Method for manufacturing immunosensor for detecting chlorpyrifos

An immunosensor, chlorpyrifos technology, applied in the field of agricultural product safety detection, can solve the problems of difficulty in meeting low residue and quantitative detection, high proportion of missed detection, affecting accuracy, etc., achieve high stability and high order, and improve electrical conductivity. and capacitance, the effect of increasing detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Preparation of nickel-aluminum hydrotalcite-graphene nanocomposite solution

[0044] The Hummers method is used to prepare graphite oxide. Specific process flow: Assemble a 250mL reaction flask in an ice water bath, add 1g graphite powder, 1g sodium nitrate and 46mL sulfuric acid, stir for 30min, then add 5g potassium permanganate in portions, control the reaction temperature not to exceed 20℃, stir After reacting for a period of time, the temperature is raised to about 35°C, stirring is continued for 30 minutes, and then 80 mL of deionized water is slowly added. After stirring for 20 minutes, 6 mL of 30% hydrogen peroxide is added to reduce the remaining oxidant and the solution becomes bright yellow. Filter while hot and wash with 5% HCl solution and deionized water until no sulfate is detected in the filtrate. Finally, the filter cake is fully dried in a vacuum drying oven at 60°C to obtain graphite oxide. Add 30mg of graphite oxide to 50mL of a mixed alkali...

Embodiment 2

[0045] Example 2 Preparation of empty-shell gold nanoparticles

[0046] Co nanoparticles are used as sacrificial templates to synthesize hollow-shell gold nanoparticles. First pass high purity N into 50mL water 2 Deoxygenate, add 8.4mg citric acid and 15mg sodium borohydride under stirring. Then inject 50μL 0.4M CoCI 2 Solution (The reaction is always carried out under the protection of nitrogen to prevent the generated Co nanoparticles from being oxidized). Stop N after 20min 2, Take 30 mL of cobalt nano colloidal solution and add it to 18 mL of chloroauric acid solution (1 mM), and continue to stir for 30 min. Finally, the product was centrifuged, the supernatant was discarded, and the resulting precipitate was dispersed in 5 mL of pH 7.5 PBS for later use. Take 2mL of the empty-shell nano-gold colloid solution and add it to 5mL of 0.5% chitosan solution, and stir for 2h at room temperature to use as electrode modification material. figure 2 In order to prepare the TEM image...

Embodiment 3

[0047] Example 3 Cleaning, activation and testing of glassy carbon electrode

[0048] Before modification of the glassy carbon electrode, first immerse it in a hot "piranha" solution (H 2 SO 4 : 30% H 2 O 2 = 3:1) Soak in the water for 15 minutes, rinse with water, and then use 0.3μm, 30nm Al 2 O 3 The slurry is polished on the suede to the mirror surface, after polishing, it is cleaned with deionized water to remove the surface dirt, and then 6mol / L HNO 3 , Anhydrous ethanol and deionized water are each ultrasonically cleaned for 5 minutes, and dried in a nitrogen environment.

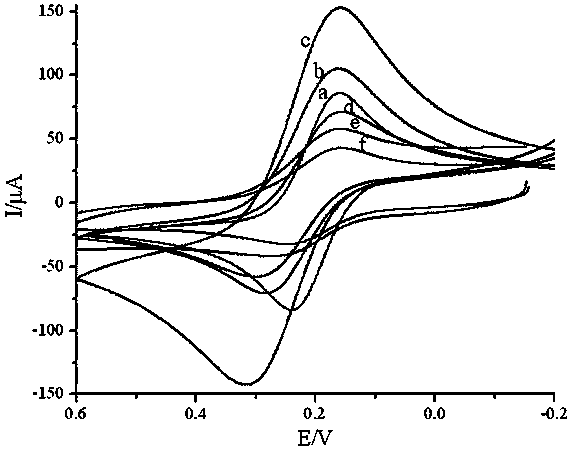

[0049] Activation of glassy carbon electrode: After thorough cleaning, the electrode is at 0.5mol / L H 2 SO 4 The solution is activated by cyclic voltammetry, and the scanning range is 1.0V~-1.0V, and the scanning is repeated until a stable cyclic voltammogram is reached.

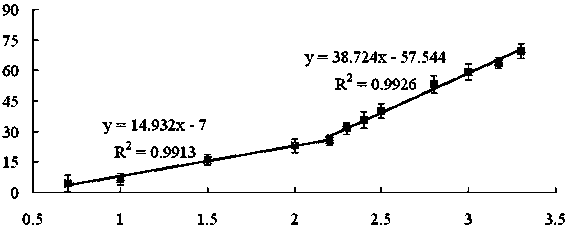

[0050] Test of pre-processed glassy carbon electrode: when containing 1×10 -3 mol / L K 3 Fe(CN) 6 0.20 mol / L KNO 3 Run a cyclic voltammet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear range | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com