Controllable high-dispersion nano simple-substance metal/carbon composite material preparation method and electrical catalytic application thereof

A carbon composite material and nano-metal technology, which is applied in the preparation of high-dispersion metal single substance nano-particle materials, and in the field of high-content mesoporous carbon loading, can solve problems such as poor impact load resistance, secondary pollution of metal ions, and complex processes. , to achieve the effect of high loading capacity, adjustable metal content and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

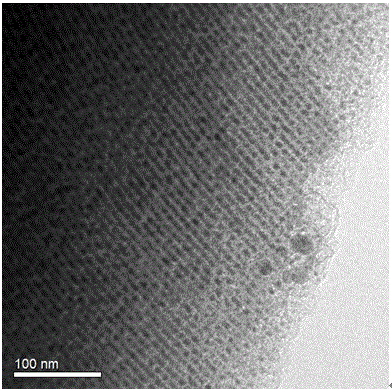

[0030]Preparation of phenolic resin and surface oxidized ordered mesoporous carbon material: first melt 12.0 g of phenol in a water bath at 40-42 °C, add 2.52 g of 20% (mass percent concentration) NaOH aqueous solution, stir for 10 minutes, and then add 20.4 g formaldehyde solution (37 wt%), reflux at 70-75°C for 1 hour, and cool to room temperature. The pH of the solution was adjusted to neutral with 0.6 M HCl. The solution system was placed in a water bath at 45°C and distilled under reduced pressure for 1-2 hours to obtain 14.1 g of phenolic resin (molecular weight 200-500). Dissolve it in 56.2 g of absolute ethanol, centrifuge to remove NaCl crystals, and prepare a light brown phenolic resin prepolymer ethanol solution with a mass fraction of 20% for later use. Add 1.6 g of nonionic surfactant polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (Pluronic F127) and 1.0 g of 0.2 M HCl to 8.0 g of ethanol at 40 °C Stirring for 1 hour gave a clear so...

Embodiment 2

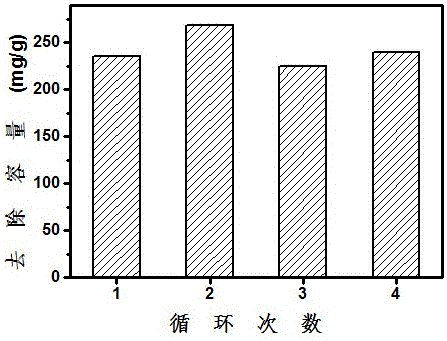

[0032] Preparation of zero-valent iron-supported mesoporous carbon materials: 0.6 g surface oxidized mesoporous carbon materials were stirred and dispersed in 8.0 g ethanol; at the same time, 0.9 g Fe(NO 3 ) 3 9H 2 O was dissolved in ethanol to form a solution with a mass fraction of 20 wt%, and 0.5 mL of 0.2 M HCl was added to inhibit Fe(NO 3 ) 3 9H 2 Hydrolysis of O. Add the dissolved solution to the carbon ethanol dispersion system, continue to stir, and keep in the fume hood until the ethanol evaporates to dryness. Put the obtained composite material into a small glass tube, place the glass tube in a polytetrafluoroethylene bottle filled with 14 wt% ammonia solution, keep the sample out of direct contact with the ammonia solution, seal it and treat it at 60°C for 3 hours, cool it, and water Wash with ethanol and filter to remove soluble impurities on the surface of the sample to obtain loaded Fe(OH) 3 mesoporous carbon materials. The composite material was dried in ...

Embodiment 3

[0034] Preparation of cobalt-loaded mesoporous carbon material: the preparation method is as in Example 2, the difference is that 1.0g Co(NO 3 ) 3 9H 2 O was dissolved in ethanol to prepare a solution with a mass fraction of 20 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com