Two-dimensional material, nanosheet and preparation method and application thereof

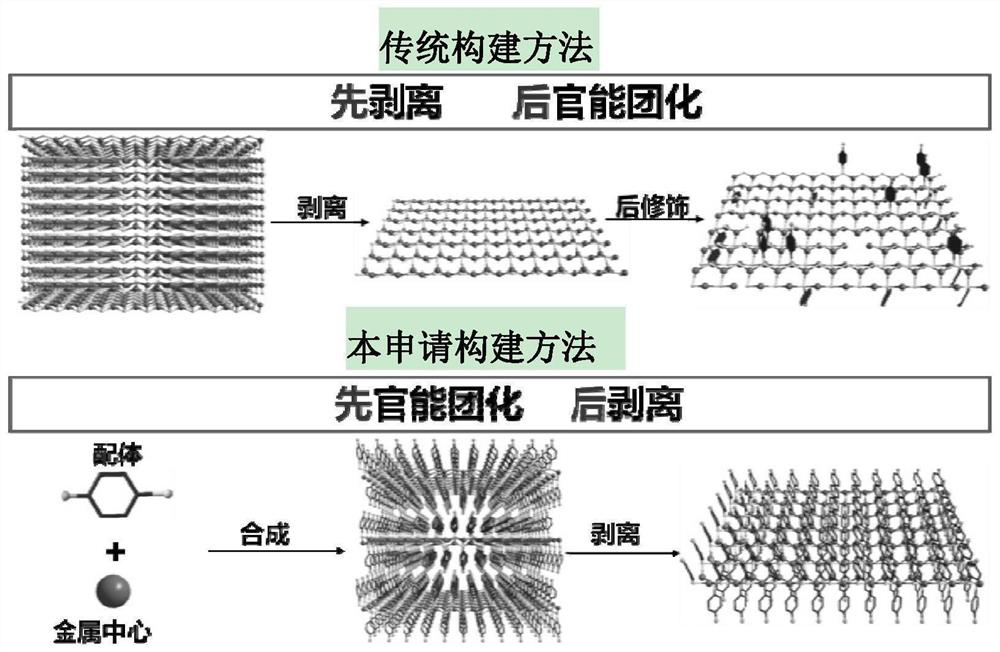

A technology of two-dimensional materials and nanosheets, applied in the field of chemistry, can solve the problems of uncontrollable material properties, difficult to achieve covalent functionalization, and inability to precisely control the type, quantity and spatial distribution of functional functional groups.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

