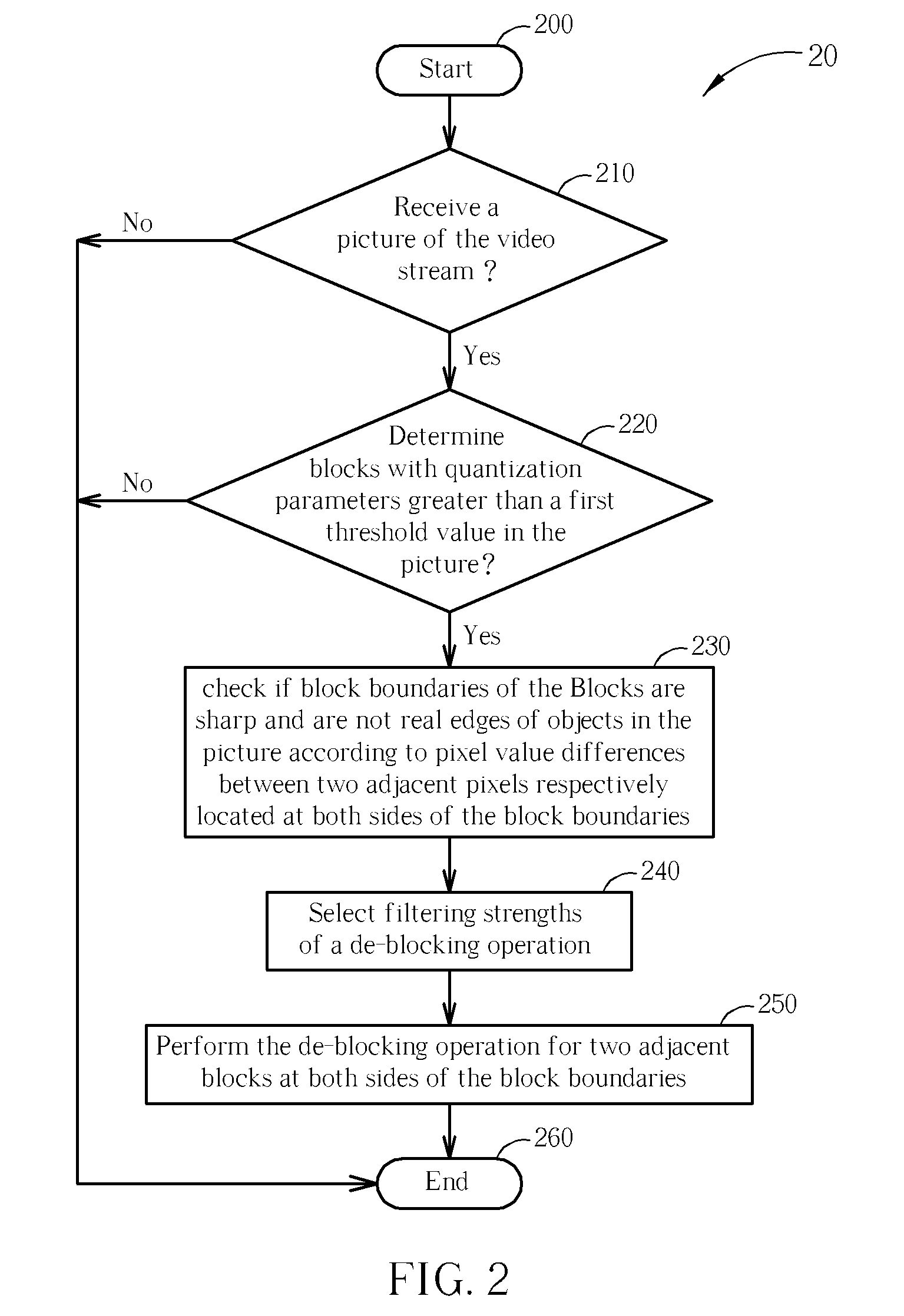

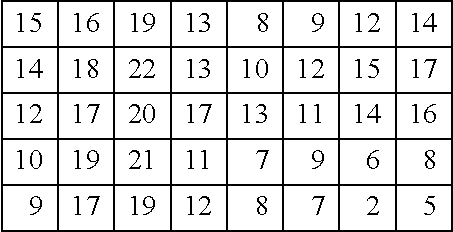

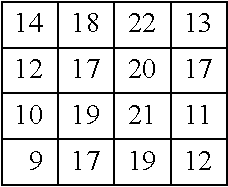

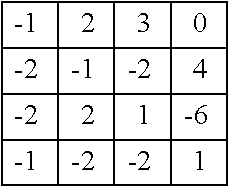

Method and Related Device for Reducing Blocking Artifacts in Video Streams

InactiveUS20090080517A1Reduce blockinessColor television with pulse code modulationColor television with bandwidth reductionPattern recognitionPixel value difference

A method for reducing blocking artifacts in a video stream comprises receiving a picture of the video stream, wherein the picture includes a plurality of macroblocks and each of the plurality of macroblock includes four blocks, determining blocks with quantization parameters greater than a first threshold value in the picture, checking if block boundaries of the blocks are sharp and are real edges of objects in the picture according to pixel value differences between two adjacent pixels respectively located at both sides of the block boundaries, selecting filtering strengths of a de-blocking operation according to the pixel value differences when the block boundaries are sharp and are not real edges of the objects in the picture, and performing the de-blocking operation for two adjacent blocks at both sides of the block boundaries.

Owner:SILICON INTEGRATED SYSTEMS

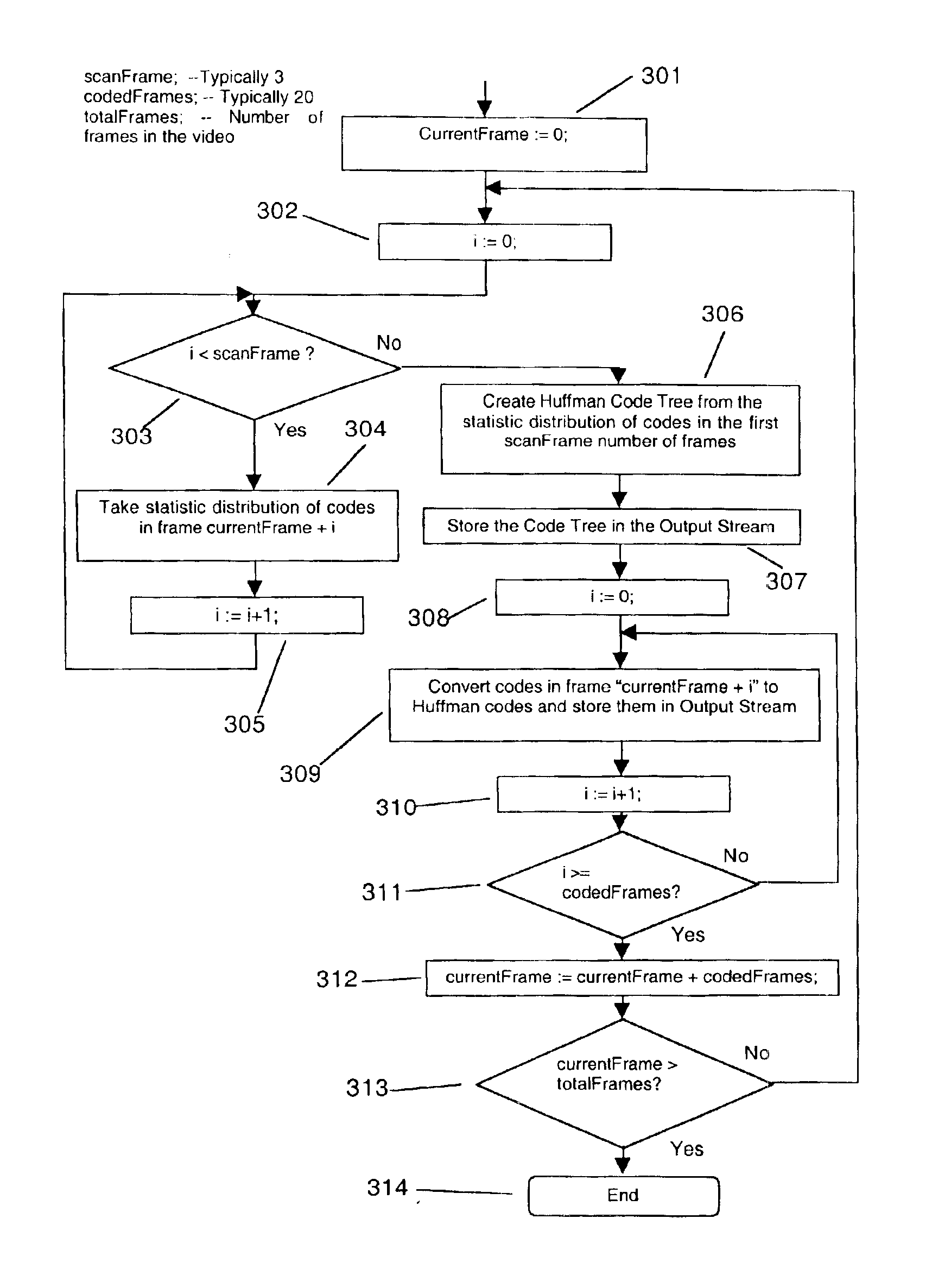

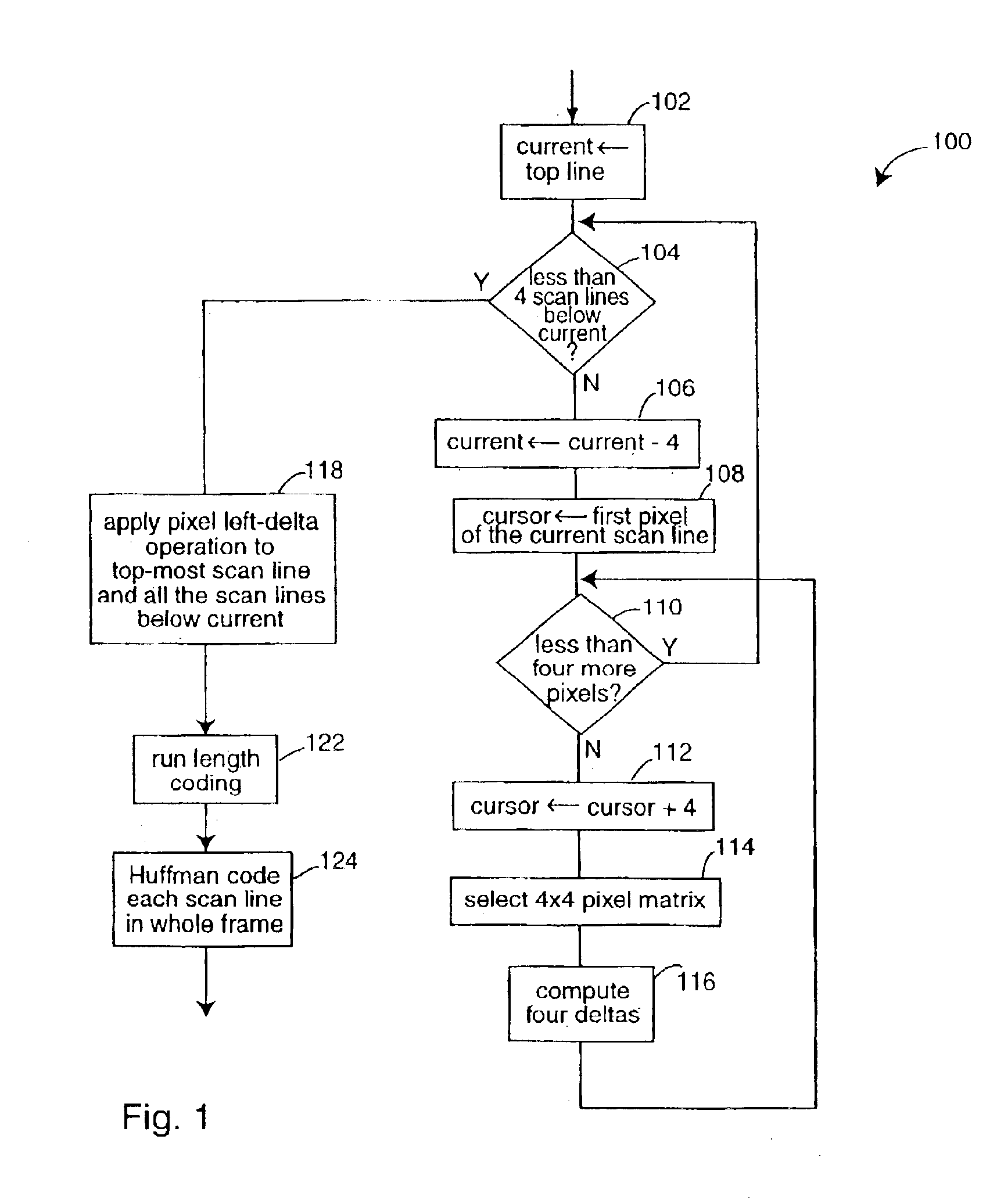

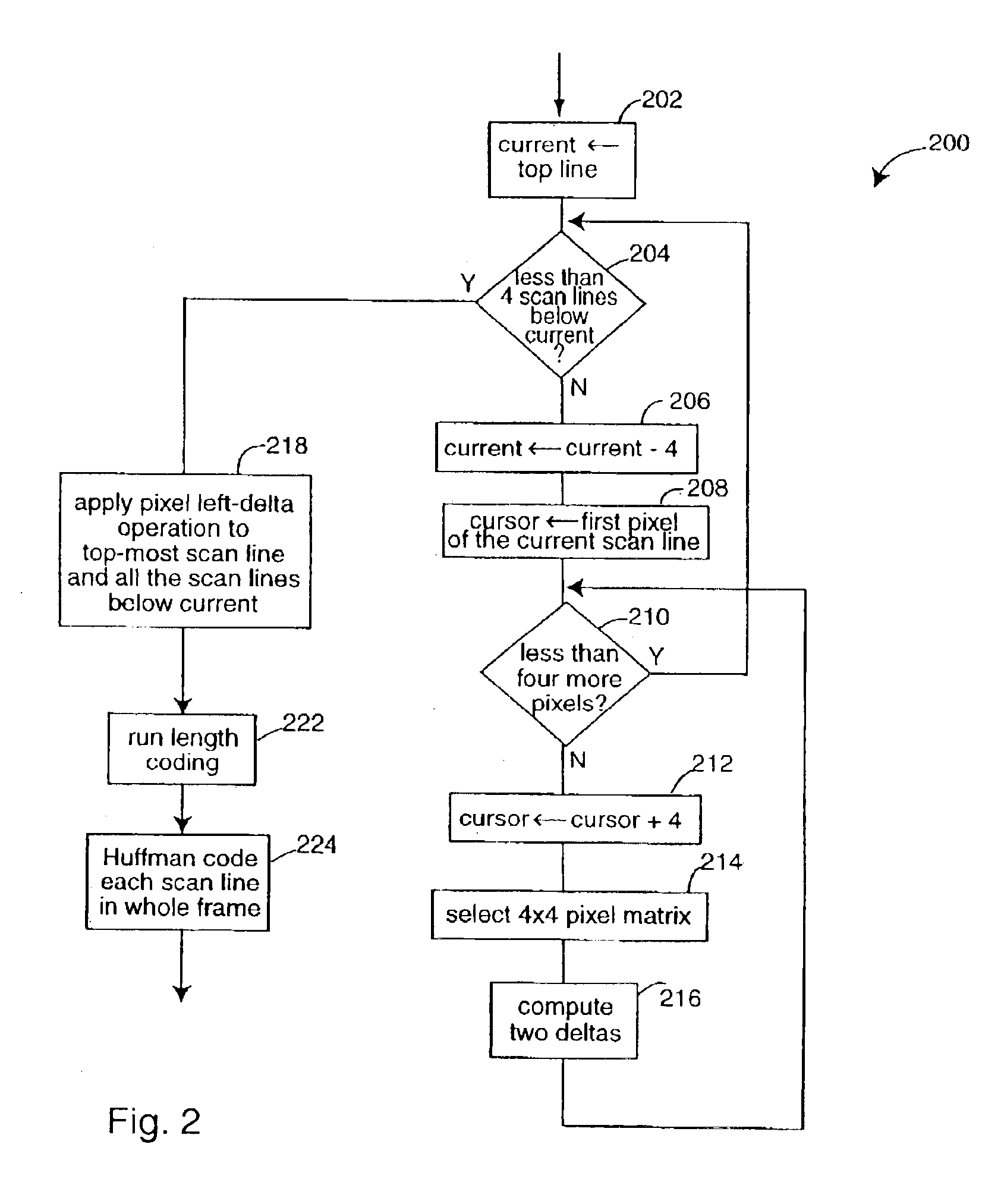

Fast loss less image compression system based on neighborhood comparisons

InactiveUS20040008896A1Reduce varianceEasy to compressCode conversionCharacter and pattern recognitionPixel value differenceImage compression

A fast loss less image compression system based on neighborhood comparisons compares pixel value differences with neighboring pixels and replaces such pixel values with the minimum of the differences. A marker is attached to a block of pixels, such that all the pixels in that block are compared with neighbors of one direction. The marker indicates how all of the pixels in that block are compared. Intermittent Huffman-tree construction is used such that one tree is used for several frames. Huffman coding is used to compress the resulting frame. A single Huffman-tree is constructed once every predetermined number of frames. The frequency of Huffman-tree construction can be performed according to the instantaneous availability of processor time to perform the construction. When more processing time is available, the Huffman-trees are computed more frequently. Such frequency variation can be implemented by using an input video frame buffer. If the buffer is a certain size, then processor time for Huffman-tree construction is available.

Owner:ZAXEL SYST

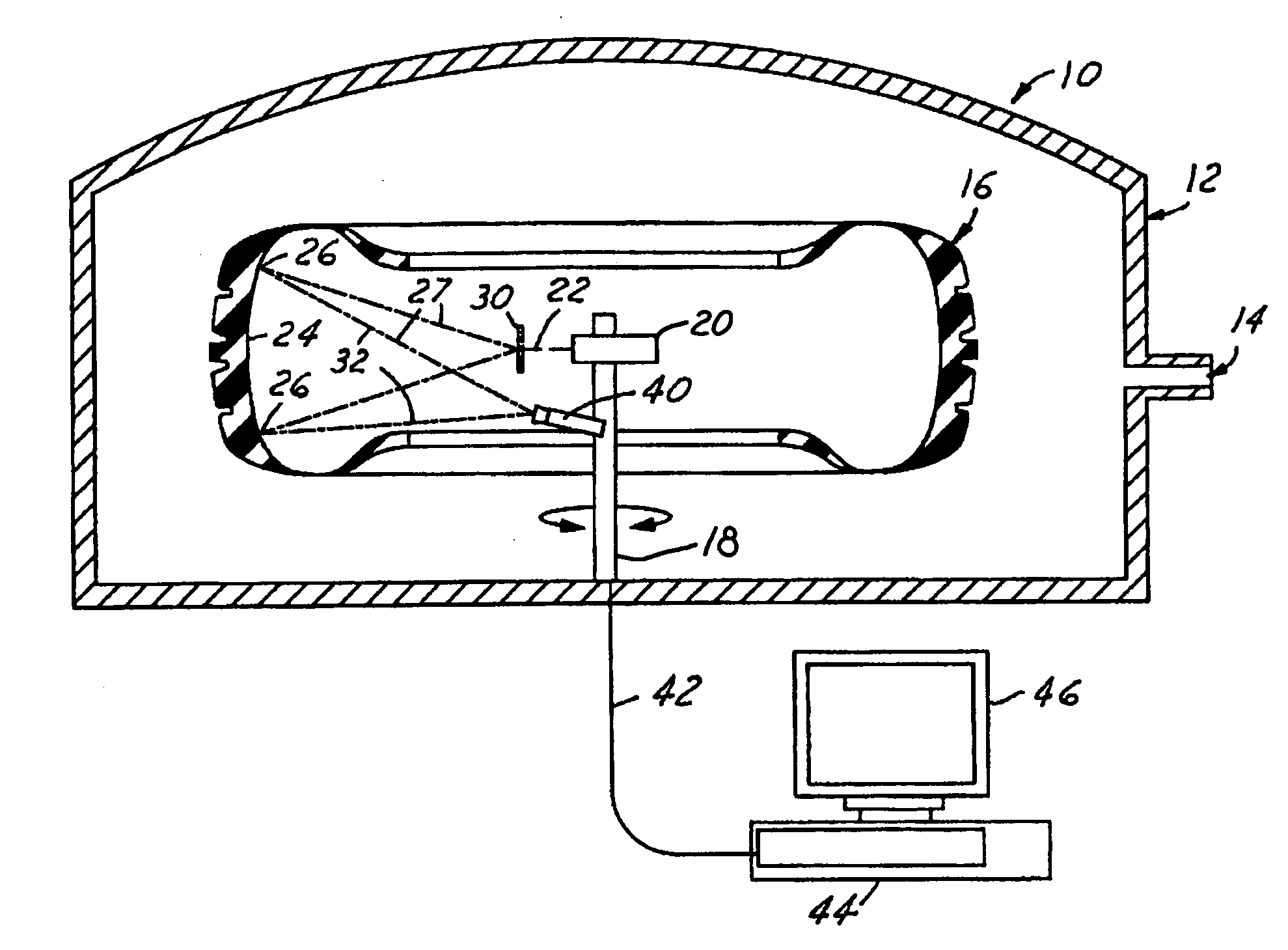

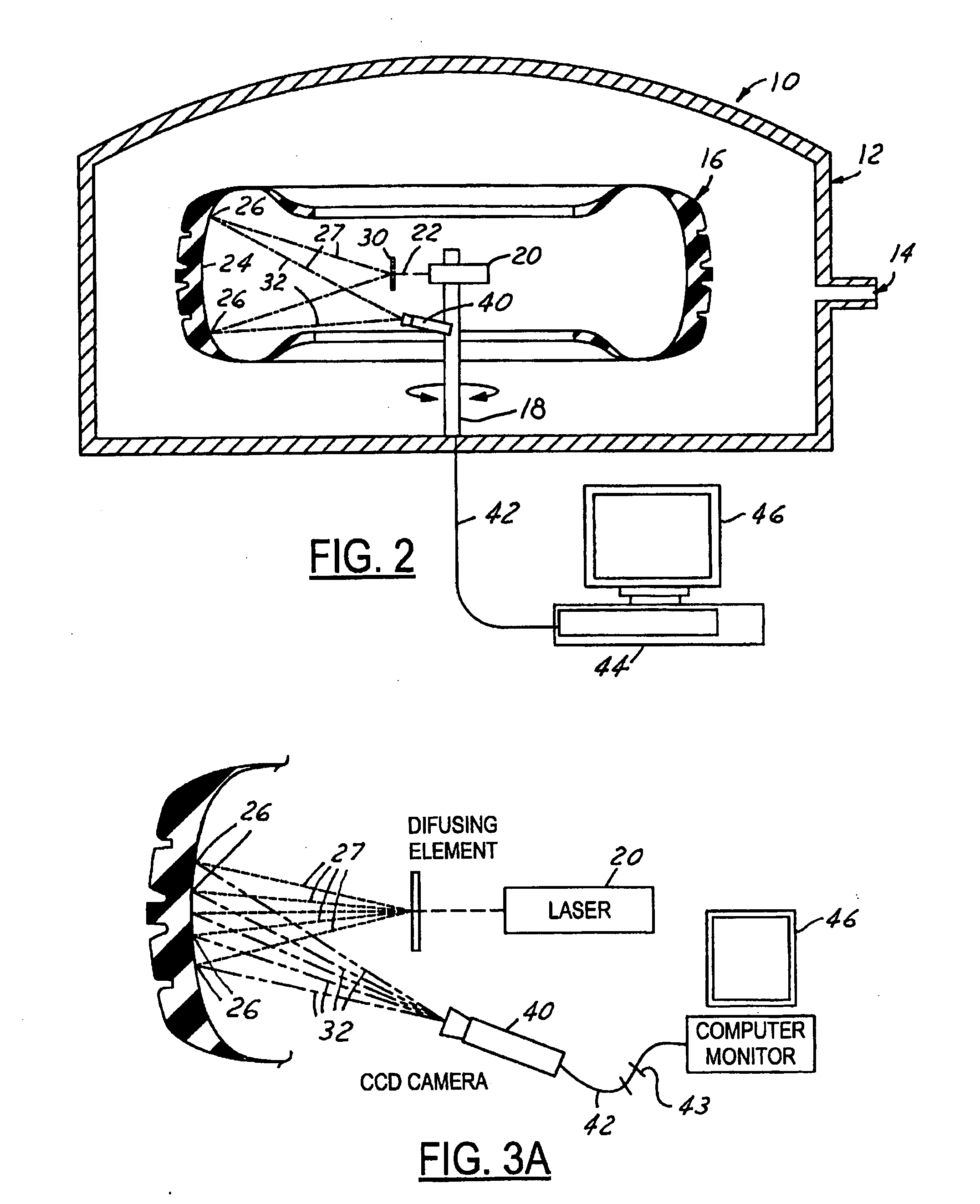

Non-destructive testing and imaging

InactiveUS20080147347A1Material analysis by optical meansUsing optical meansNon destructivePixel value difference

A method of non-destructive testing includes non-destructively testing an object over a range of test levels, directing coherent light onto the object, directly receiving the coherent light substantially as reflected straight from the object, and capturing the reflected coherent light over the range of test levels as a plurality of digital images of the object. The method also includes calculating differences between pixel values of a plurality of pairs of digital images of the plurality of digital images, and adding the pixel value differences of the plurality of pairs of digital images to yield at least one cumulative differential image.

