Production method of disease-resistant deinsectization yield-increasing organic fertilizer and application thereof

A production method and technology of organic fertilizer, applied in the direction of organic fertilizer, application, fertilization device, etc., can solve the problems of unusable cigarette production, plant disease infection, virus repeated infection, etc., achieve the prevention of physiological diseases, reduce the amount of chemical fertilizer, Eliminates the effect of soil compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

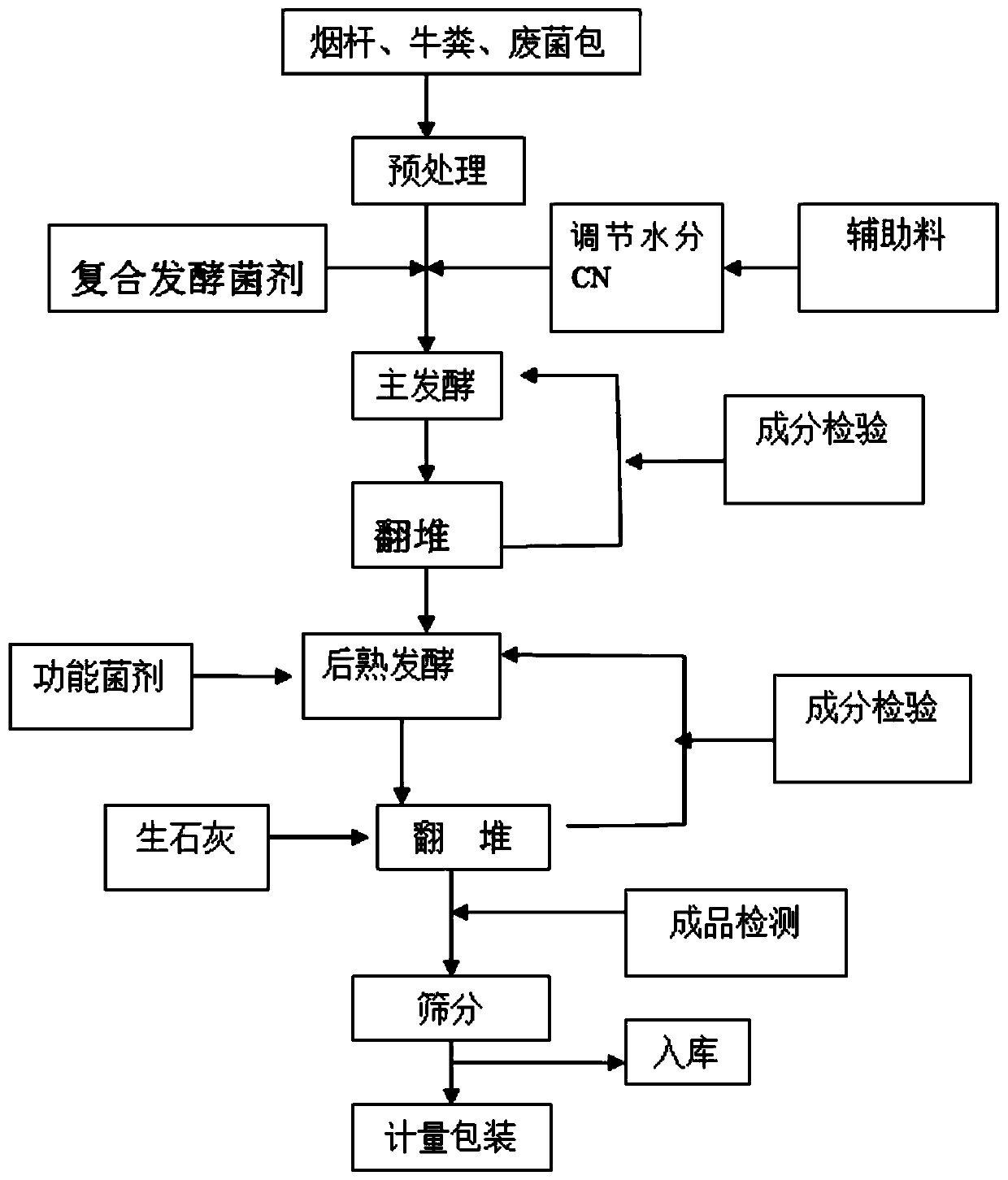

[0039] A method for producing an organic fertilizer that resists diseases, eliminates insects, and increases production, is carried out according to the following steps:

[0040](1) Pretreatment: crush the tobacco rods and the destroyed tobacco stems separately to obtain 60-80 mesh tobacco powder; control the moisture content of cow dung below 75%, and remove the obvious impurities in the feces; break the waste bacteria bag , control the particle size within 3cm, and remove the plastic film in the crushed raw materials;

[0041] (2) The raw materials are mixed according to the following parts by weight: 20-40 parts of cow dung, 10-30 parts of destroyed tobacco stem powder, 20-35 parts of humic acid, 10-20 parts of waste bacteria bag, 15 parts of tobacco rod powder -20 parts, stir well to mix;

[0042] (3) Main fermentation: prepare by adding 1 kilogram of compound fermentation bacterial agent for every 10 tons of raw material mixture, control the moisture content to 52-65%, a...

Embodiment 2

[0051] The preparation of compound fermentation agent:

[0052] ①Preparation of culture medium for each strain of compound fermentation agent:

[0053] PDA medium: 200g potatoes, add 1000ml water and boil for half an hour, filter through gauze, add 10-20g glucose and 17-20g agar, sterilize with high-pressure steam (121°C) for 20 minutes.

[0054] LB medium: tryptone 10g, yeast extract 5g, sodium chloride (NaCl) 10g, add deionized water to 1000mL, pH=7.0, sterilize by high-pressure steam (121°C) for 21 minutes;

[0055] MRS medium: tryptone 10g, beef extract powder 5g, yeast extract powder 4g, glucose 20g, Tween-80 1.08g, dipotassium hydrogen phosphate 2g, sodium acetate 5g, triammonium citrate 2g, magnesium sulfate (MgSO4.7H2O ) 0.2g, manganese sulfate (MnSO4.4H2O) 0.05g, agar 15g, add distilled water to 1000mL, final pH 6.2±0.2, sterilize by high pressure steam (121℃) for 15 minutes.

[0056] ②Activation and purification of a single strain and expanded culture on a liquid s...

Embodiment 3

[0066] Medium: medium: lactose 21.57g; compound nitrogen source 2.6g, which contains peptone and ammonium sulfate, the mass ratio of the two is 1:3; manganese sulfate 0.21g; dipotassium hydrogen phosphate 1.5g; magnesium sulfate heptahydrate 1.2g ; Add deionized water to 1000mL, pH = 7.0, and sterilize with high-pressure steam (121°C) for 21 minutes;

[0067] Inoculate the seeds of Bacillus mucilaginosus Krassilnikov into the above-mentioned medium, shake and culture at 30°C, 170r / min for 24h, and transfer to a new medium with 5% (v / v) inoculation amount at 30°C, 170r / min Shake culture for 12 hours to the logarithmic phase to obtain seed liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com