Calculus enzyme and preparation method thereof

A calculus enzyme and calculus technology, applied in biochemical equipment and methods, methods based on microorganisms, enzymes, etc., can solve the problems of long treatment time, intolerance of patients, and large side effects, and achieve simple preparation methods and no toxic side effects , The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

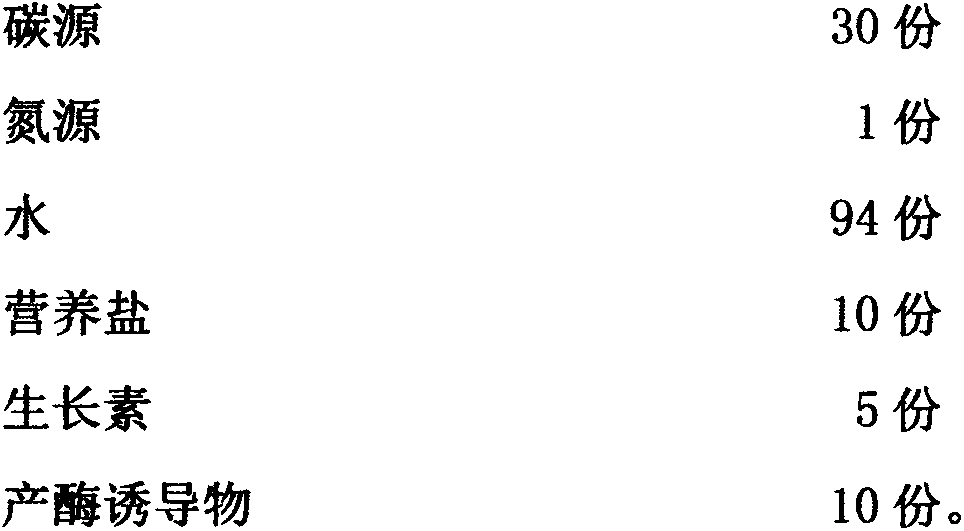

[0048] Embodiment 1, the calculus enzyme described in this embodiment is obtained by using the following parts by weight of the raw and auxiliary materials to carry out microbial fermentation culture, leaching, concentration and refining by solid-state fermentation method:

[0049]

[0050] Wherein said carbon source refers to the materials of D-glucose, flour, chaff, wort, persimmon, sugar beet and walnut residue.

[0051] Wherein the nitrogen source is dry yeast, fish meal, bean cake powder, chitin, ammonium phosphate, and ammonium nitrate.

[0052] Wherein the nutrient salt is a mixed salt solution containing magnesium, potassium, calcium, zinc and selenium.

[0053] Wherein said auxin is the material of corn steep liquor.

[0054] Wherein the enzyme-producing inducer is crushed human calculus.

[0055] The calculus enzyme is used as an enzyme for degrading calculus, specifically as an application of food, drink, health care product, medicine or injection in dissolving...

Embodiment 2

[0086] Embodiment 2, the calculus enzyme described in this embodiment is obtained by the following parts by weight of raw and auxiliary materials using solid-state fermentation method for microbial fermentation culture, leaching, concentration, and refining:

[0087]

[0088]

[0089] Wherein said carbon source refers to the materials of wheat bran, sucrose, tangerine, orange, apple and banana.

[0090] Wherein said nitrogen source is the material of beef extract, dry yeast, peanut cake powder, shrimp shell, ammonium sulfate.

[0091] Wherein the nutrient salt is a mixed salt solution containing phosphorus, sulfur, sodium, iron, calcium, zinc, cobalt and manganese ions.

[0092] Wherein said growth hormone is the material of vitamin.

[0093] Wherein, the enzyme-producing inducer is a material of artificial bovine gallstones and pulverized human body stones.

[0094] The calculus enzyme is used as an enzyme for degrading calculus, specifically as an application of food...

Embodiment 3

[0126] Embodiment 3, the calculus enzyme described in this embodiment is obtained by the following parts by weight of raw and auxiliary materials using solid-state fermentation method for microbial fermentation culture, extraction, concentration, and refinement:

[0127]

[0128] Wherein the carbon source refers to D-fructose, D-sorbitol, starch hydrolyzed sugar, starch, corn flour, straw, sunflower disc, malt, papaya, pineapple, fruit peel, fruit pomace, beet pomace, celery, pearl powder, The material of walnut powder.

[0129] Wherein the nitrogen source is yeast extract, fish meal, peptone, protein, snail, fish skin, crab shell, chitin, urea, amine, amide, purine base, pyrimidine base, ammonium phosphate, ammonium chloride, ammonium carbonate, liquid ammonia of materials.

[0130] Wherein the nutrient salt is a mixed salt solution containing phosphorus, sulfur, magnesium, potassium, sodium, iron, calcium, zinc, cobalt, manganese and selenium ions.

[0131] Wherein said...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com