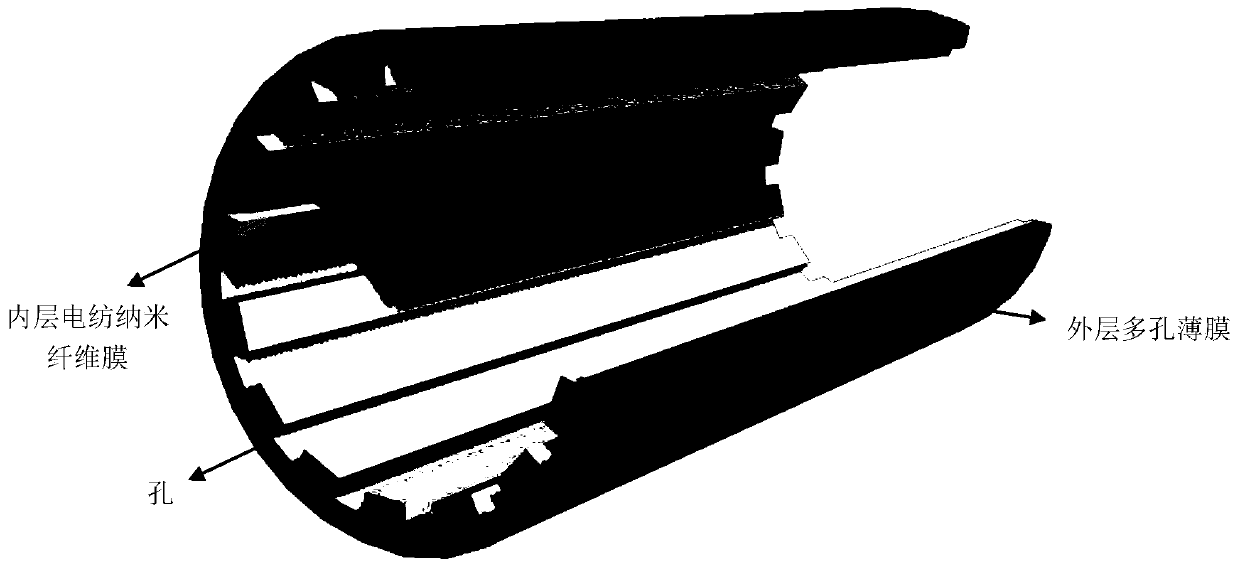

A double-layer porous nerve guide with directional guidance function and its preparation method

A nerve conduit and guiding function technology, applied in the field of double-layer porous nerve conduit and its preparation, can solve problems such as poor toughness, poor material cell affinity, difficult conduit configuration nerve regeneration, etc., to prevent invasion and repair peripheral Long-segment nerve defect and the effect of inhibiting the formation of neuroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

