Method and system for irradiation-chemical method combined treatment of plant fibrous agricultural wastes

A technology for agricultural wastes and plant fibers, which is applied in the field of irradiation-chemical combined treatment of plant fibrous agricultural wastes, can solve the problems of many types of organic solvents, high reaction temperature, environmental pollution, etc., and achieves continuous production, The effect of high extraction rate and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

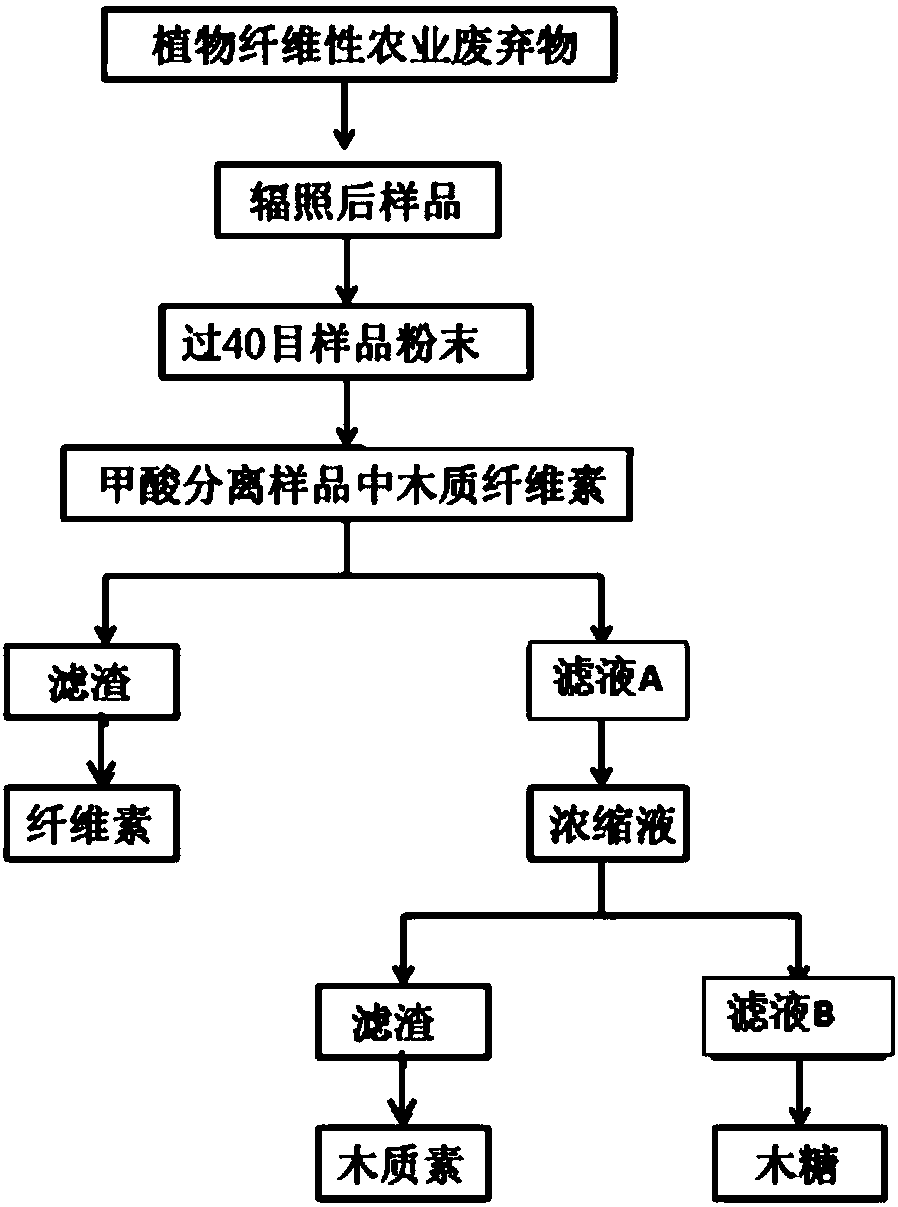

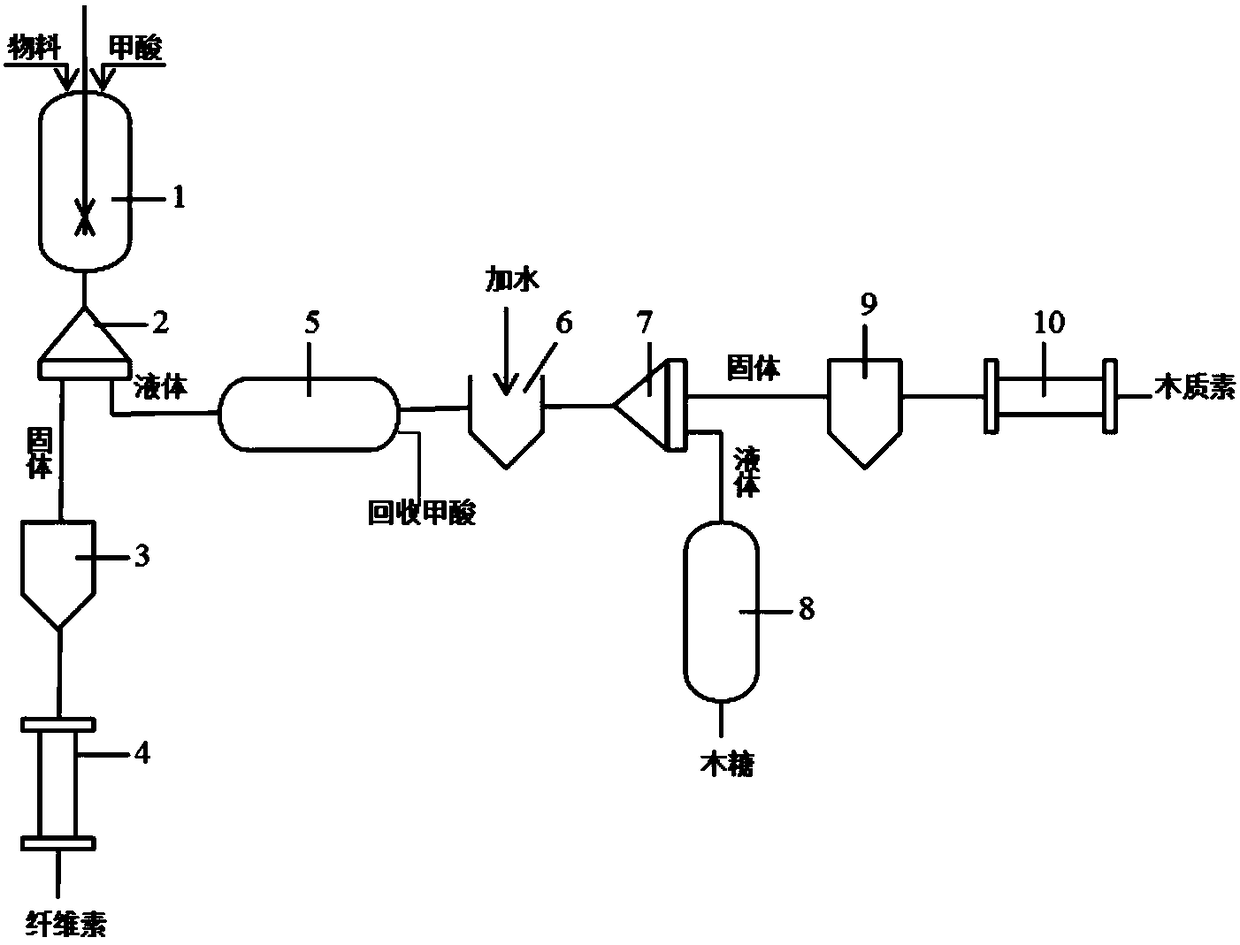

Method used

Image

Examples

Embodiment 1

[0040] The lignocellulosic raw material used is tea seed shell, which is dried naturally. After drying, perform irradiation treatment, the irradiation dose is 0-1000kGy, the irradiated samples are crushed and passed through a 40-mesh sieve, and the samples are collected for later use. According to the determination method of lignocellulose components of the National Renewable Energy Laboratory (NREL), the main components of the tea seed hulls used were analyzed, and the results are shown in Table 1.

[0041] Table 1 Lignocellulose content of tea seed hulls after treatment with different irradiation doses

[0042]

[0043] Weigh a certain quality of tea seed shell samples with different irradiation treatments in the reaction tank, add 88% formic acid solution at a ratio of 1:10 (m / v), react at a temperature of 80-100°C for 2-4h, and stir at a speed of 200rpm . After the pretreatment, the solid matter was vacuum filtered, and the solid matter was washed once with the same v...

Embodiment 2

[0052] The harvested straw is dried naturally. After drying, perform irradiation treatment, the irradiation dose is 0-1000kGy, the irradiated samples are crushed and passed through a 40-mesh sieve, and the samples are collected for later use. According to the method of Example 1, the main components of the rice straw used were analyzed, and the results are shown in Table 3.

