A preparation method of modified activated carbon fiber filaments loaded with nano-titanium dioxide on the surface

A technology of activated carbon fiber filaments and nano-titanium dioxide, which is applied in the field of photocatalytic materials, can solve the problems that the photocatalytic reaction does not have a positive promoting effect, cannot ensure the photocatalytic effect of the catalyst, and the catalyst cannot achieve the photocatalytic effect, etc. Increased efficiency and uniform load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

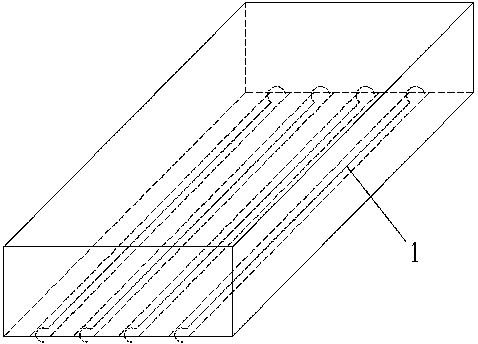

[0046] (1) Preparation of modified activated carbon fiber filaments, the steps are:

[0047] (a) Pretreatment: Soak PAN (polyacrylonitrile)-based carbon fiber filaments in deionized water, heat and boil for 2.5 hours with constant stirring, then soak in room temperature deionized water for 3 hours with constant stirring, and finally rinse with deionized water Clean and remove impurities on the surface of carbon fiber filaments. Dry the cleaned activated carbon fiber filaments in an oven at 120°C for 10 h to obtain pretreated activated carbon fiber filaments;

[0048] (b) Dipping and drying: put the pretreated activated carbon fiber in 0.15mol / L nitric acid solution, add ammonium dihydrogen phosphate (analytical pure, mass concentration 99%, molar concentration ratio to nitric acid 10:15) Soak for about 12 hours, then take it out and heat and dry for 10 hours, turn on N 2 Protected and calcined at 560°C for 0.8h, kept at 95°C for 1h, and cooled to room temperature to obtain m...

Embodiment 2

[0056] Same as the preparation method of the modified activated carbon fiber filament in Example 1. The difference is that nano-TiO 2 The method that is loaded on the modified active carbon fiber silk, its step is:

[0057] (a) Pretreatment: Soak the modified activated carbon fiber in 10% hydrogen peroxide for 1 hour, rinse it with deionized water for 5 times, and dry it at 120°C for 2.5 hours with nitrogen filling;

[0058] (b) Solution preparation: Dissolve 20g of epoxy resin in 1L of acetone, stir and add 35g of commercially available nano-TiO in sequence 2 (Degussa P25), 3.5g UV-P and 2g Nano Fe 2 o 3 ;

[0059] (c) Impregnation and drying: Put the modified activated carbon fiber filaments into the solution and immerse them for 45 minutes, and dry them at 120°C for 0.5h under a nitrogen atmosphere; 2 Modified activated carbon fiber filaments;

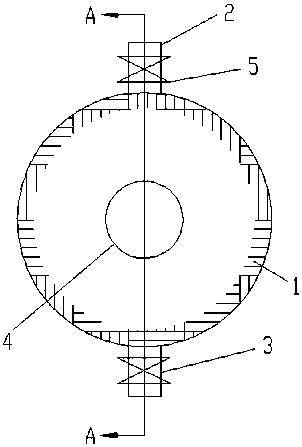

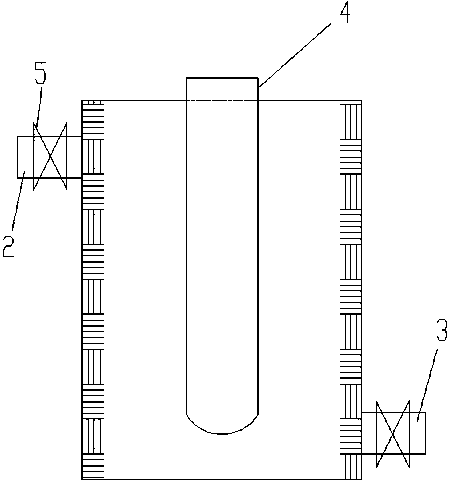

[0060] (d) Functional testing of modified activated carbon fibers: use a shallow pool structure reactor to treat dye wastewa...

Embodiment 3

[0062] Same as Example 1, except that the preparation method of the modified activated carbon fiber filament in Example 1 is the same. The difference is that nano-TiO 2 The method that is loaded on the modified active carbon fiber silk, its step is:

[0063] (a) Pretreatment: Soak the modified activated carbon fibers in 10% hydrogen peroxide for 1 hour, rinse them with deionized water for 5 times, and dry them at 120°C for 2.0 hours with nitrogen filling;

[0064] (b) Solution preparation: Dissolve 15g of epoxy resin in 1L of acetone, stir and add 25g of commercially available nano-TiO in sequence 2 (Degussa P25), 6g UV-P and 1.5g nano Fe 2 o 3 ;

[0065] (c) Impregnation and drying: Put the modified activated carbon fiber filaments into the solution and immerse them for 60 minutes, then dry them at 120°C for 0.5 hours under a nitrogen atmosphere, then raise the temperature to 400°C and dry them for 2.5 hours to obtain surface-loaded nano-TiO 2 Modified activated carbon f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com