Organosilicone acrylic acid polymerized hybrid conformal coating and preparation method thereof

A technology of acrylic polymerization and three-proof paint, which is applied in anti-corrosion coatings, fire-proof coatings, coatings, etc. It can solve the problems of general weather resistance, difficult repair, high expansion coefficient, etc., and achieve excellent aging resistance and high adhesion. Anti-corrosion effect, the effect of excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

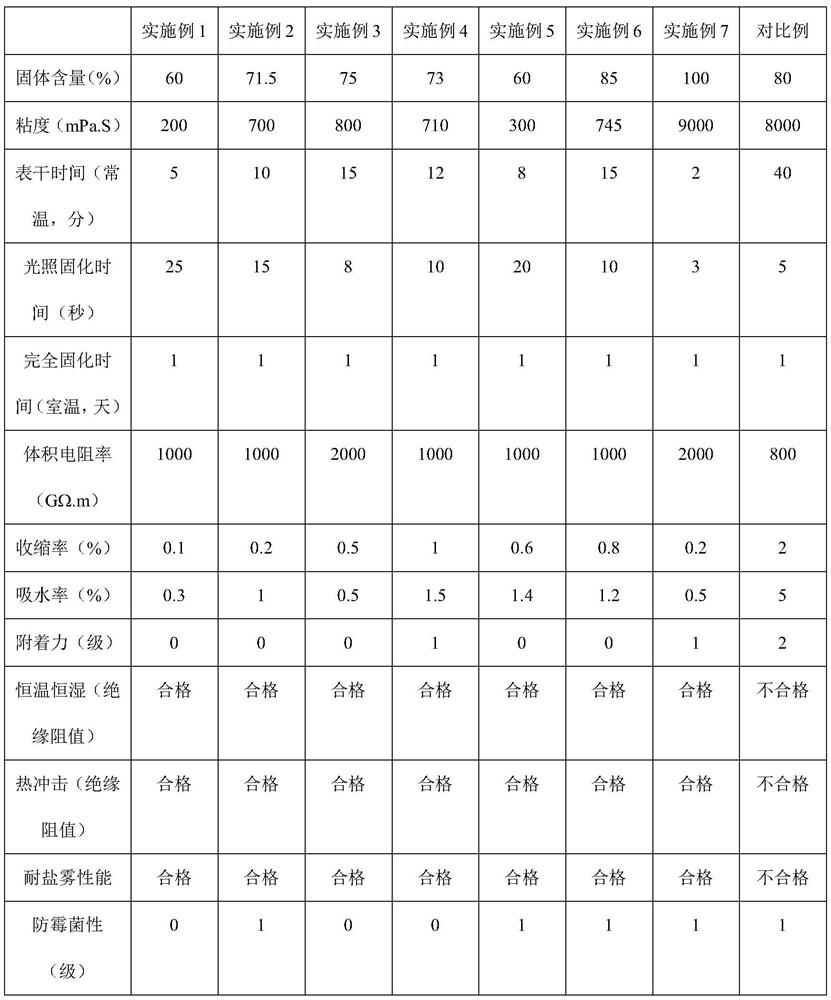

Examples

Embodiment 1

[0041] A high performance hybrid silicone acrylic polymer by UV curing and moisture bis three paint, in percentage by mass, comprising a siloxane bond compound 5% 14% of vinyl compounds, acrylate compounds 30%, 40% solvent UV crosslinker 10%, 1.0%-catalyst.

[0042] A siloxane compound is a polysiloxane bond and allyl trimethoxysilane, parts by mass ratio of 1: 1.

[0043] Vinyl compounds include vinyl chloride and vinylidene chloride, parts mass ratio of 1: 1.

[0044] Acrylate compound is methyl methacrylate.

[0045] The solvent comprises n-butyl acetate.

[0046] UV crosslinking agents include pentaerythritol triacrylate and dipentaerythritol hexaacrylate, parts by mass ratio of 1: 1.

[0047] Co-catalyst comprising methylethyl ketone peroxide polymerization co-catalyst, and a phosphoric acid moisture curing aid 184 photoinitiator.

[0048] The silicone acrylic polymer hybrid UV and moisture preparing three anti-dual cure paint, comprises the following steps:

[0049] Parts by...

Embodiment 2

[0052] A high performance hybrid silicone acrylic polymer by UV curing and moisture bis three paint, in percentage by mass, the bond comprising a siloxane compound 10% 15% vinyl compounds, acrylate compounds 25%, 28.5% solvent UV crosslinker 20%, 1.5%-catalyst.

[0053] Compound siloxane bond is an allyl trimethoxysilane and vinyltriethoxysilane, parts mass ratio of 1: 1.

[0054] Vinyl compounds include vinyl chloride and vinyl stearate, parts mass ratio of 1: 1.

[0055] Β- carboxyethyl acrylate compound is ethyl acrylate.

[0056] The solvent comprises a C12 isoparaffin.

[0057] UV crosslinking agents include trimethylol propane triacrylate and trimethylol propane oxidation diethyl triacrylate, parts mass ratio of 1: 1.

[0058] Catalytic oxidation aids include isononanoic acid tert-butyl polymerization-catalyst, p-toluenesulfonic acid and moisture curing aid 369 photoinitiator.

[0059] The silicone acrylic polymer hybrid UV and moisture preparing three anti-dual cure paint, ...

Embodiment 3

[0063] A high performance hybrid silicone acrylic polymer by UV curing and moisture bis three paint, in percentage by mass, the bond comprising a siloxane compound 15% 20% of a vinyl compound, an acrylate compound 20% 25% solvent UV crosslinker 15%, 5% co-catalyst.

[0064] Compound siloxane bond is an allyl triethoxysilane and γ- methacryloxypropyl trimethoxy silane, parts mass ratio of 1: 1.

[0065] Vinylidene chloride and vinyl compounds include vinyl octanoate, parts mass ratio of 1: 1.

[0066] Acrylate compound is isooctyl acrylate.

[0067] The solvent comprises propylene glycol butyl ether.

[0068] UV crosslinking agents include trimethylol propane triacrylate and 1,6-hexanediol diacrylate, parts mass ratio of 1: 1.

[0069] Co-catalyst comprising a peroxy 2-ethylhexyl tert-amyl polymerization-catalyst, dibutyl tin dilaurate and a moisture-curable, and a photoinitiator assistant 369.

[0070] The silicone acrylic polymer hybrid UV and moisture preparing three anti-dual c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com