Owner:SHEAROGRAPHICS

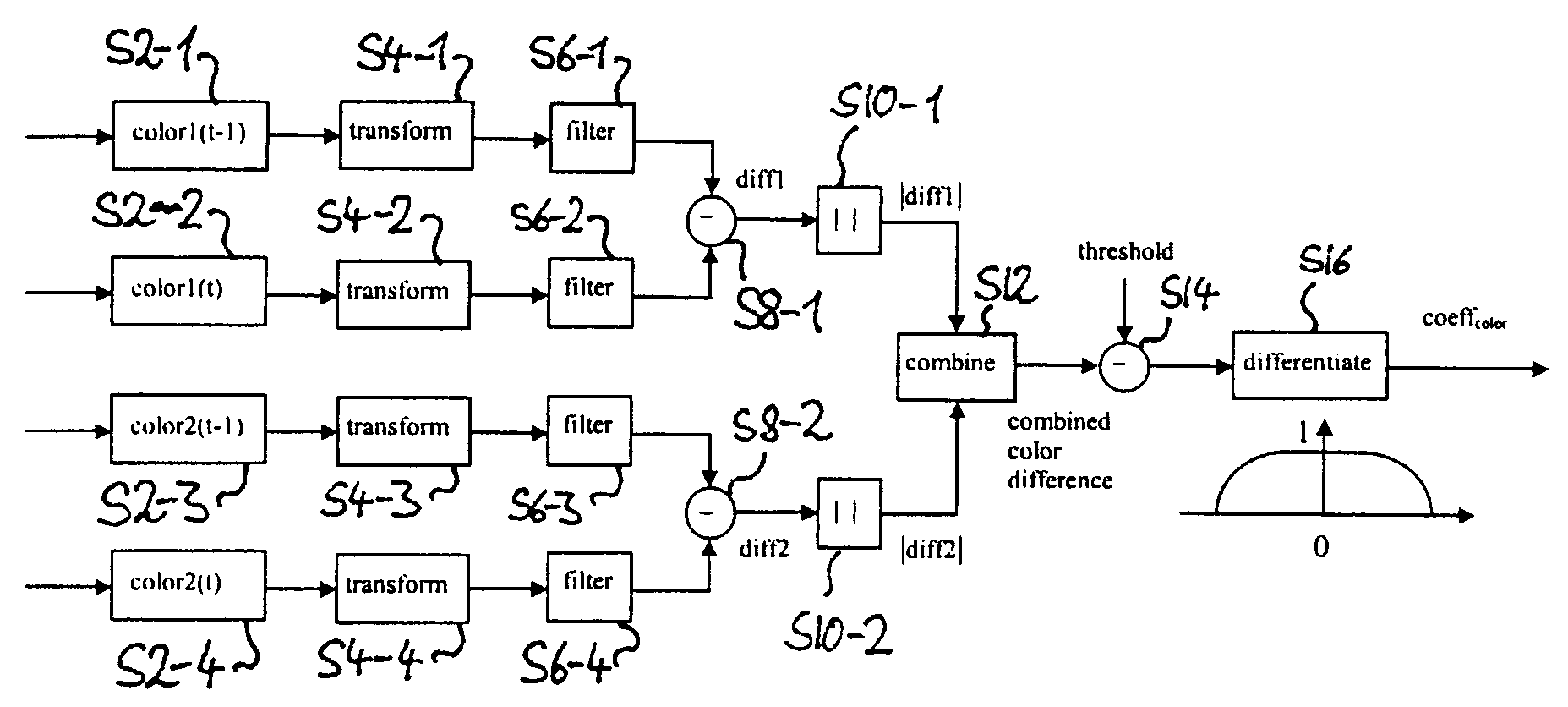

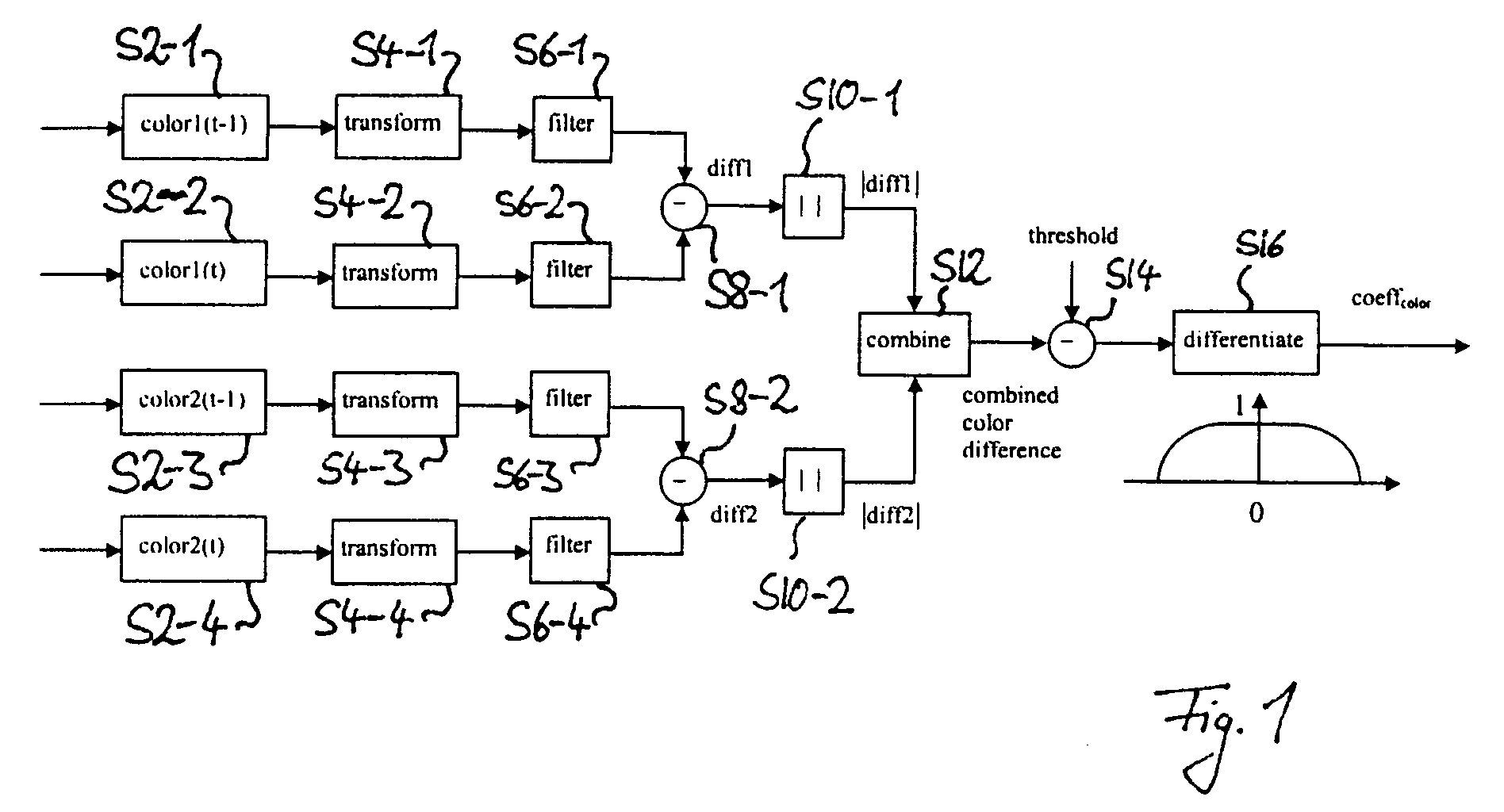

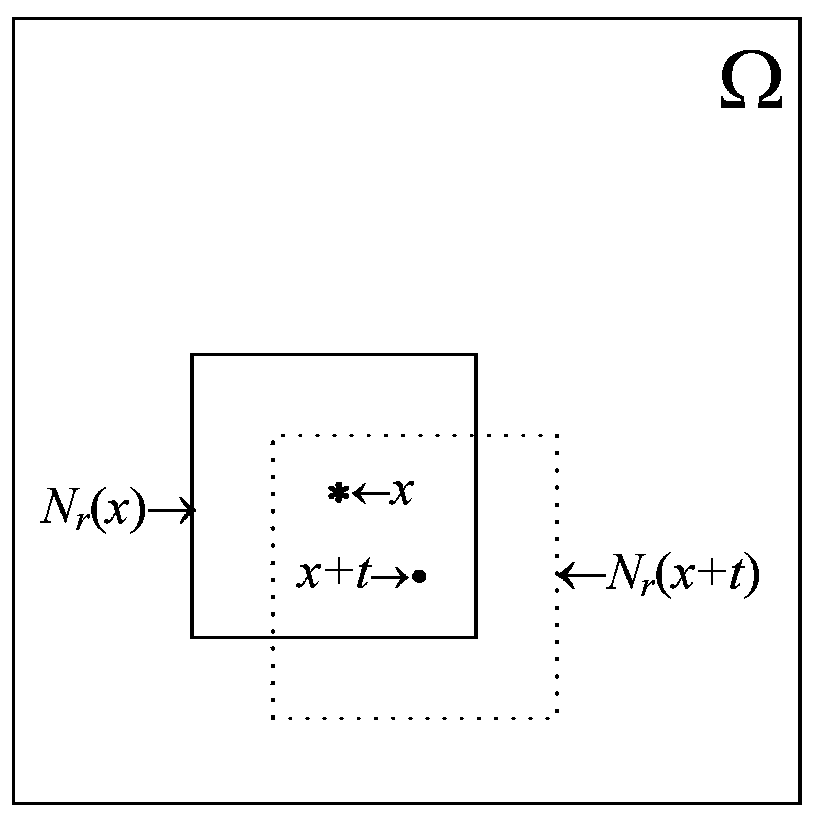

Motion and/or scene change detection using color components

InactiveUS20080129875A1Television system detailsColor signal processing circuitsPattern recognitionTime domain

The present invention relates to the fields of motion detection, scene change detection and temporal domain noise reduction. Especially, the present invention relates to a device, a method and a software for detecting motion and / or scene change in a sequence of image frames. The device for detecting motion and / or scene change in a sequence of image frames comprises a difference generator adapted to calculate one or more differences between values of pixels of separate image frames, the pixel values comprising color information, and a discriminator for providing an indication whether the calculated one or more pixel value differences correspond to noise or correspond to image content based on the one or more pixel value differences.

Owner:SONY DEUT GMBH

Guided trilateral filtering ultrasonic image speckle noise removal method

ActiveCN109767400AAccurate descriptionPrevent deviationImage enhancementNormal densityPixel value difference

A guided trilateral filtering ultrasonic image speckle noise removal method comprises the steps of calculating the space domain distance weight of a guided image through a Gaussian function, and setting the standard deviation of the guided image to be increased along with increase of noise intensity; carrying out Histogram fitting on a local area of the guide image, and selecting a Fisher-Tippettprobability density function selected as a fitting function; Estimating a distribution parameter of the Tippett probability density function by adopting a maximum likelihood method, and calculating adistribution similarity weight according to the estimated parameter; calculating Pixel value difference weight of a guide image by using an exponential function, and setting a scale parameter of the guide image as an estimated Fisher-; Wherein the Tippett distribution parameters are in direct proportion change; And carrying out local iterative filtering on the ultrasonic image by using the three calculated weights, and carrying out iterative convergence to obtain the ultrasonic image with speckle noise removed. According to the method, the filtering weight value is calculated through three aspects of information of the spatial domain distance, the pixel value difference and the distribution similarity, speckle noise can be effectively reduced, meanwhile, detail and edge information of theimage can be better reserved, and therefore visual interpretation of the ultrasonic image is enhanced.

Owner:CHINA THREE GORGES UNIV

Image processing apparatus and control method thereof

InactiveUS8866922B2Avoids image discontinuityImage enhancementTelevision system detailsImaging processingPixel value difference

Owner:CANON KK

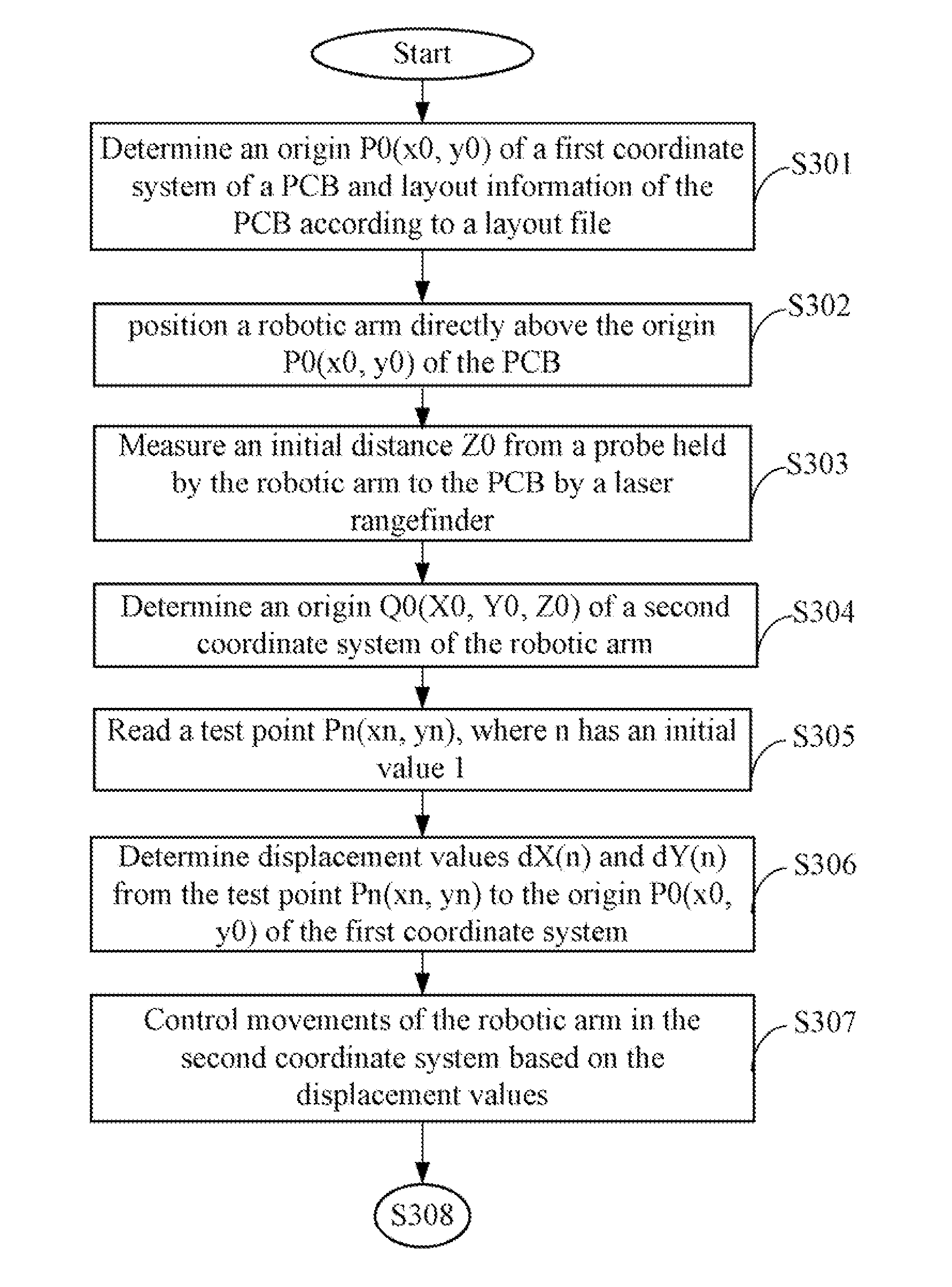

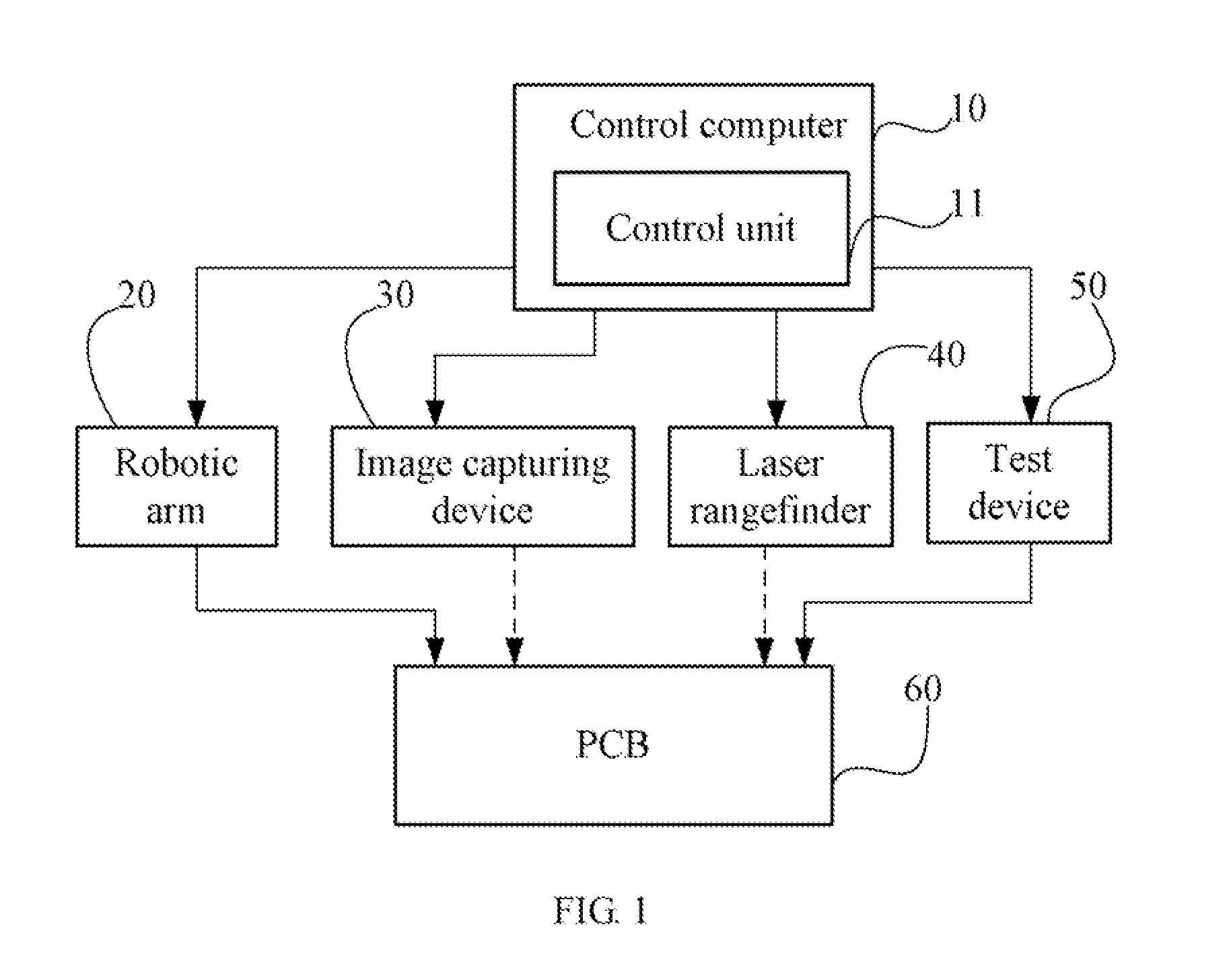

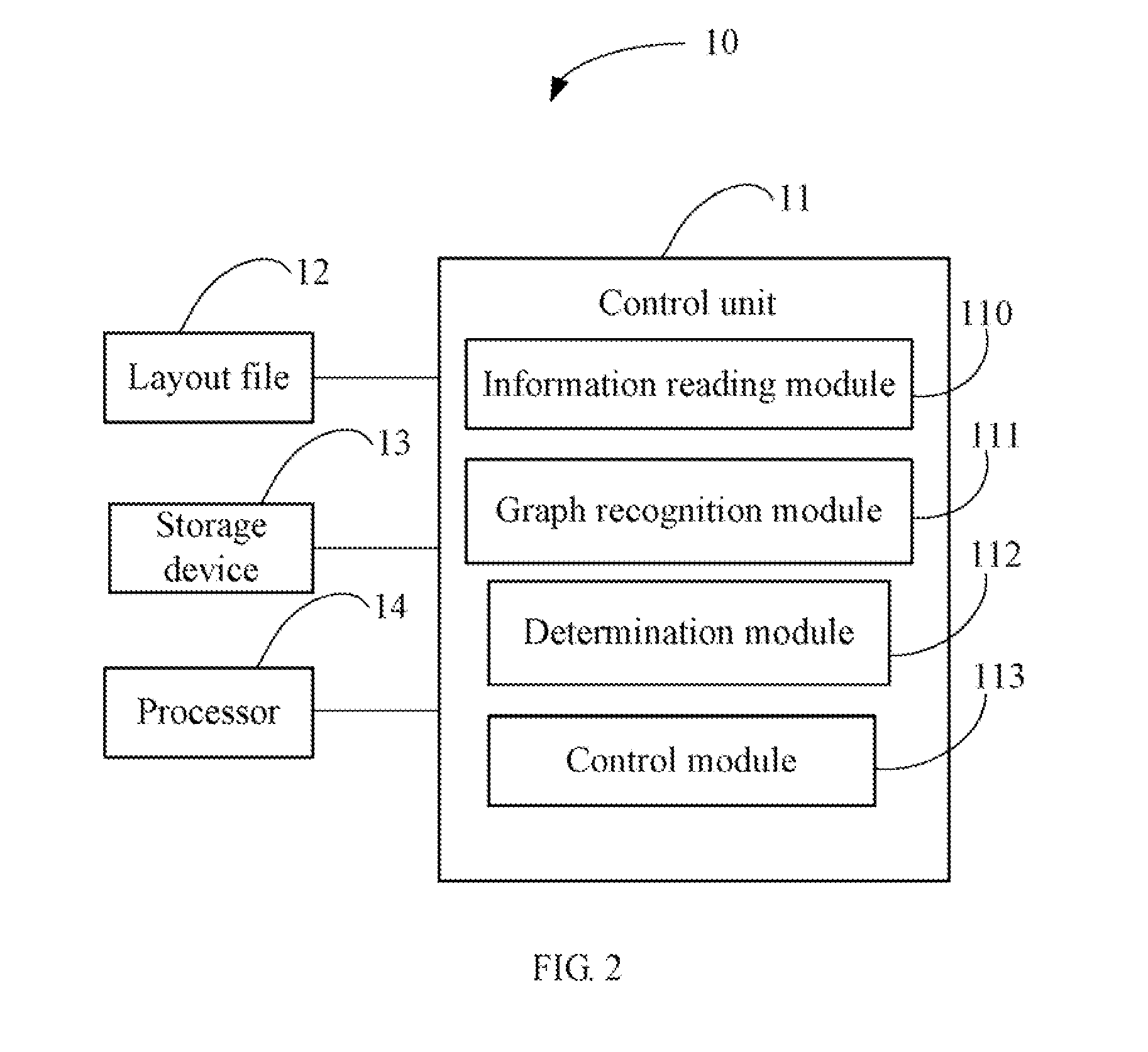

Control computer and method of controlling robotic arm

InactiveUS20120185097A1Programme controlProgramme-controlled manipulatorPixel value differenceRobotic arm

A computer determines a first origin of a first coordinate system of a PCB, and controls a robotic arm to position a probe above the first origin. Furthermore, the computer determines a second origin of a second coordinate system of the robotic arm, and determines displacement values from the first origin to a test point in controlling movements of the robotic arm in the second coordinate system. A graph representing the test point is recognized in an image of the PCB, pixel value differences between the graph center and the image center are determined and converted to displacement correction values for controlling the movements of the robotic arm and determining 3D coordinates of the test point. The robotic arm is moved along a Z-axis of the second coordinate system to precisely position the probe on the test point of the PCB.

