Magnetic material for surface finish benzene sulfonic acid, and preparation method and application thereof

A magnetic material and surface modification technology, applied in the fields of peptide preparation, inorganic material magnetism, chemical instruments and methods, etc., can solve the problems of limited adsorption capacity and few reports of magnetic materials, and achieve strong selectivity, rapid separation and enrichment. The effect of collecting and enriching active groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

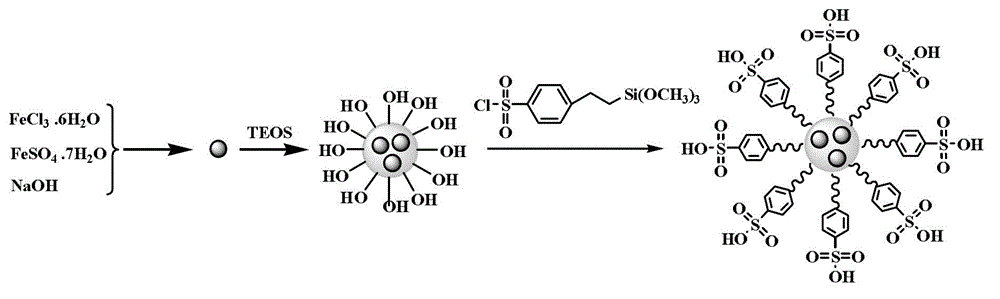

[0035] Embodiment 1: the preparation of the magnetic material of surface modification benzene sulfonic acid

[0036] Preparation of magnetic microspheres

[0037] Weigh 1.3g of FeCl 3 ·6H 2 O and 0.7 g FeSO 4 ·6H 2 Dissolve O in 50 mL of deionized water, add 20 mL of sodium hydroxide aqueous solution (1.5 mol / L) under rapid stirring (that is, weigh 1.2 g of sodium hydroxide and dissolve in 20 mL of deionized water), and then stir at room temperature for 3 hours to form Magnetic Fe 3 o 4 Nanoparticles: Magnetic nanoparticles were collected with the assistance of an external magnetic field, washed 6 times with deionized water and ethanol, and dried in vacuum at 6O°C for 24h to obtain dry magnetic Fe 3 o 4 For nanoparticles, specific reference may be made to Y.P.He, S.Q.Wang, C.R.Li, Y.M.Miao, Z.Y.Wu, and B.S.Zou, J.Phy.D: Appl.Phys.2005, 38, 1342-1350.

[0038] Fe 3 o 4 / SiO 2 Preparation of microspheres

[0039] Magnetic Fe 3 o 4 1.0g of nanoparticles was redisper...

Embodiment 2

[0044] Example 2: Magnetic materials with surface-modified benzenesulfonic acid are used to extract vancomycin and norvancomycin in environmental water samples

[0045] Use deionized water to prepare a series of mixed standard solutions with mass concentrations of 10, 20, 50, 100, 150, 200, and 300 μg / L for vancomycin and norvancomycin for liquid chromatography determination. The instrument model is Shimazu HPLC- 20A, the manufacturer is Shimadzu Corporation of Japan, the instrument is equipped with SPD-M20A diode array (DAD) detector, CTO-20AC column thermostat, SIL-20AC autosampler; the chromatographic column is Spursil C18 column, the manufacturer is Beijing Dicoma Technology Co., Ltd.; the mobile phase is acetonitrile: 5mmol potassium dihydrogen phosphate buffer solution (adjust the pH value to 3.2 with phosphoric acid) (volume ratio is 90:10), the flow rate is 1ml / min, the injection volume is 20μL, and the detection Wavelength is 230nm, is abscissa with the mass concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com