Preparation method of high-biological activity support material

A bioactive, scaffold material technology, applied in the field of artificial bone repair materials, can solve the problems of low bioactivity, poor plasticity, slow cell proliferation rate, etc., achieve good degradation performance, high chemical reactivity, and improve biocompatibility Sexual and Bioactive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

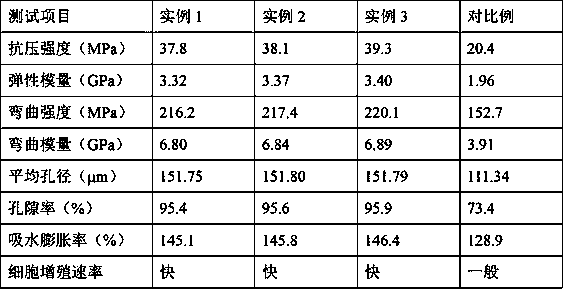

Examples

example 1

[0027] Put the titanium sheet in an ultrasonic cleaning machine, wash it with absolute ethanol and acetone for 15 min in turn, control the ultrasonic frequency to 35 kHz, put the cleaned titanium sheet in an oven with a set temperature of 80 ° C for 5 h, and then transfer it to a 15mL of sodium hydroxide solution with a mass fraction of 40% in an autoclave, heated to 240°C, and kept for 8 hours to obtain a titanium-based titanate nanowire matrix; 0.3g of graphite powder and 0.13g of sodium nitrate were added to the In a beaker with 12 mL of concentrated sulfuric acid solution with a mass fraction of 85%, place the beaker in an ice-water bath, stir for 45 min, remove the ice-water bath and stir for 2 h at room temperature, add 15 mL of deionized water and 25 mL of deionized water to the beaker with a mass fraction of 10 % hydrogen peroxide, continue to stir the reaction until no bubbles are produced; continue to add 25mL of sulfuric acid solution with a mass fraction of 8% and 1...

example 2

[0029] Put the titanium sheet in an ultrasonic cleaning machine, wash it with absolute ethanol and acetone for 13 minutes in sequence, control the ultrasonic frequency to 33 kHz, put the cleaned titanium sheet in an oven with a set temperature of 75°C for 4.5 hours, and then transfer it to a container. In an autoclave with 13mL of 40% sodium hydroxide solution, heat up to 220°C and keep the temperature for 7.5h to obtain a titanium-based titanate nanowire matrix; add 0.25g of graphite powder and 0.12g of sodium nitrate Put 11 mL of concentrated sulfuric acid solution with a mass fraction of 85% in a beaker, place the beaker in an ice-water bath, stir for 38 min, remove the ice-water bath and stir for 1.5 h at room temperature, add 13 mL of deionized water and 23 mL of mass to the beaker 10% hydrogen peroxide, continue to stir until no bubbles are produced; continue to add 23mL of sulfuric acid solution with a mass fraction of 8% and 13mL of hydrogen peroxide with a mass fractio...

example 3

[0031] Put the titanium sheet in an ultrasonic cleaning machine, wash it with absolute ethanol and acetone for 15 min in turn, control the ultrasonic frequency to 35 kHz, put the cleaned titanium sheet in an oven with a set temperature of 80 ° C for 5 h, and then transfer it to a 15mL of sodium hydroxide solution with a mass fraction of 40% in an autoclave, heated to 240°C, and kept for 8 hours to obtain a titanium-based titanate nanowire matrix; 0.3g of graphite powder and 0.13g of sodium nitrate were added to the In a beaker with 12 mL of concentrated sulfuric acid solution with a mass fraction of 85%, place the beaker in an ice-water bath, stir for 45 min, remove the ice-water bath and stir for 2 h at room temperature, add 15 mL of deionized water and 25 mL of deionized water to the beaker with a mass fraction of 10 % hydrogen peroxide, continue to stir the reaction until no bubbles are produced; continue to add 25mL of sulfuric acid solution with a mass fraction of 8% and 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com