Owner:HON HAI PRECISION IND CO LTD

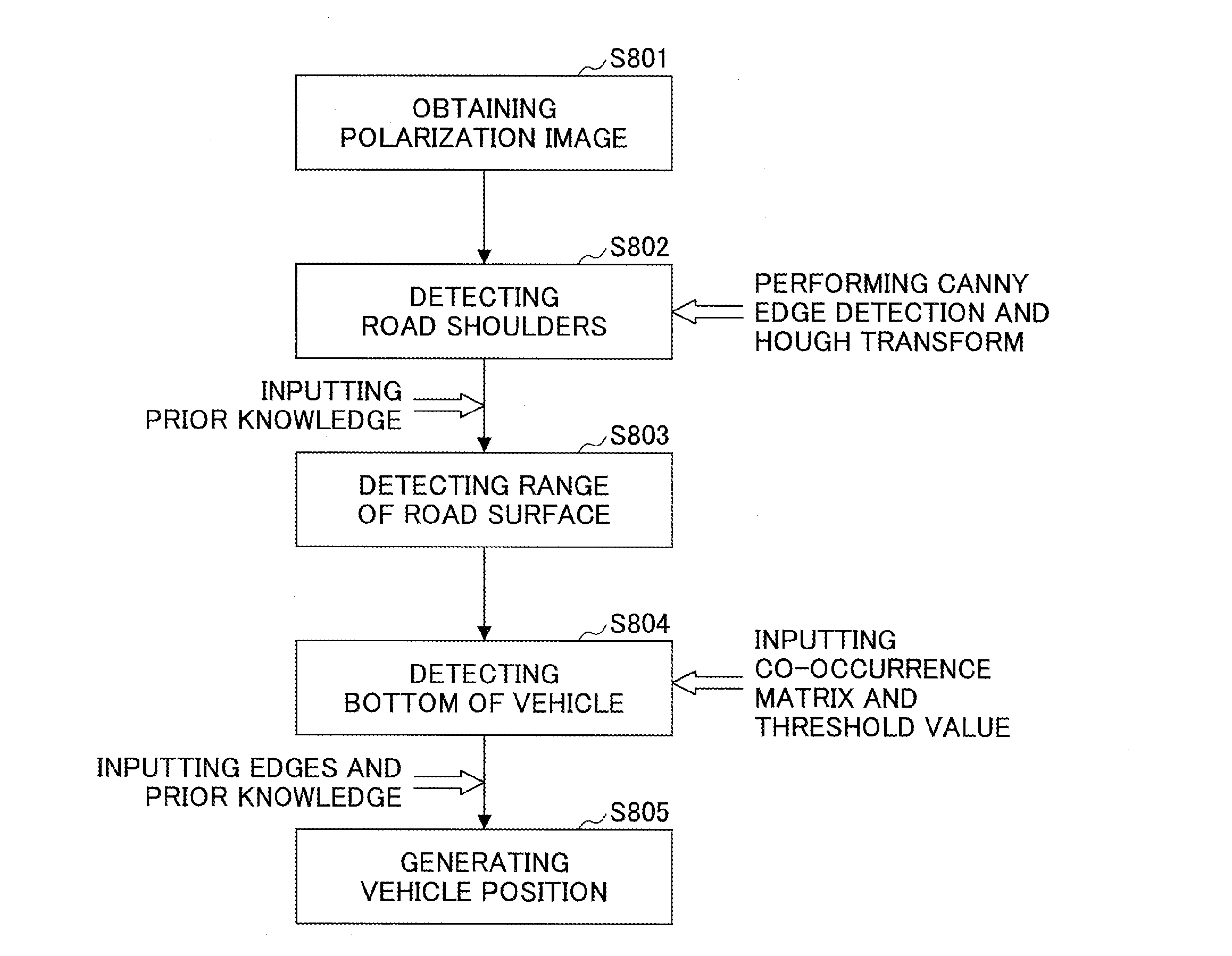

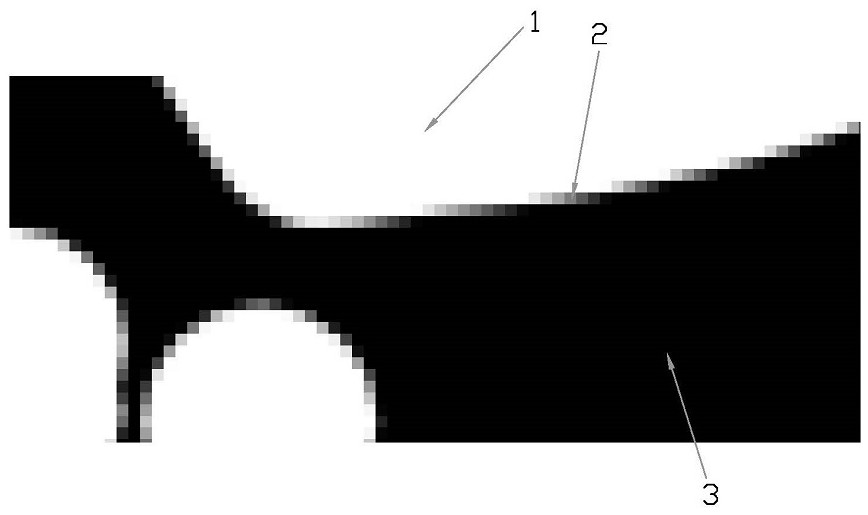

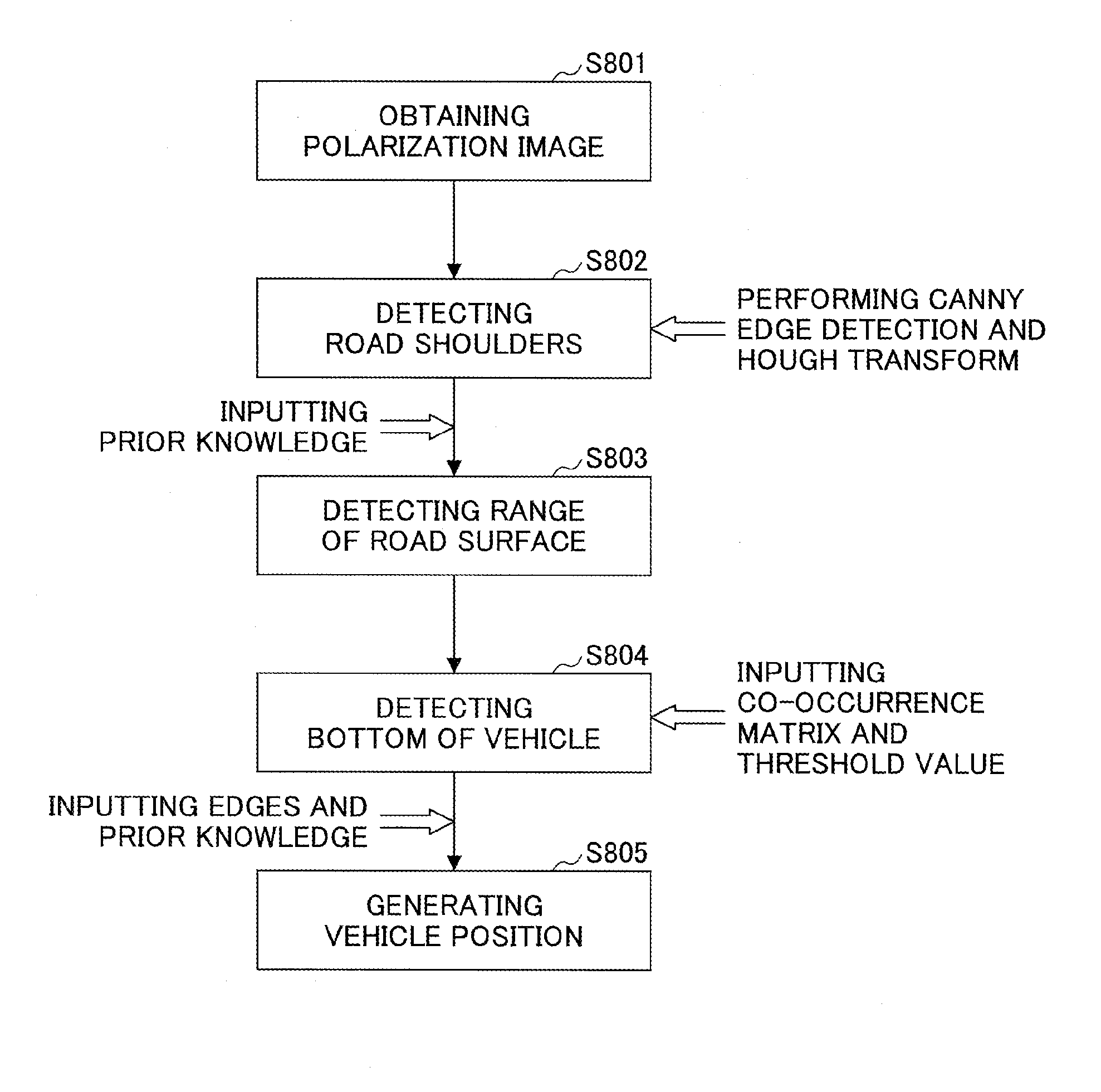

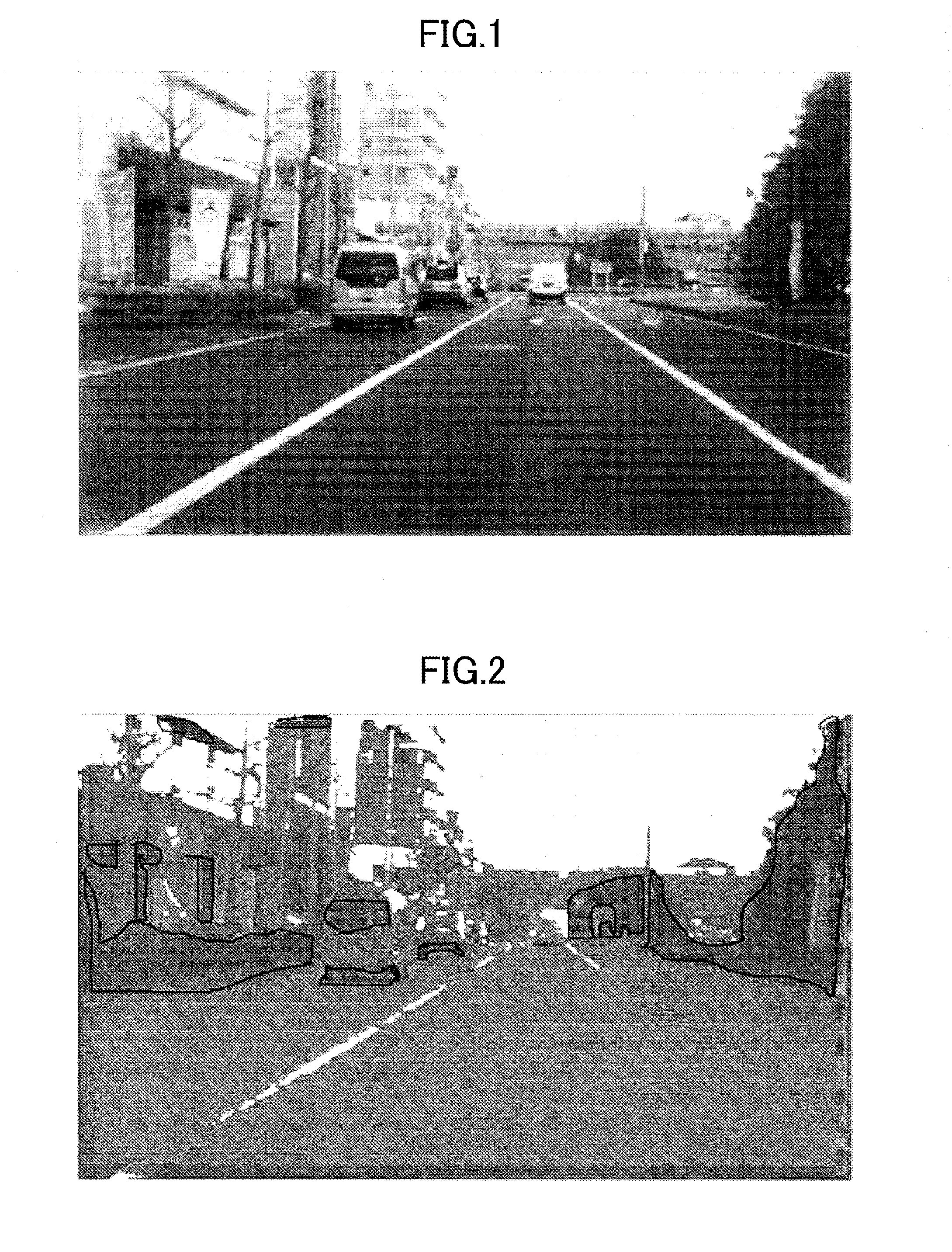

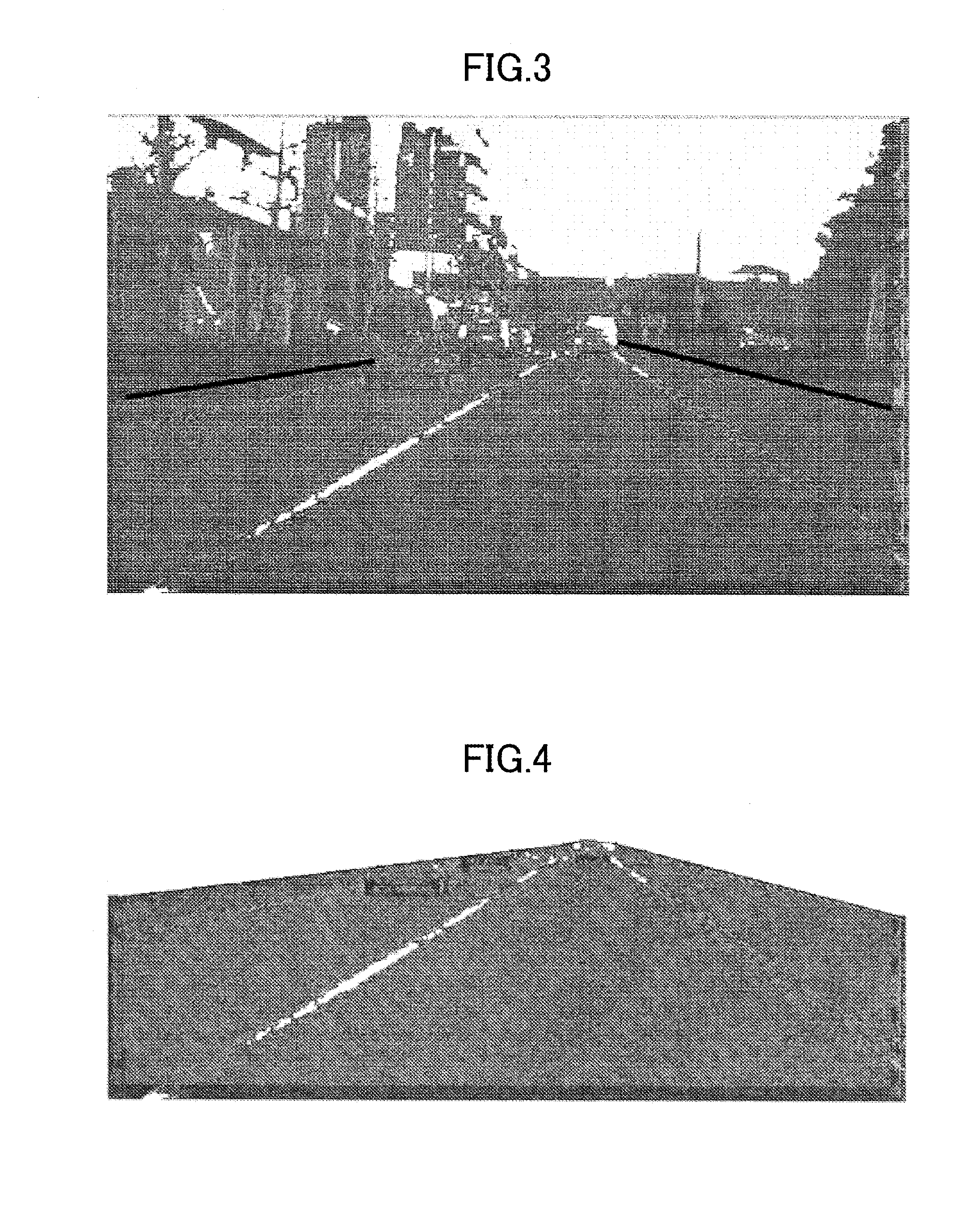

Method and system for detecting vehicle position by employing polarization image

InactiveUS20130058528A1Reduce noiseQuick buildScene recognitionPixel value differenceImage detection

Disclosed are a method and a system for detecting a vehicle position by employing a polarization image. The method comprises a step of capturing a polarization image by using a polarization camera; a step of acquiring two road shoulders in the polarization image based on a difference between a road surface and each of the two road shoulders in the polarization image, and determining a part between the two road shoulders as the road surface; a step of detecting at least one vehicle bottom from the road surface based on a significant pixel value difference between each wheel and the road surface in the polarization image; and a step of generating a vehicle position from the vehicle bottom based on a pixel value difference between a vehicle outline corresponding to the vehicle bottom and background in the polarization image.

Owner:RICOH KK

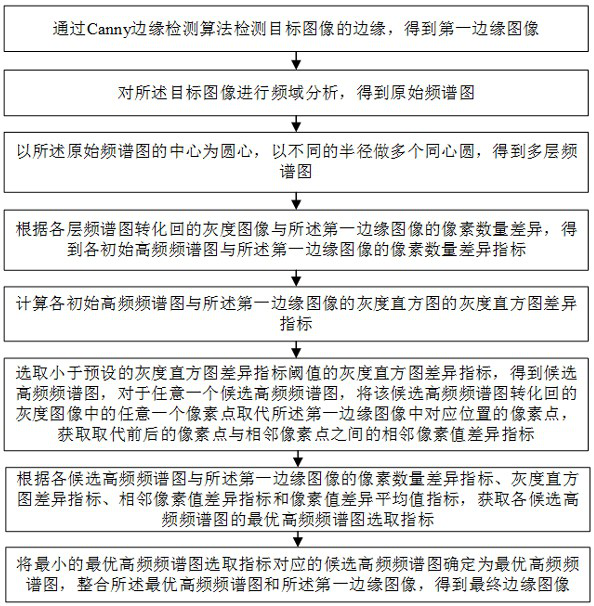

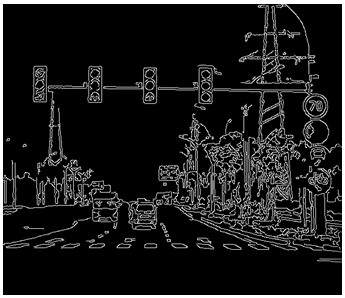

Edge detection method and system based on image multi-dimensional analysis

ActiveCN113989313AImprove accuracyReduce the impact of noiseImage enhancementImage analysisImaging processingPixel value difference

The invention relates to the technical field of image processing, in particular to an edge detection method and system based on image multidimensional analysis. The method comprises the steps: detecting the edge of a target image through a Canny edge detection algorithm, obtaining a first edge image, carrying out the frequency domain analysis of the target image, obtaining an original spectrogram, processing the original spectrogram, and obtaining a corresponding pixel number difference index, a gray level histogram difference index, an adjacent pixel value difference index and a pixel value difference average value index; calculating according to the indexes to obtain an optimal high-frequency spectrogram selection index, and further determining an optimal high-frequency spectrogram according to the optimal high-frequency spectrogram selection index; and integrating the optimal high-frequency spectrogram and the first edge image to obtain a final edge image, so that the details of the image obtained by a Canny operator can be increased, the noise influence in high-frequency information can be reduced and eliminated, and the edge detection accuracy is greatly improved.

