Expansive type double-component fireproof sealant and preparation method thereof

A fireproof sealant, two-component technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the failure of organic metal catalysts, affect product storage stability, and poor substrate adhesion to achieve excellent substrate adhesion, prevent heat transmission, and shorten curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

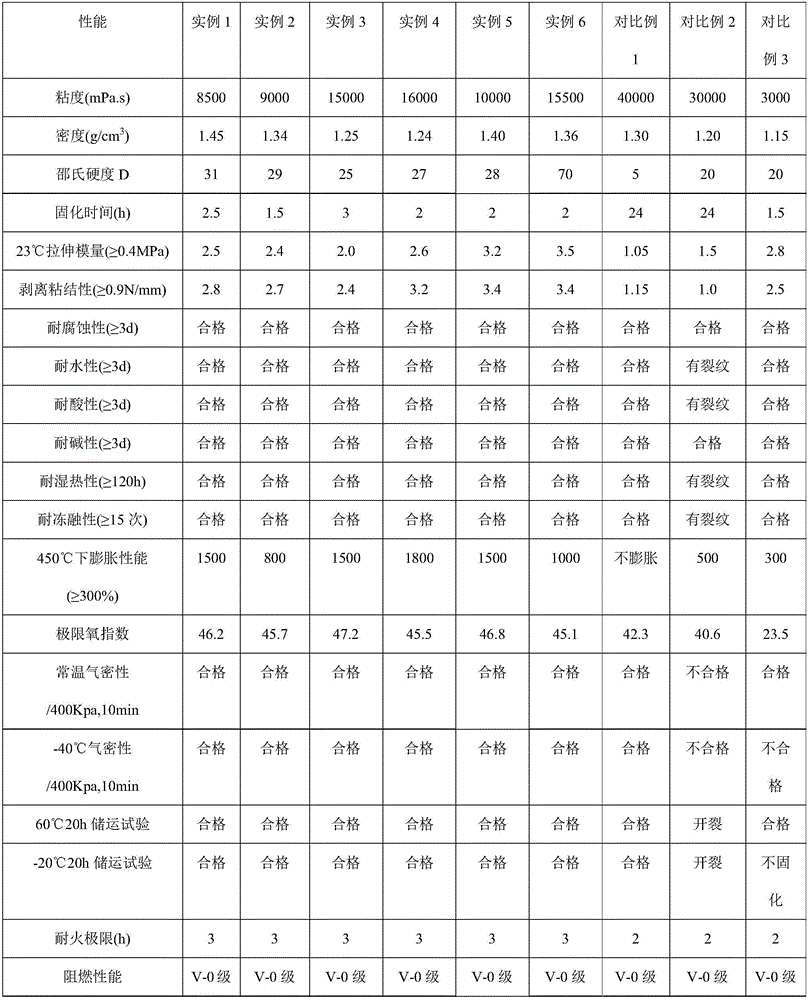

Examples

Embodiment 1

[0029] In parts by weight, 80 parts of trihydroxypolyoxypropylene ether with a hydroxyl value of 336 mgKOH / g, 20 parts of polycaprolactone diol with a hydroxyl value of 112 mgKOH / g, 38 parts of dimethyl methylphosphonate, and 50 parts of expandable graphite 70 parts of magnesium hydroxide, 32 parts of quartz powder, 50 parts of calcium carbonate, 0.03 parts of dibutyltin dilaurate, 0.2 parts of 1,8-diazabicycloundec-7-ene phenoxide, 2-amino 0.6 parts of ethanol, 4 parts of 3-ethanol-2-methylethyl oxazolidine, 8 parts of fumed silica, 2 parts of γ-aminopropyltriethoxysilane, carbodiimide modified diphenyl 30 parts of methane diisocyanate, 44 parts of polymethylene polyphenyl polyisocyanate.

[0030] The preparation method of the intumescent fireproof sealant is as follows: add trihydroxypolyoxypropylene ether, polycaprolactone diol, and dimethyl methylphosphonate into a planetary mixer, and vacuumize and dehydrate at 50°C for 2 hours; Add expandable graphite, magnesium hydroxi...

Embodiment 2

[0032] In parts by weight, 30 parts of dihydroxypolyoxypropylene ether with a hydroxyl value of 112 mgKOH / g, 70 parts of polycaprolactone trihydric alcohol with a hydroxyl value of 336 mgKOH / g, and 30 parts of tris (β-chloroethyl) phosphate , 45 parts of expandable graphite, 25 parts of micronized graphite, 25 parts of type II ammonium polyphosphate, 10 parts of melamine, 10 parts of pentaerythritol, 40 parts of mica powder, 50 parts of calcium carbonate, 0.02 parts of bismuth neodecanoate, 22% organic zinc 0.2 parts, 0.18 parts of 1,8-diazabicycloundec-7-ene octanoate, 0.66 parts of aminopropanol, bis[2-(2-isopropyl-3-oxazolinyl) ethyl Base] carbonate 5 parts, polyurethane urea oligomer solution 2 parts, γ-methacryloxypropyl trimethoxysilane 2.5 parts, carbodiimide modified diphenylmethane diisocyanate 60 parts, 3 - 8.5 parts of isocyanatomethylene-3,5,5-trimethylcyclohexyl isocyanate.

[0033] The preparation method of the intumescent fireproof sealant is as follows: add di...

Embodiment 3

[0035]In parts by weight, 85 parts of trihydroxypolyoxypropylene ether with a hydroxyl value of 168 mgKOH / g, 15 parts of polymer-grafted polyols with a hydroxyl value of 28 mgKOH / g, and 30 parts of tris(β-chloropropyl) phosphate, expandable 50 parts of graphite, 60 parts of micronized graphite, 17 parts of talc, 30 parts of wollastonite, 40 parts of calcium carbonate, 0.06 part of phenylmercury acetate, 0.1 part of lead isooctanoate, 1,8-diazabicycloundecene- 0.24 parts of 7-ene octanoate, 1.05 parts of aminobutanol, 4.5 parts of 3-butyl-2-(1-ethylpentyl) oxazolidine, 5 parts of organic bentonite, phytanic acid monoalkoxy 2.1 parts of titanate, 29 parts of polymethylene polyphenyl polyisocyanate, 5 parts of 3-isocyanatomethylene-3,5,5-trimethylcyclohexyl isocyanate.

[0036] The preparation method of the intumescent fireproof sealant is as follows: adding trihydroxypolyoxypropylene ether, polymer grafted polyol, and tris(β-chloropropyl) phosphate into a planetary mixer, and va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com