[0053] Table 3 Lignocellulose content of rice straw treated with different irradiation doses

[0054]

[0055] Weigh a certain mass of rice straw samples with different irradiation treatments in a reaction tank, add 88% formic acid solution at a ratio of 1:10 (m / v), react at a temperature of 80-100°C for 2-4h, and stir at a speed of 200rpm. After the pretreatment, the solid matter was vacuum filtered, and the solid matter was washed once with the same volume of formic acid solution, and then vacuum filtered. After the solid matter is fully washed with distilled water, it is dried, and the product obt...

Embodiment 3

[0059] The harvested corn cobs are dried naturally. After drying, perform irradiation treatment, the irradiation dose is 0-800kGy, the irradiated samples are crushed and passed through a 40-mesh sieve, and the samples are collected for later use. According to the method of Example 1, the main components of the corncobs used were analyzed, and the results are shown in Table 5.

[0060] Table 5 Lignocellulose content of corncobs treated with different irradiation doses

[0061]

[0062] Weigh a certain mass of corn cob samples with different irradiation treatments in a reaction tank, add 88% formic acid solution at a ratio of 1:10 (m / v), react at a temperature of 90° C. for 3 hours, and stir at a speed of 200 rpm. After the pretreatment, the solid matter was vacuum filtered, and the solid matter was washed once with the same volume of formic acid solution, and then vacuum filtered. After the solid matter is fully washed with distilled water, it is dried, and the obtained pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com