Owner:武汉智博通科技有限公司

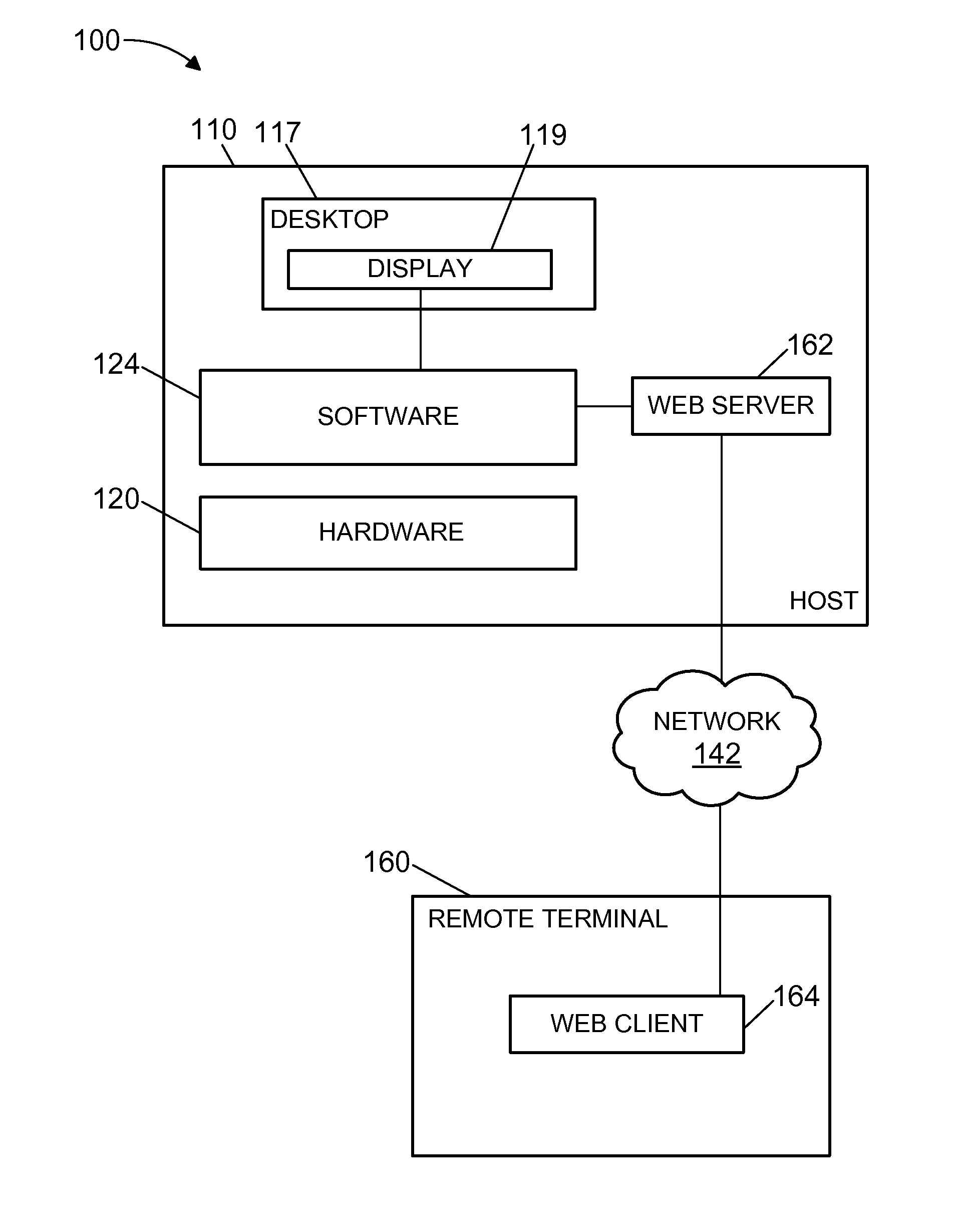

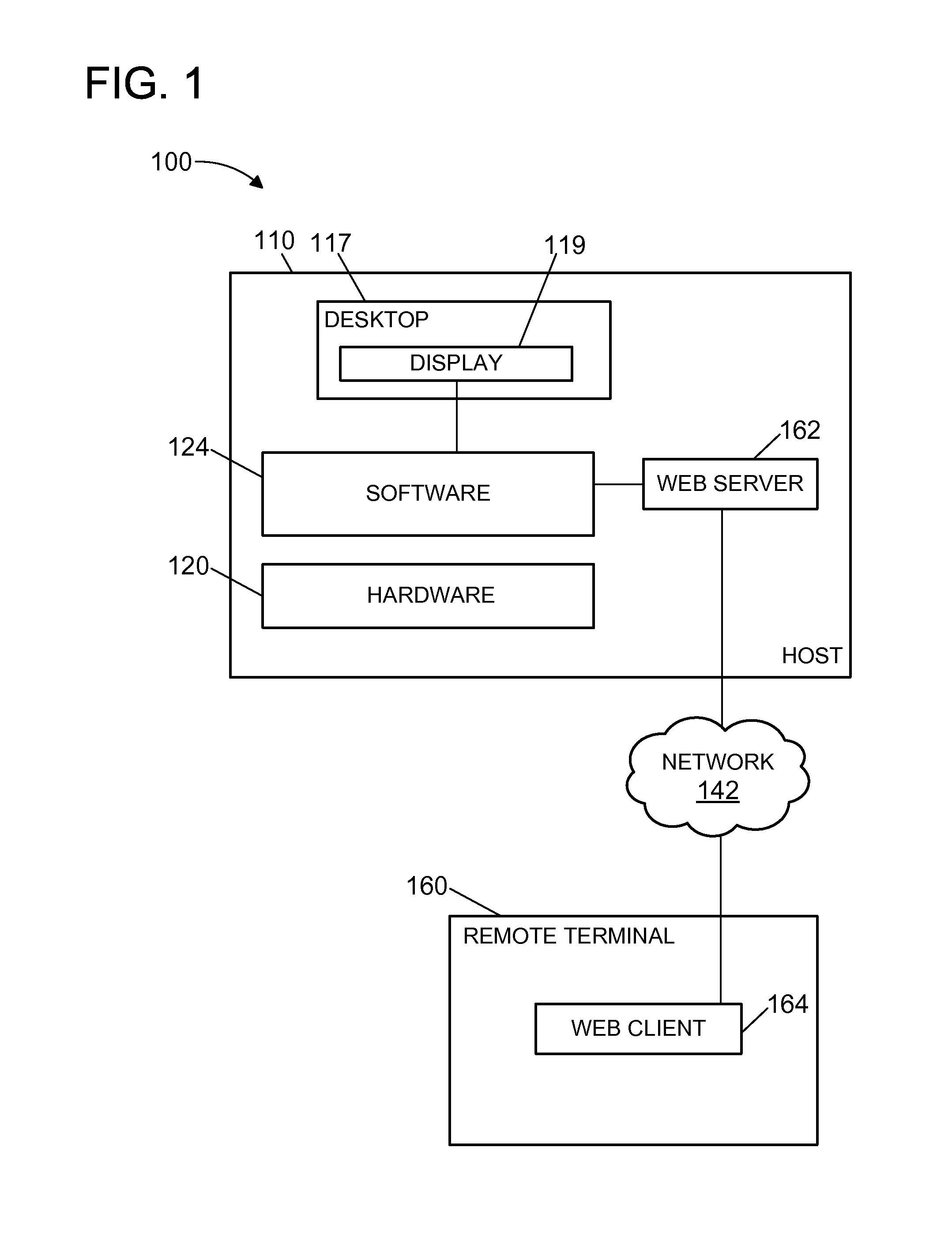

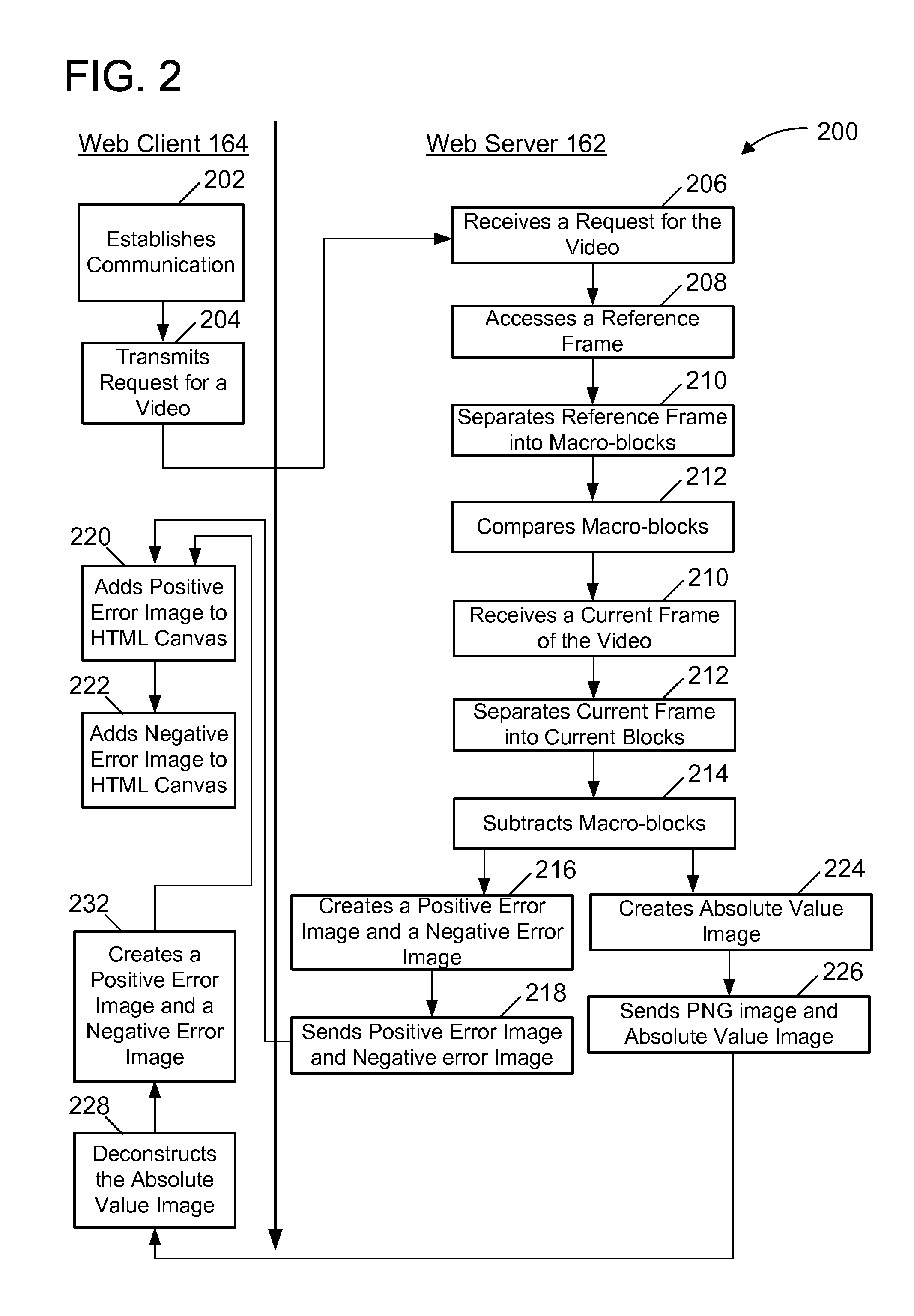

Systems and methods for applying a residual error image

ActiveUS20140181635A1Multimedia data retrievalNatural language data processingNegative errorPixel value difference

Systems and methods described herein enable a residual error image to be added and rendered in an existing HTML canvas using native primitives. A current image and a residual error image containing pixel value differences between the current image and an updated image are received. A positive residual error image and a negative error image are generated from the residual error image. The positive residual error image is added to the current image to generate a partially updated image, and the partially updated image is xored to generate an inverse image. The negative residual error image is added to the inverse image to generate an updated inverse image, and xoring the inverse image to revert the inverse image to generate the updated image.

Owner:VMWARE INC

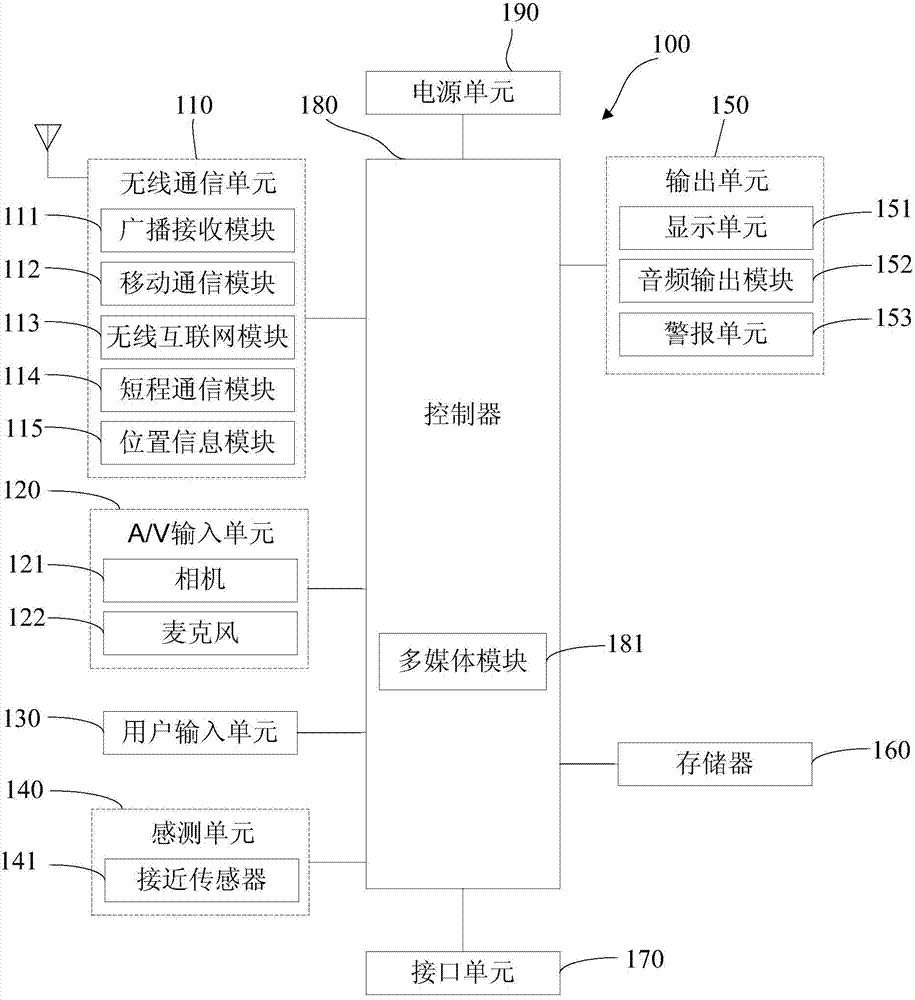

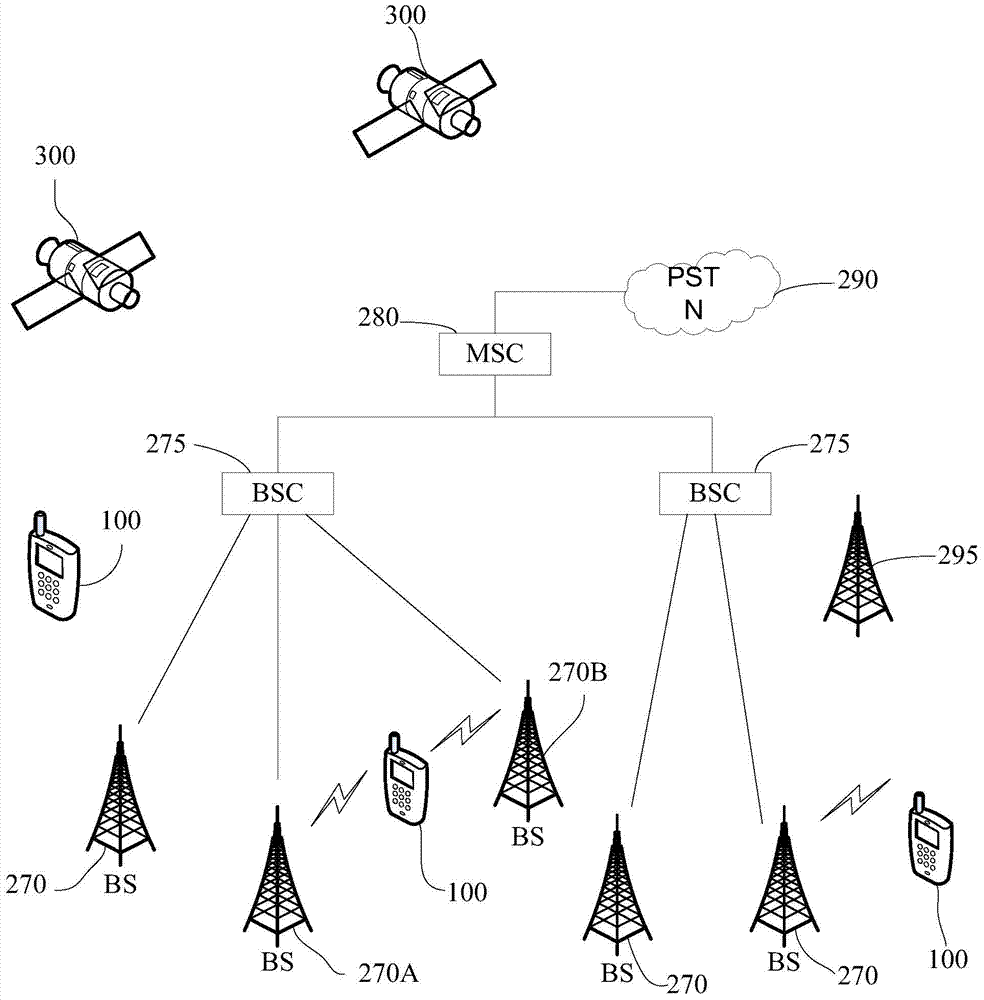

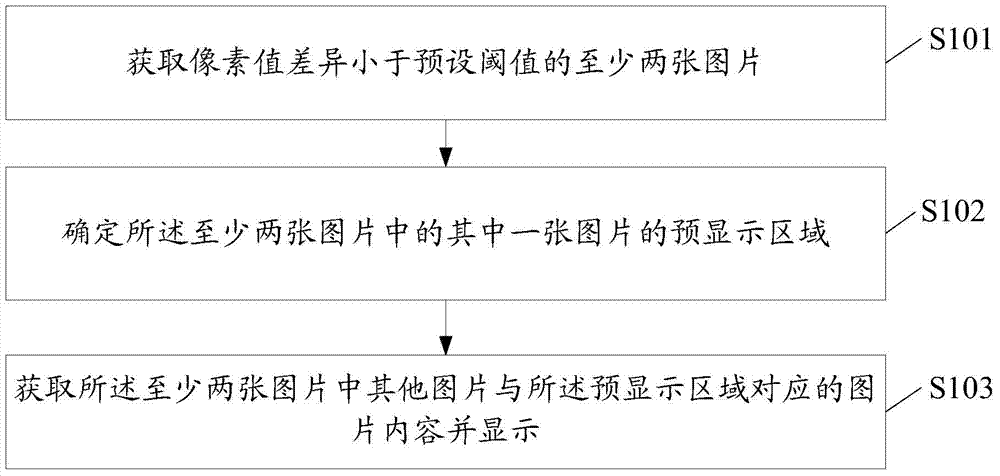

Method and device for checking pictures

ActiveCN104731484ANarrow selectionEasy to viewImage analysisInput/output processes for data processingComputer graphics (images)Algorithm

Owner:NUBIA TECHNOLOGY CO LTD

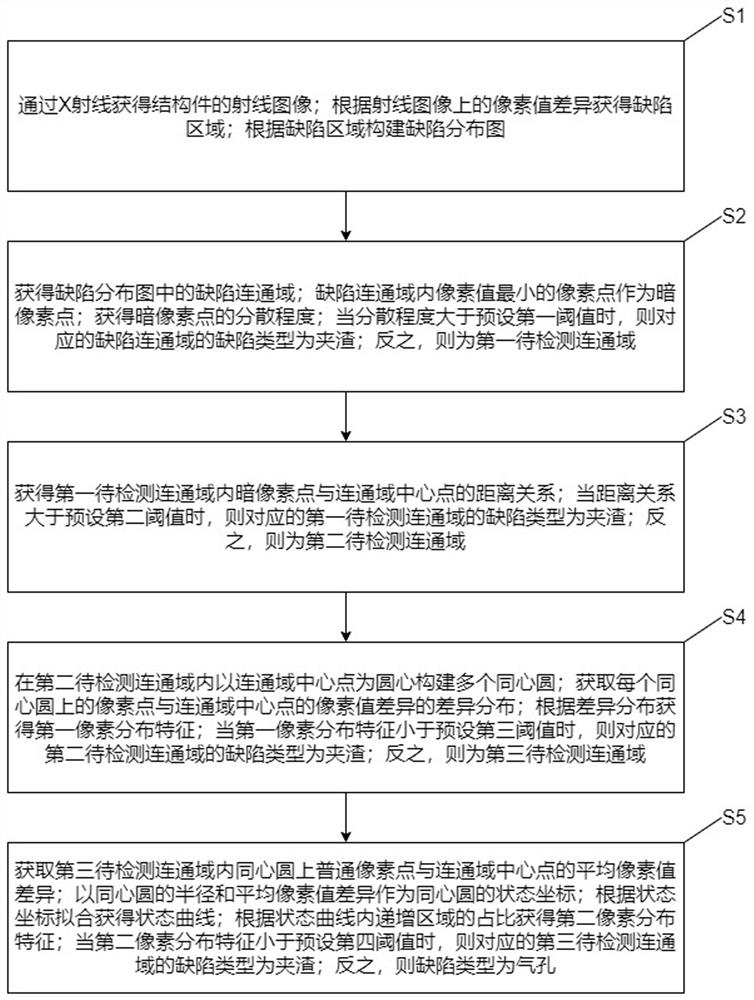

Structural member production process defect detection method based on image processing

ActiveCN113421261AImprove comprehensivenessImprove reliabilityImage enhancementImage analysisImaging processingAlgorithm

The invention relates to the technical field of artificial intelligence, in particular to a structural part production process defect detection method based on image processing. According to the method, a ray image of a structural part is obtained through X rays, and a defect distribution diagram is constructed through defect areas on the ray image. A pixel point with the minimum pixel value in the defect connected domain on the defect distribution diagram is taken as a dark pixel point, and screening is carried out twice according to the dispersion degree of the dark pixel point and the distance relationship between the dark pixel point and the center of the connected domain to obtain the defect connected domain with the defect type of slag inclusion and a second connected domain to be detected needing to be continuously detected. Twice screening is carried out through the first pixel distribution and the second pixel distribution of the pixel points in the second to-be-detected connected domain, and defect type detection of all defect connected domains is completed. According to the method, the pixel value difference characteristics of air holes and slag inclusions are fully considered, so that defect detection is accurately and efficiently completed.

Owner:金成技术股份有限公司

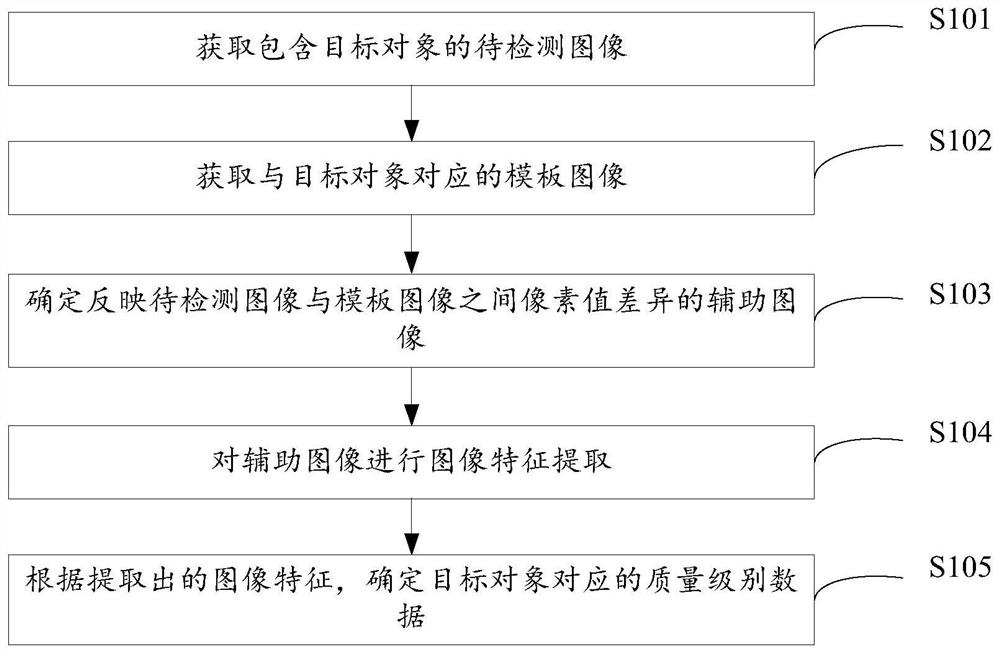

Data processing method and device, equipment and storage medium

ActiveCN113516612AGuaranteed accuracyWill not cause interferenceImage enhancementImage analysisPattern recognitionPixel value difference

The embodiment of the invention provides a data processing method and device, equipment and a storage medium. The method comprises the steps: acquiring a to-be-detected image containing a target object and a template image corresponding to the target object, and determining an auxiliary image according to the two images, wherein the auxiliary image is used for indicating the pixel value difference of corresponding pixel points between the two images; and then, extracting image features of the auxiliary image, and determining quality level data of the target object in the to-be-detected image according to the extracted image features. Therefore, the above method is a method for automatically determining the quality of the target object, and the quality inspection efficiency can be greatly improved. Besides, the auxiliary image obtained by introducing the template image can highlight the defective area in the target object, and then quality detection is performed according to the image features extracted from the auxiliary image, so that the non-defective area in the target object is ensured not to cause interference to the quality detection, and the accuracy of quality level data is ensured.

