Method for constructing medical titanium alloy surface for promoting growth and differentiation of bone marrow mesenchymal stem cells

A titanium alloy, time technology, applied in medical science, metal material coating technology, prosthesis and other directions, can solve the problems affecting the growth and differentiation of bone marrow mesenchymal stem cells, the chemical covalent binding force between the dopamine transition layer and the titanium surface needs to be improved, There is no good improvement of surface roughness and wettability, etc., and the treatment method is simple and feasible, which is beneficial to adhesion, and improves the roughness and surface wettability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This example provides a method for constructing a medical titanium alloy surface to promote the growth and differentiation of bone marrow mesenchymal stem cells.

[0049] The titanium alloy sample used in this example is a medical titanium alloy plate, the raw material is Ti-6Al-4V alloy, and the graphene oxide used is obtained by modifying graphene by the modified Hummers method. The preparation method comprises the following steps:

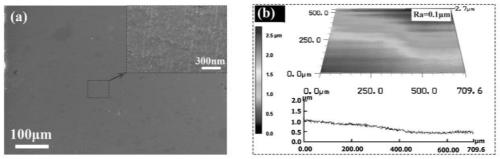

[0050] (1) The surface of the Ti-6Al-4V alloy was mechanically polished, and the surface roughness was measured to be 0.1 μm. It was ultrasonically cleaned in acetone and aqueous solution for 30 minutes, and the surface was blown dry with nitrogen after cleaning three times. The microstructure of the untreated titanium alloy surface refer to figure 1 ;

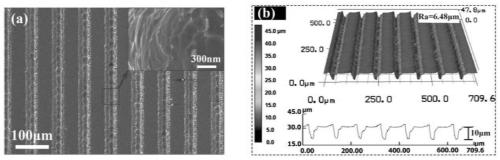

[0051] (2) Ultraviolet laser nanolaser (wavelength 355nm) is used to groove the surface of Ti-6Al-4V alloy. The textured groove parameters are: width 45μm, depth 10μm, spacing 100μm. T...

Embodiment 2

[0061] This example provides a method for constructing a medical titanium alloy surface to promote the growth and differentiation of bone marrow mesenchymal stem cells. The preparation method comprises the following steps:

[0062] (1) The surface of the Ti-13Nb-13Zr alloy was mechanically polished, and the surface roughness was measured to be 0.5 μm. The surface was cleaned with acetone and aqueous solution ultrasonically three times, and then the surface was dried with nitrogen.

[0063] (2) The surface of Ti-13Nb-13Zr alloy was grooved by ultraviolet laser nanolaser (wavelength 355nm). The textured groove parameters were: width 10 μm, depth 5 μm, spacing 20 μm. The pulse frequency used in the texturing process is 70kHz, the laser speed is 100mm / s, and the laser power is 0.6W. The roughness of this surface was measured to be 8.93 μm.

[0064] (3) The grooved Ti-13Nb-13Zr alloy was washed three times with acetone and deionized water, and dried with nitrogen gas; it was acti...

Embodiment 3

[0072] This example provides a method for constructing a medical titanium alloy surface to promote the growth and differentiation of bone marrow mesenchymal stem cells. The preparation method comprises the following steps:

[0073] (1) The surface of the Ti-6Al-7Nb alloy was mechanically polished to a roughness of about 0.9 μm. It was ultrasonically cleaned three times with acetone and deionized water, and then dried with nitrogen.

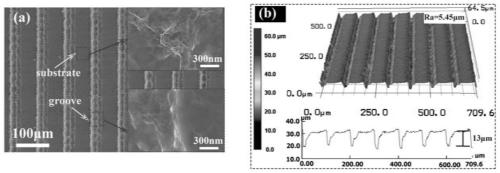

[0074] (2) A laser micromachining system was used to process microgroove patterns on the surface of the Ti-6Al-7Nb alloy, and the parameters were: width 70 μm, depth 20 μm, and spacing 100 μm. The pulse frequency used in the texturing process was 30 kHz, the laser speed was 300 mm / s, and the laser power was 1.8 W. The roughness of this surface was measured to be 7.74 µm.

[0075] (3) Wash the grooved Ti-6Al-7Nb alloy three times with acetone and deionized water, and dry at room temperature; put piranhaic acid (V 浓硫酸 / V 过氧化氢 =7:3) for 5 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com