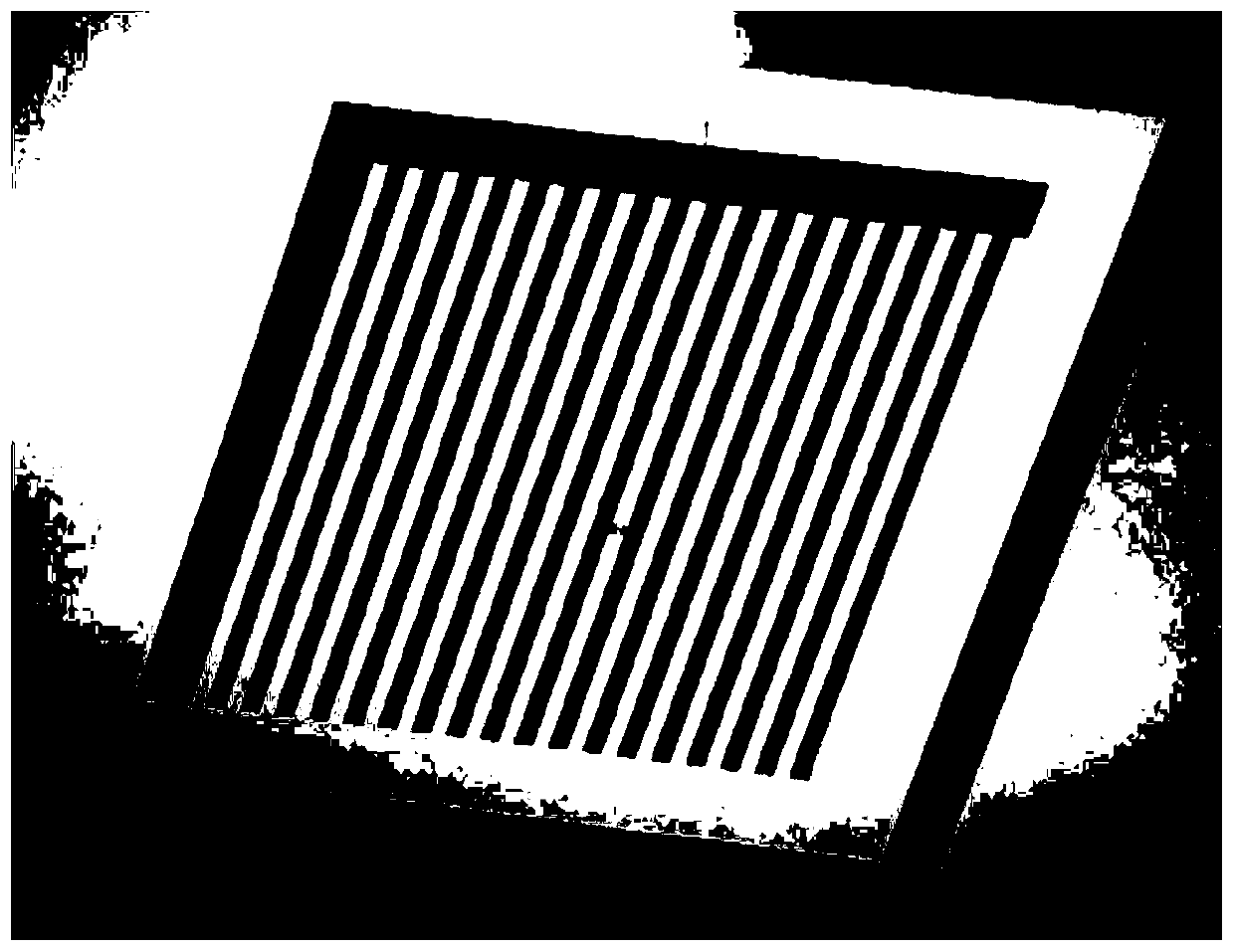

[0041] A double-layer porous nerve guide with directional guidance function, its preparation method comprises the following steps:

[0042] 1) Prepare the outer film: Dissolve 1 g of polylactic acid-glycolic acid copolymer (PLGA) in 15 ml of dichloromethane, add 6 g of sodium chloride particles with a particle size of 10 μm after complete dissolution, and pour into polystyrene after ultrasonic dispersion is complete. In a tetrafluoroethylene groove mold, air-dried for 5 days to form, then soaked in deionized water for 2 days to remove sodium chloride, and vacuum-dried for 2 days to remove organic solvent to obtain the outer film.

[0043] 2) Preparation of chitosan (CS-RGD) grafted with RGD: 0.1g (0.176mmol) biological polypeptide GRGDY was dissolved in 20mL of sodium acetate-acetic acid buffer solution (mass fraction 1%), and 0.677g of condensation activator was added (3.530mmol) 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC) and 0.406g (3.530mmol) N-hydroxy...

Embodiment 2

[0057] A double-layer porous nerve guide with directional guidance function, its preparation method comprises the following steps:

[0058] 1) Prepare the outer film: Dissolve 1 g of polylactic acid-glycolic acid copolymer (PLGA) in 15 ml of dichloromethane, add 6 g of sodium chloride particles with a particle size of 50 μm after complete dissolution, and pour into polystyrene after ultrasonic dispersion is complete. In a tetrafluoroethylene groove mold, air-dried for 5 days to form, then soaked in deionized water for 2 days to remove sodium chloride, and vacuum-dried for 2 days to remove organic solvent to obtain the outer film.

[0059] 2) Preparation of chitosan (CS-RGD) grafted with RGD: 0.1g (0.176mmol) biological polypeptide GRGDY was dissolved in 20mL of sodium acetate-acetic acid buffer solution (mass fraction 1%), and 0.677g of condensation activator was added (3.530mmol) 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC) and 0.406g (3.530mmol) N-hydroxy...

Embodiment 3

[0067] A double-layer porous nerve guide with directional guidance function, its preparation method comprises the following steps:

[0068] 1) Prepare the outer film: dissolve 1g of polyethylene lactide-ethylene glycol block copolymer (PLGA-MPEG) in 15ml of dichloromethane, and add 6g of sodium chloride particles with a particle size of 30 μm after completely dissolving After the ultrasonic dispersion is complete, pour it into a polytetrafluoroethylene groove mold, air-dry for 5 days to form, then soak in deionized water for 2 days to remove sodium chloride, and vacuum dry for 2 days to remove the organic solvent to obtain the outer film.

[0069] 2) Preparation of chitosan grafted with RGD (CS-RGD): 0.1 g (0.161 mmol) of biological polypeptide c-RGDyK was dissolved in 20 mL of sodium acetate-acetic acid buffer solution (mass fraction 1%), and a condensation activator was added 0.618g (3.227mmol) 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC) and 0.371g (3.22...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com