Owner:ALIBABA GRP HLDG LTD

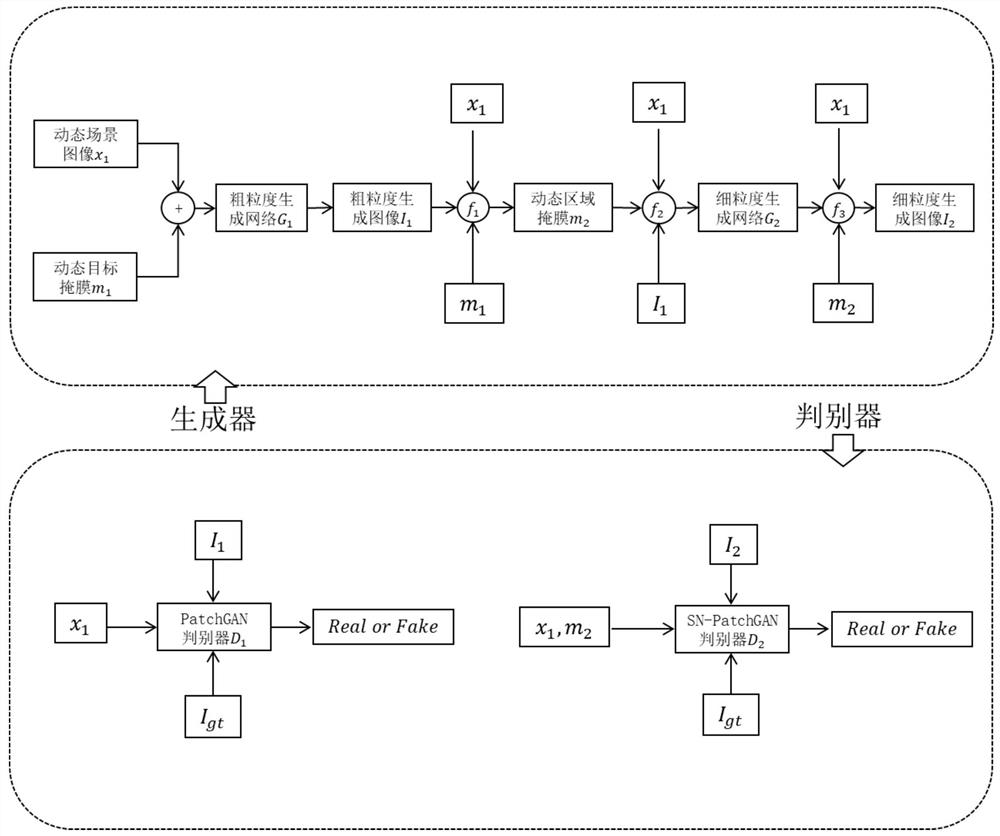

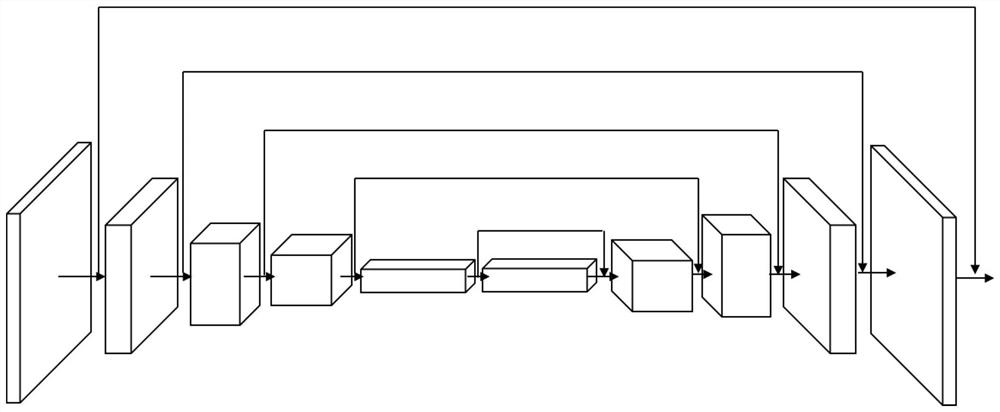

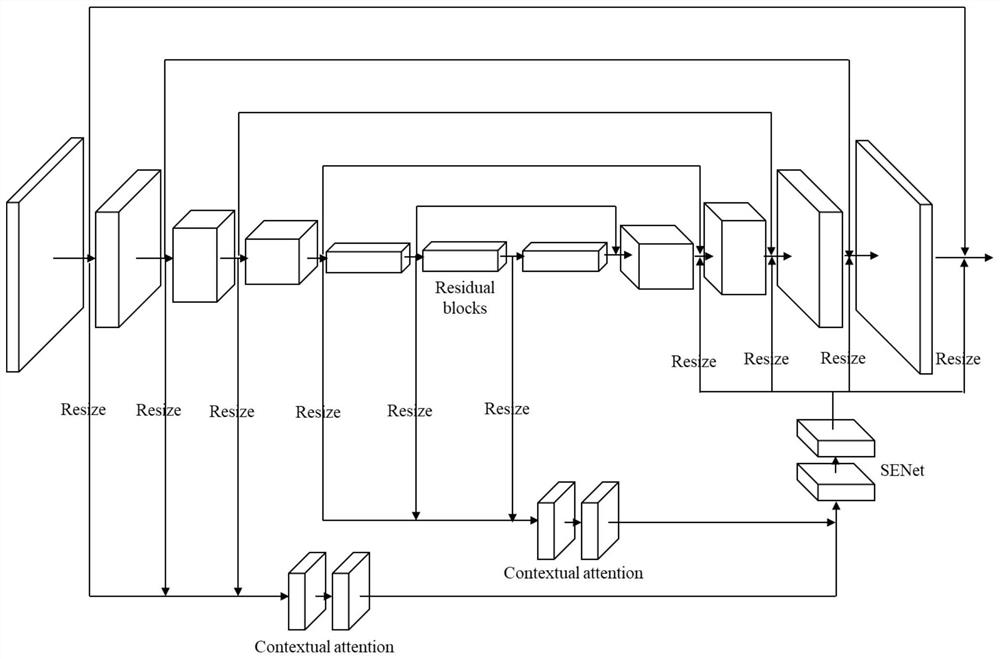

Dynamic-to-static scene conversion method based on conditional generative adversarial network

PendingCN112507849AIncrease authenticityOptimizing Semantic ConsistencyCharacter and pattern recognitionNeural architecturesAlgorithmGenerative adversarial network

The invention relates to a dynamic-to-static scene conversion method based on a conditional generative adversarial network, and the method is characterized in that a generator is a cascade two-stage network from coarse to fine, and discriminators are PatchGAN and SN-PatchGAN. According to the method, a dynamic region binary mask is deduced according to the difference between the output result of the coarse network and the pixel value of the dynamic scene, and then static recovery is performed on the dynamic region through the fine network. After deep-layer and shallow-layer features of a finenetwork coding area are extracted, a context attention mechanism is adopted to optimize dynamic area scene generation. Compared with a traditional discriminator, the discriminator adopted by the invention can pay more attention to image details, and the training process is more stable. Compared with a traditional dynamic-to-static scene conversion method, the method has the advantages that the extracted dynamic target area is more accurate, and the generated dynamic scene image is rich in texture and closer to the real situation.

Owner:SOUTHEAST UNIV

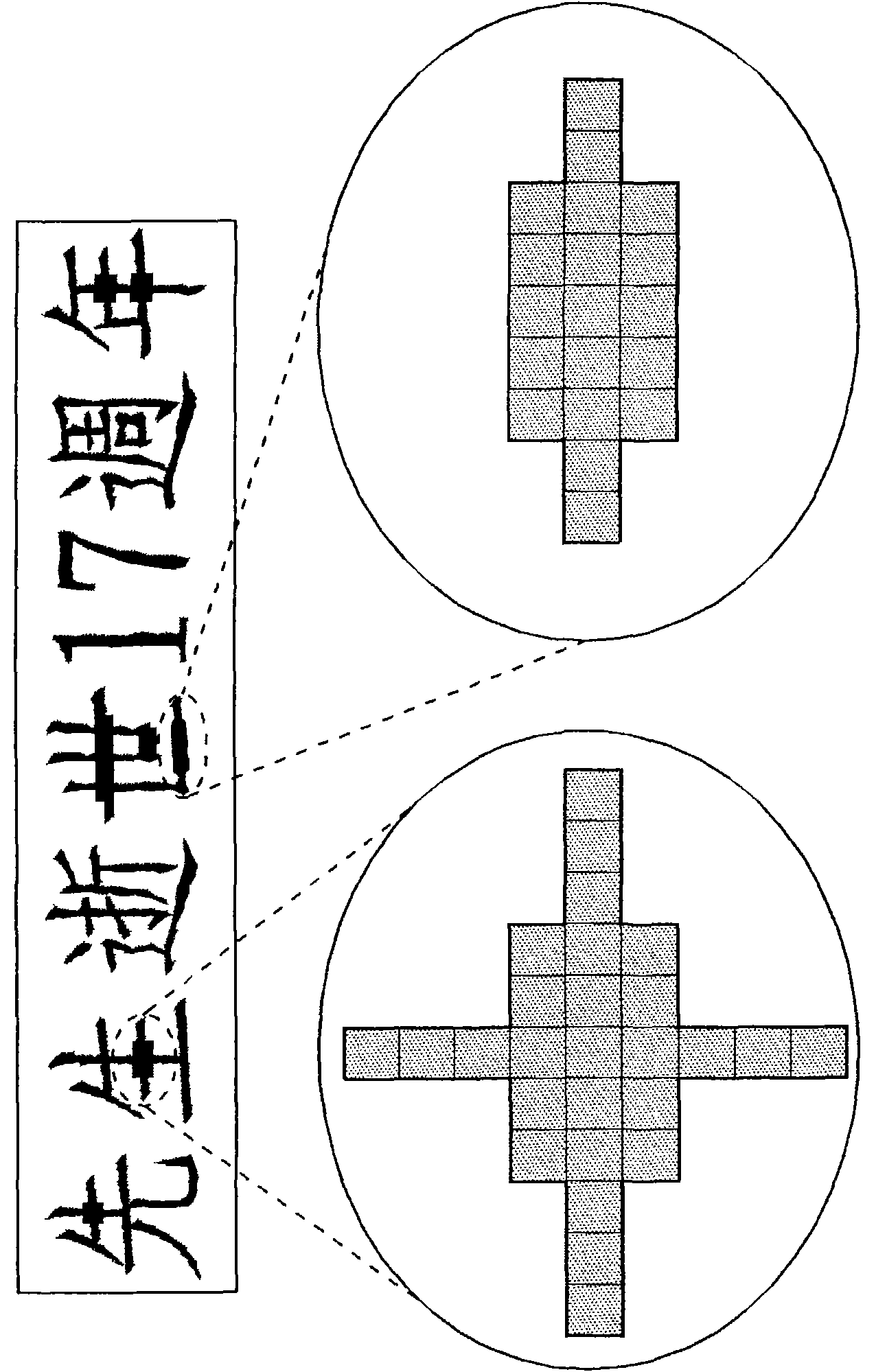

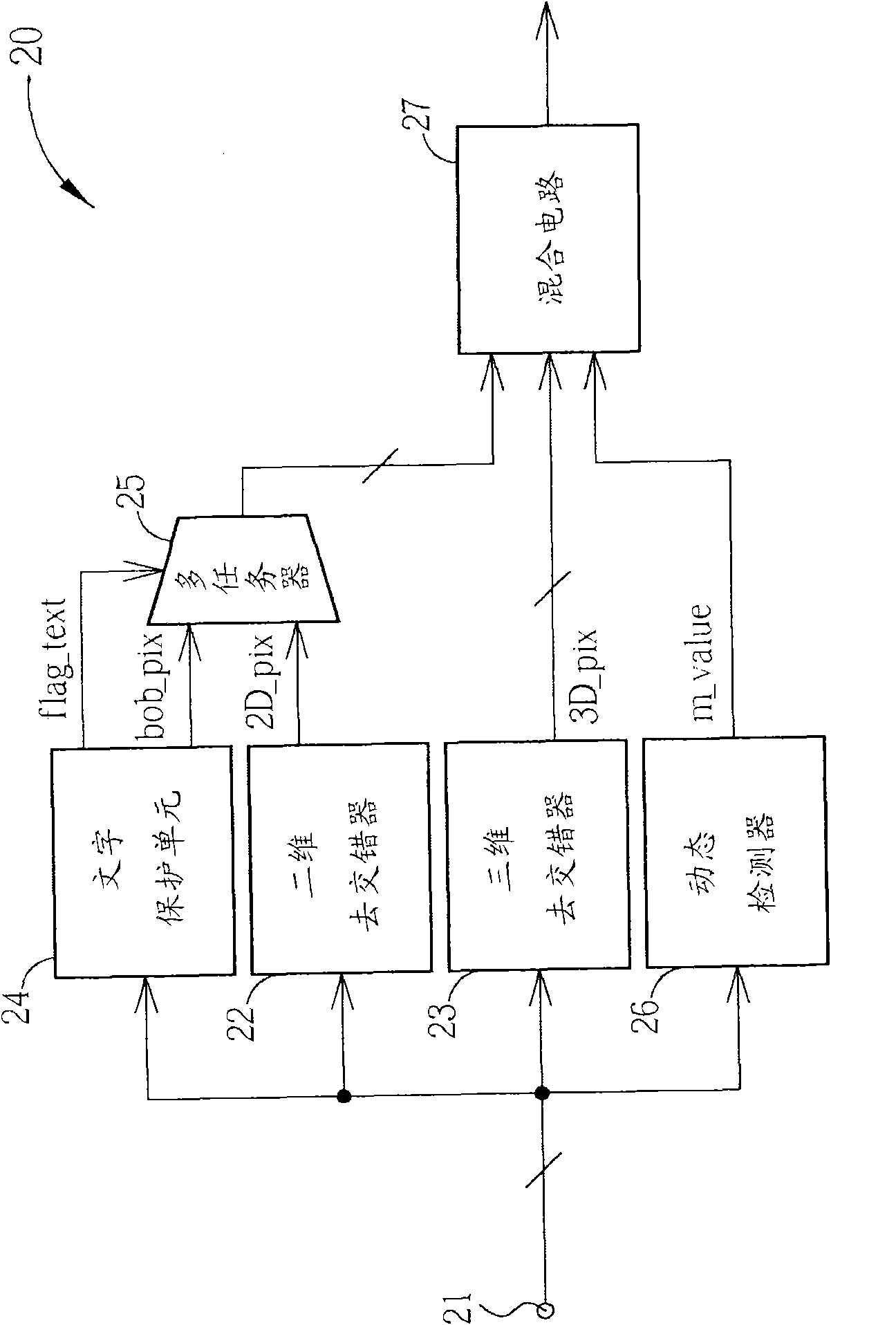

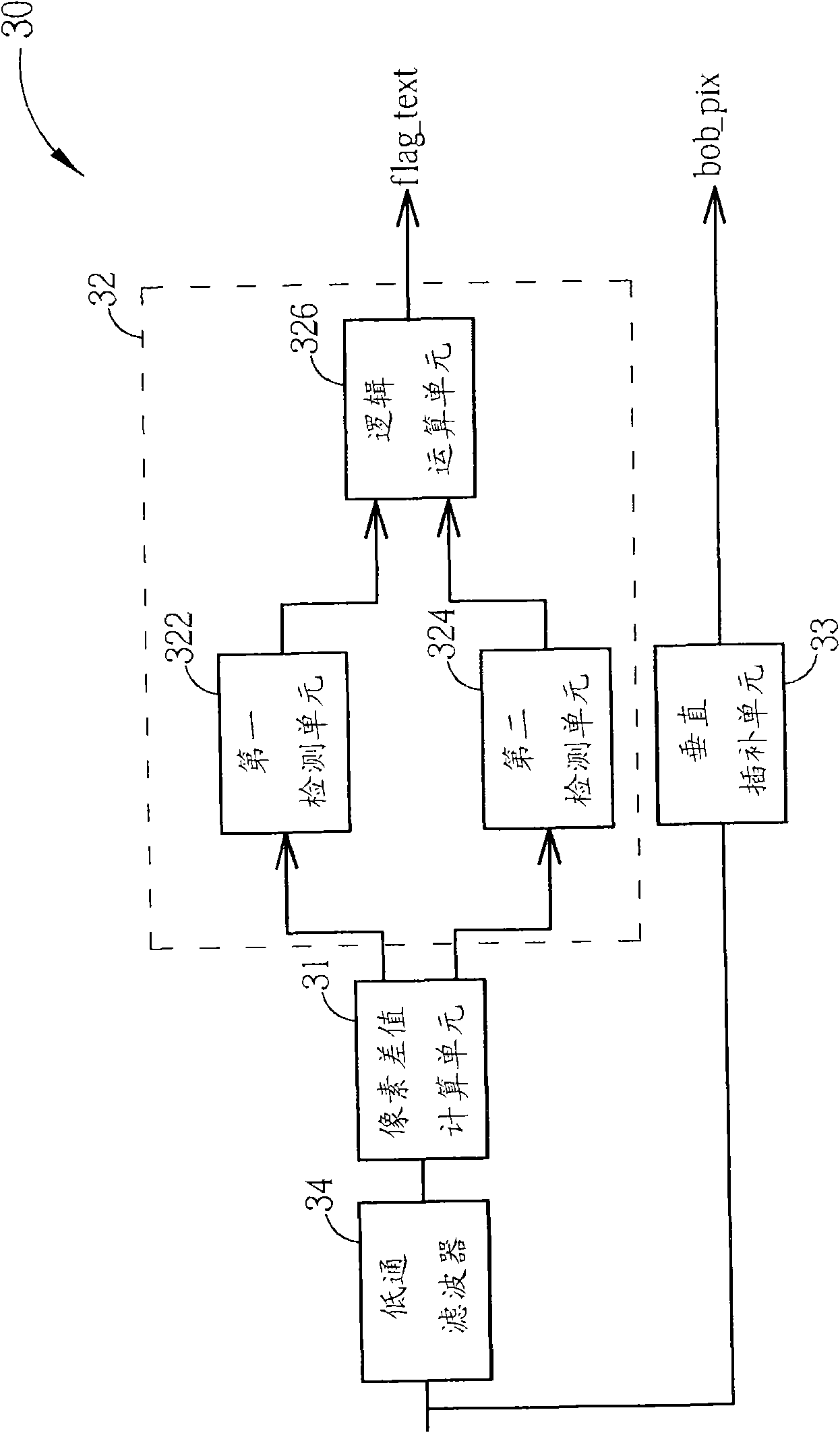

Character protection device and dynamic adaptive deinterlacing device

ActiveCN101888473ATelevision system detailsColor television detailsText detectionPixel value difference

The invention relates to a character protection device for deinterlacing operation, which comprises a pixel interpolation operation unit, a character detector and a vertical interpolation unit, wherein the pixel interpolation operation unit is used for calculating the pixel value differences among a plurality of pixel pairs in a pattern field according to the position for inserting a target pixel in the pattern field, and the plurality of the pixel pairs form a detection region which corresponds the target pixel; the character detector is used for judging whether the detection region contains character strokes or not according to the distribution of the pixel value differences of the detection region, judging whether the target pixel is positioned in the range of the character strokes or not and further producing a character detection signal; and the vertical interpolation unit is used for carrying out vertical interpolation operation according to the character detection signal and further producing a pixel value of the target pixel.

