Few-layer graphene modified oxygen vacancy stannic oxide material and preparation method thereof

A few-layer graphene, tin dioxide technology, applied in the field of gas sensors and electrochemical energy storage, can solve the problems of limited technical level, poor conductivity of tin dioxide powder, large specific surface area, etc., to achieve high sensitivity and cycle stability good dispersion, high-volume manufacturing, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

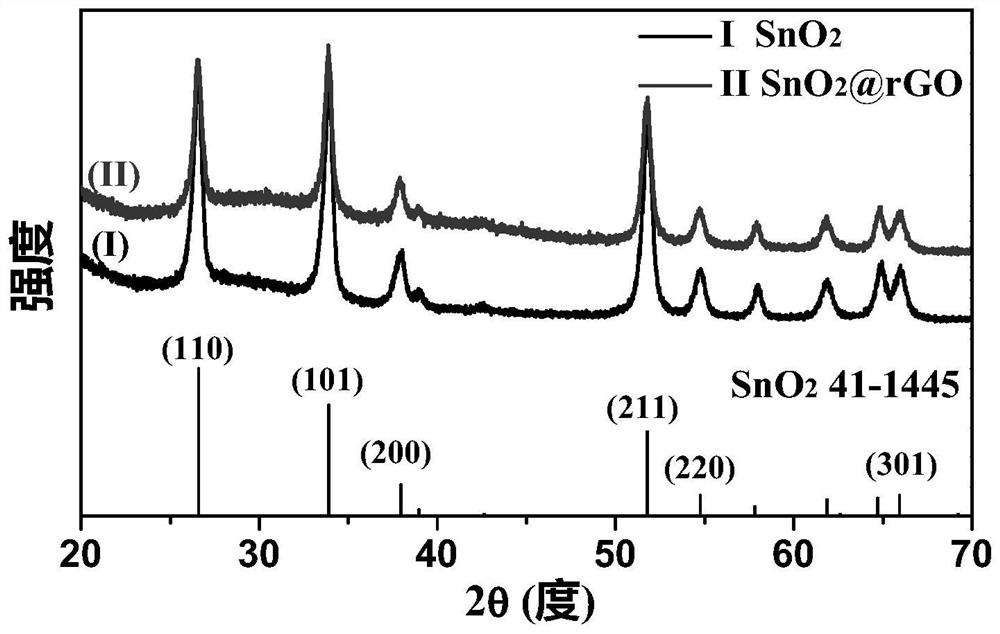

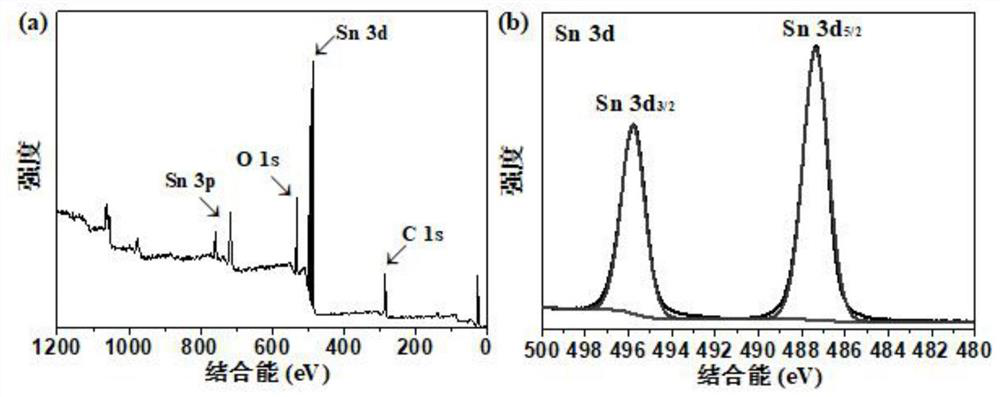

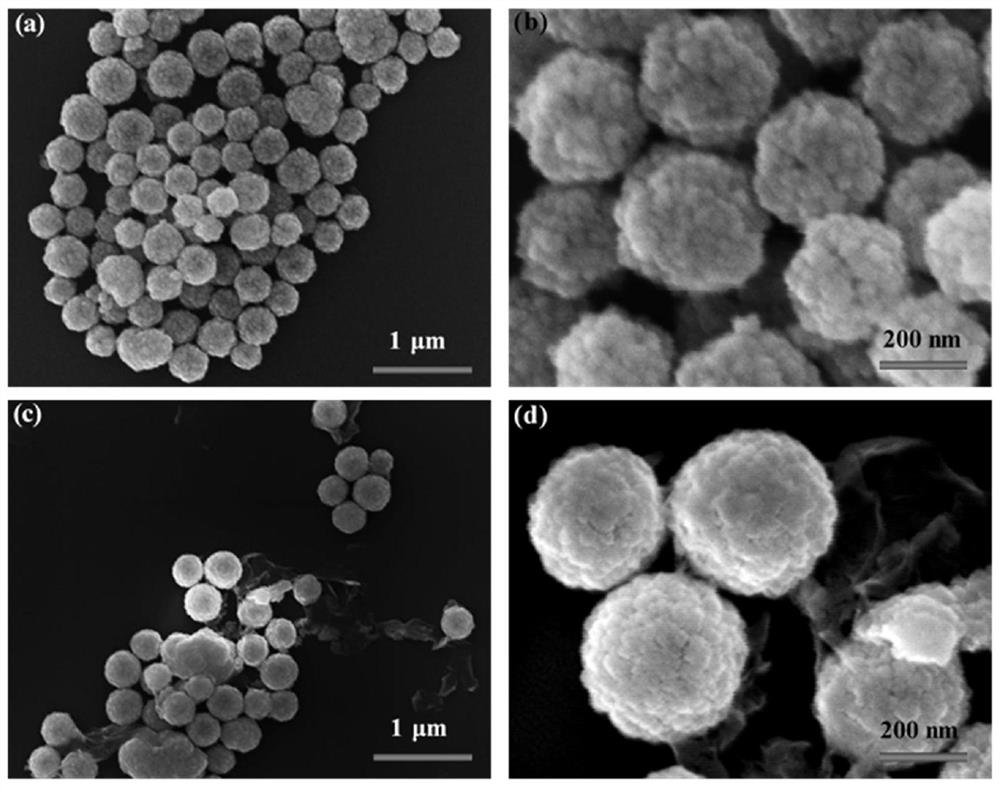

[0035] Example 1 Oxygen vacancy SnO 2 Preparation of @rGO composites

[0036] 1) Pure SnO 2 preparation of

[0037] After measuring 5mL of deionized water and 50mL of absolute ethanol and mixing them thoroughly, add 0.190g of SnCl4 Fully dissolve in the mixed solution, then add 0.5mL of concentrated hydrochloric acid.

[0038] The mixed solution was ultrasonically oscillated for 30 minutes, transferred to a reaction kettle, and heated at 200 °C for 24 hours.

[0039] The white precipitate generated by the reaction was poured out, and washed three times by centrifugation with deionized water and absolute ethanol, respectively.

[0040] The washed sample was dried at 60°C for 12 hours, put into a muffle furnace from room temperature to 400°C at a rate of 10°C / min, and calcined for 2 hours.

[0041] After the calcination, the sample was freely cooled to room temperature, and the SnO obtained from the calcined sample was collected. 2 .

[0042] 2) Preparation of few-layer gr...

Embodiment 2

[0063] Embodiment 2 electrochemical performance test

[0064] Electrode sheet preparation process:

[0065] ①Cut a piece with a size of 1×1.5cm 2 Nickel foam, weigh and record its initial weight m 1 .

