Polymer anion exchange membrane and preparation method thereof

A technology of anion exchange membrane and polymer membrane, which is applied in the field of polymer anion exchange membrane and its preparation, can solve the problems of poor thermal and chemical stability, poor stability and poor stability of anion exchange membrane, and achieve Improve alkali resistance and chemical stability, low requirements for equipment and reaction conditions, good chemical stability and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

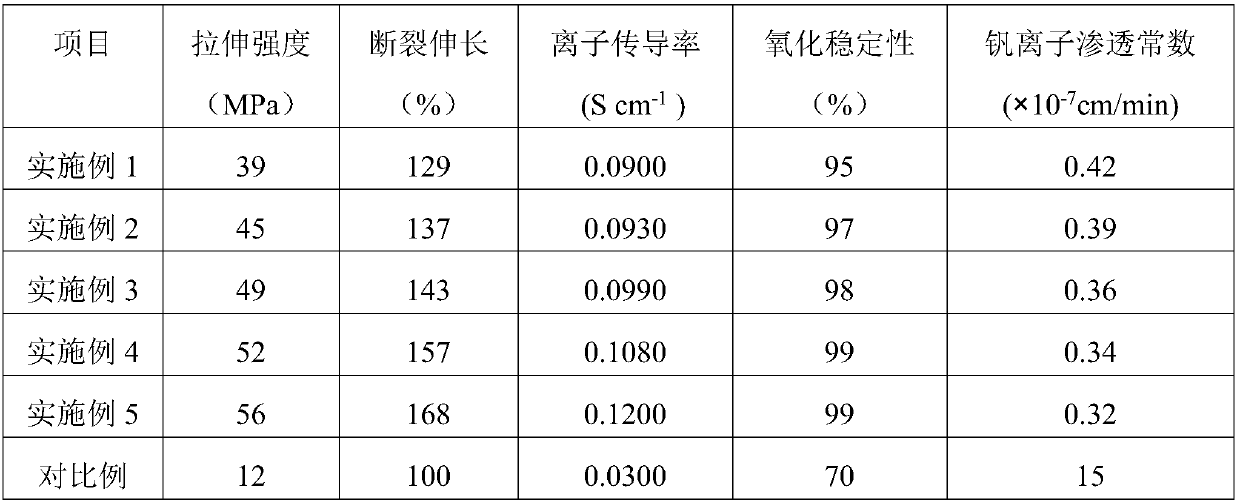

Examples

Embodiment 1

[0027] A method for preparing a polymer anion exchange membrane includes the following steps:

[0028] 1) Preparation of polymerizable monomer: Dissolve 15 g of 4,4'-bis(9-ethyl-3-carbazole vinyl)-1,1'-biphenyl and 10 g of 4-vinylbenzyl chloride in 50 g of tetrahydrofuran In, the reaction was stirred at room temperature for 6 hours, and then the solvent was removed by rotary evaporation to obtain a polymerizable monomer;

[0029] 2) Preparation of polymer film: 10 g of polymerizable monomers prepared in step 1), 10 g of bistrimethylsilyl vinyl phosphate, 10 g of butyl methacrylate, and dodecyl benzene sulfonic acid 0.2g of sodium was mixed uniformly, ultrasonicated for 10 minutes, then dropped on a glass plate, placed in a radiation field under a nitrogen atmosphere, and irradiated with α rays for 35 minutes, polymerization reaction occurred to obtain a polymer film;

[0030] 3) Ion exchange: 10g of the polymer membrane prepared in step 2) is soaked in 800g of potassium hydroxide so...

Embodiment 2

[0035] A method for preparing a polymer anion exchange membrane includes the following steps:

[0036] 1) Preparation of polymerizable monomer: Dissolve 17 g of 4,4'-bis(9-ethyl-3-carbazole vinyl)-1,1'-biphenyl and 10 g of 4-vinylbenzyl chloride in 65 g of tetrahydrofuran In, the reaction was stirred at room temperature for 6.5 hours, and then the solvent was removed by rotary evaporation to obtain a polymerizable monomer;

[0037] 2) Preparation of polymer film: 13g of polymerizable monomer prepared in step 1), 10g of bistrimethylsilyl vinyl phosphate, 12g of butyl methacrylate, and polyoxypropylene polyvinyl glycerol ether 0.3g is mixed uniformly, ultrasonicated for 12 minutes, then dropped on a glass plate, placed in a radiation field under a helium atmosphere, and irradiated with β rays for 39 minutes, polymerization reaction occurs to obtain a polymer film;

[0038] 3) Ion exchange: 10g of the polymer membrane prepared in step 2) is soaked in 950g of potassium hydroxide solutio...

Embodiment 3

[0043] A method for preparing a polymer anion exchange membrane includes the following steps:

[0044] 1) Preparation of polymerizable monomer: Dissolve 18 g of 4,4'-bis(9-ethyl-3-carbazole vinyl)-1,1'-biphenyl and 10 g of 4-vinylbenzyl chloride in 75 g of tetrahydrofuran In, the reaction was stirred at room temperature for 7 hours, and then the solvent was removed by rotary evaporation to obtain a polymerizable monomer;

[0045] 2) Preparation of polymer film: 15g of polymerizable monomer prepared in step 1), 10g of bistrimethylsilyl vinyl phosphate, 14g of butyl methacrylate, and nonylphenol polyoxyethylene ether 0.3g is mixed uniformly, ultrasonicated for 13 minutes, then dropped on a glass plate, placed in a radiation field under a neon atmosphere, irradiated with gamma rays for 40 minutes, polymerization reaction occurs to obtain a polymer film;

[0046] 3) Ion exchange: 10g of the polymer membrane prepared in step 2) is soaked in 1000g of potassium hydroxide solution with a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com