Owner:NOVATEK MICROELECTRONICS CORP

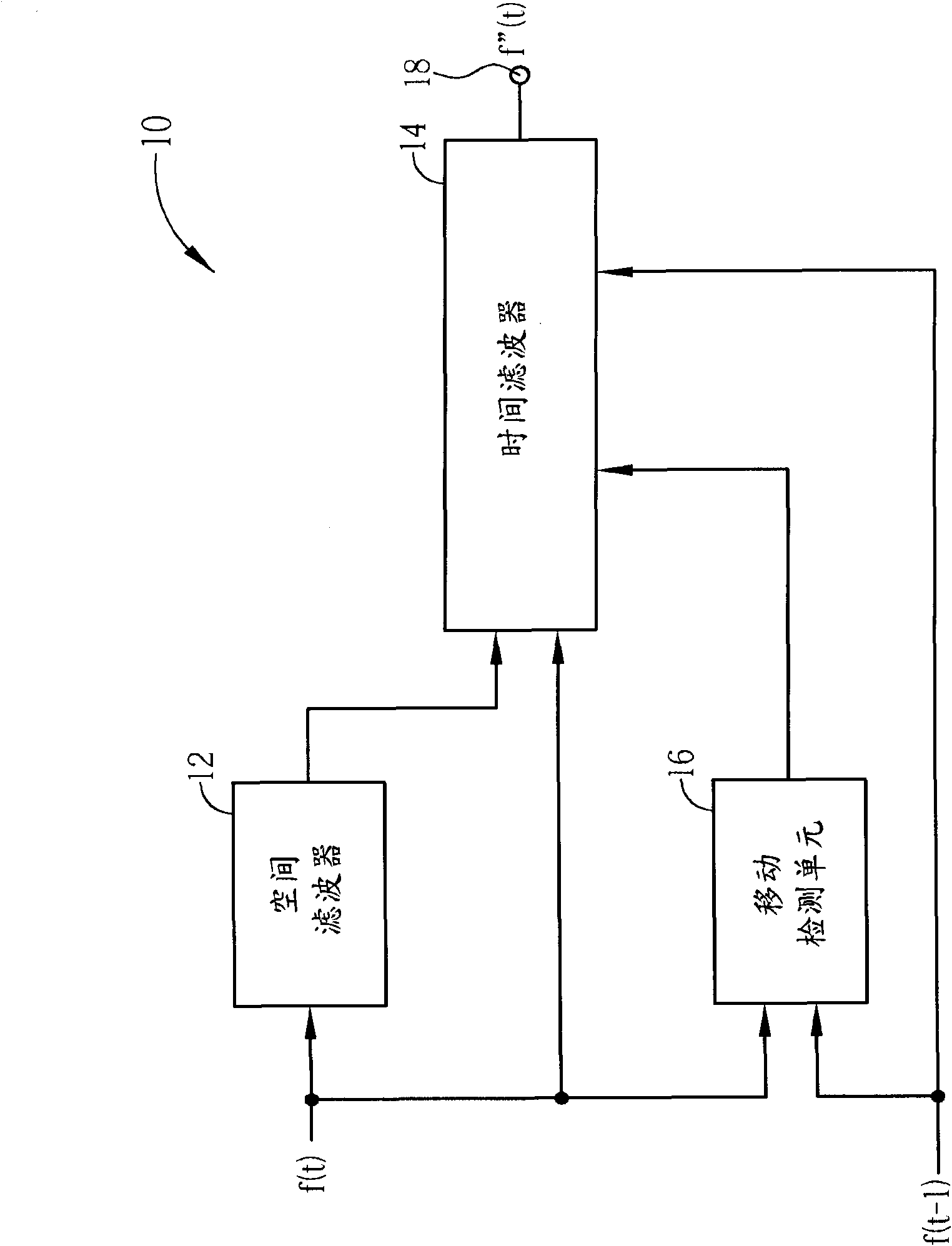

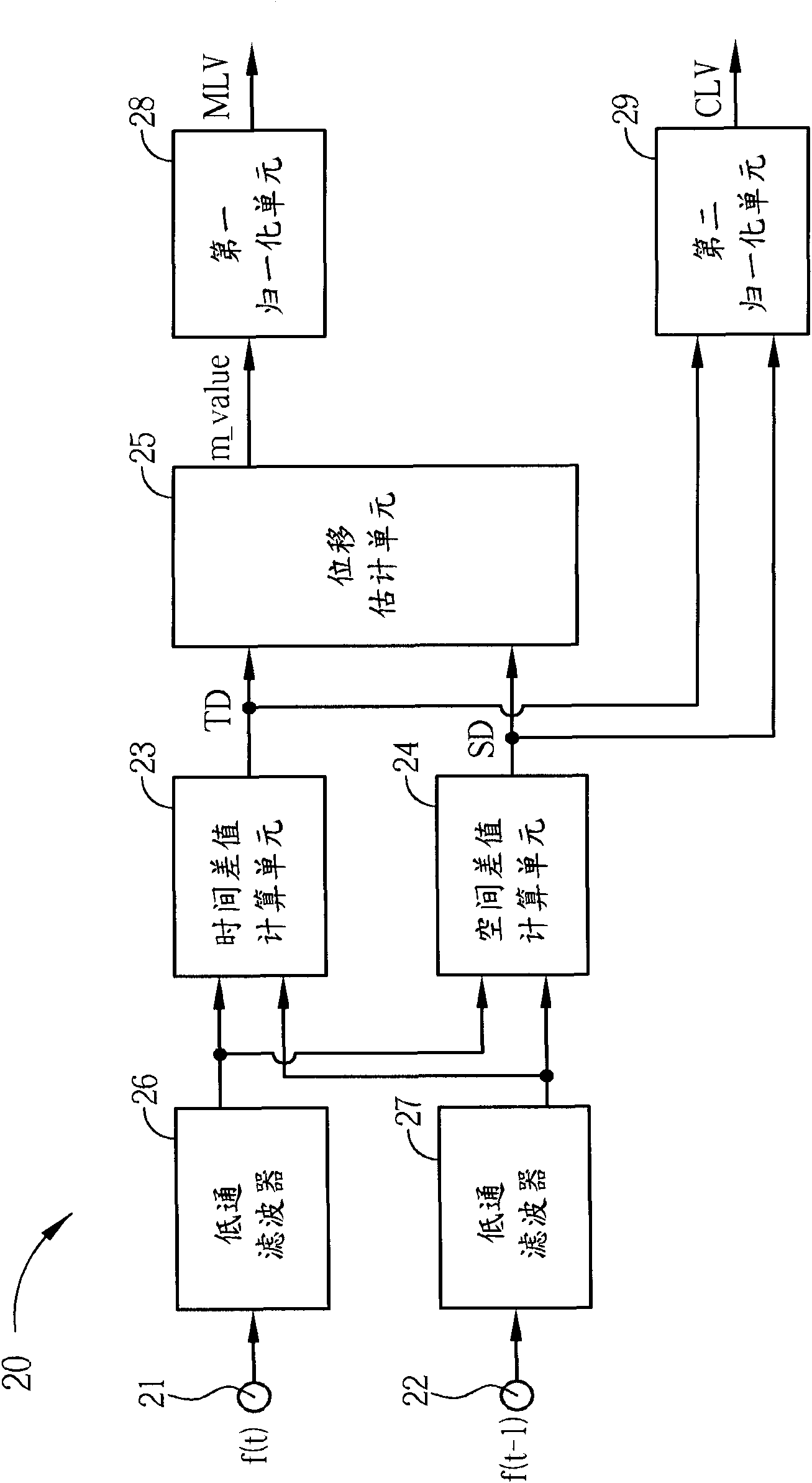

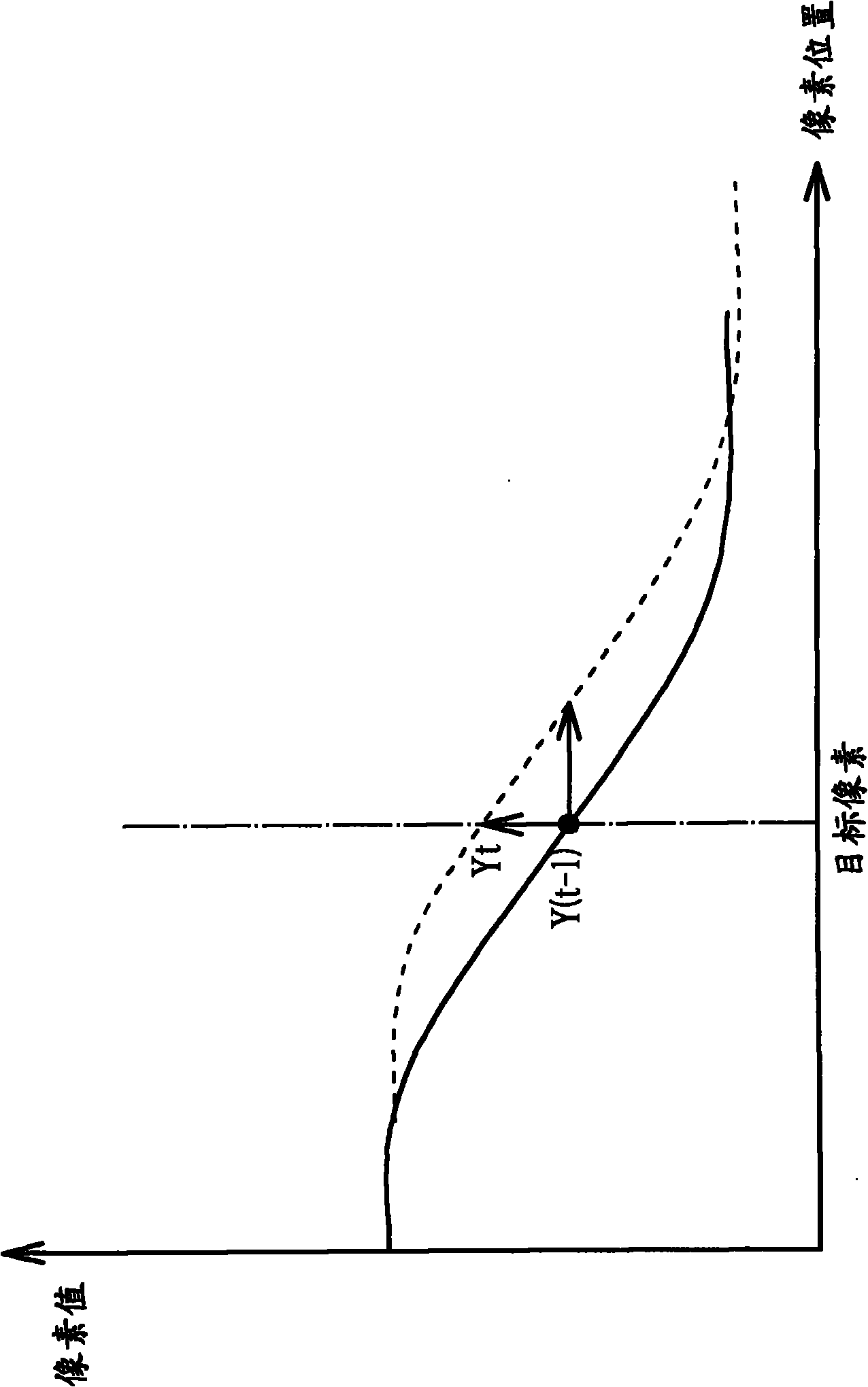

Mobile detection method and device

InactiveCN102215321ATelevision system detailsColor television detailsPixel value differenceComputer vision

The invention relates to a mobile detection method comprising the following steps of: receiving a previous image and a current image; computing the pixel value difference of a target pixel in the current image and the previous image to judge a time pixel value difference; respectively computing the pixel value difference of the target pixel and surrounding pixels of the target pixel in the previous image and the current image to judge a space pixel value difference; and dividing the space pixel value difference by the time pixel value difference to judge a displacement value of the target pixel.

Owner:NOVATEK MICROELECTRONICS CORP

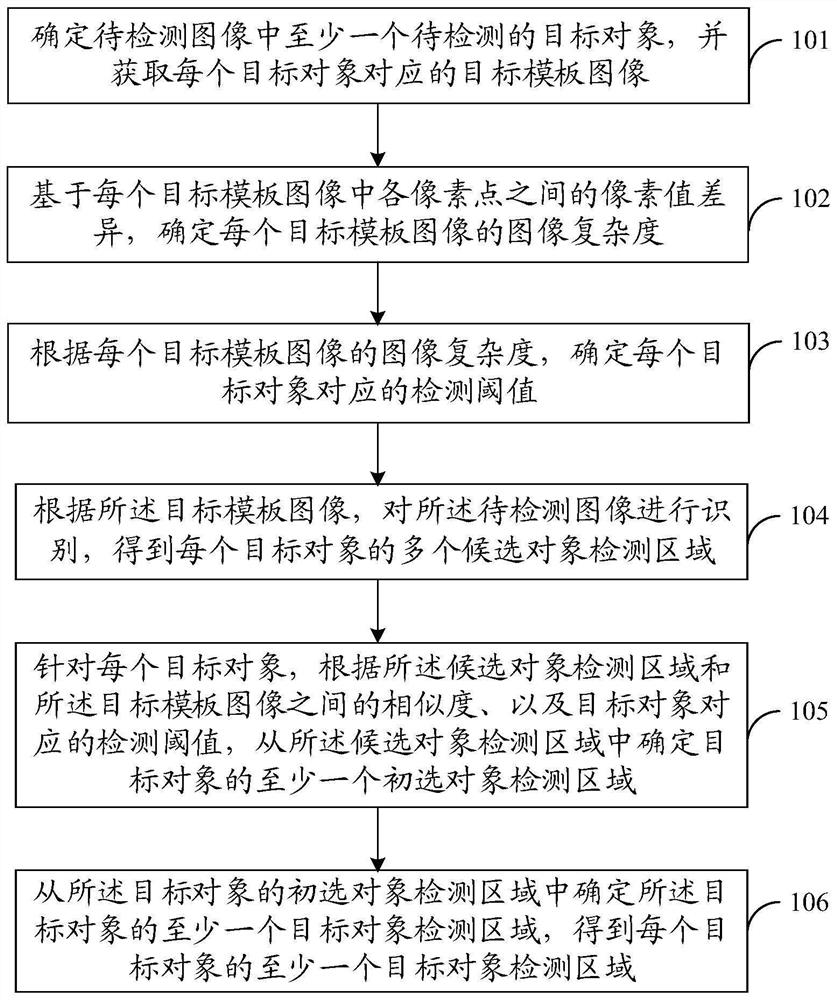

Target detection method and device, electronic equipment and storage medium

PendingCN112734747AImprove accuracySave manpower and material resourcesImage analysisGeometric image transformationPixel value differenceRadiology

The invention discloses a target detection method and device, electronic equipment and a storage medium. The method comprises the steps of determining at least one to-be-detected target object in a to-be-detected image, and obtaining a target template image of each target object; determining the image complexity of each target template image based on the pixel value difference of each pixel point in each target template image; determining a detection threshold corresponding to each target object according to the image complexity; recognizing the to-be-detected image according to the target template image to obtain a plurality of candidate object detection areas of each target object; for each target object, determining a primary object detection area of the target object from the candidate object detection areas according to the similarity between the candidate object detection areas and the target template image and a detection threshold; and determining a target object detection area of the target object from the primarily selected object detection areas. The target detection method and device can adapt to detection scenes with various types of targets, and the target detection accuracy is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Biasing a noise filter to preserve image texture

ActiveUS20200342579A1Preserve textureImage enhancementImage analysisPixel value differenceBilateral filter

Owner:APPLE INC

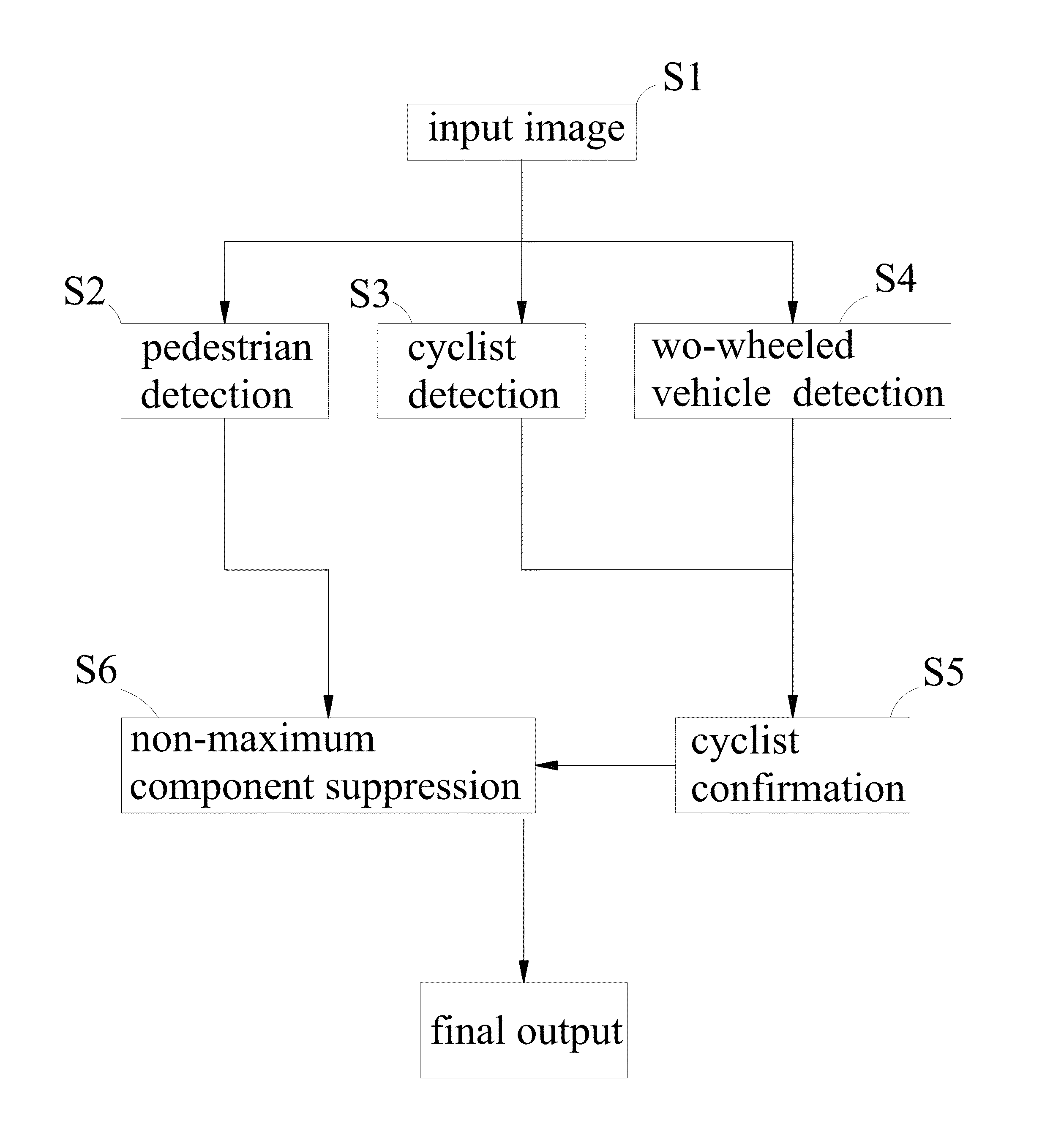

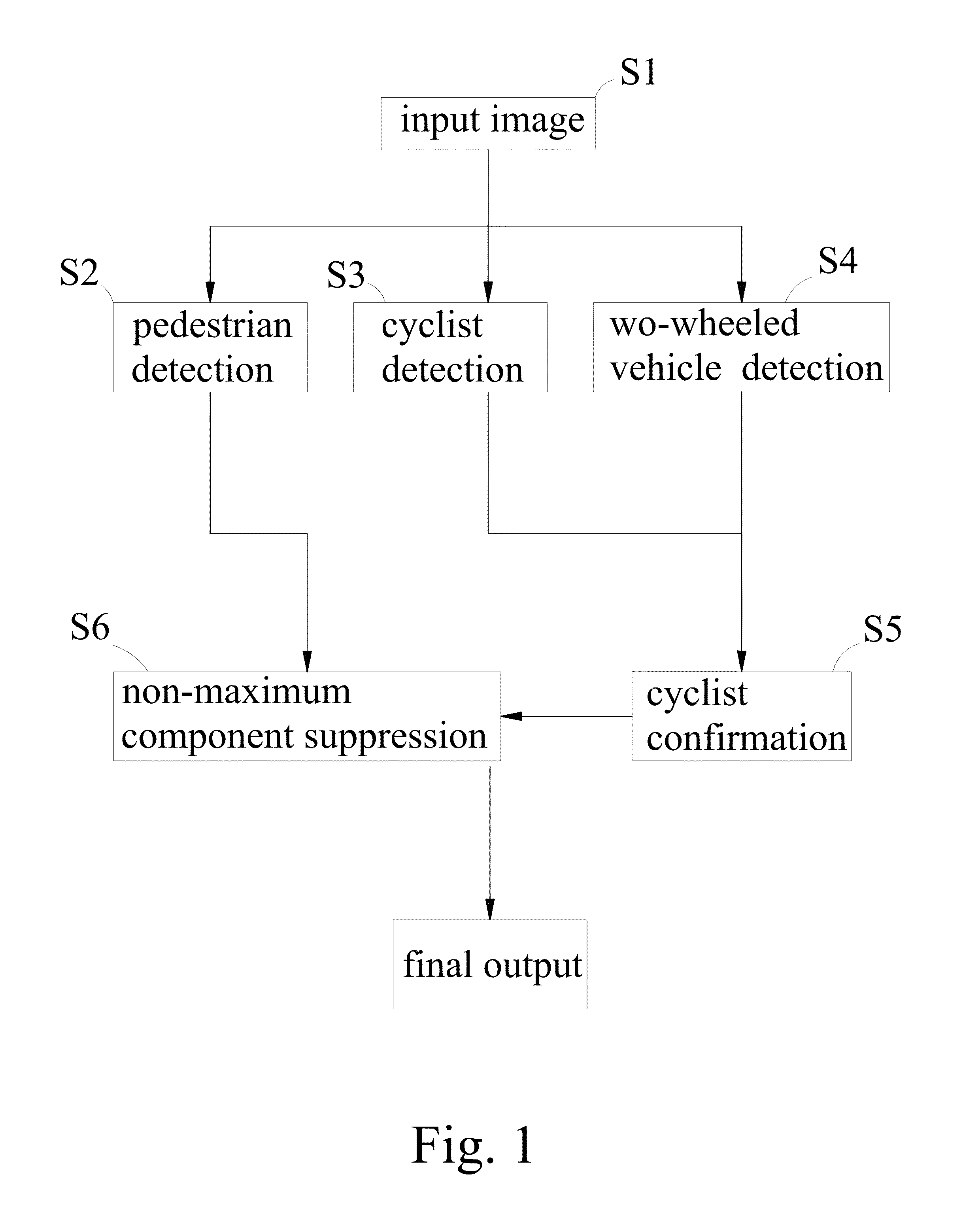

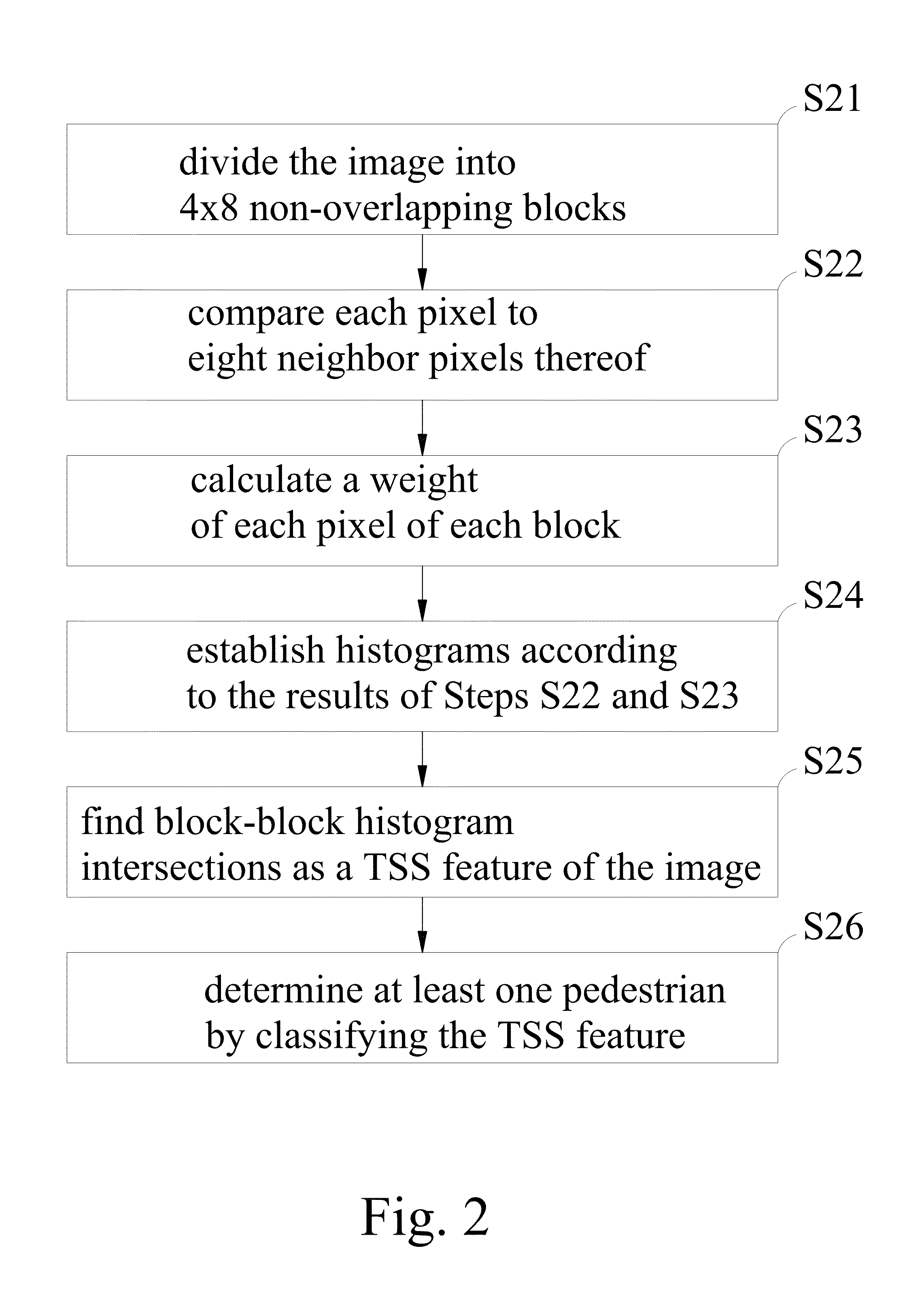

Vision based pedestrian and cyclist detection method

ActiveUS9087263B2Improve performanceImprove securityImage enhancementImage analysisPattern recognitionPixel value difference

A vision based pedestrian and cyclist detection method includes receiving an input image, calculating a pixel value difference between each pixel and the neighbor pixels thereof, quantifying the pixel value difference as a weight of pixel, proceeding statistics for the pixel value differences and the weights, determining intersections of the statistics as a feature of the input image, classifying the feature into human feature and non-human feature, confirming the human feature belonging to cyclist according to the spatial relationship between the human feature and the detected two-wheeled vehicle, and retaining one detection result for each cyclist by suppressing other weaker spatial relationships between the human feature and the detected two-wheeled vehicle.

