Medical magnesium alloy surface degradable composite protective film layer and preparation method thereof

A protective film layer, magnesium alloy technology, applied in medical science, anodic oxidation, prosthesis, etc., can solve the problems of micro-arc oxidation ceramic layer adaptability to be analyzed, corrosion resistance decline, sealing agent is difficult, etc., to achieve Good blood compatibility and tissue compatibility, improved corrosion resistance, and high membrane-base binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

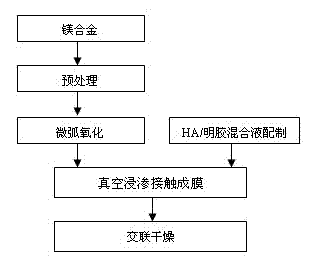

Method used

Image

Examples

Embodiment 1

[0028] (1) Sample preparation: select AZ31B magnesium alloy and process it into a wire that meets the required diameter;

[0029] (2) Pretreatment: ultrasonically clean the magnesium alloy wire with acetone, distilled water, and absolute ethanol in sequence for 10 minutes, and dry it for later use;

[0030] (3) Preparation of micro-arc oxidation electrolyte: 10 g / L of hydroxyapatite nanoparticles, 10 g / L of nano-zirconia particles, 10 g / L of silicate, 1 g / L of sodium hydroxide, and 5 g / L of phosphate;

[0031] (4) Preparation of hydroxyapatite / gelatin mixed solution: prepare a mixed solution containing 8wt% gelatin and 1wt% nano-sized hydroxyapatite, stir evenly, and set aside;

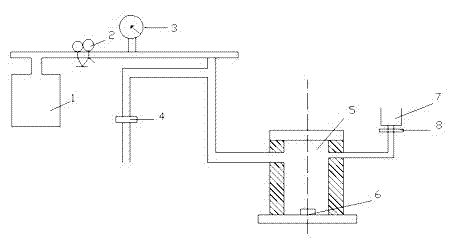

[0032] (5) Micro-arc oxidation: the magnesium alloy wire obtained in step (2) is used as the anode, and the stainless steel bucket is used as the cathode, placed in the electrolyte a, applying a positive voltage of 450V, a negative voltage of 60V, a frequency of 600Hz, and a duty cycle of 20%, the el...

Embodiment 2

[0035] (1) Sample preparation: select AZ91D magnesium alloy and process it into wires that meet the requirements;

[0036] (2) Pretreatment: ultrasonically clean the magnesium alloy wire with acetone, distilled water, and absolute ethanol in sequence for 10 minutes, and dry it for later use;

[0037] (3) Preparation of micro-arc oxidation electrolyte: hydroxyapatite nanoparticles 5g / L, nano-zirconia particles 5g / L, silicate 10g / L, potassium hydroxide 2g / L;

[0038] (4) Preparation of hydroxyapatite / gelatin mixed solution: respectively prepare mixed solutions containing 5wt% gelatin, 0.5wt% nano-sized hydroxyapatite, and 10wt% gelatin, 2wt% nano-sized hydroxyapatite mixed solution, Stir well and set aside;

[0039] (5) Micro-arc oxidation: the magnesium alloy wire obtained in step (2) is used as the anode, the stainless steel barrel is used as the cathode, and a forward current of 3A / dm is applied 2 , negative current 1A / dm 2 , the frequency is 600Hz, the duty cycle is 20%, ...

Embodiment 3

[0042] (1) Sample preparation: process the magnesium alloy into thin plates that meet the requirements;

[0043] (2) Pretreatment: adopt 200 successively # , 400 # , 600 # , 1000 # , 1200 # Grind with sandpaper, ultrasonically clean the magnesium alloy plate with acetone, distilled water, and absolute ethanol for 10 minutes, and dry it for later use;

[0044] (3) Preparation of micro-arc oxidation electrolyte: 10 g / L of hydroxyapatite nanoparticles, 5 g / L of nano-zirconia particles, 10 g / L of silicate, 1 g / L of potassium hydroxide, and 5 g / L of phosphate.

[0045] (4) Preparation of hydroxyapatite / gelatin mixed solution: prepare a mixed solution containing 6wt% gelatin and 0.5wt% nano-sized hydroxyapatite, stir evenly, and set aside;

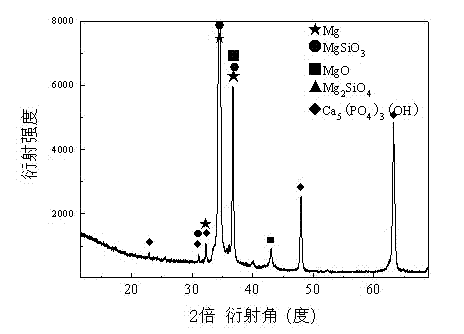

[0046] (5) Micro-arc oxidation: the magnesium alloy sheet obtained in step (2) is used as an anode, and the stainless steel barrel is used as a cathode, and a forward voltage of 450V is applied, a negative voltage of 60V, a frequency of 600...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com