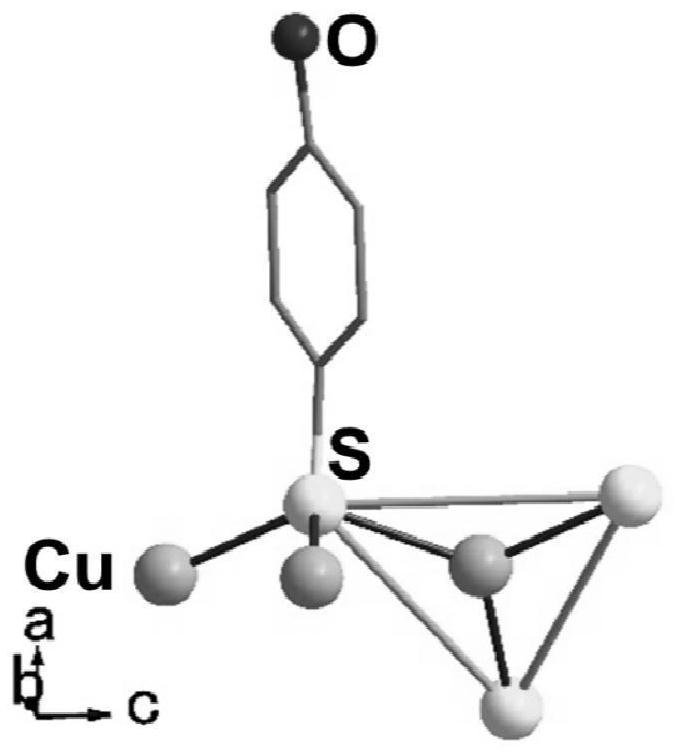

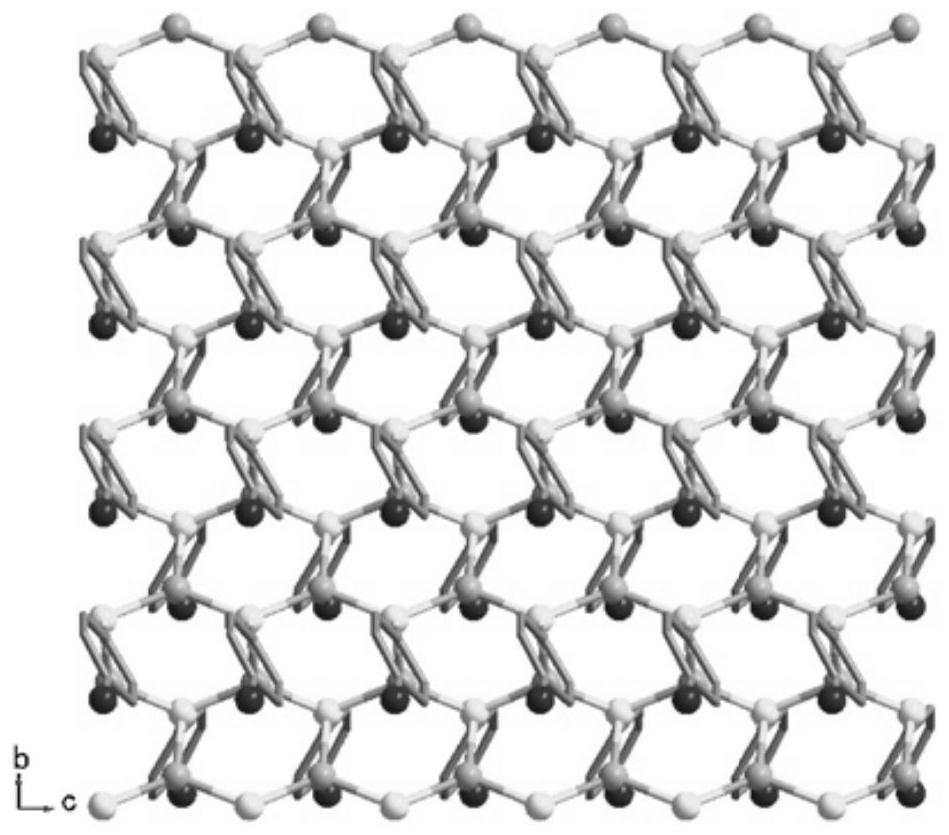

[0076] CuHBT single crystal synthesis: 4-hydroxythiophenol (0.0836g, 0.663mmol) and CuCl 2 2H 2 O (0.0158 g, 0.093 mmol) was added to a round bottom glass bottle with a volume of 10 mL, followed by absolute ethanol (5 mL) at room temperature. Afterwards, the mixture was sonicated in a sonicator for one hour, and then the reaction vial was taken out, and 0.7 mL of 1.25M NaOH was added dropwise thereto. Then put the reaction bottle after adding sodium hydroxide into an oven at 85 degrees Celsius, and finally obtained a yellow cuboid single crystal. After that, the obtained single crystal was washed with ethanol, water, ethanol and ether. Single crystals were then collected by centrifugation. get the molecular formula C 6 h 5 Crystals of CuOS. C 6 h 5 The basic structural unit and two-dimensional structure diagram of CuOS single crystal are shown in figure 2 and image 3 .

Embodiment 2

[0077] Synthesis of Example 2 OMCs series compound nanosheets:

[0078] 1.4-Hydroxythiophenol (0.0850g, 0.674mmol) and CuCl 2 2H 2 O (0.0243 g, 0.143 mmol) was dissolved in absolute ethanol (5 mL) at room temperature, and the resulting mixture was sonicated for one hour, after which 0.5 mL of 1.25M NaOH was added. Afterwards, the resulting reactant was reacted in an oven at 85 degrees Celsius for 12 days, and finally obtained yellow sheet-like nanosheets. Afterwards, the obtained nanosheets were washed with ethanol, deionized water, and ethanol repeatedly three times, and finally washed with ether in turn. Then suction or filter to get C 6 h 5 CuOS nanosheets. Named: CuHBT.

[0079] 2. Mix cuprous oxide (0.0210g, 0.147mmol) and 4-mercaptobenzoic acid (0.0677g, 0.439mmol) in 5mL of deionized water, then add 0.5mL of 12M hydrochloric acid. The resulting mixture is then sonicated for 30 minutes Afterwards, react the reactants obtained by ultrasound in an oven at 85 degrees...

Embodiment 3 2

[0088] The preparation of embodiment 3 two-dimensional material OMCs:

[0089] The OMCs series nanosheets prepared in Example 2 are stripped, and the best stripping conditions are as follows:

[0090] CuHBT: Disperse the CuHBT sample in ethanol to prepare a CuHBT dispersion with a concentration of 0.5mg / mL. Take 5mL of the CuHBT dispersion at a power of 135W, sonicate for 30 minutes, and finally centrifuge at 2000 rpm for 30 minutes. Keep the upper 2 / 3 of the dispersion to obtain a CuHBT two-dimensional material.

[0091] CuMBA: Disperse the CuMBA sample in water to prepare a CuMBA dispersion with a concentration of 1 mg / mL. Take 10 mL of the CuMBA dispersion, sonicate at 200 W for 60 minutes, and finally centrifuge at 5000 rpm for 30 minutes. Keep the upper 2 / 3 of the dispersion to obtain the CuMBA two-dimensional material.

[0092] AgHBT: Disperse the AgHBT sample in ethanol to prepare an AgHBT dispersion with a concentration of 3 mg / mL. Take 10 mL of the AgHBT dispersion,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com