Owner:NAT CHUNG SHAN INST SCI & TECH

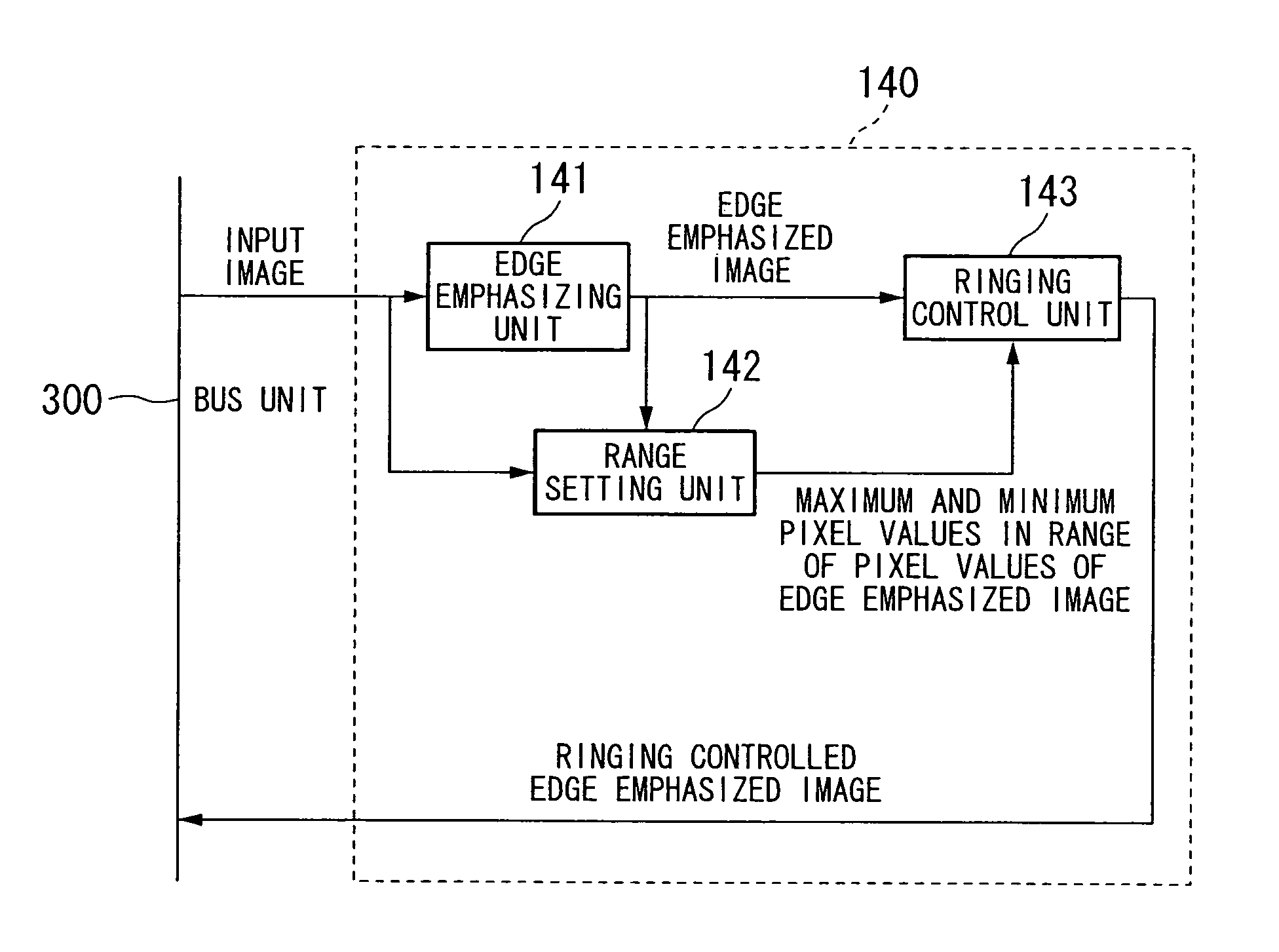

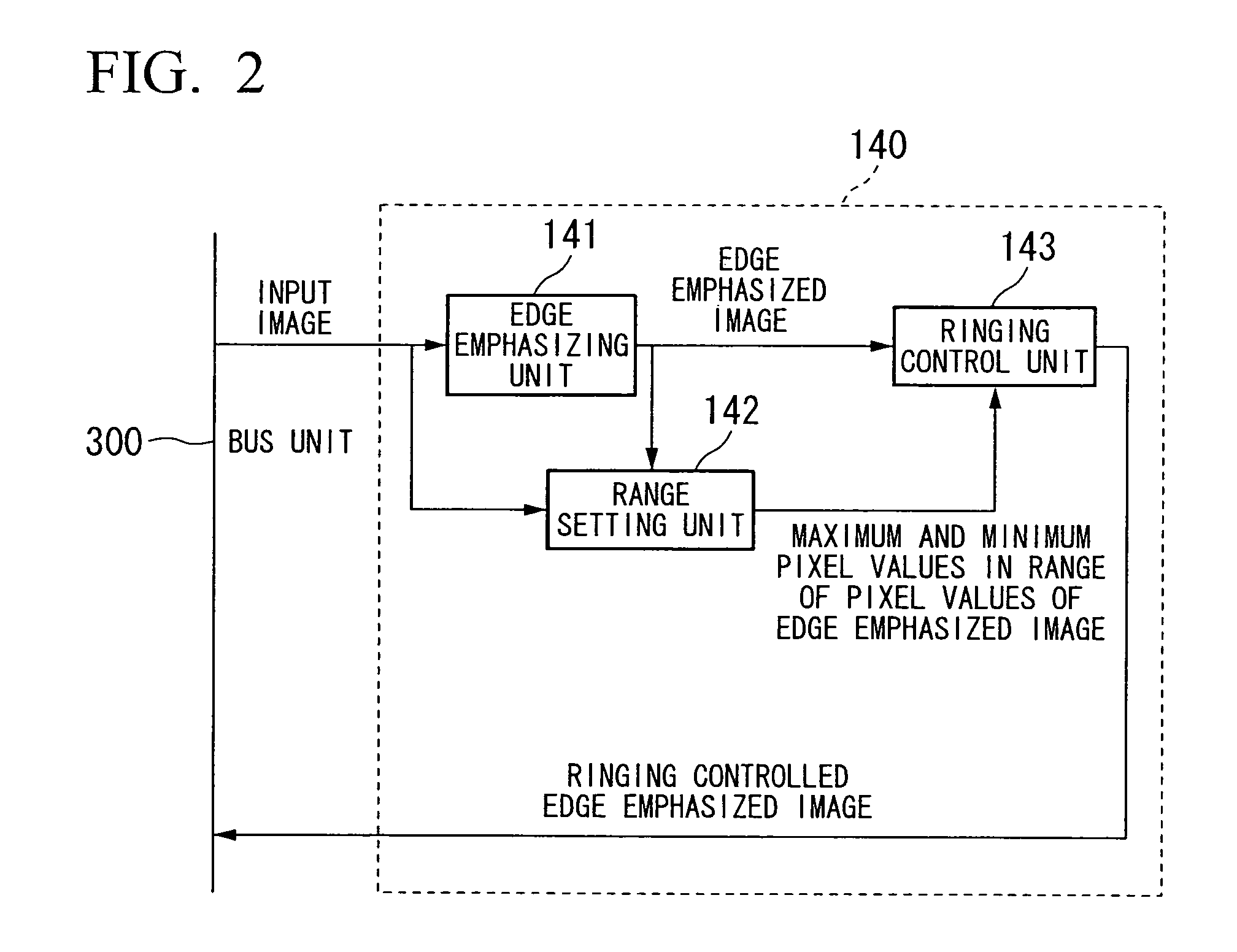

Image processing apparatus, imaging apparatus, and image processing program

ActiveUS8625923B2Improve clarityReduce artifactsImage enhancementImage analysisImaging processingPixel value difference

An image processing apparatus includes an edge emphasizing unit configured to form an edge emphasized image by emphasizing an edge of an input image, a range setting unit configured to set a pixel value range of a target pixel value of a target pixel of the input image based on a pixel value difference between the target pixel value and a neighboring pixel value of a neighboring pixel of the input image, and based on an edge emphasized neighboring pixel value of an edge emphasized neighboring pixel of the edge emphasized image, and a ringing control unit configured to restrict an edge emphasized target pixel value of an edge emphasized target pixel of the edge emphasized image in the pixel value range. The edge emphasized neighboring pixel corresponds to the neighboring pixel position of the input image.

Owner:NIKON CORP

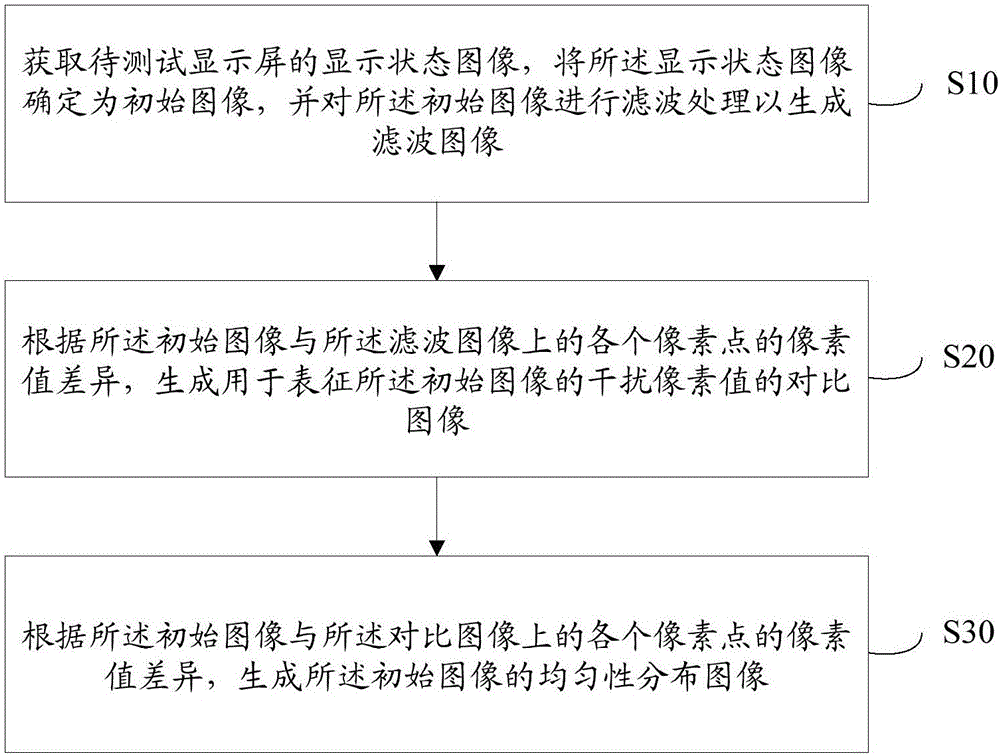

Display screen uniformity test method and system

ActiveCN106441820AUnderstanding the Uniformity DistributionTesting optical propertiesPixel value differenceComputer science

The invention discloses a display screen uniformity test method, which comprises the following steps of obtaining a display state image of a display screen to be tested; determining the display state image into an initial image; performing filtering processing on the initial image so as to generate a filtering image; generating a comparison image used for showing the interference pixel value of the initial image according to the pixel value difference of each pixel point on the initial image and the filtering image; generating a uniformity distribution image of the initial image according to the pixel value differences of each pixel point on the initial image and the comparison image. The invention also discloses a display screen uniformity test system. The method and the device provided by the invention aim at reflecting the uniformity distribution condition of the display screen through the test results.

Owner:SHENZHEN TCL NEW-TECH CO LTD

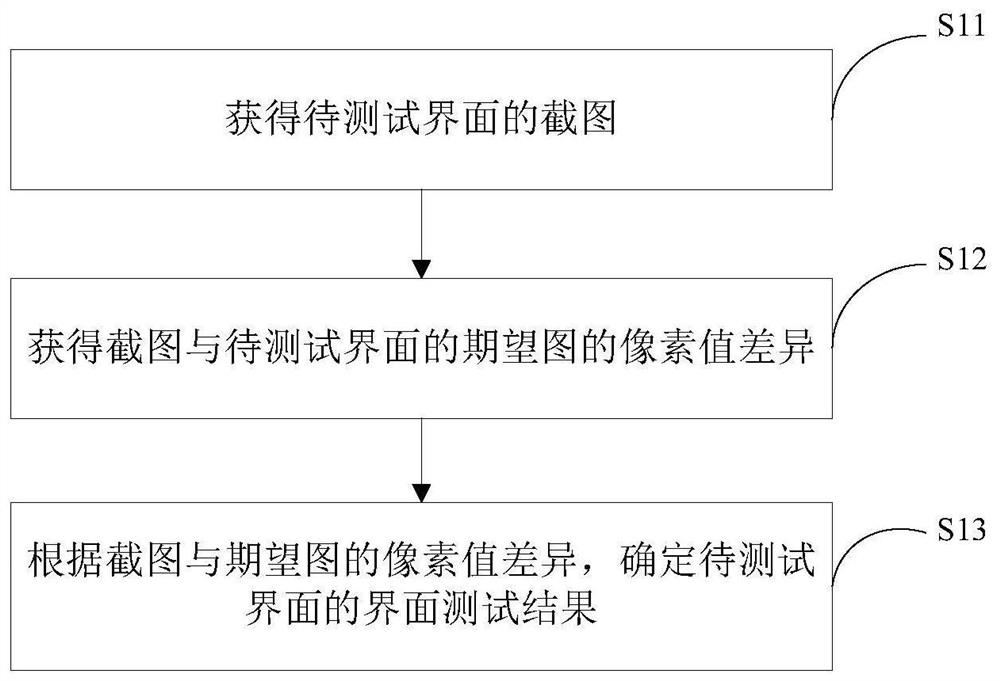

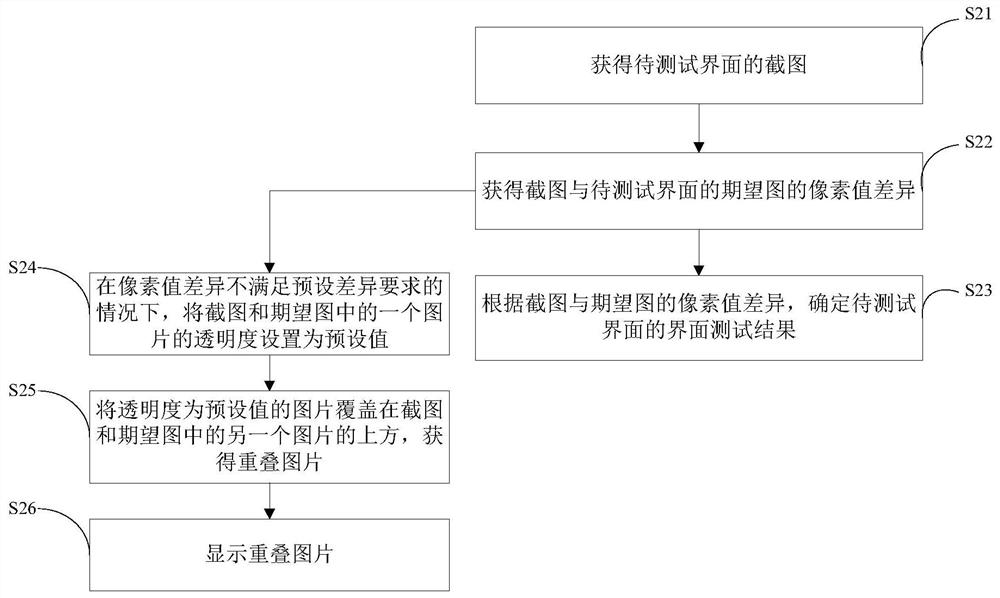

Interface testing method and device, electronic equipment and storage medium

PendingCN113407461AImprove test efficiencySoftware testing/debuggingExecution for user interfacesComputer hardwarePixel value difference

The invention relates to an interface testing method and device, electronic equipment and a storage medium, and the method comprises the steps: obtaining a screenshot of a to-be-tested interface, obtaining a pixel value difference between the screenshot and an expected image of the to-be-tested interface, and determining an interface testing result of the to-be-tested interface according to the pixel value difference between the screenshot and the expected image. Whether the interface is normally displayed or not can be determined through the pixel value difference between the screenshot and the expected image, and codes do not need to be written. Meanwhile, the interface testing method provided by the embodiment of the invention can be suitable for all page structures, so that codes do not need to be rewritten for different page structures, and the UI testing efficiency can be relatively high.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

Fast loss less image compression system based on neighborhood comparisons

InactiveUS6882750B2Prevent excessive compressionFast imagingCode conversionCharacter and pattern recognitionPixel value differenceImage compression

A fast loss less image compression system based on neighborhood comparisons compares pixel value differences with neighboring pixels and replaces such pixel values with the minimum of the differences. A marker is attached to a block of pixels, such that all the pixels in that block are compared with neighbors of one direction. The marker indicates how all of the pixels in that block are compared. Intermittent Huffman-tree construction is used such that one tree is used for several frames. Huffman coding is used to compress the resulting frame. A single Huffman-tree is constructed once every predetermined number of frames. The frequency of Huffman-tree construction can be performed according to the instantaneous availability of processor time to perform the construction. When more processing time is available, the Huffman-trees are computed more frequently. Such frequency variation can be implemented by using an input video frame buffer. If the buffer is a certain size, then processor time for Huffman-tree construction is available.

Owner:ZAXEL SYST

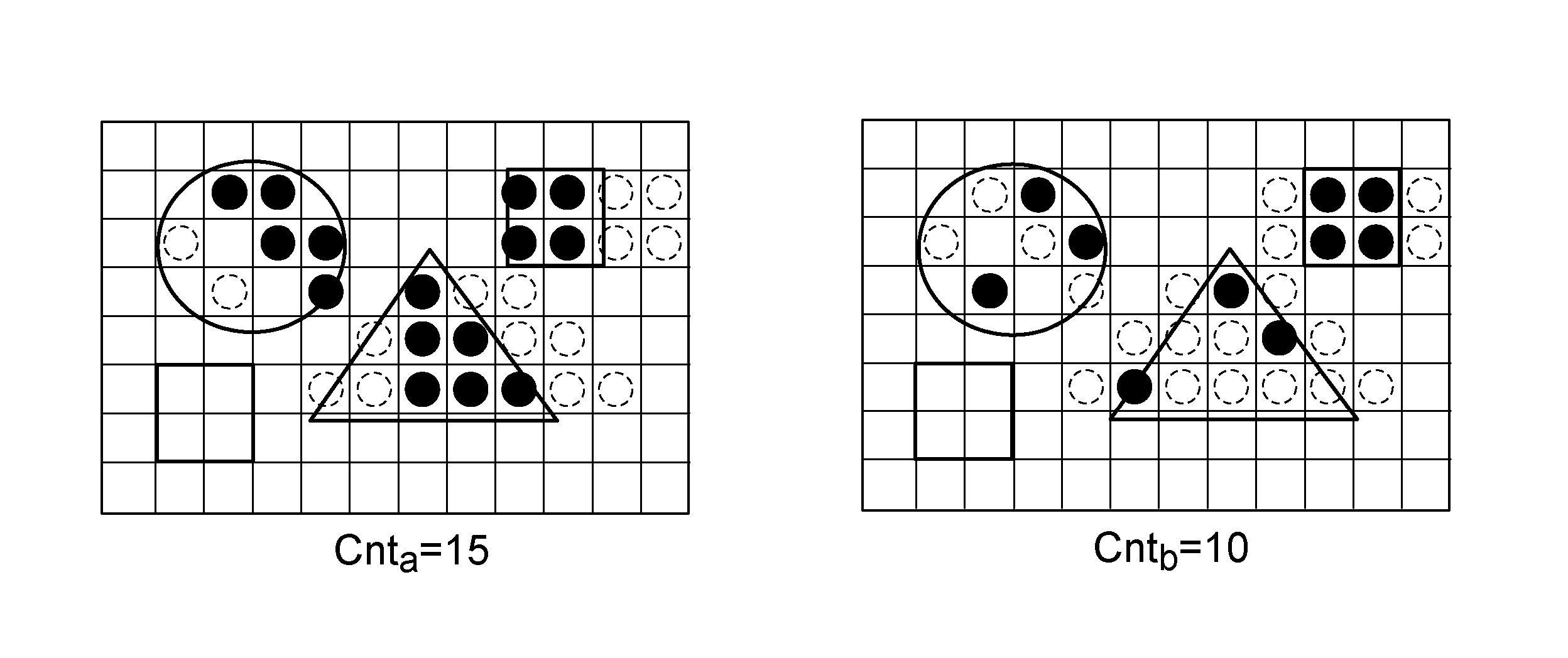

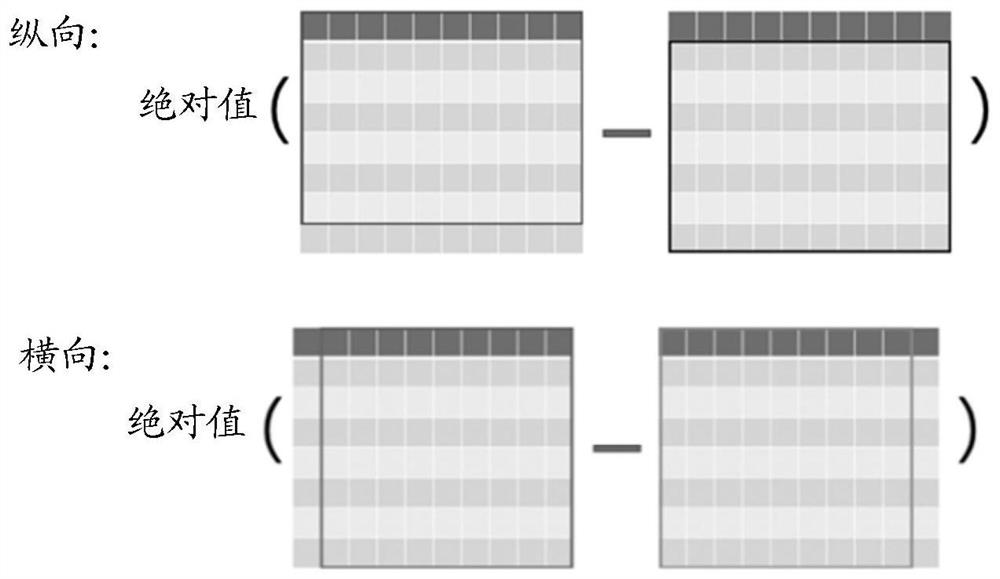

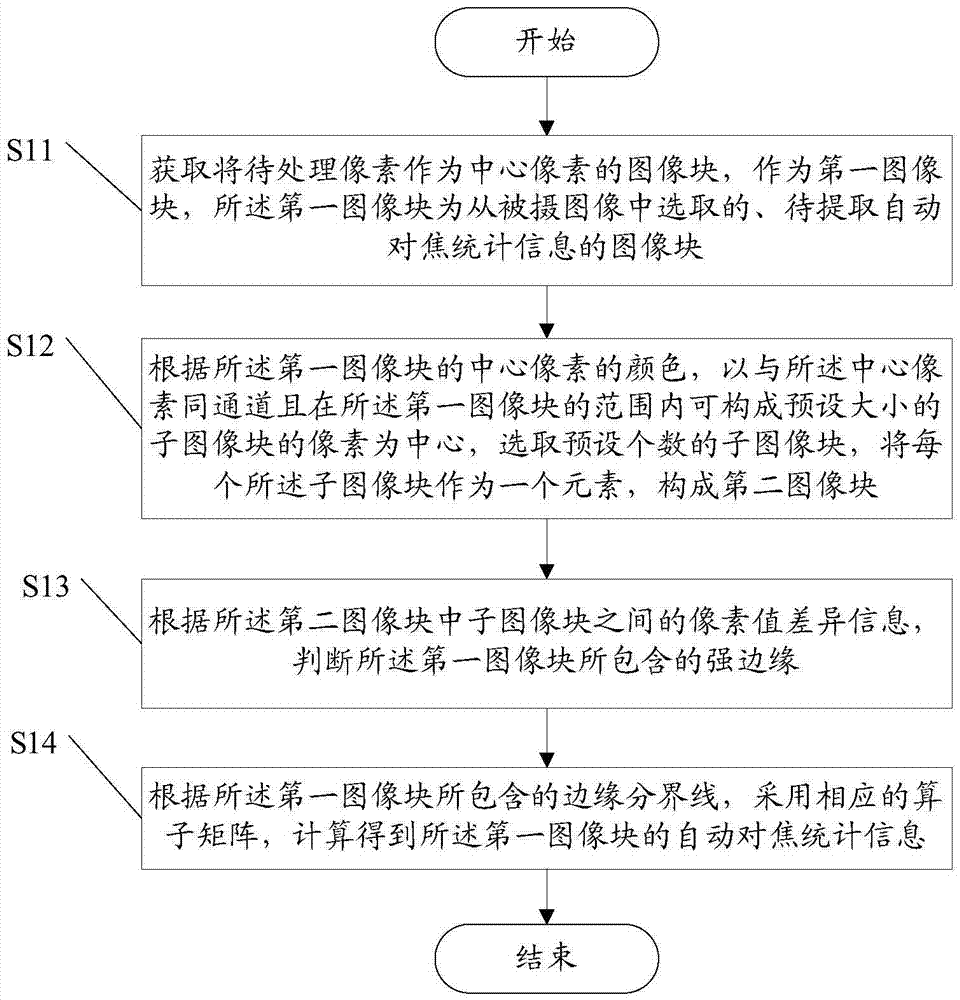

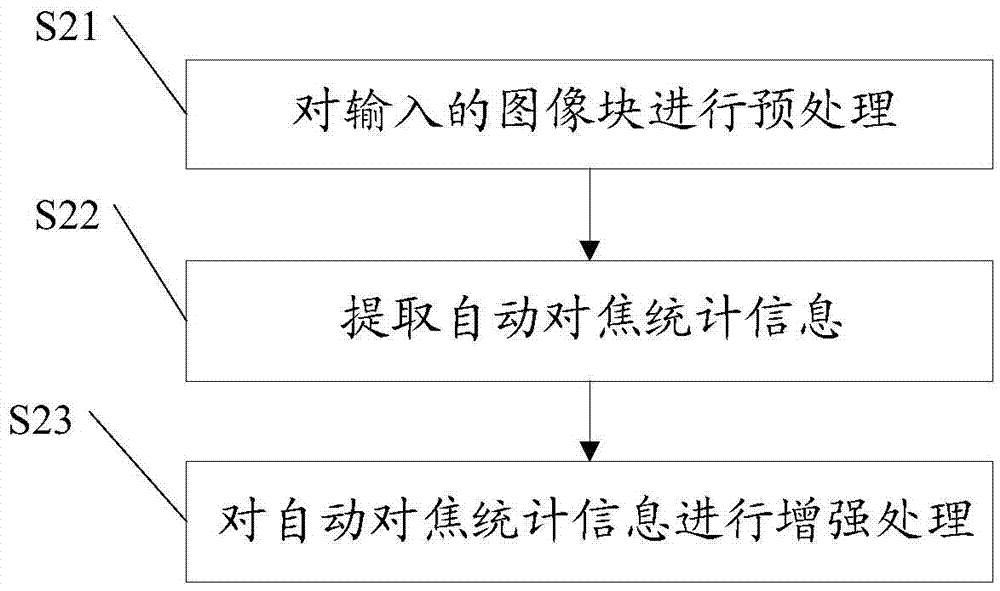

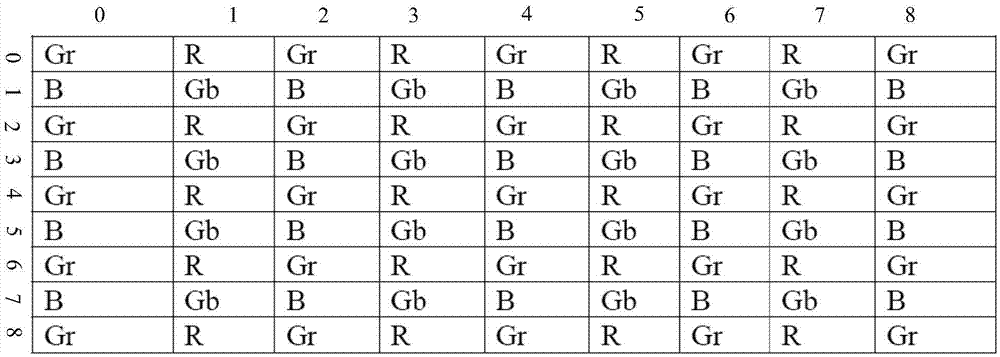

Method and device for calculating auto-focus statistical information

ActiveCN106921828AImprove accuracyFast focusingTelevision system detailsImage analysisPattern recognitionPixel value difference

The invention discloses a method and device for calculating auto-focus statistical information. The method comprises the following steps: obtaining an image block that takes a pixel to be processed as a center pixel as a first image block, wherein the first image block is selected from photographed images and has the auto-focus statistical information to be extracted; according to the color of the center pixel of the first image block, selecting the preset number of sub-image blocks to form a second image block by taking the pixel which has the same channel as the center pixel and can form the sub-image blocks with preset sizes in the range of the first image block as the center; determining the strong edge contained in the first image block according to the pixel value difference information between the sub-image blocks in the second image block; and according to the strong edge contained in the first image block, calculating to obtain the auto-focus statistical information of the first image block by adopting a corresponding operator matrix. By adopting the above scheme, the accuracy of the auto-focus statistical information of the photographed objects can be increased.