[0066] ② Measure 7mg of SnO 2 @rGO, 2mg of acetylene black and 1mg of PVDF.

[0067] ③The weighed SnO 2 Pour @rGO, acetylene black and vinylidene fluoride into a mortar, add a few drops of N-methylpyrrolidone, and grind with a pestle for 5-6 minutes to make the various materials uniformly mixed in a gel-like state.

[0068] ④Apply the ground mixture evenly on one end of nickel foam 1×1cm 2 On the surface, just apply a thin layer of the mixture on the surface. Do not apply too much, otherwise it will affect the test performance. °C for 12 hours.

[0069] ⑤ After drying, take out the nickel foam and weigh its final mass m 2 , minus the initial mass m 1 After that, the quality of the coated mixture can be known, and the active material SnO can be obtained by multiplying ...

Embodiment 3

[0086] Example 3 Gas Sensitive Performance Test

[0087] Preparation process of gas sensor components:

[0088] The alumina ceramic tube is used as the substrate, and the two sides of the ceramic tube are composed of ring substances made of gold electrodes, and are connected to the gold electrodes through four platinum wires. Ni-Cr is inserted into the alumina ceramic tube as a heater to control the temperature.

[0089] Weigh an appropriate amount of prepared SnO 2 and SnO 2 @rGO powders were dispersed in flasks filled with distilled water, and placed in an ultrasonic machine for thorough ultrasonic vibration to disperse them evenly in the solution.

[0090] In order to enhance the mechanical adhesion of the powder on the surface of the substrate, a small amount of sodium carboxymethylcellulose was added as an organic binder to the mixed powder, and finally the obtained paste was coated on the surface of the substrate.

[0091] The organic binder is removed from the substr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com