Owner:BEIJING SPREADTRUM HI TECH COMM TECH CO LTD

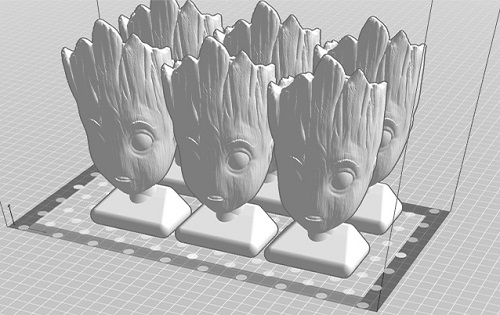

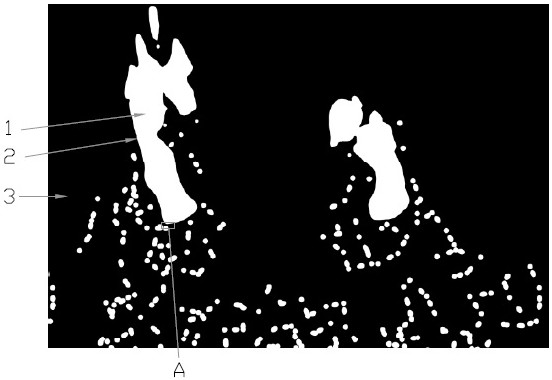

Compression method of 3D printing file

ActiveCN113704208AEasy to codeEasy to classifyDigital data information retrievalSpecial data processing applicationsPixel value differenceEngineering

The invention discloses a compression method of a 3D printing file. The method comprises the following steps of (1) traversing the image data of all layers, setting the data of which the pixel value is smaller than a set value as 0, and storing the new image data; (2) traversing the image data of all layers, obtaining a pixel value difference chart of the current layer and the previous layer, and judging and marking each layer as a difference layer, a non-difference layer or a reference layer; (3) classifying all data into valid data, gray data and invalid data according to the pixel values; (4) if the previous layer is the reference layer, classifying and coding all data of the layer; if the current layer is the difference layer, classifying and coding a difference graph of the layer; if the current layer is the non-difference layer, recording the number of layers; and (5) repeating the step (4) until all the layers are coded or the number of the layers is recorded. According to the method, the storage size of the 3D printing file is effectively compressed in a mode of invalid data filtering, subtraction of the adjacent layer image data and classification and coding.

Owner:ZHEJIANG FLASHFORGE 3D TECH CO LTD

Method and system for detecting vehicle position by employing polarization image

Disclosed are a method and a system for detecting a vehicle position by employing a polarization image. The method comprises a step of capturing a polarization image by using a polarization camera; a step of acquiring two road shoulders in the polarization image based on a difference between a road surface and each of the two road shoulders in the polarization image, and determining a part between the two road shoulders as the road surface; a step of detecting at least one vehicle bottom from the road surface based on a significant pixel value difference between each wheel and the road surface in the polarization image; and a step of generating a vehicle position from the vehicle bottom based on a pixel value difference between a vehicle outline corresponding to the vehicle bottom and background in the polarization image.

Owner:RICOH KK

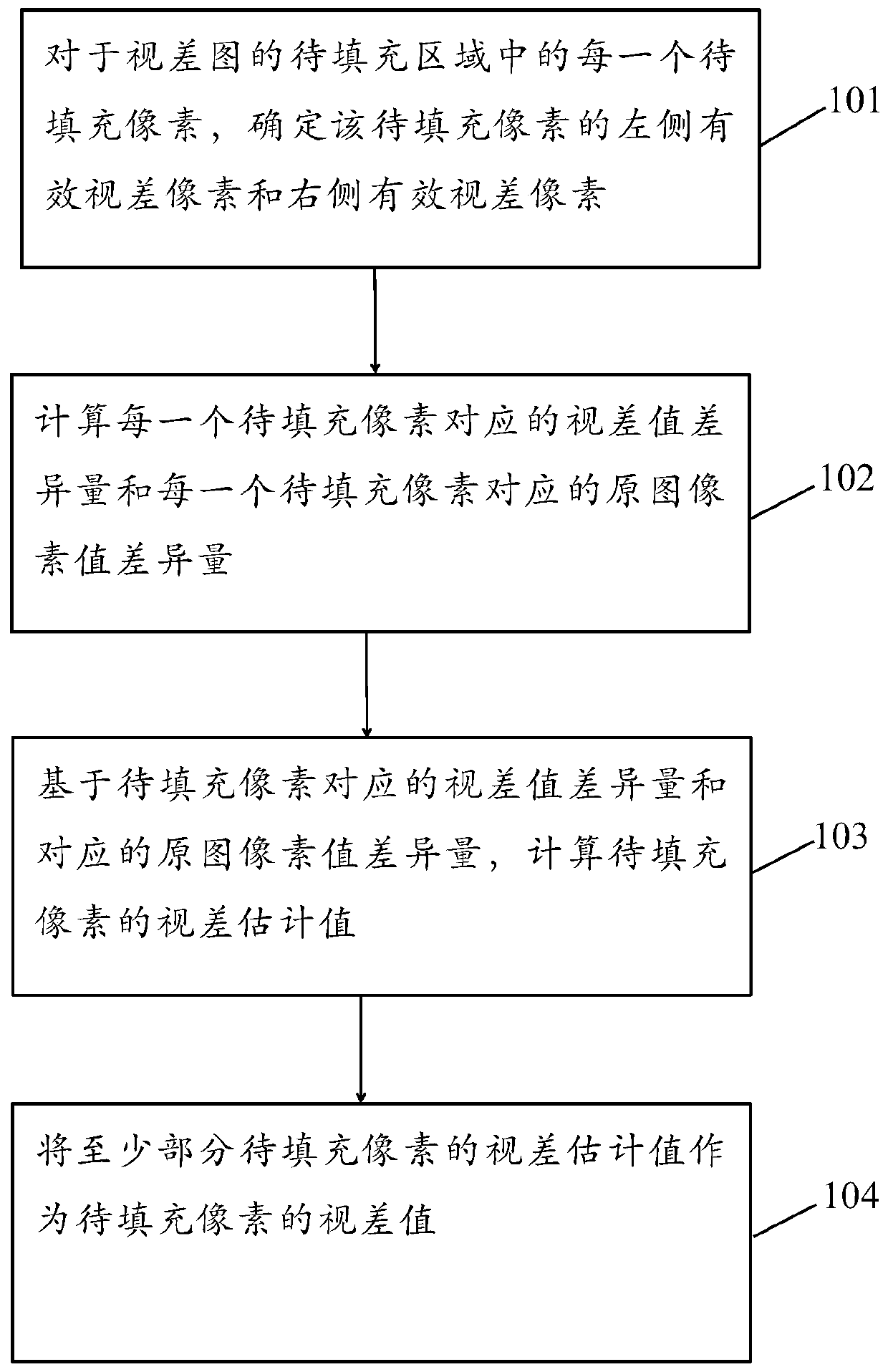

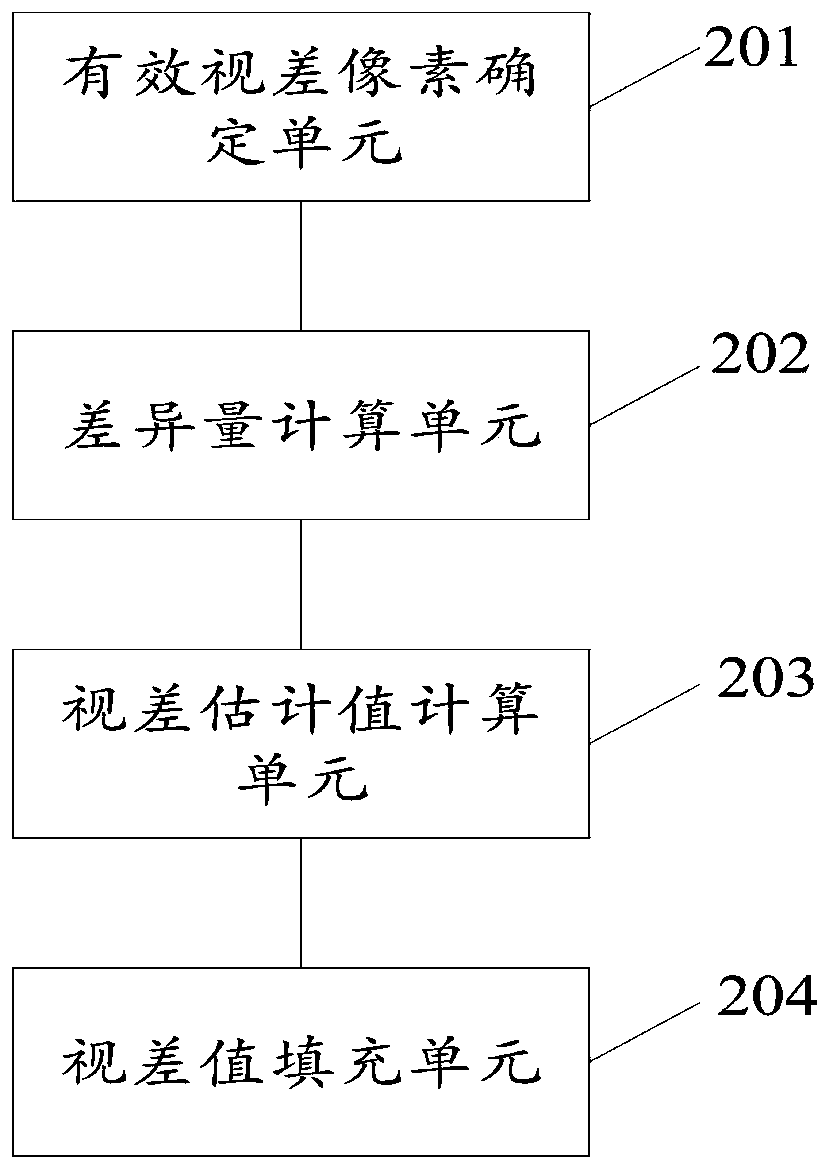

Disparity map cavity filling method and device, electronic equipment and storage medium

The embodiment of the invention provides a disparity map cavity filling method and device, and the method comprises the steps: determining a left effective disparity pixel of a to-be-filled pixel anda right effective disparity pixel of the to-be-filled pixel for each to-be-filled pixel; calculating a parallax difference value corresponding to a to-be-filled pixel and an original image pixel valuedifference value corresponding to the to-be-filled pixel, and calculating a parallax estimation value of the to-be-filled pixel based on the parallax difference value corresponding to the to-be-filled pixel and the original image pixel value difference value corresponding to the to-be-filled pixel; and taking the parallax estimation values of at least part of the to-be-filled pixels as parallax values of the to-be-filled pixels. Meanwhile, the relevance between the parallax value difference of the effective parallax pixels on the two sides of the to-be-filled pixel and the parallax value of the to-be-filled pixel and the relevance between the pixel value difference of the original image pixels corresponding to the effective parallax pixels on the two sides and the parallax value of the to-be-filled pixel are considered. Stripe flaws and highlight spots are avoided, and parallax image hole filling is completed in a short time.

Owner:MEGVII BEIJINGTECH CO LTD

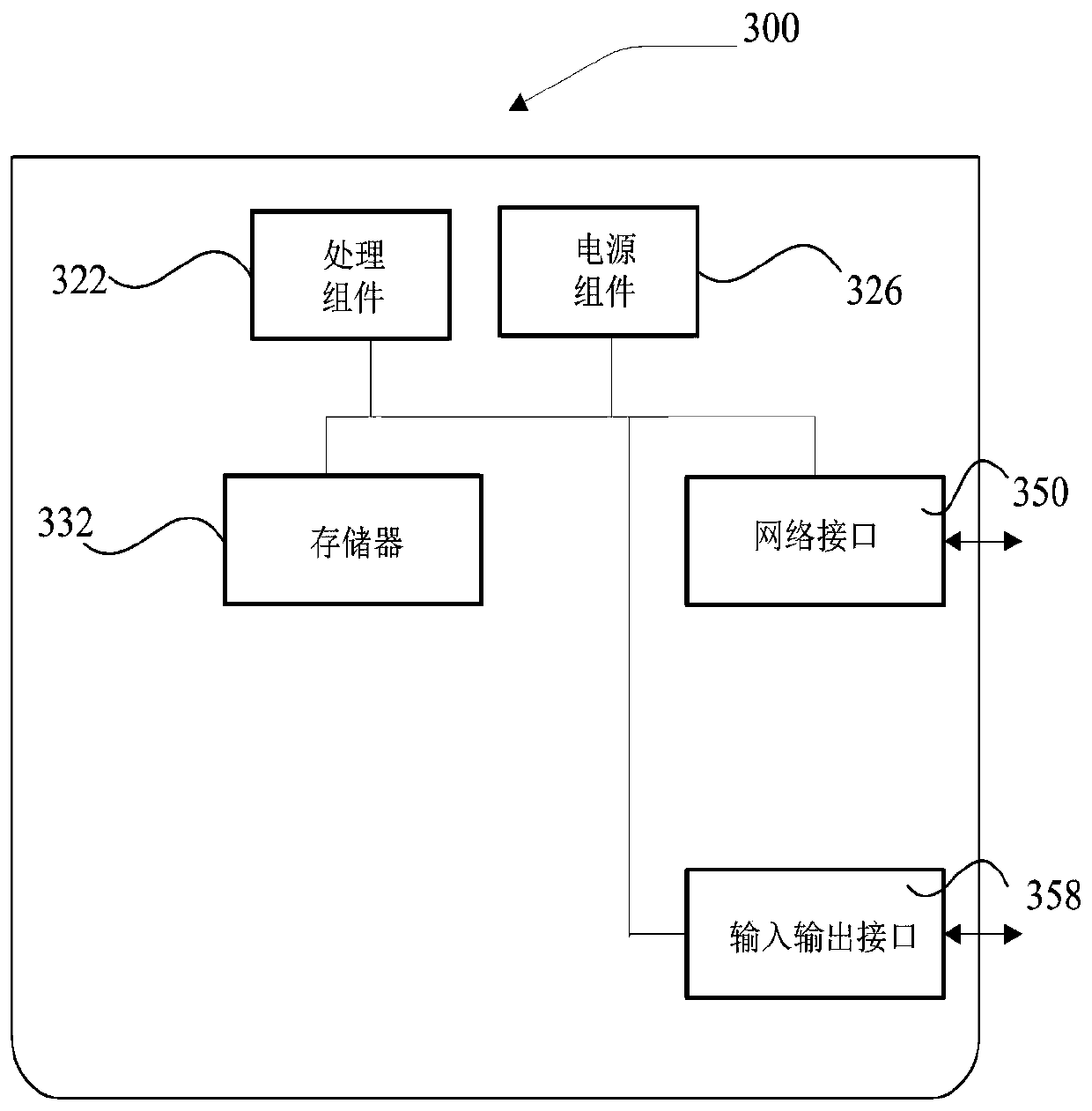

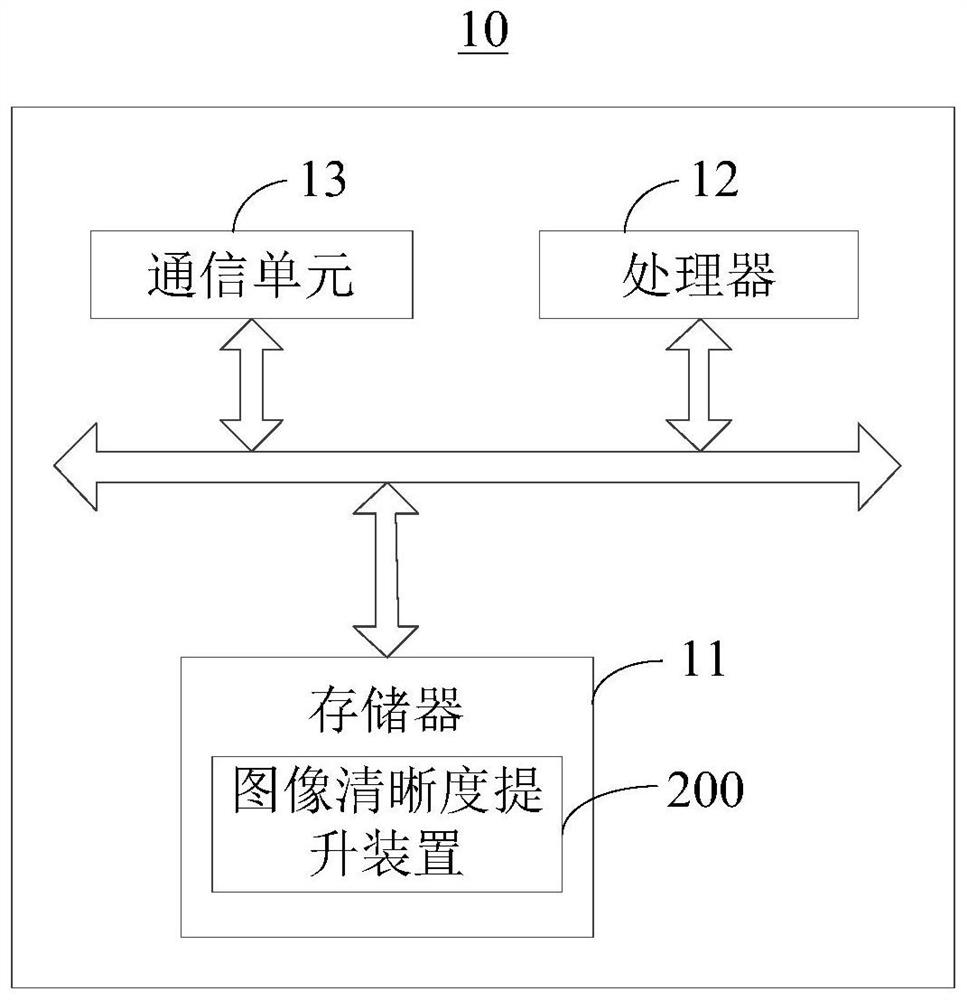

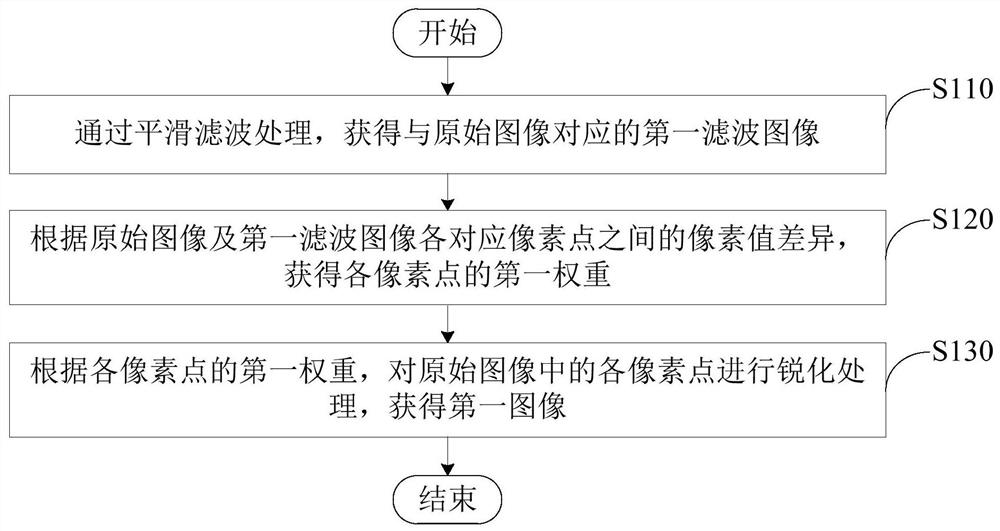

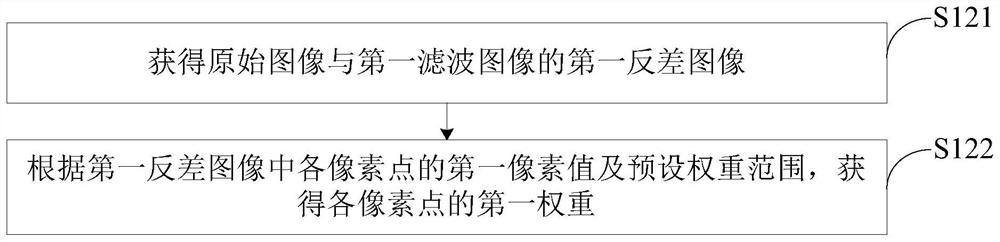

Image definition improving method and device, electronic equipment and readable storage medium

PendingCN112215768AImprove clarityAvoid unnatural situationsImage enhancementPattern recognitionImaging processing

The embodiment of the invention provides an image definition improving method and device, electronic equipment and a readable storage medium, and relates to the technical field of image processing. The method comprises the steps of obtaining a first filtering image corresponding to an original image through smooth filtering processing; obtaining a first weight of each pixel point according to thepixel value difference between the corresponding pixel points of the original image and the first filtered image, wherein the larger the pixel value difference between the pixel points is, the largerthe first weight is; and sharpening each pixel point in the original image according to the first weight of each pixel point to obtain a first image. Therefore, the image is kept natural while the image definition is improved.

Owner:GUANGZHOU HUYA TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com